Abstract

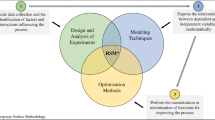

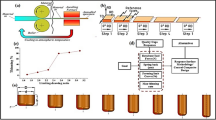

An intelligent response surface methodology (IRSM) was proposed to achieve the most competitive metal forming products, in which artificial intelligence technologies are introduced into the optimization process. It is used as simple and inexpensive replacement for computationally expensive simulation model. In IRSM, the optimal design space can be reduced greatly without any prior information about function distribution. Also, by identifying the approximation error region, new design points can be supplemented correspondingly to improve the response surface model effectively. The procedure is iterated until the accuracy reaches the desired threshold value. Thus, the global optimization can be performed based on this substitute model. Finally, we present an optimization design example about roll forming of a “U” channel product.

Similar content being viewed by others

References

Mackerle J. Finite element analyses and simulations of sheet metal forming processes [J]. Engineering Computations, 2004, 21(7–8): 891–940.

Li K Y, Yam L H. An optimization design method for large scale structures [J]. Computer Methods in Applied Mechanics and Engineering, 1998, 165(1–4): 273–289.

Schwabacher, Ellman M T, Hirsh H. Learning to set up numerical optimizations of engineering designs [J]. Ai Edam-Artificial Intelligence for Engineering Design Analysis and Manufacturing, 1998, 12(2): 173–192.

Fouskakis D, Draper D. Stochastic optimization: a review [J]. International Statistical Review, 2002, 70(3): 315–349.

Box G E P, Draper N R. Empirical model-building and response surfaces [C]// Wiley Series in Probability and Mathematical statistics. Applied Probability and Statistics. New York: Wiley. xiv, 1987: 669.

Fan S K S. Computational schema on ridge analysis [J]. Communications in Statistics-Simulation and Computation, 1999, 28(3): 767–783.

Pawlak Z. Al and intelligent industrial applications: The rough set perspective [J]. Cybernetics and Systems, 2000, 31(3): 227–252.

Benoit G. Data discretization for novel relationship discovery in information retrieval [J]. Journal of the American Society for Information Science and Technology, 2002, 53(9): 736–746.

Heislitz F. Simulation of roll forming process with the 3-D FEM code PAM-STAMP [J]. Journal of Materials Processing Technology, 1996, 59(1–2): 59.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, Gh., Wu, Y. & Li, Cx. Engineering design optimization based on intelligent response surface methodology. J. Shanghai Jiaotong Univ. (Sci.) 13, 285–290 (2008). https://doi.org/10.1007/s12204-008-0285-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-008-0285-3