Abstract

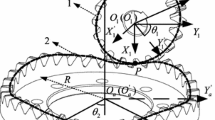

In this paper, an original analysis of the geometric design of a parallel-axis cycloid helical gear drive and an investigation on its basic meshing characteristics are presented. This type of gear drive consists of a pinion with one tooth and a cycloid-helix gear in continuous line contact along the whole length of the tooth. Firstly, mathematical formulations of their tooth surfaces are derived based on the envelope theory and homogeneous coordinate transformation. Secondly, the undercutting analysis is applied to determine the design constraint to avoid the undercutting on the cycloid-helix gear tooth surface. Then, the meshing characteristics including the contact lines, surface of action, induced normal curvature are analyzed. Numerical example is presented to demonstrate the influence of design parameters on the contact stress distribution. Finally, the loaded tooth contact analysis is performed to simulate the tooth contact condition and to validate the stress distribution by the finite element method.

Similar content being viewed by others

References

C. B. Tsay and Z. H. Fong, Computer simulation and stress analysis of helical gears with pinion circular arc teeth and gear involute teeth, Mechanism and Machine Theory, 26 (2) (1991) 145–154.

F. L. Litvin and A. Fuentes, Gear geometry and applied theory, Cambridge University Press (2004).

F. L. Litvin, V. Kin and Y. Zhang, Limitations of conjugate gear tooth surfaces, Journal of Mechanical Design, 112 (2) (1990) 230–236.

C. B. Tsay, Helical gears with involute shaped teeth geometry, computer simulation, tooth contact analysis, and stressanalysis, Journal of Mechanisms Transmissions and Automation in Design Transactions of the ASME, 110 (4) (1988) 482–491.

T. Yeh, D. C. H. Yang and S. H. Tong, Design of new tooth profiles for high-load capacity gears, Mechanism and Machine Theory, 36 (10) (2001) 1105–1120.

C. F. Chen and C. B. Tsay, Tooth profile design for the manufacture of helical gear sets with small numbers of teeth, International Journal of Machine Tools & Manufacture, 45 (12–13) (2005) 1531–1541.

F. L. Litvin, N. X. Chen, J. Lu and R. F. Handschuh, Computerized design and generation of low-noise helical gears with modified surface topology, Journal of Mechanical Design, 117 (2A) (1995) 254–261.

C. K. Chen and C. Y. Wang, Compensating analysis of a double circular-arc helical gear by computerized simulation of meshing, Proceedings of the Institution of Mechanical Engineers Part C: Journal of Mechanical Engineering Science, 215 (7) (2001) 759–771.

F. L. Litvin and C. B. Tsay, Helical gears with circular arc teeth simulation of conditions of meshing and bearing contact, Journal of Mechanisms Transmissions and Automation in Design-Transactions of the ASME, 107 (4) (1985) 556–564.

Y. Zhang, Q. Wang, H. Ma, J. Huang and C. Zhao, Dynamic analysis of three-dimensional helical geared rotor system with geometric eccentricity, Journal of Mechanical Science and Technology, 27 (11) (2013) 3231–3242.

J. Wei, P. Gao, X. Hu, W. Sun and J. Zeng, Effects of dynamic transmission errors and vibration stability in helical gears, Journal of Mechanical Science and Technology, 28 (6) (2014) 2253–2262.

J. Wei, W. Sun and L. Wang, Effects of flank deviation on load distributions for helical gear, Journal of Mechanical Science and Technology, 25 (7) (2011) 1781–1789.

X. S. Xie and H. C. Yang, Kinematic errors on helical gear of triple circular-arc teeth, Journal of Mechanical Science and Technology, 28 (8) (2014) 3137–3146.

M. Liu, C. Zhu, H. Liu and C. Wu, Parametric studies of lubrication performance of a helical gear pair with non-Newtonian fluids, Journal of Mechanical Science and Technology, 30 (1) (2016) 317–326.

H. Zeyin, L. Tengjiao, L. Tianhong, D. Tao and H. Qiguo, Parametric modeling and contact analysis of helical gears with modifications, Journal of Mechanical Science and Technology, 30 (11) (2016) 4859–4867.

S. Oh, S. Oh, J. Kang, I. Lee and S. Lyu, A study on modeling and optimization of tooth microgeometry for a helical gear pair, International Journal of Precision Engineering and Manufacturing, 14 (3) (2013) 423–427.

Q. Zhang, J. Kang, W. Dong and S. Lyu, A study on tooth modification and radiation noise of a manual transaxle, International Journal of Precision Engineering and Manufacturing, 13 (6) (2012) 1013–1020.

S. C. Yang, Mathematical model of a stepped triple circular-arc gear, Mechanism and Machine Theory, 44 (5) (2009) 1019–1031.

F. L. Litvin, A. Fuentes, I. Gonzalez-Perez, L. Carnevali and T. M. Sep, New version of Novikov-Wildhaber helical gears: computerized design, simulation of meshing and stress analysis, Computer Methods in Applied Mechanics and Engineering, 191 (49–50) (2002) 5707–5740.

D. Liang, B. K. Chen and Y. N. Gao, The generation principle and mathematical model of a new involute-helix gear drive, Proceedings of the Institution of Mechanical Engineers Part C: Journal of Mechanical Engineering Science, 227 (12) (2013) 2834–2843.

B. K. Chen, D. Liang and Y. Gao, Geometry design and mathematical model of a new kind of gear transmission with circular arc tooth profiles based on curve contact analysis, Proceedings of the Institution of Mechanical Engineers Part C: Journal of Mechanical Engineering Science, 228 (17) (2014) 3200–3208.

J. H. Yun, M. S. Jeong, S. K. Lee, J. W. Jeon, J. Y. Park and G. M. Kim, Sustainable production of helical pinion gears: environmental effects and product quality, International Journal of Precision Engineering and Manufacturing Green Technology, 1 (1) (2014) 37–41.

V. V. Stanovskoy, S. M. Kazakyavichyus, T. A. Remneva and V. M. Kuznetsov, Toothed wheel gearing (variants) and a planetary toothed mechanism based thereon (variants), USA Patents US20100095792 A1 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Ki-Hoon Shin

Xuan Li is currently a Ph.D. student at State Key Laboratory of Mechanical Transmission, Chongqing University, China. He spent two years as a Visiting Scholar at University of Cincinnati, USA. His research interests include gear design and dynamics.

Chaoyang Li received his doctor's degree in engineering from the State Key Laboratory of Mechanical Transmission, Chongqing University, China. Dr. Li is currently an Associate Professor in School of Mechanical and Engineering at Chongqing University. His research areas of interest include gear design, optimization and manufacturing.

Bingkui Chen is currently a Professor and Director for the State Key Lab of Mechanical Transmissions at Chongqing University, China. He is also Vice Director of the CMES Gear Technical Committee and a member of the CMES Gear Manufacturing Committee. Prof. Chen has conducted pioneering research related to gear geometry, kinematics, dynamics and manufacturing.

Rights and permissions

About this article

Cite this article

Li, X., Li, C., Chen, B. et al. Design and investigation of a cycloid helical gear drive. J Mech Sci Technol 31, 4329–4336 (2017). https://doi.org/10.1007/s12206-017-0831-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0831-8