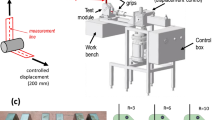

In the sheet metal forming processes, the transformed induced plasticity (TRIP) steel of RAK 40/70 grade exhibits a so-called springback effect, which is governed by strain recovery of material after the load removal. In this study, the numerical simulation of the bending process was performed and compared with experimental data. Springback can be related to many parameters, including forming conditions, tool geometry, sheet thickness, yield stress, work hardening, strain rate sensitivity, and elastic modulus. The effects of the above parameters on the springback effect were evaluated for the V-shaped sheet metal part made of TRIP steel with a thickness of 0.75 mm and a bending angle of 90°. In the numerical simulation, Hill's and Barlat’s yield criterions were used in combination with Ludwik’s and Swift’s hardening models. The numerical simulation data were compared with the experimental results, showing their close correlation.

Similar content being viewed by others

References

H. L. Dai, H. J. Jiang, T. Dai, et al., “Investigation on the influence of damage to springback of U-shape HSLA steel plates,” J. Alloy. Compd., 708, 575–586 (2017).

E. Spišák and J. Majerniková, “Plastic deformation of tin coated steel sheet under different stress-strain states,” Progress. Technol. Mater., 3, 25–35 (2009).

B. Chongthairungruang, V. Uthaisangsuk, S. Suranuntchai, and S. Jirathearanat, “Experimental and numerical investigation of springback effect for advanced high strength dual phase steel,” Mater. Design, 39, 318–328 (2012).

J. Slota and E. Spišák, “Determination of flow stress by the hydraulic bulge test,” Metalurgija, 47, No. 1, 13–17 (2008).

J. Slota, M. Ðiser, and M. Dvorák, “Experimental and numerical analysis of springback behavior of aluminum alloys,” Strength Mater., 49, No. 4, 565–574 (2017), https://doi.org/https://doi.org/10.1007/s11223-017-9900-6.

J. Jeswiet, M. Geiger, U. Engel, et al., “Metal forming progress since 2000,” CIRP J. Manuf. Sci. Technol., 1, No. 1, 2–17 (2008).

M. Banu, M. Takamura, T. Hama, et al., “Simulation of springback and wrinkling in stamping of a dual phase steel rail-shaped part,” J. Mater. Process. Technol., 173, 173–178 (2006).

B. Chongthairungruang, V. Uthaisangsuk, S. Suranuntchai, and S. Jirathearanat, “Springback prediction in sheet metal forming of high strength steels,” Mater. Design, 50, 253–266 (2013).

E. Evin and M. Tomáš, “The influence of laser welding on the mechanical properties of dual phase and trip steels,” Metals, 7, No. 7, 239 (2017).

E. Spišák, J. Slota, and J. Majerniková, “The analysis of plastic strain of single and double reduced tinplates,” Chemické Listy, 105, 485–487 (2011).

T. Yoshida, K. Sato, and K. Hashimoto, Springback Problems in Forming of High-Strength Steel Sheets and Countermeasures, Nippon Steel Technical Report No. 103 (2013).

M. Samuel, “Experimental and numerical prediction of springback and side wall curl in U-bendings of anisotropic sheet metals,” J. Mater. Process. Technol., 105, 382–393 (2013).

P. Mulidrán, E. Spišák, J. Majerniková, et al., “Influence of forming method and process conditions on springback effect in the sheet metal forming simulation,” Int. J. Eng. Sci. (IJES), 6, 62–67 (2017).

Acknowledgments

This study was financially supported by the APVV granting agency (APVV-17-0381 and ITMS 313011T594 projects) and by the VEGA granting agency (VEGA 1/0441/17 project).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 6, p. 120, November – December, 2021.

Rights and permissions

About this article

Cite this article

Mulidrán, P., Spišák, E., Tomáš, M. et al. The Effect of Material Models on Springback Prediction. Strength Mater 53, 961–965 (2021). https://doi.org/10.1007/s11223-022-00364-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-022-00364-9