Abstract

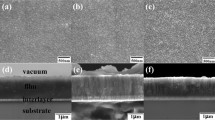

Tribological properties of chemical vapor deposition (CVD) diamond films greatly affect its application in the mechanical field. In this paper, a novel multilayer structure is proposed, with which multilayer diamond films are deposited on silicon carbide by hot filament CVD (HFCVD) method. The different micrometric diamond grains are produced by adjusting deposition parameters. The as-deposited multilayer diamond films are characterized by scanning electron microscope (SEM) and white-light interferometry. The friction tests performed on a reciprocating ball-on-plate tribometer suggest that silicon carbide presents the friction coefficient of 0.400 for dry sliding against silicon nitride (Si3N4) ceramic counterface. With the water lubrication, the corresponding friction coefficients of silicon carbide and as-deposited multilayer diamond films further reduce to 0.193 and 0.051, respectively. The worn surfaces indicate that multilayer diamond films exhibit considerably high wear resistance.

Similar content being viewed by others

References

Jones G A. On the tribological behaviour of mechanical seal face materials in dry line contact. Part II. Bulk ceramics, diamond and diamond-like carbon films [J]. Wear, 2004, 256(3–4): 433–455.

Zum Gahr K H, Blattner R, Hwang D H, et al. Micro- and macro-tribological properties of SiC ceramics in sliding contact [J]. Wear, 2001, 250(1–12): 299–310.

Masuko M, Suzuki A, Sagae Y, et al. Friction characteristics of inorganic or organic thin coatings on solid surfaces under water lubrication [J]. Tribology International, 2006, 39(12): 1601–1608.

Li J F, Huang J Q, Tan S H, et al. Tribological properties of silicon carbide under water-lubricated sliding [J]. Wear, 1998, 218(2): 167–171.

Presser V, Krummhauer O, Nickel K G, et al. Tribological and hydrothermal behaviour of silicon carbide under water lubrication [J]. Wear, 2009, 266(7–8): 771–781.

Sang K, Liu L, Jin Z H. Improvements on dry friction and wear properties for reaction-sintered silicon carbide by the matching size of SiC particles [J]. Materials and Design, 2007, 28(2): 735–738.

Tomizawa H, Fischer T E. Friction and wear of silicon-nitride and silicon-carbide in water: Hydrodynamic lubrication at low sliding speed obtained by tribochemical wear [J]. ASLE Transactions, 1987, 30(1): 41–46.

Zhang Z, Xu Y D, Zhang L T, et al. Internal friction and dynamic modulus of three-dimensional silicon carbide-matrix composites [J]. Materials Letters, 2005, 59: 2535–2538.

Kardashev B K, Burenkov Y A, Smirnov B I, et al. Internal friction and Young’s modulus of a carbon matrix for biomorphic silicon carbide ceramics [J]. Physics of the Solid State, 2005, 47(5): 886–890.

Xu J G, Kato K. Formation of tribochemical layer of ceramics sliding in water and its role for low friction [J]. Wear, 2000, 245(1–2): 61–75.

Jahanmir S, Ozmen Y, Ives L K. Water lubrication of silicon nitride in sliding [J]. Tribology Letters, 2004, 17(3): 409–417.

Amutha-Rani D, Yoshizawa Y, Hirao K, et al. Effect of rare-earth dopants on mechanical properties of alumina [J]. Journal of the American Ceramic Society, 2004, 87(2): 289–292.

Zhou F, Adachi K, Kato K. Wear-mechanism map of amorphous carbon nitride coatings sliding against silicon carbide balls in water [J]. Surface & Coatings Technology, 2006, 200(16–17): 4909–4917.

Abreu C S, Amaral M, Fernandes A J S, et al. Friction and wear performance of HFCVD nanocrystalline diamond coated silicon nitride ceramics [J]. Diamond and Related Materials, 2006, 15(4–8): 739–744.

Abreu C S, Amaral M, Oliveira F J, et al. Enhanced performance of HFCVD nanocrystalline diamond self-mated tribosystems by plasma pretreatments on silicon nitride substrates [J]. Diamond and Related Materials, 2006, 15(11–12): 2024–2028.

Abreu C S, Amaral M S, Oliveira F J, et al. Tribological testing of self-mated nanocrystalline diamond coatings on Si3N4 ceramics [J]. Surface & Coatings Technology, 2006, 200(22–23): 6235–6239.

Zhao F, Li H X, Ji L, et al. Superlow friction behavior of Si-doped hydrogenated amorphous carbon film in water environment [J]. Surface & Coatings Technology, 2009, 203(8): 981–985.

Sun F H, Ma Y P, Shen B, et al. Fabrication and application of nano-microcrystalline composite diamond films on the interior hole surfaces of Co cemented tungsten carbide substrates [J]. Diamond and Related Materials, 2009, 18(2–3): 276–282.

Shen B, Sun F H. Deposition and friction properties of ultra-smooth composite diamond films on Cocemented tungsten carbide substrates [J]. Diamond and Related Materials, 2009, 18(2–3): 238–243.

Zhang D C, Shen B, Sun F H. Study on tribological behavior and cutting performance of CVD diamond and DLC films on Co-cemented tungsten carbide substrates [J]. Applied Surface Science, 2010, 256(8): 2479–2489.

Abreu C S, Amaral M, Oliveira F J, et al. HFCVD nanocrystalline diamond coatings for triboapplications in the presence of water [J]. Diamond and Related Materials, 2009, 18(2–3): 271–275.

Vojs M, Vesely M, Redhammer R, et al. Double bias HFCVD multilayer diamond films on WC-Co cutting tools [J]. Diamond and Related Materials, 2005, 14(3–7): 613–616.

Lu X, Yang Q, Xiao C, et al. Synthesis and field electron emission characteristics of diamond multilayer films grown by graphite etching [J]. Journal of Physics D: Applied Physics, 2007, 40: 4010–4014.

Luo J L, Ying X T, Wang P N, et al. Growth and optical properties of nanocrystalline/microcrystalline diamond multilayer films [J]. Journal of the Korean Physical Society, 2005, 46(sup): 224–228.

Sun F H, Zhang Z M, Chen M, et al. Improvement of adhesive strength and surface roughness of diamond films on Co-cemented tungsten carbide tools [J]. Diamond and Related Materials, 2003, 12(3–7): 711–718.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 50975177)

Rights and permissions

About this article

Cite this article

Chen, Nc., Sun, Fh. Friction and wear performances of hot filament chemical vapor deposition multilayer diamond films coated on silicon carbide under water lubrication. J. Shanghai Jiaotong Univ. (Sci.) 18, 237–242 (2013). https://doi.org/10.1007/s12204-013-1388-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-013-1388-z