Abstract

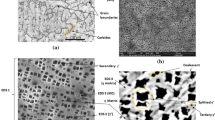

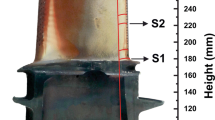

To enhance the gas turbine efficiency, the inflow temperature of the first-stage blade of the turbine system is raised to an ultra-high temperature of more than 1300°C. When the gas turbine blade is used at high temperature for a long time, its base material can become damaged. To prevent such damage, regenerative maintenance is performed after the equivalent operating hours so that the quality of the part may be restored for its reuse. After the first-cycle operation, nondestructive testing and a durability diagnosis of material quality are performed to determine whether the gas turbine blade should be reused or scrapped. For the recovery of the material properties, heat treatments are performed. So, this study aimed to analyze the condition of the heat treatment and to evaluate the influence of microstructure variation with this heat treatment for degraded superalloys. We studied the influence of HIP (hot isostatic processing) and post-heat treatment. HIP treatment has the effect of the elimination of cavities and cracks. The heat treatment processes removed the inhomogeneity of the creation and the growth of the γ′ phase due to the temperature gradation during the welding.

Similar content being viewed by others

References

J. H. Suwardie, R. Artiaga and J. L. Mier, Thermochimica acta, 295 (2002) 392–393.

S. A. Sajjadi, S. Nategh and R. I. L. Guthrie, materials science and engineering A, 484 (2002) 325.

S. Nategh and S. A. Sajjadi, Materials science and engineering A, 103 (2003) 339.

H. I. Kim, H. S. Park, B. K. Bae, Y. M. Lee, C. S. Seok and M. Y. Kim, Key engineering materials, 632 (2006) 321–323.

O. A. Ojo, N. L. Richards and M. C. Chaturvedi, Scripta materialia, 683 (2004) 51.

R. Viswanatan, Gas turbine blade superalloy material property handbook (TR 1004652, EPRI, 2001).

H. I. Kim, H. S. Park, D. J. Kim, C. S. Seok, S. H. Yang, S. Y. Park and M. Y. Kim, Proc. of design and materials division of Korean society of precision engineering (2005) 77.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Guest Editor Dong-Ho Bae

Chang-Sung Seok received his B.S., M.S., and Ph.D in Mechanical Engineering from Sungkyunkwan University, Korea in 1981, 1983 and 1990, respectively. Prof. Seok is currently a Professor of the School of Mechanical Engineering of Sungkyunkwan University, Korea. His research fields are the integrity evaluation and durability design of machine structures, development of component parts and analysis of stress and strength.

Rights and permissions

About this article

Cite this article

Kim, HI., Park, HS., Koo, JM. et al. Microstructural investigation of GTD 111DS materials in the heat treatment conditions. J Mech Sci Technol 26, 2019–2022 (2012). https://doi.org/10.1007/s12206-012-0506-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-012-0506-4