Abstract

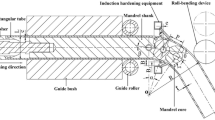

Bursting in tube hydroforming is preceded by localized deformation, which is often called necking. The retardation of the initiation of necking is a means to enhance hydroformability. Since high strain gradients occur at necking sites, a decrease in local strain gradients is an effective way to retard the initiation of necking. In the current study, the expansion at potential necking sites was intentionally restricted in order to reduce the strain gradient at potential necking sites. From the strain distribution obtained from FEM, it is possible to determine strain concentrated zones, which are the potential necking sites. Prior to the hydroforming of a trailing arm, lead patch is attached to the tube where the strain concentration would occur. Due to the incompressibility of lead, the tube expansion is locally restricted, and the resultant strain extends to adjacent regions of the tube during hydroforming. After the first stage of hydroforming, the lead is removed from the tube, and the hydroforming continues to obtain the targeted shape without the local restriction. This method was successfully used to fabricate a complex shaped automotive trailing arm that had previously failed during traditional hydroforming processing.

Similar content being viewed by others

References

M. Koc and T. Altan, Prediction of forming limits and parameters in the tube hydroforming process, International Journal of Machine Tools and Manufacture, 42 (2002) 123–138.

H. L. Xing and A. Makinouchi, Numerical analysis and design for tubular hydroforming, International Journal of Mechanical Sciences, 43 (2001) 1009–1026.

H. K. Park, H. K. Yi, C. J. Van Tyne and Y. H. Moon, Strain hardening behavior during manufacturing of tube shapes by hydroforming, Metals and Materials International, 15 (2009) 897–902.

S. Yuan, J. Qi and Z. He, An experimental investigation into the formability of hydroforming 5A02 Al-tubes at elevated temperature, Journal of Materials Processing Technology, 177 (2006) 680–683.

M. Keigler, H. Bauer, D. Harrison and A. K. M. De Silva, Enhancing the formability of aluminium components via temperature controlled hydroforming, Journal of Materials Processing Technology, 167 (2005) 363–370.

M. Imaninejad, G. Subhashand and A. Loukus, Loading path optimization of tube hydroforming process, International Journal of Machine Tools and Manufacture, 45 (2005) 1504–1514.

S. B. Jeon, J. S. Kim, K. S. Son and D. K. Kim, Assessment of hot ductility behavior of 16Mn-0.5C steel, Korean Journal of Metals and Materials, 52 (2014) 11–19.

R. Arrieux, Determination and use of the forming limit diagrams in sheet metal forming, Journal of Materials Processing Technology, 53 (1995) 47–56.

T. B. Stoughton, A general forming limit criterion for sheet metal forming, International Journal of Mechanical Sciences, 42 (2000) 1–27.

Y. M. Hwang, Y. K. Lin and H. C. Chuang, Forming limit diagrams of tubular materials by bulge tests, Journal of Materials Processing Technology, 209 (2009) 5024–5034.

T. Sokolowski, K. Gerke, M. Ahmetoglu and T. Altan, Evaluation of tube formability and material characteristics: hydraulic bulge testing of tubes, Journal of Materials Processing Technology, 98 (2000) 34–40.

S. Fuchizawa, M. Marazaki and H. Yuk, Bulge test for determining stress-strain characteristics of thin tubes, Advanced technology of plasticity, 1 (1993) 488–493.

Y. M. Hwang and Y. K. Lin, Evaluation of flow stresses of tubular materials considering anisotropic effects by hydraulic bulging tests, Journal of Engineering Materials and Technology, 129 (2007) 414–421.

W. J. Song, S. C. Heo, T. W. Ku, J. Kim and B. S. Kang, Evaluation of effect of flow stress characteristics of tubular material on forming limit in tube hydroforming process, International Journal of Machine Tools and Manufacture, 50 (2010) 753–764.

K. S. Kim, S. S. Kim, K. K. Park, K. M. Noh and K. A. Lee, Effect of alloying elements on the microstructure and repeated deformation behaviour of X60 high strength low alloy steel, Korean Journal of Metals and Materials, 51 (2013) 629–636.

R. Hashemi, K. Abrinia and A. Assempour, The strain gradient approach to predict necking in tube hydroforming, Journal of Manufacturing Processes, 15 (2013) 51–55.

S. Boumaiza, J. P. Cordebois, M. Brunet and G. Nefussi, Analytical and numerical study on plastic instabilities for axisymmetric tube bulging, International Journal of Mechanical Sciences, 48 (2006) 674–682.

N. S. P. Varma, R. Narasimhan, A. A. Luo and A. K. Sachdev, An analysis of localized necking in aluminum alloy tubes during hydroforming using a continuum damage model, International Journal of Mechanical Sciences, 49 (2007) 200–209.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Jai Hak Park

Se-Ge-Ro Shin received his B.S. degree (2011) in Control and Measurement Engineering at Pukyong National Univeristy, Busan, Korea. Since 2012, he has been pursuing MSc studies in Mechanical Engineering at Pusan National Univeristy, Busan, Korea. His research interests are related to hydroforming process.

Young-Hoon Moon received his Ph.D degree in Metallurgical and Materials Engineering from Colorado School of Mines, Golden, USA. He is a professor in the School of Mechanical Engineering, Pusan National Univeristy, Busan, Korea. His research includes hydroforming, forging, rolling, laser forming, materials processing technology, and reliability analysis.

Rights and permissions

About this article

Cite this article

Shin, S.G.R., Joo, B.D., Van Tyne, C.J. et al. Enhancing tube hydroformability by reducing the local strain gradient at potential necking sites. J MECH SCI TECHNOL 28, 4057–4062 (2014). https://doi.org/10.1007/s12206-014-0918-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-0918-4