Abstract

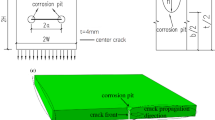

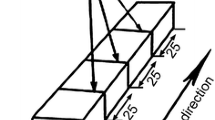

Fatigue crack initiates from corrosion pits in various metallic structures, leads to the decline of the fatigue life. In the present study, the effects of the width, depth, angle and spacing of primary and secondary pits on failure mechanism and stress concentration factor are investigated by the experimental and numerical analysis. The results show that depth-width ratio of corrosion pits is the critical factor that affects the dangerous area and stress concentration factor. The development of secondary pits will lead to the multiplier effect of stress concentration factor. The maximum stress is basically located at the mouth or middle part of secondary pits. In addition, the pit angle does not change the distribution of dangerous area, but with the pits angle increasing, the stress concentration factor increases as a whole. The contours that classical butterfly-like distribution rotates and the rotation angle is basically the same with that of the corrosion pits. Furthermore, with the pits spacing increasing, the stress concentration factor increases gradually and converges to the fixed value, which is equal to the stress concentration factor under the single pit. Finally, the relationship between the pits parameters and stress concentration factor is systematically predicted.

Similar content being viewed by others

Abbreviations

- b :

-

Pit length

- H :

-

Diameter

- H 1 :

-

Depth of primary pit

- H1/W1 :

-

Depth-width ratio of primary pit

- H 2 :

-

Depth of secondary pit

- H2/W2 :

-

Depth-width ratio of secondary pit

- K t :

-

Stress concentration factor

- L :

-

Distance of pits centerlines on the different sides

- Puave :

-

The average ultimate load of the test

- PuFEA :

-

The ultimate load of the finite element

- Pyave :

-

The average yield load of the test

- PyFEA :

-

The yield load of the finite element

- R 2 :

-

Goodness of Fit

- W 1 :

-

Width of primary pit

- W 2 :

-

Width of secondary pit

- δu :

-

The error of the ultimate load

- δ y :

-

The error of the yield load

- θ :

-

Pit rotation angle

- σnominal :

-

Nominal stress

- σpeak :

-

Peak stress

References

ABACUS (2013) User manuals, version 6.13. Dassault Systemes Simulia Corp., Province, RI, USA

An LS, Park YC, Kim HK (2019) A numerical study of the tensile stress concentration in a hemi-ellipsoidal corrosion pit on a plate. International Journal of Steel Structures 19(2):530–542, DOI: 10.1007/s13296-018-0134-7

Barton SC, Vermaas GW, Duby PF (2000) Accelerated corrosion and embrittlement of high-strength bridge wire. Journal of Materials in Civil Engineering 12(1):33–38, DOI: 10.1061/(ASCE)0899-1561(2000)12:1(33)

Betti R, West AC, Vermaas G (2005) Corrosion and embrittlement in high-strength wires of suspension bridge cables. Journal of Bridge Engineering 10(2):151–162, DOI: 10.1061/(ASCE)1084-0702(2005)10:2(151)

Cerit M (2013) Numerical investigation on torsional stress concentration factor at the semi elliptical corrosion pit. Corrosion Science 67:225–232, DOI: 10.1016/j.corsci.2012.10.028

Cerit M, Genel K, Eksi S (2009) Numerical investigation on stress concentration of corrosion pit. Engineering Failure Analysis 16(7): 2467–2472, DOI: 10.1016/j.engfailanal.2009.04.004

Cho T, Song MK (2006) Structural reliability of a suspension bridge affected by environmentally assisted cracking. KSCE Journal of Civil Engineering 10(1):21–31, DOI: 10.1007/BF02829301

Ernst P, Newman RC (2002a) Pit growth studies in stainless steel foils. I. Introduction and pit growth kinetics. Corrosion Science 44(5):927–941, DOI: 10.1016/s0010-938x(01)00133-0

Ernst P, Newman RC (2002b) Pit growth studies in stainless steel foils. II. Effect of temperature, chloride concentration and sulphate addition. Corrosion Science 44(5):943–954, DOI: 10.1016/s0010-938x(01) 00134-2

GB/T 17101 (2008) Hot-dip galvanized steel wire for bridge cables. GB/T17101, China Standards Press, Beijing, China

Hamilton IHR, Breen JE, Frank, KH (1998) Bridge stay cable corrosion protection. II: Accelerated corrosion tests. Journal of Bridge Engineering 3(2):72–81, DOI: 10.1061/(ASCE)1084-0702(1998)3:2(72)

Ji JB, Tong J (2013) Corrosion rate and mechanical properties of 316l stainless steel wires in different corrosive conditions. Applied Mechanics and Material 441:48–52, DOI: 10.4028/www.scientific.net/amm.441.48

Li R, Miao CQ, Yu J (2020) Effect of characteristic parameters of pitting on strength and stress concentration factor of cable steel wire. Construction and Building Materials 240:117915, DOI: 10.1016/j.conbuildmat.2019.117915

Mayrbaurl RM, Camo S (2001) Cracking and fracture of suspension bridge wire. Journal of Bridge Engineering 6(6):645–650, DOI:10.1061/(ASCE)1084-0702(2001)6:6(645)

Miao CQ, Li R, Yu J (2019) Effects of characteristic parameters of corrosion pits on the fatigue life of the steel wires. Journal of Constructional Steel Research, DOI: 10.1016/j.jcsr.2019.105879

Miao CQ, Yu J, Mei M (2016) Distribution law of corrosion pits on steel suspension wires for a tied arch bridge. Anti-Corrosion Methods and Materials 63(3):166–170, DOI: 10.1108/acmm-11-2015-1605

Nakamura SI, Suzumura K (2013) Experimental study on fatigue strength of corroded bridge wires. Journal of Bridge Engineering 18(3):200–209, DOI: 10.1061/(ASCE)BE.1943-5592.0000366

Nakamura SI, Suzumura K, Tarui T (2004) Mechanical properties and remaining strength of corroded bridge wires. Structural Engineering International 14(1):50–54, DOI: 10.2749/101686604777964305

Pidaparti RM, Patel RK (2010) Investigation of a single pit defect evolution during the corrosion process. Corrosion Science 52(9):3150–3153, DOI: 10.1016/j.corsci.2010.05.029

Qin GC, Lan T, Qin Q, Xu SH (2019) Degradation model and evaluation criteria for the seismic behavior of corrosion H-section steel column. KSCE Journal of Civil Engineering 23(8):3694–3705, DOI: 10.1007/s12205-019-0153-8

Suzumura K, Nakamura SI (2004) Environmental factors affecting corrosion of galvanized steel wires. Journal of Materials in Civil Engineering 16(1):1–7, DOI: 10.1061/(ASCE)0899-1561(2004)16:1(1)

Wang YD, Xu SH, Li AB (2020a) Flexural performance evaluation of corroded steel beam based on 3D corrosion morphology. Structure and Infrastructure Engineering, DOI: 10.1080/15732479.2020.1713169

Wang YD, Xu SH, Li H, Zhang HJ (2020b) Surface characteristics and stochastic model of corroded structural steel under general atmospheric environment. Acta Metallurgica Sinica 56(2):148–160, DOI: 10.11900/0412.1961.2019.00156

Wu S, Chen H, Ramandi HL (2017) Effects of environmental factors on stress corrosion cracking of cold-drawn high-carbon steel wires. Corrosion Science 132:234–243, DOI: 10.1016/j.corsci.2017.12.014

Xu J, Chen W (2013) Behavior of wires in parallel wire stayed cable under general corrosion effects. Journal of Constructional Steel Research 85:40-47, DOI: 10.1016/j.jcsr.2013.02.010

Xu SH, Li H, Wang YD, Wang YJ (2020) Influence of corrosion on the bond behavior in CFRP-steel single lap joints. Construction and Building Materials 236:117607, DOI: 10.1016/j.conbuildmat.2019.117607

Yang WJ, Yang P, Li XM, Feng WL (2012) Influence of tensile stress on corrosion behaviour of high-strength galvanized steel bridge wires in simulated acid rain. Materials and Corrosion 63(5):401–407, DOI: 10.1002/maco.201005921

Zhang ZX, Xu SH, Li R (2020) Comparative investigation of the effect of corrosion on the mechanical properties of different parts of thin-walled steel. Thin-Walled Structures 146:106450, DOI: 10.1016/j.tws.2019.106450

Acknowledgements

The financial support provided by National Natural Science Foundation of China under Grant Nos. 51778135 and 51078080 is highly acknowledged. The authors also would like to express the gratitude to the reviewers for careful comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, R., Miao, Cq. & Zhuang, Ml. Experimental and Numerical Investigation of Stress Concentration Factor of Cable Steel Wire with Corrosion Pits. KSCE J Civ Eng 24, 1581–1592 (2020). https://doi.org/10.1007/s12205-020-1787-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-020-1787-2