Abstract

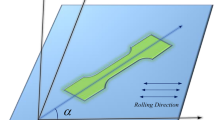

The influence of considering the variations in material properties was investigated through continuum damage mechanics according to the Lemaitre isotropic unified damage law to predict the bending force and springback in V-bending sheet metal forming processes, with emphasis on Finite element (FE) simulation considerations. The material constants of the damage model were calibrated through a uniaxial tensile test with an appropriate and convenient repeating strategy. Holloman’s isotropic and Ziegler’s linear kinematic hardening laws were employed to describe the behavior of a hardening material. To specify the ideal FE conditions for simulating springback, the effect of the various numerical considerations during FE simulation was investigated and compared with the experimental outcome. Results indicate that considering continuum damage mechanics decreased the predicted bending force and improved the accuracy of springback prediction.

Similar content being viewed by others

References

R. H. Wagoner, H. Lim and M. G. Lee, Advanced issues in springback, International Journal of Plasticity, 45 (2012) 3–20.

R. H. Wagoner, J. F. Wang and M. Li, Springback, ASM Handbook, ASM: Materials Park(2006) 733–755.

K. C. Chan, Theoretical analysis of springback in bending of integrated circuit lead frames, Journal of Material Processing Technology, 91 (1991) 111–115.

H. Li, H. Yang, F. F. Song, M. Zhan and G. J. Li, Springback characterization and behaviors of high-strength Ti-3Al-2.5V tube in cold rotary draw bending, Journal of Material Processing Technology, 212 (1987) 1973–1987.

L. Yuqi, H. Ping and W. Jinchen, Springback simulation and analysis of strong anisotropic sheet metals in U-channel bending process, Acta Mechanica Sinica, 18 (2002) 264–273.

T. Da Sisva Botelho, E. Bayraktar and G. Inglebert, Com-parison of experimental and simulation results of 2D-drawbend springback, Journal of Achievement in Materials and Manufacturing Engineering, 18 (2006) 275–278.

M. A. Farsi and B. Arezoo, Bending force and springback in V-die bending of perforated sheet metal components, Journal of Brazilian Society Mechanical Science Engineering, 1 (2011) 45–51.

M. Shahabi and A. Nayebi, Springback FE modeling of titanium alloy tubes bending using various hardening models, Structural Engineering and Mechanics, 56 (2015) 369–383.

J. T. Gau and G. L. Kinzel, A new model for springback prediction in which the Bauschinger effect is considered, International Journal of Mechanical Sciences, 43 (2001) 1813–1832.

R. Srinivasan, D. Vasudevan and P. Padmanabhan, Prediction of bend force and bend angle in air bending of electrogalvanized steel using response surface methodology, Journal of Mechanical Science and Technology, 27 (2013) 2093–2105.

J. J. Lee and G. J. Park, Optimization of the structural and process parameters in the sheet metal forming process, Journal of Mechanical Science and Technology, 28 (2014) 605–619.

D. K. Leu and Z. W. Zhuang, Springback prediction of the vee bending process for high-strength steel sheets, Journal of Mechanical Science and Technology, 30 (2016) 1077–1084.

M. Kadkhodayan, An investigation into the influence of deformable dies on the springback of circular plate, Scientia Iranica, 13 (2006) 201–205.

F. Yoshida and T. Uemori, A model of large-strain cyclic plasticity describing the Bauschinger effect and work hardening stagnation, International Journal of Plasticity, 18 (2002) 661–686.

A. Ghaei, D. Green and A. Taherizadeh, Semi-implicit numerical integration of Yoshida-Uemori two-surface plasticity model, International Journal of Mechanical Sciences, 52 (2010) 531–540.

H. Kim, M. Kimchi, N. Kardes and T. Altan, Effects of variable elastic modulus on springback predictions in stamping advanced high-strength steels (AHSS), 10th International Conference on Technology of Plasticity(2011) 628–633.

S. Chatti and N. Hermi, The effect of non-linear recovery on springback prediction, Journal of Computers and Structures, 89 (2011) 1367–1377.

M. Vrh, M. Halilovic and B. Starman, A new anisotropic elasto-plastic model with degradation of elastic modulus for accurate springback simulations, International Journal of Material Forming, 4 (2011) 217–225.

J. Lemaitre, A course on damage mechanics, Springer Verlag, Berlin(1992).

J. Lemaitre and R. Desmorat, Engineering damage mechanics, Springer Verlag, Berlin(2005).

S. Feifei, Y. He, L. Heng, Z. Mei and L. Guangjun, Springback prediction of thick-walled high-strength titanium tube bending, Chinese Journal of Aeronautics, 26 (2013) 1336–1345.

J. Lemaitre and J. L. Chaboche, Mechanics of solid materials, Cambridge University Press(1990).

M. A. Eltantawie and E. Elsoaly, A static approach for determination of bending force and springback during process, International Journal of Mechanical Engineering and Robotic Researches, 1 (2012) 1–13.

A. Mkaddem, R. Hambli and A. Potiron, Comparison between Gurson and Lemaitre damage models in wiping die bending processes, International Journal of Advanced Manufacturing Technology, 23 (2004) 451–461.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jun-Sik Kim

Ali Nayebi received his Ph.D. degree in mechanical engineering from University of Rennes, France, in 2002. He is currently a Professor of Mechanical Engineering in Shiraz University, Iran. His interests include plasticity, continuum damage mechanics, FGM, and creep and cyclic loading.

Mehdi Shahabi received his M.Sc. degree in Mechanical Engineering from Shiraz University in 2013. His interests include plasticity, FE simulation, metal formation, and continuum damage mechanics.

Rights and permissions

About this article

Cite this article

Nayebi, A., Shahabi, M. Effect of continuum damage mechanics on springback prediction in metal forming processes. J Mech Sci Technol 31, 2229–2234 (2017). https://doi.org/10.1007/s12206-017-0419-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0419-3