Abstract

A comparative study is conducted to compare the theory and application effect of two accident causation models, the human factors analysis and classification system (HFACS) and the accident causation “2-4” model (24Model), as well as to provide a reference for safety researchers and accident investigators to select an appropriate accident analysis method. The two models are compared in terms of their theoretical foundations, cause classifications, accident analysis processes, application ranges, and accident prevention strategies. A coal and gas outburst accident is then analyzed using both models, and the application results are compared. This study shows that both the 24Model and HFACS have strong theoretical foundations, and they can each be applied in various domains. In addition, the cause classification in HFACS is more practical, and its accident analysis process is more convenient. On the other hand, the 24Model includes external factors, which makes the cause analysis more systematic and comprehensive. Moreover, the 24Model puts forward more corresponding measures to prevent accidents.

Similar content being viewed by others

1 Introduction

Accidents are the main focus of research in safety science (Fu et al. 2004), and they are caused by a variety of reasons, including unsafe acts. To analyze the causes of a particular accident, it is necessary to determine which unsafe acts occur in relation to the event and also any latent failures that cause the unsafe acts (Reason 1990). Researchers and accident investigators apply various methods to analyze accidents, and these methods are crucial for the understanding of the underlying reasons accidents occur and how to improve system safety (Salmon et al. 2012).

Many accident analysis methods and accident models have been proposed. The accident causation theory consists of the accident causation chain, accident attribution theory, and accident triangle theory (Fu et al. 2013). The accident causation chain can be classified as the classical, modern, and contemporary accident causation chain according to the depth of analysis (Fu 2013). The classical accident causation chain, i.e. accident proneness theory (Greenwood and Woods 1919) and energy transfer theory (Sui et al. 2005), analyzes accidents from two viewpoints: the fault of people and physical reasons. The modern accident causation chain adds education and management factors as the root cause, such as Wigglesworth’s education model (Fu 2013) and Bird’s (1974) accident causation model. However, these models do not give specific explanations for the management factors, which make them difficult to use for practical accident analysis. As an advanced theory, the contemporary accident causation chain classifies management factors into several categories, which is helpful for practice application. The “Swiss cheese” model (Reason 1990), Stewart’s accident cause model (Stewart 2011), the 24Model (Fu et al. 2016a), and the human factors analysis and classification system (HFACS) (Shappell and Wiegmann 2000) all belong to the contemporary causation chains. HFACS, as one of the most famous models, was proposed by Shappell and Wiegmann in 2000 and established on the basis of the “Swiss cheese” model. The 24Model was proposed in 2005 (Fu et al. 2005b) and has become a common accident cause analysis method through continuous improvement. Compared with the famous HFACS, what advantages and disadvantages the 24Model actually has, as one of the latest accident cause chains, is what we need to focus on. However, until this time, few studies have researched the differences between the theories and applications of these two models. Mi et al. (2014) analyzed a fire accident to illustrate the advantages and disadvantages of the “Swiss cheese” model, HFACS, and the 24Model. However, the 24Model used in this study was not the latest version, and the comparison was not comprehensive.

This paper discusses and analyzes the differences between the HFACS and the 24Model from various perspectives: the theoretical foundations, cause classifications, accident analysis processes, application ranges, and accident prevention strategies. Then, the two models are applied, respectively, to a rough analysis of a coal and gas outburst accident, with the aim of making a comparative analysis of the models’ application results. The results of this study will provide a reference for safety researchers and accident investigators in their selection of an appropriate accident analysis method.

2 Brief introduction to HFACS and the 24Model

2.1 Human factors analysis and classification system (HFACS)

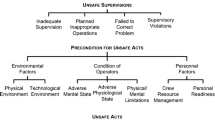

Shappell and Wiegmann defined the latent failures and active failures in Reason’s “Swiss cheese” model and described the “holes” of four level failures: unsafe acts, preconditions for unsafe acts, unsafe supervision, and organizational influences. They proposed the human factors analysis and classification system (HFACS) (Wiegmann and Shappell 2003) after analyzing thousands of aviation accidents caused by human factors. The framework of HFACS is shown in Fig. 1.

Human factors analysis and classification system (HFACS) (Wiegmann and Shappell 2003)

2.2 Accident causation “2-4” model (24Model)

The accident causation “2-4” model (24Model) is a behavior chain that was proposed based on Heinrich’s (Heinrich et al. 1980), Bird’s (Bird 1974), and Reason’s (Reason 1990) accident causation chains and organizational behavior theories (Tang 2015). This model illustrates how organizational factors and individual factors contribute to accidents (Fu 2015; Fu et al. 2016a). The 24Model divides the causes of accidents into two groups, the organization’s internal factors and the organization’s external factors. The organization’s internal factors are represented by two levels, the organizational level and the individual level. The organizational level is divided into two phases, guiding behavior and operating behavior, and the individual level is also divided into two phases, habitual behavior and one-off behavior and conditions. In this respect, guiding behavior refers to the defects of organizational safety culture. Operating behavior refers to the defects of the organizational safety management system. Habitual behavior includes the lack of safety knowledge, shortage of safety awareness, bad safety habits, and poor physiological status, and one-off behavior and conditions refer to unsafe acts and unsafe conditions. In the 24Model, each cause category has a clear definition. The accident causation “2-4” model is presented in Fig. 2.

Accident causation “2-4” model (24Model) (Fu et al. 2016a)

3 Theoretical comparison of HFACS and the 24Model

With reference to relevant literature worldwide, the differences between HFACS and the 24Model can be analyzed from multiple perspectives.

3.1 Theoretical foundations

HFACS was proposed based on Reason’s ideas and theory. Reason’s book, Human Error, was first published in 1990, and it continues to be one of the most widely cited and respected works in the field of behavior safety. HFACS provides a framework for applying Reason’s ideas and theory (Wiegmann and Shappell 2003).

The 24Model, proposed by Fu, was based on Heinrich’s, Bird’s, and Reason’s accident causation models and organizational behavior theory as well. Unsafe acts and unsafe conditions, as the direct causes of Heinrich’s theory, were retained. The management factors and the basic reason in Bird’s theory are divided into several categories in the 24Model. Reason’s ideas are considered as well in the 24Model. According to organizational behavior theory, the root cause of an accident lies in organization deficiencies. The 24Model established the relationship between organizational and individual factors to illustrate the mechanism of accidents (Fu 2013).

As described above, both models have strong theoretical foundations, and the 24Model is a scientific accident cause model.

3.2 Accident cause classification

Comprehensive improvement and supplement to the classification of human factors is carried out by analyzing thousands of accidents. Therefore, the classification standard of causal factors in HFACS is practical (Shappell and Wiegmann 1997).

In the 24Model, the definition and classification of causal factors are obtained through abundant theoretical research and the analysis of many accidents (Fu et al. 2005a; Fu 2016; Ma 2016). However, the practicability of the classification results still needs to be verified through the model’s application.

According to the definitions and categories of factors in the two models, the factors were compared. The results are shown in Table 1.

As shown in Table 1, all of the factors included in HFACS are correspondingly mentioned in the 24Model. In other words, the 24Model encompasses all of the factors included in HFACS. In addition, the 24Model takes external factors such as government regulation and social politics into consideration, which delivers a systematic and comprehensive accident analysis. Moreover, “unsafe acts” referred to in the 24Model also include operators’ “unsafe acts” and supervisors’ “unsafe supervision” in HFACS. In the 24Model, management relates solely to a manager’s individual behavior control, which makes management behavior preventable and controllable and could thus effectively improve the current safety management status. Nevertheless, both models take into account organization and individual factors.

3.3 Accident analysis process

When applying the HFACS for accident analysis, we should first directly analyze the operators’ unsafe acts leading to the accident, which can be classified into two categories: errors and violations, according to whether they are unintentional or intentional, respectively. Then, we can classify unsafe acts into specific error types (decision errors, skill-based errors, and perceptual errors) and violation types (routine violations and exceptional violations). Second, the reasons that the unsafe acts took place should be analyzed. Environmental factors, the condition of operators, and personnel factors can be identified and classified into various categories. Third, the factors of unsafe supervision affecting the condition of operators and their environment should be identified and classified into inadequate supervision, planned inappropriate operations, failure to correct problems, and supervisory violations. Finally, the factors of organizational influences directly affecting supervisory practices, the conditions and actions of operators should be identified and classified into resource management, organizational climate, and operational processes.

However, the process of applying the 24Model through accident analysis is different. First, the organization where the accident occurred should be identified. Then, the causes within the organization are analyzed and are traced forward from the occurrence of the accident. Direct causes of the accident, related events and matters, are unsafe acts and unsafe conditions, while indirect causes are habitual behavior of members in the organization. Radical causes are defects of the safety management system in the organization, while root causes are defects of the safety culture in the organization. Finally, external causes that had an effect on the occurrence of the accident are analyzed, including external supervision factors, suppliers’ products and service factors, natural factors, workers’ family, inheritance, and growth environmental factors, as well as other factors such as politics, economy, culture, and law. The aim of accident analysis is to find out all causes that are responsible for the accident, i.e. all hazards (Fu et al. 2016a).

3.4 Application range

HFACS was originally designed for the investigation and analysis of military aviation accidents and then was gradually applied to analyze accidents in multiple domains, e.g., civil aviation (Li et al. 2008), marine traffic (Celik and Cebi 2009), railways (Reinach and Viale 2006), coal mines (Patterson and Shappell 2010), and medication and medical services (Mitchell et al. 2015). In the field of aviation, most of the literature directly applied HFACS to analyze human errors of the accidents. For example, Daramola (2014) used the HFACS as a conceptual framework to analyze 45 air transport accidents in Nigeria and found that skill-based errors, physical environment, and inadequate supervision were the most frequently occurring categories. Some researchers applied HFACS combined with other methods for accident analysis. For example, Wei et al. (2014) analyzed the human error in an aviation accident using HFACS combined with the expert subjective evaluation method and gray system theory. In other fields, researchers applied the modified HFACS for accident analysis. For example, Patterson and Shappell used a modified version of HFACS (HFACS-MI) to analyze 508 coal mine incidents and accidents to identify human factor trends and system deficiencies (Patterson and Shappell 2010). Soner et al. (2015) proposed a new approach, HFACS-FCM, combining fuzzy cognitive mapping and HFACS and demonstrated it on a fire-related deficiency sample database.

In contrast, the 24Model was first used for the investigation and analysis of coal mine accidents (Fu et al. 2013). It has been applied to analyze more than 800 coal mine accidents (Fu and Yang 2015; Gao and Fu 2015; Wang et al. 2016; Fu et al. 2017), including gas explosions, coal and gas outbursts, fires, floods, and roof accidents. The accident prevention training system was established based on the 24Model (Wang and Fu 2015). At present, this model has been applied to the chemical industry, public security, food, aviation, and other fields for accident investigation and analysis. For example, the 24Model was applied to analyze the Tianjin Port fire explosion accident, and the causes of the accident at all levels were identified (Fu et al. 2016b). Zhu et al. (2014) applied the 24Model to study 20 fire accidents on university campuses and found seven unsafe acts and corresponding habitual behavior, defects of the safety management system, and defects of the safety culture.

3.5 Accident prevention strategies

Through the practical application of HFACS, an accident analysis database can be formed. The forecast model can be obtained based on the database so as to formulate corresponding prevention measures before the accident occurs, whereas HFACS does not provide corresponding measures to predict and eliminate accident causes (Jiang 2015).

In the area of individual behavior control, the 24Model proposed a new method, namely “knowledge control,” which takes case studying as a medium. Wang and Fu (2015) developed a case training system to control individual behavior with the aim of increasing organization members’ safety knowledge by a case study to implement proactive accident prevention. In the aspect of organization behavior control, Fu et al. (2009) developed a safety culture analysis program, and Fu (2013) proposed a method of setting up a safety management structure and the operation method of safety management.

4 Comparison of the two models based on their applications

The HFACS and 24Model have been widely used in coal mine accident investigations and analyses. To illustrate the differences of the application effects between HFACS and the 24Model in accident analysis, a major coal and gas outburst accident (State Administration of Work Safety 2015) listed on the Web site of the State Administration of Coal Mine Safety in China was chosen as an example and analyzed by both models.

4.1 Description of a coal and gas outburst accident

The Xintian coal mine in Guizhou, China, is a coal and gas outburst mine adopting an inclined longwall comprehensive mechanized coal mining method. Before the accident, the No. 1404 tunneling face was driven into a complex geological tectonic belt without any improvement of the regional outburst prevention measures. The drilling coverage did not meet requirements, and the danger of a gas outburst was not eliminated. At 2:00 p.m. on October 05, 2014, the captain of the excavation team arranged for the team leader and gas inspector (who was unqualified and had no certificate) to lead eight workers to the No. 1404 tunneling face. At 5:17 p.m., the gas concentration at the tunneling face increased to 1.21%, and the duty monitor immediately reported this to the mine leadership. However, the mine leadership just required the on-duty dispatcher to report it to the chief engineer, and determination was found after receiving the report. They did not come to the dispatch office within 10 min to oversee an evacuation of the workers, which should have been done according to the regulations. The team leader determined that the gas concentration was caused by rib spalling, and the chief engineer reported it to the company’s chief engineer. Prior to 6:04 p.m., the gas alarm situated in the working face rang three times in succession, and the on-duty dispatcher reported this according to regulations. However, the mine leadership accorded no importance to the event, and a coal and gas outburst incident occurred at 6:46 p.m. killing 10 workers.

4.2 Results of the accident analysis

The accident occurred in the Xintian coal mine, so the organization’s internal factors were the factors within the scope of the Xintian coal mine, and other factors were the external causes. This paper applies both the HFACS and 24Model to analyze the coal and gas outburst accident and identify the causes at all levels. The results are shown in Table 2.

4.3 Comparative analysis of the application results

A comparison of the two models is made based on their applications to the accident analysis, including a comparison of the analysis process and the results of the coal and gas outburst accident. The following results are obtained.

The analysis process of the 24Model is more complex. It identifies the unsafe acts first, and then, it analyzes the other factors (including habitual behavior, defects of the safety management system, and defects of safety culture) that contribute to unsafe acts. Second, it analyzes the unsafe acts affecting the unsafe conditions and defects in the safety management system, and it continually analyzes the other factors leading to unsafe acts. It loops until all of the organization’s internal factors are identified. Last, the external causes that have an effect on the accident should be analyzed. However, the HFACS determines other category factors according to the operators’ unsafe acts, and it has a clear route of analysis. The comparative analysis illustrates that the specific application process for the accident analysis of the two models is different.

Moreover, some of the unsafe acts (e.g. “the head of the coal mine did not study gas outburst prevention measures on a monthly and quarterly basis”) and external causes that are identified in the 24Model are not shown in HFACS. The contents of other factors are the same in both models, but their classifications differ. It is illustrated that the causes in the 24Model encompass the causes in HFACS, but the analysis results of the 24Model are more comprehensive.

In addition, psychological factors can be identified by interviewing relevant personnel when applying HFACS. In contrast, there is less interpretation and application of physiological and psychological factors in the 24Model. Since the information in accident investigation reports is limited, both models fail to identify the physiological and psychological factors.

Furthermore, HFACS’s classification is based on analyzing the causes of aviation accidents. When the model is applied to coal and gas outburst accidents, the “crew resource management” category is not applicable. In contrast, the cause classification of the 24Model does not have industry limitations. Thus, the cause classification of HFACS does not have versatility.

In summary, the applications of the two models in the coal and gas outburst accident analysis verify the results of the theoretical comparisons of the two models in terms of the accident analysis process, the comprehensiveness of accident causes, and the versatility of cause categories. What is more, the subjectivity and limitation of psychological factors analysis is a problem in both models.

5 Conclusions

This study conducted a theoretical and application comparison of the HFACS and 24Model and obtained the following conclusions.

-

(1)

Both models have strong theoretical foundations. HFACS was proposed based on Reason’s ideas and theory. The 24Model was proposed based on Heinrich’s, Bird’s, and Reason’s accident causation models as well as organizational behavior theory. Thus, they are all scientific.

-

(2)

The cause classification standards of the two models are different. The cause classification of HFACS is more practical than that of the 24Model. Both models contain individual factors as well as organization factors. Beyond that, the 24Model takes external factors into consideration, which makes the cause analysis of accidents more systematic and comprehensive.

-

(3)

The accident analysis processes of both models are much the same. The accident analyst traces the causal factors from the direct causes back up to the other level factors. However, the analysis of unsafe acts using the 24Model is comparatively complex. Unsafe acts in the 24Model could be the result of unsafe conditions and defects of the safety management system, or it could be the cause of them.

-

(4)

The promotion and application of the two models can be implemented in many areas. However, in most areas, with the exception of aviation, HFACS should be modified according to the actual conditions when used in accident analysis. Alternately, it is not necessary to modify the 24Model in the analysis of all area accidents. However, its versatility in areas, except for the coal mine category, still lacks the sufficient data to be supported.

-

(5)

The two models have different ways of guiding accident prevention. HFACS explains the causal factors of the accident but does not give the corresponding implementing measures to predict and eliminate causes. On the other hand, the 24Model presents the organization and individual behavior control methods, and the case training system of controlling individual behavior in accidents has been developed.

This study shows that the 24Model is scientific and has a certain practicability. The above conclusions are expected to be used by safety researchers and accident investigators in selecting the most appropriate model for scientific research and accident causation analysis. However, it is recommended that how the physiological and psychological factors affect direct causes and how the external factors affect an accident should be further studied, and the practicability and applicability of the 24Model should be proved by more practical applications of accident investigation and analysis.

References

Bird F. Management guide to loss control. Atlanta, GA: Institute Press; 1974.

Celik M, Cebi S. Analytical HFACS for investigating human errors in shipping accidents. Accid Anal Prev. 2009;41:66–75. doi:10.1016/j.aap.2008.09.004.

Daramola AY. An investigation of air accidents in Nigeria using the human factors analysis and classification system (HFACS) framework. J Air Transp Manag. 2014;35:39–50. doi:10.1016/j.jairtraman.2013.11.004.

Fu G. Safety management. Beijing: Science Press; 2013 (in Chinese).

Fu G. Studies on the structure of safety science. Melbourne: Safety Science Press; 2015 (in Chinese).

Fu, G. 2016.The modified 24Model and the definitions of unsafe acts and unsafe conditions. 29 March 2016. http://blog.sciencenet.cn/blog-603730-965647.html (in Chinese).

Fu G, Yang C. Comparative study of unsafe acts in case of water flooding accidents in domestic coal mines. J Saf Environ. 2015;15(4):166–71. doi:10.13637/j.issn.1009-6094.2015.04.036 (in Chinese).

Fu G, Zhang JS, Xu SR. Critical examination of safety science. Eng Sci. 2004;6(8):12–6 (in Chinese).

Fu G, Li XD, Li J. Common factors leading to accidents and behavior type research based on prevention. J Saf Environ. 2005a;5(1):80–3 (in Chinese).

Fu G, Lu B, Chen XZ. Behavior based model for organizational safety management. China Saf Sci J. 2005b;15(9):21–7. doi:10.16265/j.cnki.issn1003-3033.2005.09.005 (in Chinese).

Fu G, Li CX, Xing GJ, et al. Investigations into the impacts of enterprise safety culture and its quantitative measuring. China Saf Sci J. 2009;19(1):86–92 (in Chinese).

Fu G, Yin WT, Dong JY, et al. Behavior-based accident causation: the“2-4”model and its safety implications in coal mines. J China Coal Soc. 2013;38(7):1123–9 (in Chinese).

Fu G, Fan YX, Tong RP, et al. The universal methodology for the causation analysis of accidents (4th edition). J Accid Prev. 2016a;1:7–12 (in Chinese).

Fu G, Wang JH, Yan MW. Anatomy of Tianjin Port fire and explosion: Process and causes. Process Saf Prog. 2016b;35(3):216–20. doi:10.1002/prs.11837.

Fu G, Cao JL, Wang XM. Relationship analysis of causal factors in coal and gas outburst accidents based on the 24Model. Energy Procd. 2017;107:314–20. doi:10.1016/j.egypro.2016.12.160.

Gao P, Fu G. Analysis and prevention of unsafe acts in mine roof accidents. Ind Saf Environ Prot. 2015;41(7):67–70 (in Chinese).

Greenwood M, Woods HM. The incidence of industrial accidents upon individuals with special reference to multiple accidents. Industrial Fatigue Research Board, Medical Research Committee. Report No. 4. Her Majesty’s Stationery Office, London. 1919.

Heinrich HW, Peterson D, Roos N. Industrial accident prevention. New York: McGraw-Hill Book Company; 1980.

Jiang H. Overview on HFACS and its application research. China Sci Technol Inf. 2015;5:13–4 (in Chinese).

Li WC, Harris D, Yu CS. Routes to failure: Analysis of 41 civil aviation accidents from the Republic of China using the human factors analysis and classification system. Accid Anal Prev. 2008;40:426–34. doi:10.1016/j.aap.2007.07.011.

Ma Y. Safety culture construction evaluation based on combination weighting and fuzzy topsis methods. Chem Eng Trans. 2016;51:715–20. doi:10.3303/CET1651120.

Mi FR, Yu JL, Li SX. Analysis and comparison of accident causation chains. China Public Secur Acad Ed. 2014;31(1):41–4 (in Chinese).

Mitchell RJ, Williamson A, Molesworth B. Use of a human factors classification framework to identify causal factors for medication and medical device-related adverse clinical incidents. Saf Sci. 2015;79:163–74. doi:10.1016/j.ssci.2015.06.002.

Patterson JM, Shappell SA. Operator error and system deficiencies: analysis of 508 mining incidents and accidents from Queensland, Australia using HFACS. Accid Anal Prev. 2010;42:1379–85. doi:10.1016/j.aap.2010.02.018.

Reason J. Human error. New York: Cambridge University Press; 1990.

Reinach S, Viale A. Application of a human error framework to conduct train accident/incident investigations. Accid Anal Prev. 2006;38:396–406. doi:10.1016/j.aap.2005.10.013.

Salmon PM, Cornelissen M, Trotter MJ. Systems-based accident analysis methods: A comparison of Accimap, HFACS and STAMP. Saf Sci. 2012;50:1158–70. doi:10.1016/j.ssci.2011.11.009.

Shappell SA, Wiegmann DA. A human error approach to accident investigation: The taxonomy of unsafe operations. Int J Aviat Psychol. 1997;7:269–91. doi:10.1207/s15327108ijap0704_2.

Shappell SA, Wiegmann DA. The human factors analysis and classification system (HFACS). Report Number DOT/FAA/AM-00/7. Washington DC: Federal Aviation Administration. 2000.

Soner O, Umut A, Metin C. Use of HFACS–FCM in fire prevention modelling on board ships. Saf Sci. 2015;77:25–41. doi:10.1016/j.ssci.2015.03.007.

State Administration of Work Safety. China’s work safety yearbook. Beijing: China Coal Industry Publishing Home; 2015 (in Chinese).

Stewart JM. The turn around in safety at the Kenora pulp paper mill. Prof Saf. 2011;12:34–44.

Sui PC, Chen BZ, Sui X. Safety principles. Beijing: Chemical Industry Press; 2005 (in Chinese).

Tang XS. Organizational behavior science. Beijing: China Railway Press; 2015 (in Chinese).

Wang JH, Fu G. Individual behavior control technology and training system for coal mine accident prevention. Saf Coal Mines. 2015;46(S1):109–12. doi:10.13347/j.cnki.mkaq.2015.S1.027.

Wang JH, Zhang JS, Zhu K, et al. Anatomy of explosives spontaneous combustion accidents in the Chinese underground coal mine: Causes and prevention. Process Saf Prog. 2016;35(3):221–7. doi:10.1002/prs.11816.

Wei SX, Sui YC, Chen YC. Research into the human errors evaluation method of flight accidents based on HFACS. Aeronaut Comput Tech. 2014;44(2):50–3 (in Chinese).

Wiegmann DA, Shappell SA. A human error approach to aviation accident analysis: The human factors analysis and classification system. Burlington, VT: Ashgate Publishing Ltd; 2003.

Zhu T, Fu G, Zhang S. Behavior reason analysis and prevention of campus fire accidents. Ind Saf Environ Prot. 2014;40(3):33–5 (in Chinese).

Acknowledgements

The authors gratefully acknowledge support from the State Key Program of the National Natural Science Foundation of China (No. 51534008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Edited by Yan-Hua Sun

Handling editor: Jian Shuai

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Fu, G., Cao, JL., Zhou, L. et al. Comparative study of HFACS and the 24Model accident causation models. Pet. Sci. 14, 570–578 (2017). https://doi.org/10.1007/s12182-017-0171-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12182-017-0171-4