Abstract

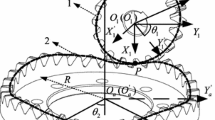

Two imaginary skew rack cutter curves with stepped triple circular-arc teeth are presented in this paper. A helical gear pair that includes the gear and pinion surfaces was generated by using two matched imaginary skew rack cutter surfaces. The mathematical models of the helical gear pair with stepped triple circular-arc teeth were developed based on theory of gearing. With the use of these models, the analysis of kinematic errors can be illustrated and evaluated by computer programming and tooth contact analysis (TCA). The assembly errors used had several kinds: ideal assembly errors, vertical misalignment angles, horizontal misalignment angles, manufacturing errors of helical angles, and center distance deviation. TCA revealed that the sensitivity of horizontal misalignment angles was lower than that of manufacturing errors of helix angles but higher than that of vertical misalignment angles.

Similar content being viewed by others

References

F. L. Litvin, Theory of gearing, NASA Reference Publication 1212, Washington, DC (1989).

F. L. Litvin, Gear geometry and applied theory, Prentices- Hall, Englewood Cliffs, NJ (1994).

F. L. Litvin and A. Fuentes, Gear geometry and applied theory, Cambridge University Press (2004) First Published.

N. G. Park and H. W. Lee, The spherical involute bevel gear: its geometry, Kinematic behavior and standardization, Journal of Mechanical Science and Technology, 25 (4) (2011) 1023–1034.

J. J. Coy, gearing, NASA reference Publication 1152, AVSCOM Technical report 84-c-15 (1985).

C. B. Tsay, Helical gears with involute shaped teeth: geometry, computer simulation, tooth contact analysis, and stress analysis, ASME J. Mech. Transmissions Automation Des., 110 (1988) 482–491.

M. L. Novikov, USSR Patent No. 109,750, 1956.

E. Wildhaber, Helical gearing, US Patent No. 1,601,750, 1926, and Gears with circular tooth profile similar to the Novikov system, VDI Berichte, No. 47, 1961.

F. L. Litvin and J. Lu, Computerized design and generation of double circular-arc helical gear with low transmission errors, Computer. Methods Appl. Mech. Eng., 127 (1995) 57–86.

F. L. Litvin and A. Fuentes, New version of Novikov-Wildhaber helical gears: computerized design, simulation of meshing and stress analysis, Computer. Methods Appl. Mech. Eng., 191 (2002) 5707–5740.

Y. Ariga and S. Nagata, Load capacity of a new W-N gear with basic rack of combined circular and involute profile, Journal of Mechanisms, Transmissions, and Automation in Design, 107 (1985) 565–572.

L. C. Chao and C. B. Tsay, Contact characteristics of spherical gears, Mechanism and Machine Theory, 43 (2008) 1317–1331.

J. Lu, F. L. Litvin and J. S. Chen, Load share and finite element stress analysis for double circular-arc helical gears, Mathematical and Computer Modelling, 21 (1995) 13–30.

H. Zhang, L. Hua and X. Han, Computerized design and simulation of meshing of modified double circular-arc helical gears by tooth end relief with helix, Mechanism and Machine Theory, 45 (2010) 46–64.

F. L. Litvin and C. B. Tsay, Helical gears with circular arc teeth: simulation of conditions of meshing and bearing contact, Journal of Mechanisms, Transmissions, and Automation in Design, 107 (1985) 556–564.

S. C. Yang, Mathematical model of a stepped triple circular-arc gear, Mechanism and Machine Theory, 44 (2009) 1019–1031.

F. L. Litvin, J. Lu, D. P. Townsend and M. Howkins, Computerized simulation of meshing of conventional helical involute gears and modification of geometry, Mechanism and Machine Theory, 34 (1999) 123–147.

Y. Zhang and Z. Fang, Analysis of tooth contact and load distribution of helical gears with crossed axes, Mechanism and Machine Theory, 34 (1999) 41–57.

C. K. Chen and C. Y. Wang, Compensating analysis of a double circular-arc helical gear by computerized simulation of meshing, Proc. Inst. Mech. Eng. PartC: J. Mech. Eng. Sci., 215 (2001) 759–771.

F. L. Litvin, J. Lu, D. P. Townsend and M. Howkins, Computerized simulation of meshing of conventional helical involute gears and modification of geometry, Mechanism and Machine Theory, 34 (1999) 123–147.

F. L. Litvin and M. D. Donno, Alternative approach for determination of singularity of envelope to a family of parametric surfaces, Comput. Methods Appl. Mech. Eng., 167 (1998) 153–165.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Eung-Soo Shin

Xiao-Shun Xie received his B.E. and M.E. degrees in Mechanical Engineering from Department of Industrial Education and Technology, National Changhua University of Education, Taiwan (R.O.C) in 2009 and 2011, respectively. Xie is currently a Teacher of Department of Mechanical Engineering of National Kangshan Agricultural and Industrial Vocational Senior High School, Taiwan(R.O.C). He have taught in the Municipal Kaohsiung Senior Vocational Industrial High School and The Affiliated Senior High School of National University of Tainan, Taiwan (ROC) in 2011 and 2013, respectively. His research field is design technology of gear model.

Hsueh-Cheng Yang received B.S. and M.S. degrees in Mechanical Engineering and Power Mechanical Engineering from National Chiao Tung University in 1994 and National Tsing Hua University in 1995, respectively. He got Ph.D. of Mechanical Engineering at National Cheng Kung University in 1999. Prof. Yang is currently a professor of was a professor of a studying gear region at Graduate Institute of Vehicle Engineering, National Changhua University of Education University, Changhua City, Taiwan. His research fields are gear theory and application and biomass energy in engine application.

Rights and permissions

About this article

Cite this article

Xie, XS., Yang, HC. Kinematic errors on helical gear of triple circular-arc teeth. J Mech Sci Technol 28, 3137–3146 (2014). https://doi.org/10.1007/s12206-014-0722-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-0722-1