Abstract

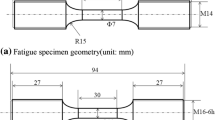

High-cycle fatigue (HCF) has been identified as one of the primary causes of gas turbine engine failure. To verify the reliability of the high cycle fatigue fracture of the 5 MW gas turbine engine blade being developed by Doosan Heavy Industries & Construction Co., Ltd., dynamic tests were conducted using real size compressor rigs according to previous studies. The dynamic safety margin of the 5MW gas turbine engine blade was calculated on the basis of the ratio between the dynamic stress and endurance limit stress respectively determined through the compressor rig and fatigue tests. The HCF characteristics and the fatigue life stability of the DGT-5 compressor blades were verified through these processes. A fatigue life design procedure for the gas turbine compressor blade was established on the basis of the design, analysis, and test processes implemented in a previous study. In sum, the 5 MW class gas turbine compressor blades were found to be well designed in terms of resonance stability and fatigue life.

Similar content being viewed by others

References

A. S. Lee, Y. C. Kim and D. W. Lee, Evaluation of blades vibration reliabilities of KGT-74 small gas turbine, Trans. of the KSNVE, 14(5) (2004) 410–415.

J. S. Rao, Turbine blade life estimation, Alpha Science International Ltd. (2000).

D. E. Thomson and T. G. Griffin, The national turbine engine high cycle fatigue program, IGTI Global Gas Turbine News, 39(1) (1999) 14–17.

A. S. Lee, Vibration design of the gas turbine engine blade, Journal. of the KSME, 38(8) (1998) 55–58.

P. K. Wright, M. Jain1 and D. Cameron, High cycle fatigue in a single crystal superalloy: time dependence at elevated temperature, Proc. of the 10th International Symposium on Superalloys, TMS (2004).

W. Tarar, O. Scott-Emuakpor and M. H. Herman Shen, A new finite element for gas turbine engine fatigue life prediction, Proc. of ASME Turbo Expo, GT2007-27427, Montreal, Canada (2007).

C. W. Cho and K. H. Yang, An experimental study on vibration mode of steam turbine blade, Proceeding of KSME Symposium (2002) 2417–2422.

Guide Technical Material 108.022.104-77, The Standards for Vibration Reliability of Axial Compressor Rotor Blades, written in Russian (1977).

M. P. Sigh, J. J. Vargo, D. M. Schiffer and J. D. Dello, Safe diagram — a design and reliability tool for turbine blading, Proc. of the Seventeenth Turbomachinery Symposium (1988) 93–102.

A. V. Srinivasan, Flutter and resonant vibration characteristics of engine blades, Trans. of the ASME. Journal of Engineering for Gas Turbine and Power, 119(4) (1997) 742–775.

A. M. Hashem and I. H. Aly, High-cycle fatigue life of coated low-carbon steel, International journal of fatigue, 16(5) (1994) 321–326.

E. Poursaeidi, M. Aieneravaie and M. R. Mohammadi, Failure analysis of a second stage blade in a gas turbine engine, Journal of Sound and Vibration, 282 (2005) 1065–1083.

K. K. Kim and Y. S. Lee, Modal characteristics according to the tip shape and assembly condition of the turbine blade, Journal of Mechanical Science and Technology, 27(11) (2013) 3409–3417.

K. K. Kim and Y. S. Lee, Modal characteristics and fatigue strength of the compressor blades, Journal of Mechanical Science and Technology, accepted, 28(4) (2014).

ANSYS Theory Reference, ANSYS Corporation, 2011. T. Misek, A. Tetiva, L. Prchlik and K. Duchek, Prediction of high cycle fatigue life of steam turbine blading based on unsteady cfd and fem forced response calculation. Proc. of ASME Turbo Expo, GT2007-278, Montreal, Canada (2007).

J. Liu, J. Gao and Tieyu Gao, Forced convection heat transfer of steam in a square ribbed channel, Journal of Mechanical Science and Technology, 26(4) (2012) 1291–1298.

Y. S. Choi and K. H. Lee, Investigation of blade failure in a gas turbine, Journal of Mechanical Science and Technology, 24(10) (2010) 1969–1974.

A. N. Arkhipov, A. V. Pipopulo and L.V. Putchkov, Design tuning of high aspect ratio shrouded turbine blades, Proc. of ASME Turbo Expo, GT2008-50607, Berlin, Germany (2008).

O. S. Emuakpor, M. H. H. Shen, C. Cross, J. C. and T. George, Development of an improved high cycle fatigue criterion, Proc. of ASME Turbo Expo, GT2004-53851, Vienna, Austria (2004).

T. J. George, M. H. Herman Shen, T. Nicholas and C. J. Cross, A new multiaxial fatigue testing method for variableamplitude loading and stress ratio, Proc. of ASME Turbo Expo, GT2003-38512, Atlanta, Georgia, USA (2003).

C. M. Sonsino, Course of sn curves especially in the highcycle fatigue regime with regard to component design and safety, International Journal of Fatigue, 29(12) (2007) 2246–2258.

P. B. Mikhailov-Mikheev, Handbook of metallic materialsturbine and motor machines, Mashgiz (1961).

I. A. Birger, B. F. Shorr and R. M. Shneyderovich, Strength analysis of machine parts, Mashinostroenie (1966).

C. C. Osgood, Fatigue design, 2nd edition. Pergamon Press (1982).

J. A. Graham, Fatigue design handbook, Vol. 4, SAE Inc. (1968).

H. O. Fuchs and R. I. Stephens, Metal fatigue in engineering, John Wiley & Sons (1980).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Jin Weon Kim

Kyungkook Kim received his B.S. degree in Mechanical Engineering from the Korea Aerospace University, Korea in 2000. He received his master’s degree in Mechanical Design Engineering from Chungnam National University, Korea. He is currently working for Doosan Heavy Industries & Construction as a Senior Research Engineer. His research interests are in area of gas turbine design.

Young-Shin Lee received his B.S. degree in Mechanical Engineering from Yonsei University, Korea in 1972. He received his master’s and Ph. D. degrees in Mechanical Engineering from Yonsei University, Korea in 1974 and 1980, respectively. He is currently a professor of the Department of Mechanical Design Engineering at Chungnam National University, Korea. Prof. Lee’s research interests are in area of impact mechanics, optimal design, biomechanical analysis, and shell structure analysis.

Rights and permissions

About this article

Cite this article

Kim, K., Lee, Y.S. Dynamic test and fatigue life evaluation of compressor blades. J MECH SCI TECHNOL 28, 4049–4056 (2014). https://doi.org/10.1007/s12206-014-0917-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-0917-5