Abstract

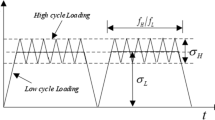

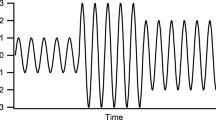

In order to predict the lifetime of products appropriately with long lifetime and high reliability, the accelerated degradation testing (ADT) has been proposed. Composite wind turbine blade is one of the most important components in wind turbine system. Its fatigue cycle is very long in practice. A full-scale fatigue testing is usually used to verify the design of a new blade. In general, the full-scale fatigue testing of blade is accelerated on the basis of the damage equivalent principle. During the full-scale fatigue testing, blade is subjected to higher testing load than normal operating conditions; consequently, the performance degradation of the blade is hastened over time. The full-scale fatigue testing of blade is regarded as a special ADT. According to the fatigue failure criterion, we choose blade stiffness as the characteristic quantity of the blade performance, and propose an accelerated model (AM) for blade on the basis of the theories of ADT. Then, degradation path of the blade stiffness is modeled by using Gamma process. Finally, the lifetime prediction of full-scale megawatt (MW) blade is conducted by combining the proposed AM and blade stiffness degradation model. The prediction results prove the reasonability and validity of this study. This can supply a new approach to predict the lifetime of the full-scale MW blade.

Similar content being viewed by others

References

YE Z S, CHEN L P, TANG L C, et al. Accelerated degradation test planning using the inverse gaussian process [J]. IEEE Transactions on Reliability, 2014, 63(3): 750–763.

CHANG M S, PARK T K, SUNG B J, et al. Life prediction of brazed plate heat exchanger based on several accelerated life test data [J]. Journal of Mechanical Science and Technology, 2015, 29(6): 2341–2348.

LIU Z Y, MA X B, YANG J, et al. Reliability modeling for systems with multiple degradation processes using Inverse Gaussian process and copulas [J]. Mathematical Problems in Engineering, 2014, 2014(1-2): 1–10.

WU Q, YANG J Z, WANG J Y, et al. Reliability analysis of degradation with a new independent increment process [J]. Journal of Mechanical Science and Technology, 2014, 28(10): 3971–3976.

PENG C Y, TSENG S T. Progressive-stress accelerated degradation test for highly-reliable products [J]. IEEE Transactions on Reliability, 2010, 59(1): 30–37.

WANG H W, XU T X, MI Q L, et al. Approach of lifetime prediction based on Gamma process under accelerated stresses [J]. Science Technology and Engineering, 2013, 13(35): 10455–10459 (in Chinese).

ZHOU H F, DOU H Y, QIN L Z, et al. A review of fullscale structural testing of wind turbine blades [J]. Renewable and Sustainable Energy Reviews, 2014, 33(2): 177–187.

KONG C, KIM T, HAN D, et al. Investigation of fatigue life for a medium scale composite wind turbine blade [J]. International Journal of Fatigue, 2006, 28(10): 1382–1388.

YUN J J, CHANW C, LEE J H, et al. Development of fatigue life prediction method and effect of 10-minute mean wind speed distribution on fatigue life of small wind turbine composite blade [J]. Renewable Energy, 2015, 79(1): 187–198.

WESTPHAL T, NIJSSEN R P L. Fatigue life prediction of rotor blade composites: Validation of constant amplitude formulations with variable amplitude experiments [J]. Journal of Physics: Conference Series, 2014, 555(1): 012107.

International Electrotechnical Commission. Wind turbine generator systems-part 23: Full-scale structural testing of rotor blades: IEC TS 61400-23 [S]. Geneva, Switzerland: IEC, 2014.

ZHAO J Y, LIU F. Models and statistical analysis for accelerated degradation test [J]. Journal of Harbin Institute of Technology, 2008, 40(12): 2088–2090 (in Chinese).

ZHANG L A, HUANG X M, WEI X T. Energy consumption analysis of large wind turbine blade fatigue loading mode [J]. Renewable Energy Resources, 2012, 30(8): 50–58 (in Chinese).

SI X S, WANG W B, HU C H, et al. Remaining useful life estimation: A review on the statistical data driven approaches [J]. European Journal of Operational Research, 2011, 213(1): 1–14.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 51665029)

Rights and permissions

About this article

Cite this article

Kou, H., An, Z., Ma, Q. et al. Lifetime Prediction of Wind Turbine Blade Based on Full-Scale Fatigue Testing. J. Shanghai Jiaotong Univ. (Sci.) 25, 755–761 (2020). https://doi.org/10.1007/s12204-020-2174-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-020-2174-3

Key words

- composite wind turbine blade

- accelerated degradation testing (ADT)

- accelerated model (AM)

- full-scale fatigue testing

- blade stiffness

- lifetime prediction