Abstract

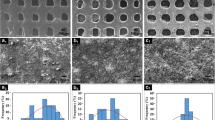

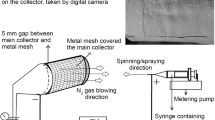

Three-dimensional (3D) porous scaffolds have been fabricated recently for tissue engineering applications through solid free-form fabrication (SFF) technologies. A multi-scaffold fabrication system for the fabrication of scaffolds, such as polymer, polymer/ceramic, ceramic, and nanofiber, was designed in this study. The various components, including a dispenser with a maximum pressure of 750 kPa, a thermostat with a maximum temperature of 250°C, a high-voltage power supply with a maximum output of 60 kV, and a syringe pump with small flow control, play important roles in determining the process characteristics of scaffolds. The system can process applicable biomaterials with extremely high accuracy with a precision nozzle. Several 3D scaffolds, including PCL, PCL/PLGA/β-TCP, β-TCP, and PCL nanofibers, were fabricated. The morphology and pore size of fabricated scaffolds were observed through scanning electron microscopy. Results show that the scaffolds manufactured in this study can be effectively utilized as bone regeneration scaffolds.

Similar content being viewed by others

References

A. Butscher, M. Bohner, S. Hofmann, L. Gauckler and R. Muller, Structural and material approaches to bone tissue engineering in powder-based three-dimensional printing, Acta Biomater., 7(3) (2011) 907–920.

D. W. Hutmacher, Scaffolds in tissue engineering bone and cartilage, Biomaterials, 21(24) (2000) 2529–2543.

M. I. Sabir and X. Xu, A review on biodegradable polymeric materials for bone tissue engineering applications, J. Mater. Sci., 44 (2009) 5713–5724.

C. Liu, Z. Xia and J. T. Czernuszka, Design and development of tree-dimensional scaffolds for tissue engineering, Chem. Eng. Res., 85(A7) (2007) 1051–1064.

V. V. Gaikwad, A. B. Patil and M. V. Gaikwad, Scaffolds for drug delivery in tissue engineering, Int. J. Pharm. Sci., 1(2) (2008) 113–122.

F. Cruz, Fabrication of HA/PLLA composite scaffolds for bone tissue engineering using additive manufacturing technologies, Biopolymers, Magdy Elnashar, eds., 28 (2010).

S. H. Oh, I. K. Park, J. M. Kim and J. H. Lee, In vitro and in vivo characteristics of PCL scaffolds with pore size gradient fabricated by a centrifugation method, Biomaterials, 28 (2007) 1664–1671.

Y. S. Sohn, J. W. Jung, J. Y. Kim and D. W. Cho, Investigation of bi-pore scaffold based on the cell behaviors on 3D scaffold patterns, Tissue Eng. Regen. Med., 8(2) (2011) 66–72.

J. Y. Kim, J. J. Yoon, E. K. Park, S. Y. Kim and D. W. Cho, The fabrication of rapid prototype based 3D PCL and PLGA scaffolds using precision deposition system, Tissue Eng. Regen. Med., 5(3) (2008) 506–511.

S. H. Hwang and M. Todo, Characterization of compressive deformation behavior of multi-layer porous composite materials for articular tissue engineering, J. Mech. Sci. Tech., 26(7) (2012) 1999–2004.

X. Zheng, F. Yang, S. Wang, S. Lu, W. Zhang, S. Liu and et al., Fabrication and cell affinity of biomimetic structured PLGA/articular cartilage ECM composite scaffold, J. Mater. Sci. — Mater. Med., 22 (2011) 693–704.

S. Xu, W. Guo, J. Lu and W. Li, Fabrication and mechanical properties of PLLA and CPC composite scaffolds, J. Mech. Sci. Tech., 26(9) (2012) 2857–2862.

J. Glowacki and S. Mizuno, Collagen scaffolds for tissue Table engineering, Biopolymers, 89(5) (2007) 338–344.

J. K. Park et al., Solid free-form fabrication of tissue-engineering scaffolds with a poly(lactic-co-glycolic acid) grafted hyaluronic acid conjugate encapsulating an intact bone morphogenetic protein-2/poly(ethylene glycol) complex, Adv. Funct. mater., 21 (2011) 2906–2912.

N. Nwe, T. Furuike and H. Tamura, The mechanical and biological properties of chitosan scaffolds for tissue regeneration templates are significantly enhanced by chitosan from gongronella butleri, Materials, 2 (2009) 374–398.

Y. J. Seol, D. Y. Park, J. Y. Park, S. W. Kim, S. J. Park and D. W. Cho, A new method of fabricating robust freeform 3D ceramic scaffolds for bone tissue regeneration, Biotechnol. Bioeng., 110(5) (2013) 1444–1455.

Y. J. Seol, J. Y. Park and D. W. Cho, Fabrication of calcium phosphate scaffolds using projection-based micros-tereolithography and their effects on osteogenesis, Trans. Korean Soc. Mech. Eng B, 35(11) (2011) 1237–1242.

H. S. Ryu, H. J. Youn, K. S. Hong, B. S. Chang, C. K. Lee and S. S. Chung, An improvement in sintering property of btricalcium phosphate by addition of calcium pyrophosphate, Biomaterials, 23 (2002) 909–914.

H. J. Kim, I. K. Park, J. H. Kim, C. S. Cho and M. S. Kim, Gas foaming fabrication of porous biphasic calcium phosphate for bone regeneration, Tissue Eng. Regen. Med., 9(2) (2012) 63–68.

M. Mour, D. Das, T. Winkler, E. Hoenig, G. Mielke, M. M. Morlock and A. F. Schilling, Advances in porous biomaterials for dental and orthopaedic applications, Materials, 3 (2010) 2947–2974.

R. Gauvin, Y. C. Chen, J. W. Lee, P. Soman, P. Zorlutuna, J. W. Nichol, H. J. Bae, S. C. Chen and A. Khademhosseini, Microfabrication of complex porous tissue engineering scaffolds using 3D pojection stereolithography, Biomaterials, 33 (2012) 3824–3834.

J. Y. Kim et al., Evaluation of solid free-form fabricationbased scaffolds seeded with osteoblasts and human umbilical vein endothelial cells for use in vivo osteogenesis, Tissue Eng. A, 16(7) (2010) 2229–2236.

J. Korpela, A. Kkkari, H. Korhonen, M. Malin, T. Närhi and J. Seppälä, Biodegradable and bioactive porous scaffold structures prepared using fused deposition modeling, J. Biomed. Mater. Res. B, 101B (2013) 610–619.

I. Zein, D. W. Hutmacher, T. C. Kim and S. H. Teoh, Fused deposition modeling of novel scaffold architectures for tissue engineering applications, Biomaterials, 23(4) (2002) 1169–1185.

J. W. Lee, K. S. Kang, S. H. Lee, J. Y. Kim, B. K. Lee and D. W. Cho, Bone regeneration using a microstereolithographyproduced customized poly(propylene fumarate)/diethyl fumarate photopolymer 3D scaffold incorporating BMP-2 loaded PLGA microspheres, Biomaterials, 32(3) (2011) 44–752.

H. W. Kang, Y. J. Seol and D. W. Cho, Development of an indirect solid freeform fabrication process based on microstereolithography for 3D porous scaffolds, J. Micromech. Microeng.,19 015011 (2009).

F. J. Martínez-Vázquez, F. H. Perera, P. Miranda, A. Pajares and F. Guiberteau, Improving the compressive strength of bioceramic robocast scaffolds by polymer infiltration, Acta Biomater., 6 (2010) 4361–4368.

S. Michna, W. Wu and J. A. Lewis, Concentrated hydroxyapatite inks for direct-write assembly of 3-D periodic scaffolds, Biomaterials, 26 (2005) 5632–5639.

H. Yoshimoto, Y. M. Shin, H. Terai and J. P. Vacanti, A biodegradable nanofiber scaffold by electrospinning and its potential for bone tissue engineering, Biomaterials, 24 (2003) 2077–2082.

R. Vasita and D. S. Katti, Nanofibers and their applications in tissue engineering, Int. J. Nanomed., 1(1) (2006) 15–30.

M. W. Sa and J. Y. Kim, Effect of various blending ratios on the cell characteristics of PCL and PLGA scaffolds fabricated by polymer deposition system, Int. J. Precis. Eng. Manuf., 14(4) (2013) 649–655.

S. H. Park, T. G. Kim, H. C. Kim, D. Y. Yang and T. G. Park, Development of dual scale scaffolds via direct polymer melt deposition and electrospinning for applications in tissue regeneration, Acta Biomater., 4 (2008) 1198–1207.

J. Su, L. Chen and L. Li, Characterization of polycaprolactone and starch blends for potential application within the biomaterials field, African J. Biotech., 11(3) (2012) 694–701.

J. H. Shim, J. B. Huh, J. Y. Park, Y. C. Jeon, S. S. Kang, J. Y. Kim, J. W. Rhie and D. W. Cho, Fabrication of blended polycaprolactone/poly(Lactic-co-glycolic acid)/b-tricalcium phosphate thin membrane using solid freeform fabrication technology for guided bone regeneration, Tissue Eng. A, 19(3 and 4) (2013) 317–328.

M. Hamadouche and L. Sedel, Ceramics in orthopaedics, J. Bone Joint surg, 82-B(8) (2000) 1095–1099.

F. Samani, M. Kokabi and M. R. Valojerdi, Optimising the eletrospinning process conditions to produce polyvinyl alcohol nanofibres, Int. J. Nanotechnol., 6(10–11) (2009) 1031–1040.

J. Y. Park, I. H. Lee and G. N. Bea, Optimization of the electrospinning conditions for preparation of nanofibers from polyvinylacetate (PVAc) in ethanol solvent, J. Ind. Eng. Chem., 14 (2008) 707–713.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Guest Editor Haedo Jeong

Jong Young Kim is an associate professor at the Department of Mechanical Engineering at Andong National University, Korea. He received his Ph.D. (2009) degree in the Department of Mechanical Engineering, Pohang University of Science and Technology, Korea. His current research interests are design of biomimetic scaffolds and development of rapid prototyping systems for bone tissue regeneration.

Rights and permissions

About this article

Cite this article

Sa, MW., Kim, J.Y. Design of multi-scaffold fabrication system for various 3D scaffolds. J Mech Sci Technol 27, 2961–2966 (2013). https://doi.org/10.1007/s12206-013-0810-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-013-0810-7