Abstract

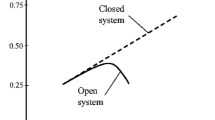

This paper presents an experimental and numerical study of the fatigue-corrosion behavior of the high strength low alloy steel known as HSLA steel in marine environment. Based on a case study of steel removed from of hull ship after about 1300 h of service in seawater, microstructural fatigue-corrosion indicators are detected such as micro-cracks, micro-pits, and beach marks. In addition, the mechanical properties decreased dramatically. Pitting corrosion acts as the main phenomena leading to the metal deterioration. This is confirmed through electromechanical calculation and potentiodynamic curves. Since, the environment is harsh and out of our control, a numerical study of the effect of pitting and the coupling between fatigue and pitting corrosion is held. The results show that the geometry of corrosion defect is responsible for the propagation of the pit and can lead to the crack formation. von Mises stress propagation is controlled too by the corrosion potential distribution.

Similar content being viewed by others

References

S. Fetni, Microstructure evolution and corrosion behaviour of an ASTM A213 T91 tube after long term creep exposure. Eng. Failure Anal. (2017). https://doi.org/10.1016/j.engfailanal.2017.03.023

A. Toumi, C. Boubahri, J. Briki et al., HSLA naval grade steel failure investigation in marine environment under ship hull operational conditions. J Fail. Anal. Preven. 21, 2224–2233 (2021)

Grumbach, M. (2000). Aciers microalliés. Dans Techniques de l'ingénieur Propriétés et usages des aciers et fontes

Zghal, J. (2016). Etude du comportement en fatigue à grand nombre de cycles d'un acier à haute limite d'élasticité HC360LA : endommagement, plasticité et phénomènes dissipatifs associés. Paris

K. Berchem, M.G. Hocking, The influence of pre-straining on the corrosion fatigue performance of two hot-dip galvanised steels. Corros. Sci. Corros. Sci. 48, 4094–4112 (2006)

T. Datta, Fractal behavior of surface oxide crack patterns on AISI 4140 high-strength low-alloy steel exposed to the simulated offshore environment. Appl. Surf. Sci. Adv. (2021). https://doi.org/10.1016/j.apsadv.2021.100110

T. Zhao, Corrosion fatigue crack initiation and initial propagation mechanism of E690 steel in simulated seawater. Mater. Sci. Eng. A. 708, 181–192 (2017)

E.J. Dolley, B. Lee, The effect of pitting corrosion on fatigue life. Fatigue Fract. Eng. Mater. Struct. 23, 555–560 (2000)

A.T. Kermanidis, P.V. Petroyiannis, Fatigue and damage tolerance behaviour of corroded 2024 T351 aircraft aluminum alloy. Theor. Appl. Fract. Mech. 43, 121–132 (2005)

M. Talebi, M. Zeinoddini, Collapse of HSLA steel pipes under corrosion exposure and uniaxial inelastic cycling. J. Constr. Steel Res. 144, 253–269 (2018)

H. Ma, J. Zhao, Comparative study on corrosion fatigue behaviour of high strength low alloy steel and simulated HAZ microstructures in a simulated marine atmosphere. Int. J. Fatigue. 137, 105666 (2020)

S.T. Sivaprasad, Corrosion fatigue crack growth behaviour of naval steels. Corros. Sci. (2006). https://doi.org/10.1016/j.corsci.2005.08.005

COMSOL, Multiphysics structural mechanics module users’s guide. (Burlington, USA, 2008)

Xu, L. (2013). Assessment of corrosion defects on high-strength steel pipelines. Calgary.

Y. Kondo, Prediction of fatigue crack initiation life based on pit growth. Corrosion. (1989). https://doi.org/10.5006/1.3577891

G.S. Chen, K.C. Wan, Transition from pitting to fatigue crack growth—modeling of corrosion fatigue crack nucleation in a 2024–T3 aluminum alloy. Mater. Sci. Eng. A-Struct. Mater. (1996). https://doi.org/10.1016/S0921-5093(96)10414-7

J. Lemaitre, Prévision de la progression des fissures de fatigue dans les structures minces renforcées. Revue de Physique Appliquée, Société Française de Physique/EDP. 9(4), 667–672 (1974)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Toumi, A., Boubahri, C. & Briki, J. Experimental and Numerical Study of HSLA Steel Fatigue and Pitting Corrosion Behavior. J Fail. Anal. and Preven. 23, 108–117 (2023). https://doi.org/10.1007/s11668-022-01559-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-022-01559-7