Abstract

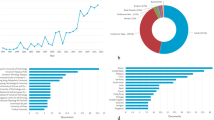

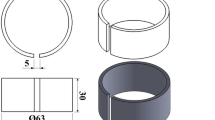

The study proves that the conformal cooling channel can overcome the disadvantages of the conventional cooling channel resulting from the limitation in complicated shape. The simulation analyses of the fragrance lamp with different cooling layouts show that the conformal cooling channel can offer a more uniform heat dissipation, lower volume shrinkage and shorter time to freeze than the conventional channel, which indicates significantly improvements in productivity and quality.

Similar content being viewed by others

References

Xu X R, Sachs E, Allen S, et al. Designing conformal cooling channels for tooling [C]// Solid Freeform Fabrication Proceedings. Austin, TX: University of Texas, 1998: 131–146.

Sachs E, Wylonis E, Allen S, et al. Production of injection molding tooling with conformal cooling channels using the three dimensional printing process [J]. Polymer Engineering and Science, 2000, 40(5): 1232–1247.

Dalgarno K W, Stewart T D, Allport J M. Layer manufactured production tooling incorporating conformal heating channels for transfer moulding of elastomer compounds [J]. Plastics Rubber and Composites, 2001, 30(8):384–388.

Li C L. A feature-based approach to injection mould cooling system design [J]. Computer Aided Design, 2001, 33(14): 1073–1090.

Ferreira J C, Mateus A. Studies of rapid soft tooling with conformal cooling channels for plastic injection moulding [J]. Journal of Materials Processing Technology, 2003, 142(2): 508–516.

Au K M, Yu K M. A scaffolding architecture for conformal cooling design in rapid plastic injection moulding [J]. International Journal of Advanced Manufacturing Technology, 2007, 34(5): 496–515.

Rannar L E, Glad A, Gustafson C G. Efficient cooling with tool inserts manufactured by electron beam melting [J]. Rapid Prototyping Journal, 2007, 13(3): 128–135.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 50875096)

Rights and permissions

About this article

Cite this article

Zheng, Z., Zhang, Ho., Wang, Gl. et al. Finite element analysis on the injection molding and productivity of conformal cooling channel. J. Shanghai Jiaotong Univ. (Sci.) 16, 231–235 (2011). https://doi.org/10.1007/s12204-011-1128-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-011-1128-1