Abstract

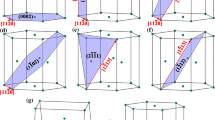

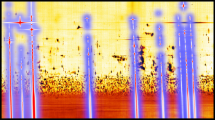

Uniaxial tensile and compressive tests were performed at room temperature on extruded AZ31 Mg alloy specimens and distinct tensile-compressive anisotropy was detected. Deformed specimens were examined and the results indicate that the generation of {10\(\bar 1\)2}〈10\(\bar 1\)1〉 twin is responsible for the mechanical anisotropy. A rate independent crystal plasticity model, which accounts for both slip and twinning, was developed for polycrystalline hexagonal close packed (HCP) materials. Model predictions for the stress-strain curves and texture evolution were in reasonable agreement with the experimental results. Specifically, the model captured the three stages of strain hardening for uniaxial-compression. By comparing stress-strain curves and texture evolution between model predictions and experimental measures, information about the dominant slip and twinning systems active at room temperature was deduced.

Similar content being viewed by others

References

Yoo M H. Slip, twinning, and fracture in hexagonal close-packed metals [J]. Metallurgical and Materials Transactions A, 1981, 12A(3): 409–418.

Wang Y N, Huang J C. The role of twinning and untwinning in yielding behavior in hot-extruded Mg-Al-Zn alloy [J]. Acta Materialia, 2007, 55(3): 897–905.

Brown D W, Agnew S R, Bourke M A M, et al. Internal strain and texture evolution during deformation twinning in magnesium [J]. Materials Science and Engineering A, 2005, 399(1–2): 1–12.

Barnett M R, Keshavarz Z, Beer A G, et al. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn [J]. Acta Materialia, 2004, 52(17): 5093–5103.

Nave M D, Barnett M R. Microstructures and textures of pure magnesium deformed in plane-strain compression [J]. Scripta Materialia, 2004, 51(9): 881–885.

Kleiner S, Uggowitzer P J. Mechanical anisotropy of extruded Mg-6%Al-1%Zn alloy [J]. Materials Science and Engineering A, 2004, 379(1–2): 258–263.

Chino Y, Kimura K, Hakamada M, et al. Mechanical anisotropy due to twinning in an extruded AZ31 Mg alloy [J]. Materials Science and Engineering A, 2008, 485(1–2): 311–317.

Jiang L, Jonas J J, Luo A A, et al. Influence of {10–12} extension twinning on the flow behavior of AZ31 Mg alloy [J]. Materials Science and Engineering A, 2007, 445–446(15): 302–309.

Tang W Q, Zhang S R, Peng Y H, et al. Simulation of magnesium alloy AZ31 sheet during cylindrical cup drawing with rate independent crystal plasticity finite element method [J]. Computational Materials Science, 2009, 46(2): 393–399.

Wang X M, Xu B X, Yue Z F. Micromechanical modelling of the effect of plastic deformation on the mechanical behaviour in pseudoelastic shape memory alloys [J]. International Journal of Plasticity, 2008, 24(8): 1307–1332.

Takahashi H. Stress-strain relations of polycrystalline metals. 3. Proportional loading of FCC metals [J]. Bulletin of the Japan Society of Mechanical Engineers, 1976, 19(136): 1115–1121.

Tomé C N, Lebensohn R A, Kocks U F. A model for texture development dominated by deformation twinning: Application to zirconium alloys [J]. Acta Metallurgica et Materialia, 1991, 39(11): 2667–2680.

Koike J. Enhanced deformation mechanisms by anisotropic plasticity in polycrystalline Mg alloys at room temperature [J]. Metallurgical and Materials Transactions A, 2005, 36A(7): 1689–1696.

Christian J W, Mahajan S. Deformation twinning [J]. Progress in Materials Science, 1995, 39(1–2): 1–157.

Styczynski A, Hartig Ch, Bohlen J, et al. Cold rolling textures in AZ31 wrought magnesium alloy [J]. Scripta Materialia, 2004, 50(7): 943–947.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 50821003), the National Basic Pre-Research Program of China (No. 2006CB708611), the Shanghai Science and Technology Projects (Nos. 07XD14016 and 10JC1407300) and the Program for New Century Excellent Talents in University (No. NCET-07-0545)

Rights and permissions

About this article

Cite this article

Tang, Wq., Huang, Sy., Zhang, Sr. et al. Polycrystalline behavior analysis of extruded magnesium alloy AZ31. J. Shanghai Jiaotong Univ. (Sci.) 18, 186–189 (2013). https://doi.org/10.1007/s12204-012-1295-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-012-1295-8