Abstract

Biodiesel obtained from mustard seed is found to be a promising alternative for petroleum diesel fuel owing to its similarity in physical and chemical properties. In this work, TiO2 nano-fluid which acts as an oxygen buffer during combustion was added to mustard oil biodiesel (MOBD) to study its effect on emission characteristics of MOBD. TiO2 nano-fluid can provide high surface energy during the course of combustion and reduces the limitations of neat biodiesel. A four-stroke, multi-cylinder, water-cooled, diesel engine was used in the experiments and was fueled with diesel, neat MOBD and MOBD with TiO2 nanoparticles at 100 ppm (MOBDT100), 200 ppm (MOBDT200) and 300 ppm (MOBDT300). Experimental results revealed that the TiO2 nanoparticles had positive effect on the emission characteristics of MOBD as it acted as an oxidation buffer. MOBDT300 showed a reduction in HC, CO and smoke emissions as compared to pure MOBD. In addition, NO x emissions were also reduced by the catalytic activity of the TiO2 nanoparticles which reduce the peak combustion temperature. Therefore, TiO2 nano-fluid had a positive effect on reducing the emissions associated with neat biodiesel.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Availability of crude oil and petroleum products is likely to become limited and expensive in the future. On the other hand, the fuel economy of engine is improving and will continue to progress. However, the massive increase in the number of vehicles has started dictating the fuel demand. Gasoline and diesel fuels may become limited and costly in the future. Of the various alternate fuels under consideration, biodiesel derived from vegetable oils is the most promising alternative fuel to diesel due to its limited need for modification (Britto and Martins 2014), free from sulfur, better lubricating property and improving fuel or energy security. Biodiesel is mainly comprised of mono-alkyl esters of long chain fatty acids, and it is defined in standard ASTM D6751. Normally feedstock such as vegetable oil and animal fat is used to produce biodiesel through the transesterification process (Lesnik et al. 2014). Through this process glycerol is extracted from the vegetable oil and can be used in existing engines (Yuvarajan and Venkata Ramanan 2016a). Further, by this process the oil properties of biodiesel are made closer to diesel. It may be used in any diesel automotive engine in its pure form or blended with diesel (Lahane and Subramanian 2015; Kannan et al. 2011).

Mustard oil biodiesel has higher kinematic viscosity and oxygen content which will result in increase in nitrous oxide (NO x ) emission during the combustion process in diesel engines (Mahbubul Alam 2014; Tabtabaei et al. 2015). Many studies of mustard oil biodiesel have been reported for its effective usage in the compression ignition engine applications (Yuvarajan and Venkata Ramanan 2016b; Singh et al. 2010). Yuvarajan and Venkata Ramanan (2016b) studied the working of a diesel engine fueled with neat mustard oil biodiesel and found a reduction in brake thermal efficiency and significant increase in NO x emission when compared with normal diesel. However, HC and CO emission was found to be lower for MOBD fuel operation compared to diesel. Singh et al. (2010) tested the mustard oil biodiesel MOBD in a CI engine and found increases in NO x emissions. They found that emission value of HC, CO and smoke is reduced by 3.8%, 5% and 4.1%, respectively. Issariyakul and Dalai (2011) employed mustard oil biodiesel in a constant speed diesel engine and found a significant reduction in HC, CO and smoke emission. However, NO x emissions were found to increase with increase in biodiesel content.

Adding nanoparticles in powder form to the biodiesel results in a higher evaporation rate and shortened delay period and promotes secondary atomization which results in lower engine emissions. This also provides catalytic activity during combustion process (Keskin et al. 2008). Nano-sized metal oxide particles have the ability to hold energy within. This results in improved reactivity. Further they also have a large specific surface area which improves the combustion. Nano-fluid improves the reaction between fuel and oxygen present in the cylinder owing to high surface-to-volume ratio to improve the combustion (Khond and Kriplani 2016). In addition, nano-sized metal oxide particles produce hydroxyl radicals during the reaction between the metal oxide and water which in turn improves the oxidation of soot, thereby reducing oxidation temperature (Keskin et al. 2008). Due to many inbuilt features, many metal oxides namely MnO, ZnO, CuO and TiO2 are used as additives in diesel engines.

Much research had been carried out to reduce emissions in biodiesel operation by adding nano-sized metal oxide particles in different proportions. Keskin et al. (2008) investigated the effect of doping synthesized Mn and Mo nano-metal oxides as an additive in diesel fuel. They found improvement in fire point, flash point and viscosity. Further manganese oxide additive reduced CO emission by 37%, NO x by 4% compared to the diesel fuel. Khond and Kriplani (2016) studied the effect of nano-fluid additives on performance and emission characteristics of emulsified diesel and biodiesel fueled in a stationary CI engine. They found the nano-fluid reduces NO x emissions by 6.7%. Venu and Madhavan (2016) investigated the effect of titanium and zirconium oxide in biodiesel and ethanol blends and reported that additives in the fuel blend result in reduced emissions. Balaji et al. (2016) investigated the impact of propyl gallate antioxidant in neem oil biodiesel. They concluded that the NO x emission of neem oil biodiesel was found to be decreased by adding oxygenated additive. Kasireddy Sravani and Ravindra Reddy (2016) investigated the effect of zinc oxide nano-fluid with Pongamia biodiesel and reported the considerable reduction of emissions with slight increase in NO x in the exhaust. Yang et al. (2013) studied the effect of novel nano-organic additives in biodiesel and found 4%, 9.2% and 8.2% reduction in NO x , CO and smoke emissions, respectively. Sadhik Basha (2014) employed alumina nanoparticles as an additive in neat water–biodiesel emulsion fuels and found that the CO and HC emission was decreased by 22% and 16%, respectively, when compared to neat diesel.

From the outcome of various studies available in the technical literature, there exists a gap in implementing 100% neat mustard oil biodiesel as a replacement of diesel for practical applications owing to increased exhaust NO x emissions. The literature studies have not arrived at an organized investigation employing 100% MOBD in diesel engines to reduce the emissions by adding emulsified titanium dioxide nano-additives. Based on this critical situation, a methodology has been developed in order to use emulsified nano-metal oxides with neat mustard oil biodiesel. Emulsification of titanium oxide at different concentrations with MOBD biodiesel leads to reduced engine emissions.

Mustard oil is biodegradable and non-toxic oil, essentially free from sulfur and aromatics. Mustard oil has a high boiling point and flash point which makes it safer to handle and transport. Further, mustard oil has a low vapor pressure and volumetric energy density compared to diesel. In addition, mustard oil has low better lubricating property than diesel as it removes the deposits in the fuel lines and improves the engine life. Mustard oil has high cetane index and hence it possesses less knocking tendency. Hence, it is inferred that mustard oil can be used as fuel in existing diesel engine with minor or no modifications. No work of similar nature has been tried by adding metal oxide nano-additives to 100% MOBD biodiesel as an alternative source of energy for replacing diesel. Neat biodiesel will result in higher NO x emissions and a longer delay period which makes the fuel unfit for practical usage. Hence this work focuses on employing 100% mustard oil biodiesel incorporated with metal oxide nano-additives by emulsification in a diesel engine. Titanium dioxide (TiO2) nanoparticles were added to the mustard oil biodiesel (MOBD) at three different dosage levels of 100, 200 and 300 ppm. The present work also investigates the effect of TiO2 nanoparticles on the emission characteristics of neat biodiesel.

2 Materials and methods

2.1 Experimental setup

Table 1 represents the experimental setup and its specifications used for this study. Eddy current dynamometer is used to measure the torque and load during the trial. The engine exhausts are measured by an AVL DiGas 444 five gas analyzer. Table 2 presents the uncertainties in the calculated results and the accuracies of the measurements. A K-type thermocouple having a range of 0–1500 °C is used to measure the temperature on the test bed. The whole experimentation was carried out under ambient condition (35 °C, 1 bar). Schematic layout of the test engine is shown in Fig. 1.

2.2 Fuel preparation

For experimentation, the biodiesel was prepared from neat mustard oil with the conventional transesterification process based on the ASTM D6751 standard. TiO2 nanoparticles were procured from local suppliers (Royal Scientific Suppliers). Chemical properties of TiO2 nanoparticles are listed in Table 3. TiO2 nano-fluid was prepared by adding 100, 200 and 300 ppm of TiO2 nano-powder to distilled water on a volume basis. TiO2 nano-fluid was then mixed with mustard oil biodiesel (MOBD) with the help of surfactant (Span 80) using a magnetic stirrer for 60 min at a speed of 510 rpm under atmospheric conditions. The fuel comprising MOBD with 100, 200 and 300 ppm of TiO2 nano-fluid was denoted as MOBDT100, MOBDT200 and MOBDT300. Span 80 was used as a surfactant to bond the nano-fluid with the mustard oil biodiesel. Figure 2a shows the scanning electron microscope image of TiO2 nano particles dispersed in the fuel. Figure 2b shows transmission electron microscopy image of TiO2 nanoparticles dispersed in the fuel. MOBDT100, MOBDT200 and MOBDT300 comprise of 93% MOBD, 5% nano-fluid and 2% surfactant on basis of volume. The prepared samples were found stable without any phase separation. The properties of all the tested fuels are listed in Table 4.

3 Results and discussion

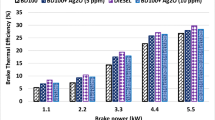

3.1 Hydrocarbon (HC) emission

Change in the unburned hydrocarbon emission with respect to load for diesel, MOBD, MOBDT100, MOBDT200 and MOBDT300 is shown in Fig. 3. Diesel engine exhibits more HC emissions due to improper mixing of fuel with air during the course of combustion (Keskin et al. 2008). Biodiesel has lower HC emission than diesel at all loads. This is due to the presence of inbuilt oxygen in it. Further, hydrocarbon emission increases with load for all tested fuels. At higher loads, additional quantities of fuel are supplied to maintain the power output at constant rate (Venkata Ramanan and Yuvarajan 2015). HC emissions for MOBDT100, MOBDT200 and MOBDT300 are lower than that of MOBD. TiO2 nano-fluids present in the fuel improve the rate of combustion by providing additional oxygen molecules and result in improved combustion (Venu and Madhavan 2016). Reduction in HC emission was more significant for MOBDT300. This is due to secondary atomization of MOBD with considerable fuel distribution in the combustion chamber with higher content of TiO2 nanoparticles (Venu and Madhavan 2016). In addition, the oxygen content in the fuel increases with increase in TiO2 nanoparticles causing improved combustion (Arulprakasajothi et al. 2015). By adding 300, 200 and 100 ppm of TiO2 nanoparticle to MOBD resulted in 3.6%, 2.4% and 1.8% decrease in HC emission, respectively, at full load compared to neat MOBD. This result is in line with other research (Venu and Madhavan 2016; Yuvarajan and Munuswamy 2016c; Sadhik Basha 2014).

3.2 Carbon monoxide (CO) emission

Figure 4 shows the variation in CO emission with load for diesel, MOBD, MOBDT100, MOBDT200 and MOBDT300. CO emissions are caused due to deficient burning of fuel throughout the combustion (Sadhik Basha 2014). Carbon monoxide emission for MOBD, MOBDT100, MOBDT200 and MOBDT300 is lower than for petroleum diesel. This is because of the excess oxygen molecules present in the biodiesel (Yuvarajan et al. 2017b). It is also observed that the carbon monoxide emission increases with increase in load for all tested fuels. As the load increases, additional quantity of fuel has to be supplied which in turn ends in a richer mixture and leads to higher CO emissions. CO emissions for MOBDT100, MOBDT200 and MOBDT300 are lower than that of MOBD at all loads. TiO2 nanoparticle improves the combustion rate by increasing the heat transfer rate of fuel during combustion owing to its catalytic activity and reduce CO emissions (Arulprakasajothi et al. 2015). In addition, the water present in biodiesel detonates and creates turbulence between air and fuel and reduces CO emissions (Sadhik Basha 2014). By adding 300 ppm of TiO2 nano-fluid to MOBD, 6.1% and 10.8% reduction in CO emissions is obtained when compared to MOBD and diesel, respectively.

3.3 Oxides of nitrogen (NO x ) emissions

Variation in nitrogen oxide (NO x ) emission with load for diesel, MOBD, MOBDT100, MOBDT200 and MOBDT300 is shown in Fig. 5. NO x emission from biodiesel was found to be higher than from diesel. This is owing to excess inbuilt oxygen content present in it. Fuel with higher oxygen content will enhance the combustion process and result in higher temperature combustion and higher NO x emission (Devarajan et al. 2017). However, TiO2 nano-fluid-blended biodiesel shows significant reduction in NO x emission when compared to neat biodiesel. This is due to the combined effect of TiO2 nano-fluids and the water present in fuel. The catalytic effect of TiO2 nano-fluids promotes the combustion by reducing the ignition delay period (Arulprakasajothi et al. 2015). The water present in MOBDT100, MOBDT200 and MOBDT300 reduces the peak temperature during combustion by absorbing the heat during combustion (Sadhik Basha 2014; Keskin et al. 2008). TiO2 nano-fluids increase the effective surface area of fuel with air and result in improved combustion and lower NO x emissions (Venu and Madhavan 2016).

3.4 Smoke opacity

Variations in smoke emissions with load for all the tested fuels are shown in Fig. 6. Smoke emission for MOBD, MOBDT100, MOBDT200 and MOBDT300 is less than that of diesel at all the loads. This is a result of higher inbuilt oxygen content of the fuel (Yuvarajan et al. 2017a). Smoke emission increases with load for all tested fuels. As the load increases, additional quantity of fuel is supplied which in turn ends in a richer mixture and leads to higher smoke emissions (Yuvarajan et al. 2016). Smoke emissions for MOBDT100, MOBDT200 and MOBDT300 are lower than that for MOBD at all the loads. TiO2 nanoparticles enhance the rate of evaporation of fuel owing to the inbuilt excess oxygen present in it. TiO2 nanoparticles reduce the activation temperature of carbon which aids complete combustion and lower smoke emissions (Arulprakasajothi et al. 2015). TiO2 nano-fluids increase the mixing rate of fuel with air by creating micro-detonation of water present in fuel during combustion. This result agrees with many other similar works (Venu and Madhavan 2016; Sadhik Basha 2014).

4 Conclusion

This study examined the emissions from the effect of TiO2 nano-fluids of varying proportions on mustard oil biodiesel in a constant speed diesel engine. The main intention of this study was to investigate the reductions in HC, CO, NO x and smoke emissions when deploying three different fuels. TiO2 nano-fluids are mixed with mustard oil biodiesel (MOBD) with the help of surfactant (Span 80) at 100, 200 and 300 ppm. The result confirmed that the HC, CO, NO x and smoke emission were reduced significantly by incorporating TiO2 nano-fluids in the biodiesel. Significant reductions in all the emissions were achieved by MOBDT300 owing to catalytic effects, improved thermal conductivity and better oxidation capability of TiO2 nano-fluids. Further, it is also concluded that the neat mustard oil biodiesel can be used in existing diesel engine with minor modification. Further, TiO2 nano-fluid had a positive effect on reducing the emissions associated with neat biodiesel

References

Arulprakasajothi M, Elangovan K, Reddy KH, Suresh S. Heat transfer study of water-based nanofluids containing titanium oxide nanoparticles. Mater Today Proc. 2015;2(4–5):3648–55. doi:10.1016/j.matpr.2015.07.123.

Balaji S, Kapilan N, Saravanan R. Influence of propyl gallate antioxidant on performance and emissions of a ci fuelled with neem oil biodiesel. J Biofuels. 2016;7(2):62. doi:10.5958/0976-4763.2016.00009.x.

Britto RF, Martins CA. Experimental analysis of a diesel engine operating in diesel–ethanol dual-fuel mode. Fuel. 2014;134:140–50. doi:10.1016/j.fuel.2014.05.010.

Devarajan Y, Munuswamy Babu D, Nagappan B. Emission analysis on diesel engine fuelled with cashew nut shell biodiesel and pentanol blends. Environ Sci Pollut Res. 2017;24(14):13136–41. doi:10.1007/s11356-017-8915-7.

Issariyakul T, Dalai AK. Comparative kinetics of transesterification for biodiesel production from palm oil and mustard oil. Can J Chem Eng. 2011;90(2):342–50. doi:10.1002/cjce.20679.

Kannan GR, Karvembu R, Anand R. Effect of metal based additive on performance emission and combustion characteristics of diesel engine fuelled with biodiesel. Appl Energy. 2011;88(11):3694–703. doi:10.1016/j.apenergy.2011.04.043.

Keskin A, Guru M, Altiparmak D. Influence of tall oil biodiesel with Mg and Mo based fuel additives on diesel engine performance and emission. Bioresour Technol. 2008;99(14):6434–8. doi:10.1016/j.biortech.2007.11.051.

Khond VW, Kriplani VM. Effect of nanofluid additives on performances and emissions of emulsified diesel and biodiesel fueled stationary CI engine: a comprehensive review. Renew Sust Energy Rev. 2016;59:1338–48. doi:10.1016/j.rser.2016.01.051.

Lahane S, Subramanian KA. Effect of different percentages of biodiesel–diesel blends on injection, spray, combustion, performance, and emission characteristics of a diesel engine. Fuel. 2015;139:537–45. doi:10.1016/j.fuel.2014.09.036.

Lesnik L, Iljaz J, Hribernik A, Kegl B. Numerical and experimental study of combustion, performance and emission characteristics of a heavy-duty DI diesel engine running on diesel, biodiesel and their blends. Energ Convers Manag. 2014;81:534–46. doi:10.1016/j.enconman.2014.02.039.

Mahbubul Alam M. Mustard oil based biodiesel: a sustainable engine fuel substitute for Bangladesh. Int J Sustain Energy Dev. 2014;3(1):127–35. doi:10.20533/ijsed.2046.3707.2014.0018.

Sadhik Basha J. An experimental analysis of a diesel engine using alumina nanoparticles blended diesel fuel. SAE Tech Pap Ser. 2014;. doi:10.4271/2014-01-1391.

Singh B, Kaur J, Singh K. Production of biodiesel from used mustard oil and its performance analysis in internal combustion engine. J Energy Res Technol. 2010;132(3):031001. doi:10.1115/1.4002203.

Sravani K, Ravindra Reddy G. Performance and emission characteristics of CI engine when fuelled with Pongamia biodiesel and zinc oxide nano fluid as additive. Int J Eng Res. 2016;. doi:10.17577/ijertv5is050825.

Tabtabaei S, Boocock DGB, Diosady LL. Biodiesel production from mustard emulsion by a combined destabilization/adsorption process. J Am Oil Chem Soc. 2015;92(8):1205–17. doi:10.1007/s11746-015-2677-5.

Venkata Ramanan M, Yuvarajan D. Performance study of preheated mustard oil methyl ester on naturally aspirated CI engine. Appl Mech Mater. 2015;787:761–5. doi:10.4028/www.scientific.net/amm.787.761.

Venu H, Madhavan V. Effect of nano additives (titanium and zirconium oxides) and diethyl ether on biodiesel-ethanol fuelled CI engine. J Mech Sci Technol. 2016;30(5):2361–8. doi:10.1007/s12206-016-0446-5.

Yang WM, An H, Chou SK, Vedharaji S, Vallinagam R, Balaji M. Emulsion fuel with novel nano-organic additives for diesel engine application. Fuel. 2013;104:726–31. doi:10.1016/j.fuel.2012.04.051.

Yuvarajan D, Venkata Ramanan M. Effect of magnetite ferrofluid on the performance and emissions characteristics of diesel engine using methyl esters of mustard oil. Arab J Sci Eng. 2016a;41(5):2023–30. doi:10.1007/s13369-016-2060-3.

Yuvarajan D, Venkata Ramanan M. Experimental analysis on neat mustard oil methyl ester subjected to ultrasonication and microwave irradiation in four stroke single cylinder diesel engine. J Mech Sci Technol. 2016b;30(1):437–46. doi:10.1007/s12206-015-1248-x.

Yuvarajan D, Venkata Ramanan M. Investigation on effect of magnetite nanofluid on performance and emission patterns of methyl esters of bio diesel. J Environ Eng Landsc Manag. 2016c;24(2):90–6. doi:10.3846/16486897.2016.1142447.

Yuvarajan D, Munuswamy DB. Analysis on the influence of nanoparticles of alumina, copper oxide, and zirconium oxide on the performance of a flat-plate solar water heater. Energy Fuel. 2016;30(11):9908–13. doi:10.1021/acs.energyfuels.6b02264.

Yuvarajan D, Ravi Kumar J, Devanatahan R, Harish V. Emissions analysis on second generation biodiesel. Front Environ Sci Eng. 2017a;11(1). doi:10.1007/s11783-017-0891-0.

Yuvarajan D, Nagappan BK, Dinesh Babu M. Performance and emissions analysis on diesel engine fuelled with cashew nut shell biodiesel and pentanol blends. Korean J Chem Eng. 2017b;34(4):0364–3. doi:10.1007/s11814-016-0364-3.

Author information

Authors and Affiliations

Corresponding author

Additional information

Edited by Xiu-Qin Zhu

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kishore Pandian, A., Munuswamy, D.B., Radhakrishana, S. et al. Influence of an oxygenated additive on emission of an engine fueled with neat biodiesel. Pet. Sci. 14, 791–797 (2017). https://doi.org/10.1007/s12182-017-0186-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12182-017-0186-x