Abstract

With shale oil reservoir pressure depletion and recovery of hydrocarbons from formations, the fracture apertures and conductivity are subject to reduction due to the interaction between stress effects and proppants. Suppose most of the proppants were concentrated in dominant fractures rather than sparsely allocated in the fracture network, the fracture conductivity would be less influenced by the induced stress effect. However, the merit of uniformly distributed proppants in the fracture network is that it increases the contact area for the injection gas with the shale matrix. In this paper, we address the question whether we should exploit or confine the fracture complexity for CO2-EOR in shale oil reservoirs. Two proppant transport scenarios were simulated in this paper: Case 1—the proppant is uniformly distributed in the complex fracture system, propagating a partially propped or un-propped fracture network; Case 2—the proppant primarily settles in simple planar fractures. A series of sensitivity studies of the fracture conductivity were performed to investigate the conductivity requirements in order to more efficiently produce from the shale reservoirs. Our simulation results in this paper show the potential of CO2 huff-n-puff to improve oil recovery in shale oil reservoirs. Simulation results indicate that the ultra-low permeability shales require an interconnected fracture network to maximize shale oil recovery in a reasonable time period. The well productivity of a fracture network with a conductivity of 4 mD ft achieves a better performance than that of planar fractures with an infinite conductivity. However, when the conductivity of fracture networks is inadequate, the planar fracture treatment design maybe a favorable choice. The available literature provides limited information on the relationship between fracture treatment design and the applicability of CO2 huff-n-puff in very low permeability shale formations. Very limited field test or laboratory data are available on the investigation of conductivity requirements for cyclic CO2 injection in shale oil reservoirs. In the context of CO2 huff-n-puff EOR, the effect of fracture complexity on well productivity was examined by simulation approaches.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Reservoir simulation was undertaken to study the impact of proppant allocation in the fractures on well production performance (Cipolla et al. 2009). The proppant distribution scenarios include an evenly distributed un-propped fracture network and dominant planar fractures. A simulation study on shale gas production in a 0.0001-mD shale matrix shows that the percentage of area filled by proppant and the proppant concentration in the network does not have a significant effect on gas production once the un-propped fracture network conductivity reaches 5 mD ft (Cipolla et al. 2009). However, when the un-propped fracture conductivity decreases further down to an order of 0.5 mD ft, the significance of network conductivity is clearly noticed and the well productivity is impaired by conductivity loss. This finding provides an understanding of the conductivity requirements in order to economically produce shale gas reservoirs. From points of fracturing treatments, employing a low proppant concentration would save on treatment costs. However, an optimum fracture design is not only to consider economic factors but it requires an essential fracture conductivity which would not compromise the well productivity due to conductivity loss. Cipolla et al. (2010) examined the relationship between fluid leak off and growth of complex fractures. Three categories of hydraulic fracture growth were used to describe the fracture propagation: planar growth, complex planar growth and network growth. The mechanism of proppant transport when the fracture growth is complex is not well understood. The distribution of proppant particles may be uniformly dispersed in the fracture network or mainly settled in dominant primary fractures.

Experimental studies of CO2 huff-n-puff EOR in shale oil core plugs include investigation of injection pressure, injection period, soaking time and the cycle efficiency (Gamadi et al. 2013; Meng et al. 2017; Song and Yang 2013). Nitrogen huff-n-puff and water huff-n-puff efficacy in the Eagle Ford shale outcrop was compared (Yu and Sheng 2016). The experimental results show that the shale oil recovery by nitrogen huff-n-puff outperformed water huff-n-puff under the same conditions. The oil recovery by water huff-n-puff using 24 h of soaking time after 12 cycles is 15%, while the nitrogen huff-n-puff recovers 25% shale oil. Soaking time influences the oil recovery in the laboratory. Using 24 h of soaking recovered 25% oil in place, while 18% of oil in place was produced by 1 h of soaking. Li and Sheng (2016) conducted cyclic CH4 injection in the Eagle Ford Shale, and their results indicated that the cyclic CH4 injection recovered more oil than cyclic nitrogen injection under identical operation conditions (Li and Sheng 2016). They found a larger size of core achieves a lower oil recovery than the smaller scale diameter under the same operation schedules. Numerical simulation approaches were used to history-match the experimental oil production and pressure profiles in the Bakken tight oil formations. The simulation results show that CO2 huff-n-puff achieves a superior recovery performance compared to waterflooding (Song and Yang 2017).

The role of molecular diffusion in recovering oil from tight and shale oil reservoirs has been examined in previous work (Chen et al. 2014; Sanchez-Rivera et al. 2015; Wan and Sheng 2015). The CME-GEM simulator was used to examine the possible influential factors that decide the oil response in the huff-n-puff process. The simulation results indicate that longer soaking periods recover less oil than shorter soaking times. They suggested that no soaking period is required in the huff-n-puff process in the Bakken shale. This statement is in contradiction with the experimental results mentioned earlier (Gamadi et al. 2013; Yu and Sheng 2016). The disagreement between experimental data and simulation methods indicates that more effort is required in understanding the mechanisms happening in the soaking process. Molecular diffusion effects in the soaking period were found to be important in huff-n-puff recovery prediction. The effect of molecular diffusion in cyclic gas injection on shale oil recovery has been investigated (Wan and Sheng 2015; Wan et al. 2015). Comparison of the laboratory data with the numerical simulation results shows that without the diffusion effect included in the simulation model a lower recovery factor is predicted than experimentally observed. Chen and Gu (2017) used a simulation approach to investigate the optimal injection and production duration in a cycle to achieve the maximum oil recovery. The sensitivity analyses show that short injection and production periods were favorable for CO2 huff-n-puff performance. A series of sensitivity studies of CO2 huff-n-puff EOR in shale oil reservoirs was examined (Alfarge et al. 2017b; Kong et al. 2016; Sheng 2015; Yu et al. 2014). The simulation results show that the most influential variables are injection time, CO2 injection rate and the number of cycles employed. However, CO2 soaking, fracture half-length and permeability were listed as less sensitive parameters to simulation output, while they are influential in the experimental EOR process. The soaking period is not a critical factor to improved oil recovery by gas huff-n-puff in shale oil reservoirs (Boosari et al. 2015). CO2 huff-n-puff is more favorable for reservoirs with high heterogeneity by using long hydraulic fractures (Yu et al. 2015).

A pioneering published work documents the factors that control the well production performance in shale oil reservoirs (Wilson 2015). Wan et al. (2016) used a numerical simulation approach to evaluate the fracture complexity effect on the EOR potential of cyclic gas injection in fractured shale oil reservoirs. They did not consider the proppant distribution effect on the growth of fracture complexity. The purpose of this paper is to extend earlier work performed by our research group. This work builds upon previous work by considering the proppant distribution in the fracture growth. This paper aims to show what types of proppant distribution would achieve a maximum liquid production by CO2 huff-puff in shale oil reservoirs. It is a question that needs to be addressed: should we exploit the fracture complexity or avoid complex fracture growth in shale oil reservoirs. Suppose a fixed amount of proppant was used in a fracture treatment, is a propped planar fracture or complex fracture network which is partially propped superior for shale oil production? This paper interrelates numerical simulation approaches with the fracture characteristics to investigate related factors that affect the performance of the cyclic injection recovery process.

2 Simulation model description and methods

The pseudo-component description model of the Eagle Ford Shale fluid used in this paper is shown in Table 1 (Phi and Schechter 2017). The fluid equation of state (EOS) model was tuned on the production PVT data. The EOS model provides a good agreement with the Eagle Ford PVT data. The parameters in the reservoir simulation model in Table 2 were adjusted to history-match the observed production data. Then, the history-matched model was employed to investigate the CO2-EOR studies.

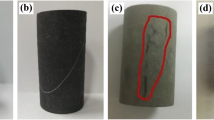

Figure 1 shows two proppant transport scenarios in a pioneering work (Cipolla et al. 2010). In Case 1, the proppant particles are uniformly distributed in the complex fracture system. In Case 2, the proppant is mainly concentrated in planar fractures without forming a complex fracture network. If the proppants are sparsely distributed in the fracture network, the proppant concentration is inadequate to provide support to the fracture system. It leads to a creation of an un-propped or partially propped fracture network that provides insufficient fracture network conductivity. The finite fracture conductivity of the network may undermine the well productivity in shales. On the contrary, an infinite conductivity of the planar fracture is formed when proppant is concentrated in dominant fractures without opening fissures or the natural fracture network. The drawback of planar fractures is that they have less contact area with the shale matrix than a fracture network. Injected CO2 primarily disperses through the fracture network into the shale matrix. CO2-EOR in simple and planar fractures has been extensively studied. This paper will focus on comparing the CO2 huff-n-puff EOR performance in these two fracture scenarios (Case 1 and Case 2). Figure 2 shows the simulation model of a fracture network (Case 1) and planar fractures (Case 2). The network size is 2000 ft × 1000 ft of the stimulated reservoir volume. In the base model of Case 1, the spacing of the fracture network is 200 ft with a partially propped fracture conductivity of 4 mD ft. In the base model of Case 2 where proppants settled in planar fractures, the fracture spacing also is 200 ft with a propped fracture conductivity of 80 mD ft.

Proppant transport scenarios (Cipolla et al. 2010)

The mechanical fracture model was not considered in this paper. Modeling the deformation, failure of rocks and fracture propagation process can be found in the literature (Sahimi 1995). In the stimulated reservoir volume, the complexity of the fracture network is simplified by uniformly spaced at 200-ft orthogonal cross fractures (as shown in Fig. 3. The fracture network is described by a uniform fracture intensity and apertures (0.12-inch gaps). The simulation models attempt to account for the effect of the proppant distribution on the CO2-EOR well production performance. We performed a series of fracture conductivity sensitivity studies to examine the well performance in these two scenarios. The shale matrix permeability is 0.0001 mD. The shale reservoir is under primary production for 10 years. The CO2 huff-n-puff process is 6 months of injection and 6 months of production in a cycle. The secondary CO2-EOR process is conducted for 10 cycles. The process optimization questions such as how much gas should be injected during a cycle, at what rate should it be injected and how long should a producing period be in a cycle are beyond the scope of this paper. These can be found in the published literature (Sheng 2017; Li et al. 2016; Tang et al. 2016). The objective of this paper is to examine the effect of fracture characteristics on CO2 huff-n-puff performance in liquid rich shales.

3 Stress-dependent fracture conductivity modeling approach

The conductivity of a partially propped or un-propped fracture network is subject to reduction induced by stress, especially when the proppant is sparsely allocated, and the proppant concentration in the network is low. The stress-dependent conductivity between the fracture permeability and the effective stress can be described by an existing formula (Raghavan and Chin 2004):

Gao et al. (2013) developed an analytical model to calculate the proppant embedment, proppant deformation and fracture conductivity without considering the proppant crush. The calculated results from their model were compared with the experimental data, and they matched well. In this paper, Gao’s model was used to simulate the propped fracture conductivity (high proppant concentration), which is affected by factors such as closure pressure, the size of proppant and the concentration of proppant.

where f1 and f2 are defined as:

The experimental results were compared against the model prediction, and the author (Culter et al. 1985) proposed the fitting parameters of bauxite as: C1 = \(1.3479 \times 10\) −5 MPa−1, C2 = \(9.6014 \times 10\) −6 MPa−1. The related fitting parameters of the various proppants (bauxite, porcelain and alumina-mullite) can refer to Culter et al. (1985).

4 Results and discussion

Figure 3 illustrates the reservoir pressure change in the base model-Case 1 after the first year of primary depletion. It indicates that the reservoir pressure drop first occurs surrounding the fracture network. Figure 4 shows the model history-matching results with a well from Wilson County in the Eagle Ford shale. A good match of the well production data was obtained. The well bottom-hole pressure was also history-matched which was not shown in the paper. It was noted that there are several points dropped to zero rate when the well was shut off for well operations.

The structure of this paper is first to examine the CO2 huff-n-puff efficacy in a 200-ft spacing of fracture network. In most simulation runs, Case 1 and Case 2 were compared for cyclic CO2 injection efficacy. Then, a comparison of CO2-EOR performance in shale reservoirs was conducted on different fracture spacing scenarios (the 200-ft and 100-ft fracture spacing).

Mayerhofer et al. (2006) used a reservoir simulation approach to estimate the fracture conductivity in the Barnett Shale for the partially propped and un-propped fractures, within a range from 1 to 5 mD ft. Figure 5 presents the well oil production for Case 1 and Case 2 for 10 cycles of CO2 huff-n-puff. The fracture conductivity requirement for CO2-EOR in shale oil reservoirs was initiated with a value larger than the base model (4 mD ft). The result shown in Fig. 5 indicates that the well performance is not sensitive to conductivity change once the fracture conductivity becomes larger than the base model. This reflects that the base model fracture conductivity is adequate enough to provide flow capacity. In subsequent studies, examination of the fracture conductivity effect on well performance should focus on a point below the base model value. The grid size effect on the simulation results has been evaluated. Grid sensitivity analysis was performed to find a tradeoff between obtaining adequate precision and saving computational effort.

Figure 6 shows the cumulative oil production in the base model-Case 1 with a fracture spacing of 200 ft. Different fracture conductivity sensitivity was performed including the effect of stress-dependent fracture conductivity on CO2-EOR performance. Improved oil recovery by CO2 huff-n-puff over the primary production is observed in all simulation runs. In the base model-Case 1, the cumulative oil production driven by primary pressure depletion is 223,000 barrels. The incremental oil production by CO2 huff-n-puff EOR is 139,000 barrels. The well productivity is not affected by the stress-induced conductivity loss in the primary production, while it causes a loss of 48,588 barrels in the secondary CO2-EOR process. In the base model, the fracture conductivity of the network is 4 mD ft. Comparing the recovery profiles of the base model, the impact of fracture network conductivity on primary production is not significant, but a larger fracture conductivity contributes to a higher oil recovery in the cyclic CO2-EOR process. However, when the conductivity of the fracture network is reduced to an order of 0.2–0.02 mD ft, the well productivity is remarkably reduced by the conductivity loss both in the primary production and secondary CO2-EOR process. The fall in cumulative oil production is pronounced as the fracture conductivity decreases below 1 mD ft. The magnitude of the oil production fall depends on the fracture conductivity requirement in liquid-rich shales.

The results shown in Fig. 7 are similar to those in Fig. 6. A noticeable difference is that the effect of the reduction in the stress-dependent fracture conductivity on CO2 huff-n-puff enhanced oil recovery is not as significant as shown in Fig. 6. In the planar fracture base model-Case 2, the fracture conductivity is set to 80 mD ft, considered as an infinite fracture conductivity. The effect of stress-induced fracture conductivity loss on well productivity is not observed. When the fracture conductivity is infinite and sufficiently high, the well productivity in shales is not sensitive to the reduction in conductivity. Figure 10 illustrates more in detail of this.

As the well injectivity or productivity in a shale formation is dependent on the matrix and fracture conductivity, the CO2 injection rate at an equal injection pressure would differ with the fracture conductivity. Figure 8 shows the CO2 injection rate and injection pressure in fracture networks of different conductivity. The horizontal well constraint for the injector is 1000 bbl/day, and the maximum allowable injection pressure is 7000 psi. Figure 8 shows that the CO2 injection rates rapidly decrease from the initial constraint value and the well then is switched to injection pressure control. The wells with a higher fracture network conductivity inject at a higher CO2 injection rate (or well injectivity index). Figure 9 compares the well injection and produced CO2 volume for different conductivity of fracture networks. With an increase in fracture network conductivity, the total CO2 injection and production volumes are also augmented. This is consistent with the data presented in Fig. 8. A lower CO2 production volume than injection indicates the CO2 sequestration in shale reservoirs. Since the effect of CO2 adsorption on the surface of the shale is not included in the simulation model, the only factor that results in CO2 reduction is that CO2 is captured and reacted with the formation fluid. The utilization of CO2-EOR in the context of CO2 capture and sequestration has been reported extensively in the literature (Boosari et al. 2015; Carpenter 2015a; Faltinson and Gunter 2013).

Figure 10 compares the recovery profiles for Case 1 and Case 2 with different fracture conductivities. The results indicate that the well production for Case 1 is higher than Case 2 under the same fracture conductivity. It is not an indicator that the cyclic CO2-EOR process would achieve a better performance in un-propped fracture networks than propped planar fractures. If the fracture conductivity of Case 1 is excessively low, for instance 0.02 mD ft, the propped planar fractures will have a superior performance to the fracture network. The decision of whether to exploit or avoid the fracture complexity should be different case by case. In the simulation results depicted in Fig. 10, if the fracture network conductivity can reach 4 mD ft or essentially higher, then the partially propped fracture network exhibits a better performance in comparison with the propped planar fractures. In another extreme case when the un-propped fracture network conductivity is as low as 0.02 mD ft, the propped fracture is more favorable for CO2-EOR production.

Figure 11 presents a comparison of the oil recovery performance for two different fracture spacings: Dx = 100 ft and Dx = 200 ft. In all cases, the fracture conductivity with 4 mD ft was used. It is observed that the primary production difference for the Dx = 200 ft case is larger than the 100-ft fracture spacing. It is attributed to the fact that in the 100-ft fracture spacing the average reservoir pressure can be depleted to the constraint bottom-hole flowing pressure for both Case 1 and Case 2. The smaller fracture spacing provides sufficient conduit for fluid mass transfer, while in the case of 200-ft fracture spacing, the average reservoir pressure cannot drop to the minimum well constraint pressure, as shown in Fig. 11. The primary benefit of the CO2 huff-n-puff process is an increase in the reservoir pressure in shales as shown in Fig. 11.

Figure 12 shows a comparison of normalized oil recovery profiles for Cases 1 and 2 at different fracture spacings. The cumulative oil production was normalized by dividing by the maximum possible oil production or oil production from an infinite conductivity.

The maximum oil production can be achieved by enlarging the fracture network conductivity to an infinite value. An upper fracture conductivity limit exists over which incremental oil production is not possible. In Fig. 12, the cumulative oil production from a 100-ft spacing fracture network with 4 mD ft is adopted as the maximum oil production value. Fracture conductivity divided by the square root of reservoir permeability and fracture spacing \(\left( {F_{\text{RCDC}} = F_{\text{RCD}} /\sqrt {D_{x} K} } \right)\) is plotted as the x-axis against the normalized oil production (Cipolla et al. 2008). From Fig. 12, it was found that FRCDC with a value of 40 is considered as an optimum value, which represents a 4 mD ft of fracture conductivity. It suggests that when the conductivity of fracture network approaches 4 mD ft, any decrease in fracture conductivity would result in a well productivity reduction.

Figure 13 shows the distribution of global CO2 mol fractions in the simulation model at the end of the first CO2 huff-n-puff cycle (left plots) and end of the tenth cycle (right plots). It is noted that we only simulate one quarter of the stimulated reservoir volume. The results indicate that the injected CO2 migrates along the fracture network or surrounding the network at the first cycle. However, after 10 cycles of CO2 injection, the CO2 penetrates deeper into the shale matrix. Compared with the planar fracture model, the fracture network provides more contact area for CO2 dispersion. The swept volume of the processed zone by CO2 injection in the fracture network is larger than the planar fracture model. The total CO2 mol fraction in the fracture network is higher than the planar fracture model. A larger stimulated volume by CO2 injection in the fracture network is achieved compared to the planar fracture case. As the injection cycle increases, the volume of CO2 dissolved in the oil phase is expanding accompanied by an increase in the average matrix pressure.

Table 3 summarizes the well oil production by primary depletion and the CO2-EOR process at a fracture spacing of 200 and 100 ft. It is observed that the oil recovery from a smaller fracture spacing (100 ft) is higher than a larger spacing (200 ft). Under the same fracture conductivity, CO2 huff-n-puff yields more oil recovery in the fracture networks compared to the planar fractures. When the fracture conductivity is below 4 mD ft, the role of fracture conductivity in the mobilization of oil in shale reservoirs is highlighted. Ye (2016) used CMG-GEM to explicitly model the fracture system and investigate the optimum fracture conductivity in producing shale gas reservoirs under various scenarios: different production time, matrix permeability, rock stiffness and hydraulic fracture spacing (Gu et al. 2014; Ye 2016). The criteria for determining the optimum fracture conductivity is based on acquiring the maximum gas production of the first year. However, the optimum fracture conductivity in this paper is targeted at achieving a maximum combined production of 10 years of primary recovery and 10 years of CO2-EOR recovery. The optimum fracture conductivity decreases with an increase in production period. The optimum fracture conductivity or fracture requirement in a complex fracture network is lower than that of planar fractures in that the interconnected fracture network provides a larger contact area for shale gas flow (Ye 2016). Considering the stress-dependent fracture conductivity, the requirement for fracture conductivity in soft rock is higher than the stiff case because it needs to compensate for the conductivity loss due to proppant embedment. A distinction found in producing shale oil reservoirs is that the impact of fracture spacing overwhelms the fracture conductivity. Fracture complexity should be exploited so that the network can provide essentially a desired conductivity. In cases where the fracture conductivity is severely compromised by maximizing fracture complexity, the shale oil recovery performance by CO2 huff-n-puff would be negatively affected.

5 Further discussions on the factors that have impact on CO2-EOR

5.1 Effect of molecular diffusion on CO2-EOR performance

Molecular diffusion is considered as an important recovery mechanism in modeling gas injection in fractured reservoirs (Hoteit and Firoozabadi 2009; Shojaei and Jessen 2014; Wan and Sheng 2015; Wan et al. 2015). The intensive fractures provide huge potential for mass diffusive flux between the matrix and fractures. The Péclet number was commonly used to evaluate which recovery mechanism is dominant, molecular diffusion or convection. The importance of molecular diffusion in producing from nanoscale pores of shale formations was examined in our previous studies (Wan and Sheng 2015; Wan et al. 2015). It is not the scope of this paper to expand the discussion of molecular diffusion effect on CO2-EOR performance in the presence of complex fractures. However, it is of interest to include what has been done in this area and the status of molecular diffusion on CO2-EOR projects.

Alfarge et al. (2017a) investigated the effect of molecular diffusion on CO2 huff-n-puff in the Bakken shale oil formations. The influencing factors of CO2 molecular diffusion are the contact area and the exposure time within the reservoir fluid and CO2. The simulation results indicate that by considering the molecular diffusion mechanism CO2 penetrates deeper into the shale matrix than without diffusion. The role of molecular diffusion in heterogeneous shale formations was studied by Jia et al. (2017). Their simulation results showed that a high reservoir heterogeneity is favorable for oil recovery at a long correlation length. Excluding the effects of molecular diffusion leads to an underestimation of reservoir oil recovery by 39% in the CO2 huff-n-puff process. Including the molecular diffusion effect results in a decline of reservoir pressure, which is caused by the reduction of interfacial tension. The diffusion coefficients of species during the CO2 injection process were measured by fluid saturation profiles gathered from X-ray CT (Carpenter 2015b). The effect of molecular diffusion on oil mobilization depends heavily on system size. The oil production rate from diffusion alone is very high at core scales. It needs to be reconsidered to upscale the CO2 diffusion rate from laboratory conditions to field scale. In our future work, we need to identify the diffusivity of CO2 and light components with experimental methods in order to accurately predict the CO2 diffusion mechanism in fractured shale reservoirs.

5.2 Effect of proppant distribution in the secondary fractures on CO2-EOR performance

The effect of fracture conductivity on CO2-EOR performance needs further investigation due to proppant being transported limited distances away to the dominant fractures in slickwater fracture treatments. A modeling case study of the Barnett shale gas well hydraulic fracturing treatment with Formation mechanical properties illustrates the propagation process of complex hydraulic fracture networks (Xu et al. 2010). Proppant settles very quickly near the wellbore due to the low viscosity of slickwater. (The viscosity of slickwater is low so it is not able to carry the sand long distances). However, the settling velocity of 100 mesh sands is slower than 40/70 mesh sands. The 100 mesh sands tend to be transported further from the wellbore and placed in the secondary fracture networks. The chance that the proppant is evenly distributed in the fracture networks is small (Warpinski et al. 2008; Warpinski 2009). The Bakken field fracturing observations reported that the 20/40 mesh sand was transported to distances of 2200 ft away at the offset wells with cross-linked fluids. With slickwater fracturing, the radioactive traced 40/70 mesh sand was identified at a distances of 500 ft (Warpinski et al. 2008). Laboratory and field applications indicate that the distances that particles will be transported is a function of fracturing fluid viscosity, slurry rate and particle sizes. A lower slurry rate is designed to create larger fracture width and spacing. Similarly, experimental results also demonstrate that a low injection rate has a greater chance of increasing the complexity of fracture networks and interconnecting more natural fractures (Wang and Miskimins 2010).

A significant concern about fracturing low permeability reservoirs is the fracture conductivity requirements in nano-darcy formations. Cipolla et al. (2009) suggested that the impact of proppant fill would be insignificant in low permeability (0.0001 mD) formations if the un-propped fracture conductivity can reach 5 mD ft. The production increase by the effect of proppant distribution in the networks is noticed when the network conductivity is less than 0.5 mD ft. The presence of proppant in the fracture network has a significant impact on well production performance if the un-propped fracture conductivity is inadequate. In this case, the transport and settling of proppant in the secondary fractures are critical to improve the shale oil well productivity. In fracturing treatment of low permeability formations, the leak-off rates are very low. It provides sufficient time for proppant transport and settling. Smaller mesh proppants are inclined to settle into natural fractures and sheared bedding planes (Shrivastava and Sharma 2018). Simulation work by Gu et al. (2016) suggests that the presence of natural fractures is similar to increase the effective reservoir permeability. The fracture network conductivity requirement is closely related to the hydraulic fracture spacing and production time. The production design for CO2-EOR in shale reservoirs needs further experimental work to achieve maximum productivity while reducing the proppant cost. In our future work, we will implement experimental methods combined with numerical simulation models to characterize the fracture complexity effect on CO2-EOR performance.

6 Conclusions

In this paper, we have examined the effect of fracture complexity on the performance of cyclic CO2 injection process in detail. The recovery mechanisms of two types of proppant transport scenarios were simulated: Case 1—a partially propped or un-propped fracture network and Case 2—propped planar fractures. Simulation results indicate that achieving fracture conductivity over 4 mD ft is adequate to meet the conductivity requirements in shale oil reservoirs. However, the exact value of the fracture network conductivity requirement is uncertain. This depends heavily on the hydraulic fracture spacing, the reservoir matrix permeability and reservoir fluid properties. If the conductivity of the fracture network approaches an upper conductivity limit in the normalized conductivity graph, the fracture treatment design should be targeted at maximizing the fracture complexity. However, it is desirable to generate an infinite conductivity of planar fractures when the fracture network fails to meet the conductivity requirement. At the same fracture conductivity, the CO2 huff-n-puff process is more favorable in fracture networks compared to planar fractures. The normalized oil recovery profile comparison for Case 1 and Case 2 suggests that when the conductivity of fractures approaches a cut-off value, any decrease in fracture conductivity would result in a well productivity reduction. A distinct feature of extracting from shale oil reservoirs by cyclic CO2 injection is that the fracture-network spacing is more critical than fracture conductivity, but the network has to meet an essential conductivity requirement. Whether to exploit fracture complexity or not for extraction of hydrocarbons from shale oil formations is dependent upon the created fracture network conductivity.

Abbreviations

- F RCD :

-

Fracture conductivity, mD cm

- D :

-

Initial fracture aperture, mm

- D 1 :

-

Diameter of Sphere 1 (proppant), mm

- D 2 :

-

Thickness of coal bed, mm

- f 1 :

-

Function related to the closure pressure elastic modulus etc., dimensionless

- f 2 :

-

Function related to the closure pressure elastic modulus etc., dimensionless

- E 1 :

-

Elastic modulus of Sphere 1 (proppant), MPa

- E 2 :

-

Elastic modulus of Sphere 2 (proppant), MPa

- v 1 :

-

Poisson’s ratio of Sphere 1, dimensionless

- v 2 :

-

Poisson’s ratio of Sphere 2, dimensionless

- p :

-

Closure pressure, MPa

- k f :

-

Fracture permeability, mD

- k fi :

-

Initial permeability, mD

- d f :

-

Experimental fitting data, psi−1

- Δp :

-

Effective mean stress, psi

References

Alfarge D, Wei M, Bai B, Almansour A. Effect of molecular-diffusion mechanisim on CO2 huff-n-puff process in shale-oil reservoirs. In: SPE Kingdom of Saudi Arabia technical symposium and exhibition; 24–27 April, Dammam, Saudi Arabia; 2017a. https://doi.org/10.2118/188003-ms.

Alfarge D, Wei M, Bai B. Feasibility of CO2-EOR in shale-oil reservoirs: numerical simulation study and pilot tests. In: Carbon management technology conference, 17–20 July, Houston, Texas, USA; 2017b. https://doi.org/10.7122/485111-MS.

Boosari SSH, Aybar U, Eshkalak MO. Carbon dioxide storage and sequestration in unconventional shale reservoirs. J Geosci Environ Prot. 2015;3(1):7–15. https://doi.org/10.4236/gep.2015.31002.

Carpenter C. Enhanced gas recovery by CO2 sequestration vs. refracturing treatment. J Pet Technol. 2015a;67:125–7. https://doi.org/10.2118/0715-0125-JPT.

Carpenter C. Visualization of CO2 EOR by molecular diffusion in fractured chalk. JPT. 2015b;7(7):122–4. https://doi.org/10.2118/0715-0122-JPT.

Chen C, Gu M. Investigation of cyclic CO2 huff-and-puff recovery in shale oil reservoirs using reservoir simulation and sensitivity analysis. Fuel. 2017;188:102–11. https://doi.org/10.1016/j.fuel.2016.10.006.

Chen C, Balhoff M, Mohanty KK. Effect of reservoir heterogeneity on primary recovery and CO2 huff ‘n’ puff recovery in shale-oil reservoirs. SPE Reserv Eval Eng. 2014;17:404–13. https://doi.org/10.2118/164553-PA.

Cipolla CL, Warpinski NR, Mayerhofer MJ, Lolon E, Vincent MC. The relationship between fracture complexity, reservoir properties, and fracture treatment design. In: SPE annual technical conference and exhibition, 21–24 September, Denver, Colorado, USA; 2008.

Cipolla CL, Lolon E, Mayerhofer MJ, Warpinski NR. The effect of proppant distribution and un-propped fracture conductivity on well performance in unconventional gas reservoirs. In: SPE hydraulic fracturing technology conference, January 19–21, The Woodlands, Texas; 2009. https://doi.org/10.2118/119368-MS.

Cipolla CL, Warpinski NR, Mayerhofer MJ, Lolon EP, Vincent MC. The relationship between fracture complexity, reservoir properties, and fracture treatment design. SPE Prod Oper. 2010;25(4):438–52. https://doi.org/10.2118/115769-PA.

Cutler RA, Enniss DO, Jones AH, Swanson SR. Fracture conductivity comparison of ceramic proppants. SPE J. 1985;25:57–170. https://doi.org/10.2118/11634-PA.

Faltinson JE, Gunter B. Net CO2 stored in North American EOR projects. J Can Pet Technol. 2013;50(7):55–60. https://doi.org/10.2118/137730-PA.

Gamadi TD, Sheng JJ, Soliman MY. An experimental study of cyclic gas injection to improve shale oil recovery. In: SPE annual technical conference and exhibition held in New Orleans, 30 September-2 October Louisiana, USA; 2013. https://doi.org/10.2118/166334-MS.

Gao YP, Lv YC, Wang M, Li KW. New mathematical models for calculating the proppant embedment and conductivity. In: The 6th international petroleum technology conference, Mar 26–28, Beijing, China; 2013. https://doi.org/10.2523/16410-MS.

Gu M, Kulkarni PM, Rafiee M, Ivarrud E, Mohanty KK. Understanding the optimum fracture conductivity for naturally fractured shale and tight reservoirs. In: SPE/CSUR unconventional resources conference, 30 September-2 October, Calgary, Alberta, Canada; 2014. https://doi.org/10.2118/171648-MS.

Gu M, Kulkarni P, Rafiee M, Ivarrud E, Mohanty K. Optimum fracture conductivity for naturally fractured shale and tight reservoirs. SPE Prod Oper. 2016;31(4):289–99. https://doi.org/10.2118/171648-PA.

Hoteit H, Firoozabadi A. Numerical modeling of diffusion in fractured media for gas-injection and recycling schemes. SPE J. 2009;14(02):323–37. https://doi.org/10.2118/103292-PA.

Jia B, Tsau JS, Barati R. Role of molecular diffusion in heterogeneous shale reservoirs during CO2 huff-n-puff. In: SPE Europe featured at 79th EAGE conference and exhibition, 12–15 June, Paris, France; 2017. https://doi.org/10.2118/185797-MS.

Kong B, Wang S, Chen S. Simulation and optimization of CO2 huff-and puff processes in tight oil reservoirs. In: SPE improved oil recovery conference, April 11–13, Tulsa, OK; 2016. https://doi.org/10.2118/179668-MS.

Li L, Sheng JJ. Experimental study of core size effect on CH4 huff-n-puff enhanced oil recovery in liquid-rich shale reservoirs. J Nat Gas Sci Eng. 2016;34:1392–402. https://doi.org/10.1016/j.jngse.2016.08.02.

Li L, Sheng JJ, Sheng J. Optimization of huff-n-puff gas injection to enhance oil recovery in shale reservoirs. In: SPE low perm symposium, May 5–6, Denver, Colorado, USA; 2016. https://doi.org/10.2118/180219-MS.

Mayerhofer MJ, Lolon EP, Youngblood JE, Heinze JR. Integration of microseismic-fracture-mapping results with numerical fracture network production modeling in the Barnett shale. In: SPE annual technical conference and exhibition, September 24–27, San Antonio, Texas, USA; 2006. https://doi.org/10.2118/102103-MS.

Meng X, Sheng JJ, Yu Y. Experimental and numerical study on enhanced condensate recovery by gas injection in shale gas condensate reservoirs. SPE Reserv Eval Eng. 2017;20(2):471–7. https://doi.org/10.2118/183645-P.

Phi T, Schechter D. CO2 EOR simulation in unconventional liquid reservoirs: an Eagle Ford case study. In: SPE unconventional resources conference, Calgary, February 15–16, Alberta, Canada, 2017. https://doi.org/10.2118/185034-MS.

Raghavan R, Chin LY. Productivity changes in reservoirs with stress-dependent permeability. In: SPE annual technical conference and exhibition, 29 September-2 October, San Antonio, TX; 2004. https://doi.org/10.2118/88870-PA.

Sahimi M. Flow and transport in porous media and fractured rocks: from classical methods to modern approaches. 2nd ed. Weinheim: VCH; 1995.

Sanchez-Rivera D, Mohanty K, Balhoff M. Reservoir simulation and optimization of huff-and-puff operations in the Bakken shale. Fuel. 2015;147:82–94. https://doi.org/10.1016/j.fuel.2014.12.062.

Sheng JJ. Increase liquid oil production by huff-n-puff of produced gas in shale gas condensate reservoirs. J Unconv Oil Gas Resour. 2015;11:19–26. https://doi.org/10.1016/j.juogr.2015.04.004.

Sheng JJ. Optimization of huff-n-puff gas injection in shale oil reservoirs. Petroleum. 2017;3(4):431–7. https://doi.org/10.1016/j.petlm.2017.03.004.

Shojaei H, Jessen K. Diffusion and matrix-fracture interactions during gas injection in fractured reservoirs. In: SPE improved oil recovery symposium, 12–16 April, Tulsa, Oklahoma, USA; 2014. https://doi.org/10.2118/169152-MS.

Shrivastava K, Sharma MM. Proppant transport in complex fracture networks. In: SPE hydraulic fracturing technology conference and exhibition, 23–25 January, The Woodlands, Texas, USA; 2018. https://doi.org/10.2118/189895-MS.

Song C, Yang D. Performance evaluation of CO2 huff-n-puff processes in tight oil formations. In: SPE unconventional resources conference Canada, November 5–7, Calgary, Alberta, Canada; 2013. https://doi.org/10.2118/167217-ms.

Song C, Yang D. Experimental and numerical evaluation of CO2 huff-n-puff processes in Bakken Formation. Fuel. 2017;190:145–62. https://doi.org/10.1016/j.fuel.2016.11.041.

Tang Y, Su Z, He J, Yang F. Numerical simulation and optimization of enhanced oil recovery by the in situ generated CO2 huff-n-puff process with compound surfactant. J Chem. 2016. https://doi.org/10.1155/2016/6731848.

Wan T, Sheng JJ. Compositional modelling of the diffusion effect on EOR process in fractured shale-oil reservoirs by gas flooding. J Can Pet Technol. 2015;54(2):107–15. https://doi.org/10.2118/2014-1891403-PA.

Wan T, Yu Y, Sheng JJ. Experimental and numerical study of the EOR potential in liquid-rich shales by cyclic gas injection. J Unconv Oil Gas Resour. 2015;12:56–67. https://doi.org/10.1016/j.juogr.2015.08.004.

Wan T, Sheng J, Soliman MY, Zhang Y. Effect of fracture characteristics on behavior of fractured shale-oil reservoirs by cyclic gas injection. SPE Reserv Eval Eng. 2016;19:350–5. https://doi.org/10.2118/168880-PA.

Wang Y, Miskimins JL. Experimental investigations of hydraulic fracture growth complexity in slickwater fracturing treatments. In: Tight gas completions conference, 2–3 November, San Antonio, Texas, USA; 2010. https://doi.org/10.2118/137515-MS.

Warpinski NR. Stress amplification and arch dimensions in proppant beds deposited by waterfracs. In: SPE hydraulic fracturing conference, January 19–21, The Woodlands, Texas; 2009. https://doi.org/10.2118/119350-MS.

Warpinski NR, Mayerhofer MJ, Vincent MC, Cipolla CL, Lolon EP. Stimulating unconventional reservoirs: maximizing network growth while optimizing fracture conductivity. In: SPE unconventional reservoirs conference, February 10–12, Keystone, Colorado; 2008. https://doi.org/10.2118/114173-MS.

Wilson A. Modeling of EOR in shale reservoirs stimulated by cyclic gas injection. J Pet Technol. 2015;67(1):75–7. https://doi.org/10.2118/0115-0075-JPT.

Xu W, Thiercelin MJ, Le Calvez J, Zhao R, Ganguly U, Weng X, Moros H. Fracture network development and proppant placement during slickwater fracturing treatment of Barnett shale laterals. In: SPE annual technical conference and exhibition, 19–22 September, Florence, Italy; 2010. https://doi.org/10.2118/135484-MS.

Ye XD. Optimum hydraulic fracture conductivity for shale/tight reservoirs. Ph.D. dissertation. University of Calgary, 2016.

Yu W, Lashgari HR, Sepehrnoori K. Simulation study of CO2 huff-n-puff process in Bakken tight oil reservoirs. In: SPE Western North American and rocky mountain joint meeting, April 17–18, Denver, Colorado; 2014. https://doi.org/10.2118/169575-MS.

Yu W, Lashgari HR, Wu K, Sepehrnoori K. CO2 injection for enhanced oil recovery in Bakken tight oil reservoirs. Fuel. 2015;159:354–63. https://doi.org/10.1016/j.fuel.2015.06.092.

Yu Y, Sheng JJ. A comparative experimental study of IOR potential in fractured shale reservoirs by cyclic water and nitrogen gas injection. J Pet Sci Eng. 2016;149:844–50. https://doi.org/10.1016/j.petrol.2016.11.034.

Acknowledgements

This work was supported by the Science Foundation of China University of Petroleum-Beijing at Karamay (No. KL01JB201700003) and Xinjiang Uygur Autonomous Region Tianchi 100 Talent Plan which is highly appreciated. We greatly appreciate the detailed and valuable comments from two anonymous referees.

Author information

Authors and Affiliations

Corresponding author

Additional information

Edited by Yan-Hua Sun

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wan, T., Liu, HX. Exploitation of fractured shale oil resources by cyclic CO2 injection. Pet. Sci. 15, 552–563 (2018). https://doi.org/10.1007/s12182-018-0226-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12182-018-0226-1