Abstract

CO2 flooding is regarded as an important method for enhanced oil recovery (EOR) and greenhouse gas control. However, the heterogeneity prevalently distributed in reservoirs inhibits the performance of this technology. The sweep efficiency can be significantly reduced especially in the presence of “thief zones”. Hence, gas channeling blocking and mobility control are important technical issues for the success of CO2 injection. Normally, crosslinked gels have the potential to block gas channels, but the gelation time control poses challenges to this method. In this study, a new method for selectively blocking CO2 channeling is proposed, which is based on a type of CO2-sensitive gel system (modified polyacrylamide-methenamine-resorcinol gel system) to form gel in situ. A CO2-sensitive gel system is when gelation or solidification will be triggered by CO2 in the reservoir to block gas channels. The CO2-sensitivity of the gel system was demonstrated in parallel bottle tests of gel in N2 and CO2 atmospheres. Sand pack flow experiments were conducted to investigate the shutoff capacity of the gel system under different conditions. The injectivity of the gel system was studied via viscosity measurements. The results indicate that this gel system was sensitive to CO2 and had good performance of channeling blocking in porous media. Advantageous viscosity-temperature characteristics were achieved in this work. The effectiveness for EOR in heterogeneous formations based on this gel system was demonstrated using displacement tests conducted in double sand packs. The experimental results can provide guidelines for the deployment of the CO2-sensitive gel system for field applications.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, sequestration and utilization of CO2 is becoming an important research topic (Ren et al. 2010; Zhang et al. 2010). With the promotion of CO2 capture and storage technology, the problem of CO2 gas source can be solved and an increasing number of oil reservoirs will be candidates for CO2 EOR projects (Ren et al. 2014). Injection of CO2 into oil and gas reservoirs may have both economic and environmental benefits (Elsharkawy et al. 1996; Sweatman et al. 2009; Talebian et al. 2014). Targets for reducing greenhouse gas emission were also emphasized during the 21st session of the conference of the parties (COP21) which was held in 2015. Carbon dioxide capture and storage (CCS) is a promising way of making low-carbon energy solutions sustainable. However, CCS has made limited progress. An important route to making CCS a more sustainable option is via CO2 EOR as part of carbon capture, utilization and storage (CCUS) systems (http://www.bbc.co.uk/news/science-environment-35086346). In the southern states of the United States, CO2 flooding has been one of the main techniques for EOR due to their abundant natural CO2 sources (Zhu et al. 2011). It has been demonstrated that CO2 flooding can be one of the most effective EOR technologies proven in field tests and indoor experiments. There is a large-scale CO2 EOR project in the Weyburn Oilfield of Canada to deal with the industrial carbon emissions. Since 2000, about 1.8 million tons of CO2 per year captured from a coal gasification plant in the North Dakota have been transported to the Weyburn Oilfield through pipelines for injection to meet the requirements of storage and enhancing oil recovery. The potential of CO2 storage in the field is over 50 million tons and the incremental oil recovery can be achieved is approximately 9.8 % OOIP (Preston et al. 2005). Also a large-scale CO2 EOR project has been under way in China since 2006 in the Jinlin Oilfield (Northeast China) (Li and Fang 2007), in which CO2 produced and separated from natural gas reservoirs nearby is utilized, and about 0.3–0.5 million tons of CO2 per year have been injected into oil reservoirs since then. Meanwhile, in the Shengli Oilfield CO2 is captured from a coal-fired electricity plant for EOR and the capacity of CO2 injection will be over 0.5 million tons per year.

For the oil and gas industry, CO2 EOR has been demonstrated as a feasible technology to improve oil recovery. The EOR mechanisms include interfacial tension (IFT) reduction, CO2 dissolution into oil to reduce its viscosity and swell oil, permeability improvements as the reaction of carbonic acid (due to CO2 dissolution in water) with the limestone/dolomite, and wettability alteration due to asphaltene precipitation. It is notable that CO2 and oil may become miscible when the reservoir pressure exceeds the minimum miscible pressure (MMP) which can greatly reduce the residual oil saturation and improve oil recovery (Li et al. 2015). However, viscous fingering (due to the viscosity contrast of CO2 and oil) and gravity segregation (due to the lower density of CO2) can develop quickly and lead to lower macroscopic sweep efficiency during the process of CO2 injection. Reservoir heterogeneity leads to more severe early breakthrough of CO2 in production wells (Hamouda et al. 2009; Hou and Yue 2010; Enick et al. 2012). Early breakthrough of CO2 at production wells can reduce the sweep efficiency and undermine the oil recovery factor (Chakravarthy et al. 2006; Nezhad et al. 2006). A key issue of CO2 flooding is to mitigate the problem of gas channeling, especially for the reservoirs associated with high-permeability zones (thief zones) (Xing et al. 2010). Different techniques have been developed for blocking channels with high permeability and controlling the mobility of CO2, such as the water-alternating-gas (WAG) process (Christensen et al. 2001; Luo et al. 2013; Majidaie et al. 2015), injection of CO2 foam (Khalil and Asghari 2006; Yu et al. 2012; Zhang et al. 2013a), and use of CO2 thickener (Enick et al. 2012; Zhang et al. 2011; Mclendon et al. 2012). However, the technologies mentioned above have their own limitations, for example technical feasibility, economy, environmental friendliness, and safety. Gel polymer systems have been applied successfully in oil and gas wells to control unwanted water production in recent years. A gel system consists of polymer, crosslinker, water as the solvent, and some additive materials. The polymers used in gel systems mainly include polyacrylamides (PAM), partially hydrolyzed polyacrylamides (PHPA), xanthan gum, carboxymethylcellulose, furfural alcohol, acrylic/epoxy resins, silicate based gels, and block copolymers. Meanwhile, the crosslinker can be classified into two groups: organic (such as phenol, formaldehyde, and polyethyleneimine (PEI)) and inorganic (such as Cr3+, Al3+, Zr3+) (Dalrymple et al. 1994; Prada 1998; Niu et al. 2013). For inorganically crosslinked gels, nanotechnology was used to extend the gelation time of PHPA/Cr3+ systems (Cordova et al. 2008). The particles based on PEI and dextran sulfate (DS) can sequester Cr3+. In addition, PHPA/Cr3+ system assisted by foam was evaluated to block deep wormholes (Asghari et al. 2005). Copolymers of PAM were also studied for crosslinking with Cr3+ (Prada et al. 2000). Colloidal dispersion gels (CDGs) were investigated for blocking of “thief zones” in heterogeneous formations (Chang et al. 2006). With respect to the organically crosslinked gels, a system was designed by the PDVSA Research and Development Center that can exhibit blocking performance at temperature up to 160 °C. The PAtBA (PAM tert-butyl acrylate)/PEI system was developed for near-wellbore treatments, and it also can tolerate temperature up to 160 °C in fields. In order to enhance the strength of gels, materials were also added into the PAtBA/PEI system like cement, silica flour, and rigid-setting materials (RSMs). For the deep modification of injection profiles, two gel systems were identified: microspheres using PAM monomers crosslinked with N,N′-methylenebisacrylamide and microspheres produced by crosslinking 2-acrylamido-2-methylpropane sulfonic acid (AMPS) with diacrylamides and methacrylamides of diamines (El-Karsani et al. 2014). Polymer microsphere emulsion attracts considerable attention for water shutoff material with relatively low viscosity that can be injected continuously and prepared using formation water produced from oilfields (Guo et al. 2014). Preformed particle gels (PPGs) were also used to overcome different drawbacks, which include the uncertainty of gelling due to shear degradation and gelant composition changes caused by dilution by formation water and chromatographic fractionation, inevitable in situ gelation systems (Elsharafi and Bai 2016). Although generally gel treatment is performed with waterflooding for conformance control, several laboratory experiments and field applications have been conducted to divert CO2 (Martin and Kovarik 1987; Martin et al. 1988; Seright 1995; Hughes et al. 1999; Karaoguz et al. 2007; Hou and Yue 2010; Pipes and Schoeling 2014). However, gelation time limits the application of this technology mentioned above. In matrix treatments, it must be long enough so that the gel can penetrate into the reservoir to ensure sufficiently deep placement. It is difficult to control the gelation time with various factors affecting it, such as temperature, salinity of mixing water, and concentration of polymer. Hence, new types of gel systems need to be developed for blocking the gas channeling during the CO2 injection process with more reliable operation.

In this study, a new method for selectively controlling CO2 channeling and reducing its mobility is proposed, which is based on a CO2 sensitive gel system (modified polyacrylamide-methenamine-resorcinol) to form gel in situ. The CO2 sensitive gel system is gelation that will be triggered by CO2 in the reservoir, and the chemical can be dissolved in water and injected separately via a simple and economic slug injection technique. This method based on CO2 sensitivity makes the gelation process more reliable because the gelation needs not only the gelation time but also the presence of CO2. In this paper, the mechanisms of the gelation and their rheological behavior under different conditions were described. The CO2-sensitivity of the gel system was demonstrated using transparent tubes and the gel strength and gelation time were evaluated based on a gel strength code method. By means of viscosity measurements, the injectivity of the gel system was investigated. The effectiveness of the gel system for blocking gas channels in porous media was studied in sand pack flow experiments. The performance of EOR in simulated heterogeneous formations assisted by this gel system was also exhibited through displacement tests conducted in double sand packs.

2 Gelation mechanisms

A modified polyacrylamide-methenamine-resorcinol gel system investigated in this study has been used successfully as a water shutoff gel system (Zhang and Yang 1988). Its mechanism of gelation can be described as below under reservoir conditions in the presence of CO2.

In an acidic environment and at a high temperature, methenamine can release methanal (formaldehyde), and the released methanal can react with polyacrylamide (PAM) and resorcinol to generate phenolic resin via a polycondensation process. Phenolic resin can react further with PAM to produce linear polymers that can block channels (Noller 1965; Xing et al. 2005). Under normal reservoir conditions, an acid (such as HCl solution) is injected to trigger the chain reactions. While in the process of CO2 flooding, CO2 dissolves in formation water and reduces its pH to 2–4 (an acidic environment) (Raje et al. 1999; Hild and Wackowski 1999; Cai 2010; Zhang et al. 2013b, c), then the gel system can become CO2-sensitive that only works in high-permeability zones where CO2 can readily breakthrough or channel out. Therefore, the gel system can selectively block the high-permeability zones or gas channels. The reaction mechanisms involved are as follows: (1) CO2 dissolves in formation water and generates carbonic acid in situ. Carbonic acid creates an acidic environment that is conductive to the formation of gels. (2) Methenamine releases methanal in the acidic environment at relatively high temperatures. (3) Multi-hydroxymethyl resorcinol may be formed through the reaction between methanal and resorcinol, and via polycondensation of multi-hydroxymenthyl resorcinol, phenolic resin is formed. (4) Large linear polymers may be formed through further polycondensation between phenolic resin and polyacrylamide that can make the gel more stable and strong.

3 Experimental

3.1 Materials

Modified polyacrylamide (PAM) was supplied by the Sinopharm Chemical Reagent Co., Ltd, with an average molecular weight (MW) over 3 × 106 and a solid content of 85.0 % above. Methenamine (colorless or white crystals, MW 140.9, purity ≥99.0 %), resorcinol (white needle-like crystals, MW 110.1, purity ≥99.5 %), and CaCl2 (purity ≥96.0 %) were also supplied by the Sinopharm Chemical Reagent Co., Ltd. CO2 (purity ≥99.8 %), N2 (purity ≥99.999 %), NaCl (purity ≥99.5 %), and deionized water were used in experiments. In the experiments, the simulated formation water was prepared using NaCl2 and CaCl2, with total salinity of 20,000 ppm or 200,000 ppm that included 1000 ppm of CaCl2, representative of the typical formation (Zhang et al. 2013a). In order to provide enough crosslinker for the gelation in the presence of CO2, relatively high concentrations of resorcinol (0.1 wt%) and methenamine (0.4 wt%) were applied in these experiments. The gel solution (modified PAM-methenamine-resorcinol solution) was prepared with the simulated formation water. The oil used was taken from TP block in the Tahe Oilfield, China, with a viscosity of 72.3 mPa s at 50 °C. Quartz sand with grain sizes in the range of 60–100 mesh was used to make sand packs in order to investigate the effect of the gel system on permeability reduction and EOR performance in porous media.

3.2 Methods

3.2.1 Improved bottle test

Sydansk’s gel strength code (GSC), which is an intuitive, rapid, and semi-quantitative method to evaluate the gelation rate and gel strength through visual observations in the gel formation process (Sydansk and Argabright 1987), was used in this paper. In this study, the transparent tubes for bottle tests were improved, with a pressure tolerance up to 1.5 MPa. The correspondence of the gel state and strength and the strength codes were described in Table 1.

The experimental apparatus for measuring gelation rate and gel strength at reservoir conditions was shown in Fig. 1. The key devices were the transparent tubes (inner diameter 2.5 cm, length 20.5 cm, effective volume 100 mL). In order to observe the gelation process more easily and directly, the transparent tubes were made from polymethyl methacrylate.

Experimental procedures are as follows. (1) The gel solution (modified PAM with different concentrations, methenamine of 0.4 wt%, and resorcinol of 0.1 wt%) of 25 mL was pumped into the transparent tubes. The concentration of the modified PAM solution (prepared with the formation water) were 0.5, 1.0, 1.5, and 2.0 wt%, respectively. The salinity of the formation water used in bottle tests was 20,000 ppm (with 1000 ppm Ca2+). (2) CO2 and N2 were separately injected into the two transparent tubes at a pressure of 1 MPa. (3) The tubes were then placed in the air bath at a given temperature and a pressure of 1 MPa for gelation. Please note, in the case of CO2 experiments, the pressure of 1 MPa is high enough for CO2 to dissolve in water and create an acid environment (pH < 4) in terms of safety considerations. (4) At regular intervals, the gelation processes in the transparent tubes were monitored, and the gelation time and gel strength were recorded. As time passed, the state and strength of the gel system changed until it stabilized. (5) The experiments were repeated at different temperatures and PAM concentrations.

3.2.2 Sand pack experiments

An experimental set-up was built to evaluate the capability of the CO2-sensitive gel system for water or gas shutoff and EOR performance in simulated heterogeneous reservoirs, as shown in Fig. 2. This set-up consisted of two sand packs, a fluid injection system, an air bath, and pressure and temperature control systems. Before each experiment, the sand packs filled with quartz sand were connected into the experimental system and high-pressure CO2 was injected into the system to carry out a leak test and ensure the gas tightness of the system.

3.2.2.1 Blocking performance experiments

Experimental procedures are as follows. (1) In these tests, only one sand pack (No. 1, as shown in Fig. 2) was used and saturated with the simulated formation water of different salinities (20,000 and 200,000 ppm) at a backpressure of 10.28 MPa under different temperatures. The pressure difference across the sand pack, ΔP 1, was measured for calculating the initial permeability of the sand pack. The water injection rate was maintained at 1 mL/min. (2) CO2 was injected into the sand pack until a gas breakthrough occurred at the outlet of the sand pack. (3) A slug of the gel solution (modified PAM-methenamine-resorcinol gel system) (normally 0.3 pore volume (PV)) was injected into the sand pack. The concentration of the modified PAM used in brine was 1.0 wt%. (4) A slug of CO2 (0.3 PV) was then injected into the sand pack, and all the valves were turned off for gel reactions. (5) After 8 h, the simulated formation water was injected into the sand pack at an injection rate of 1 mL/min, and the pressure difference (ΔP 2) was measured at different injection volumes. The backpressure regulator may control the water flow more steadily than a CO2 flow in sand packs and the pressure difference can be measured with relatively higher accuracy using water flow. Hence, the performance of the gel system for water shutoff was employed to reflect the blocking capacity to CO2 based on this gel system indirectly.

Normally, the capability of the gel system for water or gas shutoff can be evaluated by the reduction in permeability of the sand pack after the gel treatment, which is defined as

where k 1 is the initial permeability to water before the gel treatment; k 2 is the permeability to water after the gel treatment. In this study, the injection rate was kept constant before and after the gel treatment, Eq. (1) may be expressed as follows:

where K R is a measure of the flow resistance after the formation of gels in the sand pack. The permeability reduction can directly reflect the changes of permeability in porous media. It is feasible and effective for evaluating the gel performance for water shutoff treatments. However, the backpressure and temperature should be set to the initial condition in order to achieve the parameter of k 2. Therefore, the parameter K R achieved in Eq. (2) was convenient and used in these experiments for exhibiting the gel performance in porous media dynamically.

3.2.2.2 Displacement tests in simulated heterogeneous formations

Double sand packs were used to simulate heterogeneous formations. In the displacement tests, two sand packs (Nos. 1 and 2 sand packs as they were exhibited in Fig. 2) with different permeability were used to evaluate the EOR performance assisted by the gel system in the simulated heterogeneous reservoir. The permeability values of these two sand packs were 1993.2 and 150.6 mD, respectively. Therefore, the permeability ratio of these two sand packs was greater than 13 with different compaction degrees. The pore volume of the high-permeability sand pack was 130 mL and that of the low permeability one was 80 mL. The experimental procedures are as follows. (1) The temperature of the air bath was set to 90 °C and the backpressure was 10.28 MPa to simulate reservoir conditions. (2) The formation water (with a total salinity of 20,000 ppm that included 1000 ppm Ca2+) was injected into each sand pack separately until a steady state was reached. The water injection rate was maintained at 1 mL/min. (3) Oil was injected into each sand pack until no more water was produced at the end of the sand packs to establish initial oil saturation. (4) CO2 was injected into the double sand packs simultaneously when no more oil was produced at the end of each sand pack. (5) The modified PAM-methenamine-resorcinol gel solution (0.3 PV) was then injected into the double sand packs and then all the valves were turned off for gel reactions. The PAM concentration in this solution was 1.0 wt%. (6) After 8 h, CO2 was injected into the sand pack at an injection rate of 1 mL/min, and the EOR performance assisted by this technology was achieved until no more oil was produced.

4 Experimental results and discussion

4.1 CO2 solubility in water

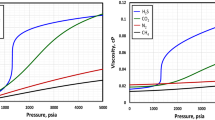

CO2 solubility in formation water is the key factor for the trigger of CO2-sensitive chemicals. It directly influences the pH value of the formation water with CO2 dissolved. The CO2 solubility in the formation water has significant effect on the performance of CO2-sensitive chemicals. To measure and predict the CO2 solubility in water, a large number of experiments have been done and many types of prediction models built (Duan and Sun 2003; Duan et al. 2006; Bastami et al. 2014). The accuracy of the Duan and Sun model is relatively high with an average relative error of 2.86 % (Duan and Sun 2003; Duan et al. 2006). So the Duan and Sun model was used to evaluate the factors influencing CO2 solubility in formation water. The prediction results are shown in Fig. 3. CO2 solubility in water is a function of temperature, pressure, and salinity. CO2 solubility decreases with an increase in temperature and salinity. An increase in pressure increased the solubility of CO2 in water. Although the high salinity of formation water may inhibit the dissolution of CO2, the effective CO2 solubility (0.0634 mol CO2/kg H2O) in the formation water of salinity of 200,000 ppm can be achieved at a relatively high pressure of 1 MPa and at 90 °C.

4.2 CO2-sensitivity

In the improved bottle tests, the gelation time and strength of gels formed were investigated at 1 MPa N2 or CO2 pressure and at different temperatures (50–80 °C). The gel solution contained 1.0 wt% PAM, 0.4 wt% methenamine, and 0.1 wt% resorcinol. The results in Table 2 and Fig. 4 show that gels were formed in a CO2 atmosphere, with a high gel strength; while no gel was formed or very weak gels were formed in an N2 atmosphere. The phenomena of gelation processes with the presence of CO2 were exhibited in the right tube and the phenomena in a N2 atmosphere were achieved in left tube in Fig. 4. This indicates that the gel solution used in these experiments was sensitive to CO2 and the injection of CO2 can induce crosslinking reaction. Under experimental conditions, gaseous CO2 can dissolve in water and distribute uniformly, which makes the gels generated with a good strength (strength code of H). Under reservoir conditions, CO2 is in a supercritical state and its mass transfer can be greatly improved (Li et al. 2015). It is expected that the gelation condition can be improved.

4.3 Influence of temperature

As seen in Table 2, the gelation time of the gel system was shortened with an increase in temperature (50–80 °C). The gel formed in the CO2 atmosphere was strong, strength code H, and the gelation rate improved with an increase in temperature. However, little or no gel was formed in the N2 atmosphere.

In general, the temperature had a positive effect on the gelation process at experimental temperatures. The solubility of CO2 in water decreases with increasing temperature, which may affect the pH value of the solution. However, the molecular motion of CO2 may be accelerated with increasing temperature, a low pH environment may appear quickly with the improved mass transfer of CO2, which reduces the gelation time. Meanwhile, the release rate of formaldehyde from methenamine becomes higher under relatively higher temperatures, which may promote the formation of gel with a more timely supply of crosslinkers. So, the positive effects of temperature dominated the gelation process in the experimental range.

4.4 Influence of the PAM concentration

Table 3 lists the effect of the PAM concentration on gelation time and gel strength in CO2 and N2 atmospheres at 80 °C. The PAM concentrations in the modified PAM-methenamine-resorcinol gel solution were 0.5, 1.0, 1.5, and 2.0 wt%, respectively. In the N2 atmosphere, no gel was observed using the modified PAM-methenamine-resorcinol gel solution with different PAM concentrations during the 24-h experimental period. The gelation time was postponed with increasing PAM concentration in the CO2 atmosphere. Specifically, the strength of the formed gel can be high with the code of H once the PAM concentration was equal to or higher than 1.0 wt%. A highly deformable nonflowing gel (strength code F) was observed for the gel system with 0.5 wt% PAM concentration after 1.78 h and the gel structure disappeared after 6 h, with the generation of dispersed brown floccules. Under the same temperature condition, the viscosity of the gel system would be thickened with an increase in the PAM concentration and the increase in viscosity may slow the molecular motion (including CO2, formaldehyde, and hydroxyl resorcinol, etc.) and diffusion rate down in the whole gel system. So the gel formation rate was reduced with increasing PAM concentration. Although a part of the gel solution can form gel structure with the formation of a gelation environment, the gel structure was weak and unstable when the PAM concentration was low (such as the PAM concentration of 0.5 wt%). When the PAM concentration exceeded 1.0 wt%, the gel strength did not improve with an increase of the PAM concentration.

4.5 Influence of pressure

In the evaluation of the influence of pressure on gel performance, the PAM concentration in the modified PAM-methenamine-resorcinol gel solution was 1.0 wt%. As exhibited in Table 4, the gelation time of the gel system became shorter with an increase in pressure (0.2–1 MPa). The gel formed in the CO2 atmosphere had high levels of strength, code H or F, when the pressure was higher than 0.2 MPa, and the gelation rate improved with increasing pressure. However, little or no gel formed in the N2 atmosphere.

Generally speaking, the increase in pressure had a positive effect on the gelation process at experimental pressures. The solubility of CO2 in water increases with increasing pressure as exhibited in Fig. 3, which decreases the pH of the solution. At the same time, the concentration of CO2 may be increased with increasing pressure, a low pH environment may appear quickly with the higher concentration of CO2, which reduces the gelation time. Meanwhile, the release rate of formaldehyde from methenamine becomes higher under an enhanced environment of low pH with relatively higher CO2 pressure, which may also promote the formation of gel with a more timely supply of crosslinkers. So increased pressure has positive effects on the gel performance in the experimental range.

4.6 Injectivity of the gel system

During CO2 and chemical injection, the formation temperature in the vicinity of the wellbore is usually lower than that in the deep formation. The injectivity of the gel system should be considered in order to reduce energy dissipation and pumping pressure. The viscosity of the gel systems with different PAM concentrations were evaluated with a Brookfield viscometer and shown in Fig. 5. The viscosity of the gel system increased with an increase in the PAM concentration, but decreased with an increase in temperature. These characteristics are beneficial to migration of the gel system to the deep formation. Generally speaking, the near-wellbore temperature is relatively lower, but the fluid absorption ability is comparatively higher after some kind of stimulation and EOR works. The relatively higher viscosity of the gel system in the near-wellbore area is good for the control of the gel system injection and preventing injected fluid channeling. With the gel system flowing into the formation, the viscous effect accumulates and the resistance to fluid flow increases which makes the injection process more difficult. At the same time, the temperature is relatively higher in extended horizontal direction and this can decrease the viscosity of the gel system. So the decreased viscosity of the gel system is expected to improve the injectivity, which can contribute to the conformance improvement of deep reservoirs.

4.7 Shutoff capacity of the gel system in porous media

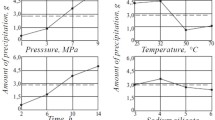

The shutoff capacity of the gel system was evaluated via flow tests in the sand packs. As shown in Table 3, the gelation time and gel strength obtained from gel systems with a polymer concentration of 1.0, 1.5, and 2.0 wt% were similar, so the PAM concentration of 1.0 wt% was recommended for further examinations via sand pack experiments in terms of better injectivity of the gel system. The sand packs used were 60 cm in length and 2.5 cm in diameter. The experimental conditions for shutoff capacity in porous media and experimental results are shown in Table 5 and Fig. 6.

The data of ΔP 2 were collected after a constant flow of water was obtained at the outlet of the sand pack (approximately 0.5 PV water injected). Table 5 and Fig. 6 show that the permeability of the sand pack reduced by 94.5 % at 80 °C after treatment with the PAM-methenamine-resorcinol gel solution. This indicates that the PAM-methenamine-resorcinol gel solution, a CO2-sensitive gel, can effectively block the CO2 channels in the sand pack. With more formation water injected into the sand pack, the sand pack permeability changed slightly and the final permeability reduction remained at 93.8 %.

It was worth noting that this type of CO2-sensitive gel also had remarkable resistance to scouring compared to other CO2-sensitive shutoff systems such as sodium aluminate (with 2.0 PV water injected, less than 83 % permeability reduction) and resol phenol–formaldehyde resin (with 2.0 PV water injected, less than 31 % permeability reduction because the curing resin is brittle).

Table 5 also shows that after the low-permeability sand packs were treated with 0.3 PV PAM-methenamine-resorcinol gel solution the permeability reduced by 97–99 % at 70 °C. For the high-permeability sand pack treated by PAM-methenamine-resorcinol gel solution, the final permeability reduced by above 90 % at 90 °C even after 3 PV formation water of high salinity (200,000 ppm with 1000 ppm Ca2+) was injected into the sand pack. This demonstrates that the PAM-methenamine-resorcinol gel had good stability at high salinity (200,000 ppm) and at high temperatures. In the second round of CO2 injection for enhancing the gelation environment, the permeability reduction rate increased with the injection of CO2 and can reach to more than 80 %, which was observed during the experimental processes. This performance indicates that gel with a certain extent of strength can be achieved under the condition of fluid flow.

4.8 EOR performance in simulated heterogeneous formation

In the displacement tests conducted in double sand packs, the EOR performance was evaluated after the simulated heterogeneous reservoir was treated with the gel system (modified PAM-methenamine-resorcinol gel system). The experimental results are shown in Fig. 7. Before the gel treatment, 1 PV CO2 was injected into the sand packs, the oil recovery from the high-permeability sand pack (1993.2 mD) was higher than that from the low-permeability one (150.6 mD). The final oil recovery by CO2 flooding was 71 % in the high-permeability sand pack, but only 15.5 % oil was recovered in the low-permeability sand pack after injection of approximately 1 PV of CO2. In this stage (0–1 PV), the oil recovery in the higher permeability sand pack was the main contributor to the comprehensive oil recovery. The so-called comprehensive oil recovery represents total oil recovery in the simulated heterogeneous formation. In order to further displace or mobilize the oil in the sand packs, 0.3 PV of the gel system was injected into these heterogeneous sand packs (simulated heterogeneous formations) to block the channeling. The oil recovery increased slightly both in the high- and low-permeability sand packs during the injection of the gel system. After gelation for 8 h, CO2 was then injected into the sand packs again at an injection rate of 1 mL/min, and the EOR performance was evaluated until no more oil was produced at the end of the sand packs. After the gel treatment, the oil recovery increased slightly in the high-permeability sand pack. Meanwhile, the oil recovery increased sharply in the low-permeability sand pack and finally reached 62 %. The oil recovery increase in lower permeability sand pack dominated the increase in the comprehensive oil recovery in this stage (1.3–2.5 PV). This indicates that gel was formed in the high-permeability sand pack due to the high CO2 saturation and blocked the channels and pores. Therefore, CO2 subsequently injected was diverted into the low-permeability sand pack from the high-permeability sand pack to increase the oil recovery of the low-permeability sand pack.

5 Conclusions

-

(1)

A modified polyacrylamide-methenamine-resorcinol system was investigated as CO2-sensitive chemicals to form gels in situ in the presence of CO2 under reservoir conditions. Bottle tests demonstrate that this gel system had good CO2-sensitivity, and strong gel was formed with a strength code of H at temperatures of up to 80 °C.

-

(2)

The improved bottle tests indicate that the gelation time was reduced with an increase in temperature, which was attributed to the promoting effects of high temperature on the molecular motion of CO2 and the release of the crosslinkers. The concentration of polymer (PAM) also influenced the gelation process and the strength of gels formed. The higher the PAM concentration, the stronger the gel formed. However, a high polymer concentration can reduce the injectivity of the gel system. A PAM concentration of 1.0 wt% in the solution was recommended. The increase in pressure had a positive effect on the gelation process at experimental pressures.

-

(3)

The analysis of injectivity shows good viscosity-temperature characteristics of the CO2-sensitive gel system. With the temperature increasing, the viscosity of this gel system decreased which can contribute to deep conformance improvement. An effective viscosity can be maintained under relatively higher temperatures which may inhibit the channeling of the injection system in deep formations.

-

(4)

The water shutoff capacity of the gel system was determined through sand pack flow tests, the test results show that the 90 % final permeability reduction was achieved at high salinity (200,000 ppm with 1000 ppm Ca2+) and at temperature up to 90 °C in the high-permeability sand pack (1698.5 mD).

-

(5)

The modified PAM-methenamine-resorcinol solution can flow into and form strong gel in the high-permeability zone in a heterogeneous formation in a CO2 atmosphere. This performance would increase the sweep efficiency of injected CO2, and improve the final oil recovery in heterogeneous formations.

References

Asghari K, Taabbodi L, Dong M. A new gel-foam system for water shut-off purposes in wormhole reservoirs. In: SPE international thermal operations and heavy Oil symposium, 1–3 November, Calgary, Alberta, Canada; 2005. doi:10.2118/97765-MS.

Bastami A, Allahgholi M, Pourafshary P. Experimental and modelling study of the solubility of CO2 in various CaCl2 solutions at different temperatures and pressures. Pet Sci. 2014;11(4):569–77. doi:10.1007/s12182-014-0373-1.

Cai SZ. Study of CO2 mobility control using cross-linked gel conformance control and CO2 viscosifiers in heterogeneous media. Master Thesis. Texas A & M University; 2010.

Chakravarthy D, Muralidaharan V, Putra E, et al. Mitigating oil bypassed in fractured cores during CO2 flooding using WAG and polymer gel injections. In: SPE/DOE symposium on improved oil recovery, 22–26 April, Tulsa, Oklahoma, USA; 2006. doi:10.2118/97228-MS.

Chang HL, Sui X, Xiao L, et al. Successful field pilot of in-depth colloidal dispersion gel (CDG) technology in Daqing oil field. SPE Reserv Eval Eng. 2006;9(6):664–73. doi:10.2118/89460-PA.

Christensen JR, Stenby EH, Skauge A. Review of WAG field experience. SPE Reserv Eval Eng. 2001;4(2):97–106. doi:10.2118/71203-PA.

Cordova M, Cheng M, Trejo J, et al. Delayed HPAM gelation via transient sequestration of chromium in polyelectrolyte complex nanoparticles. Macromolecules. 2008;41(12):4398–404. doi:10.1021/ma800211d.

Dalrymple D, Tarkington JT, Hallock J. A gelation system for conformance technology. In: SPE annual technical conference and exhibition, 25–28 September, New Orleans, Louisiana, USA; 1994. doi:10.2118/28503-MS.

Duan ZH, Sun R. An improved model calculating CO2 solubility in pure water and aqueous NaCl solutions from 273 to 533 K and from 0 to 2000 bar. Chem Geol. 2003;193(3–4):257–71. doi:10.1016/S0009-2541(02)00263-2.

Duan ZH, Sun R, Zhu C, et al. An improved model for the calculation of CO2 solubility in aqueous solutions containing Na+, K+, Ca2+, Mg2+, Cl−, and SO4 2−. Mar Chem. 2006;98(2–4):131–9. doi:10.1016/j.marchem.2005.09.001.

El-Karsani KSM, Al-Muntasheri GA, Hussein IA. Polymer systems for water shutoff and profile modification: a review over the last decade. SPE J. 2014;19(1):135–49. doi:10.2118/163100-PA.

Elsharafi MO, Bai B. Influence of strong preformed particle gels on low permeable formations in mature reservoirs. Pet Sci. 2016;13(1):77–90. doi:10.1007/s12182-015-0072-3.

Elsharkawy AM, Poettmann FH, Christiansen RL. Measuring CO2 minimum miscibility pressures: slim-tube or rising bubble method? Energy Fuels. 1996;10(2):443–9. doi:10.1021/ef940212f.

Enick RM, Beckman EJ, Johnson JK. Synthesis and evaluation of CO2 thickeners designed with molecular modeling. Technical report prepared for National Energy Technology Laboratory (U.S DOE, under Contact No. DE-FG26-04NT-15533), University of Pittsburgh, Pittsburgh PA; 2010.

Enick RM, Olsen DK, Ammer JR, et al. Mobility and conformance control for CO2 EOR via thickeners, foams, and gels-a literature review of 40 years of research and pilot tests. In: SPE improved oil recovery symposium, 14–18 April, Tulsa, Oklahoma, USA; 2012. doi:10.2118/154122-MS.

Guo A, Geng Y, Zhao L, et al. Preparation of cationic polyacrylamide microsphere emulsion and its performance for permeability reduction. Pet Sci. 2014;11(3):408–16. doi:10.1007/s12182-014-0355-0.

Hamouda AA, Chukwudeme EA, Mirza D. Investigating the effect of CO2 flooding on asphaltenic oil recovery and reservoir wettability. Energy Fuels. 2009;23(2):1118–27. doi:10.1021/ef800894m.

Hild GP, Wackowski RK. Reservoir polymer gel treatments to improve miscible CO2 flood. SPE Reserv Eval Eng. 1999;2(2):196–204. doi:10.2118/56008-PA.

Hou Y, Yue X. Research on a novel composite gel system for CO2 breakthrough. Pet Sci. 2010;7(2):245–50. doi:10.1007/s12182-010-0028-6.

Hughes TL, Friedmann F, Johnson D, et al. Large-volume foam-gel treatments to improve conformance of the Rangely CO2 flood. SPE Reserv Eval Eng. 1999;2(1):14–24. doi:10.2118/54772-PA.

Karaoguz OK, Topguder NN, Lane RH, et al. Improved sweep in Bati Roman heavy-oil CO2 flood: bullhead flowing gel treatments plug natural fractures. SPE Reserv Eval Eng. 2007;10(2):164–75. doi:10.2118/89400-PA.

Khalil F, Asghari K. Application of CO2-foam as a means of reducing carbon dioxide mobility. J Can Pet Technol. 2006;45(5):37–42. doi:10.2118/06-05-02.

Li DX, Ren B, Zhang L, et al. CO2-sensitive foams for mobility control and channeling blocking in enhanced WAG process. Chem Eng Res Des. 2015;102:234–43. doi:10.1016/j.cherd.2015.06.026.

Li XC, Fang ZM. Status quo of connection technologies of CO2 geological storage in China. Rock Soil Mech. 2007;28(10):2229–33, 2239 (in Chinese).

Luo P, Zhang YP, Huang S. A promising chemical-augmented WAG process for enhanced heavy oil recovery. Fuel. 2013;104:333–41. doi:10.1016/j.fuel.2012.09.070.

Majidaie S, Onur M, Tan IM. An experimental and numerical study of chemically enhanced water alternating gas injection. Pet Sci. 2015;12(3):470–80. doi:10.1007/s12182-015-0033-x.

Martin FD, Kovarik FS. Chemical gels or diverting CO2: baseline experiments. In: SPE annual technical conference and exhibition, 27–30 September, Dallas, Texas, USA; 1987. doi:10.2118/16728-MS.

Martin FD, Kovarik FS, Chang PW, et al. Gels for CO2 profile modification. In: SPE enhanced oil recovery symposium, 16–21 April, Tulsa, Oklahoma, USA; 1988. doi:10.2118/17330-MS.

McLendon WJ, Koronaios P, McNulty S, et al. Assessment of CO2-soluble surfactants for mobility reduction using mobility measurements and CT imaging. In: SPE improved oil recovery symposium, 14–18 April, Tulsa, Oklahoma, USA; 2012. doi:10.2118/154205-MS. .

Nezhad SAT, Mojarad MRR, Paitakhti SJ, et al. Experimental study of applicability of water-alternating-CO2 injection in the secondary and tertiary recovery. In: International oil conference and exhibition in Mexico, August 31–September 2, Cancun, Mexico; 2006. doi:10.2118/103988-MS.

Niu LW, Lu XG, Xiong CM, et al. Experimental study of gelling property and plugging effect of inorganic gel system (OMGL). Pet Explor Dev. 2013;40(6):780–4. doi:10.1016/S1876-3804(13)60104-4.

Noller CR. Chemistry of organic compounds. Philadelphia: Saunders; 1965. p. 221.

Pipes JW, Schoeling LG. Performance review of gel polymer treatments in a miscible CO2 enhanced recovery project, SACROC unit Kelly-Snyder Field. In: SPE improved oil recovery symposium, 12–16 April, Tulsa, Oklahoma, USA; 2014. doi:10.2118/169176-MS.

Prara A. Experimental study of the effectiveness of gels for profile modification. Master Thesis. The University of Oklahoma, Norman, Oklahoma; 1998.

Prada A, Civan F, Dalrymple ED. Evaluation of gelation systems for conformance control. In: SPE/DOE improved oil recovery symposium, 3–5 April, Tulsa, Oklahoma, USA; 2000. doi:10.2118/59322-MS.

Preston C, Monea M, Jazrawi W, et al. IEA GHG Weyburn CO2 monitoring and storage project. Fuel Process Technol. 2005;86(14–15):1547–68. doi:10.1016/j.fuproc.2005.01.019.

Raje M, Asghari K, Vossoughi S, et al. Gel systems for controlling CO2 mobility in carbon dioxide miscible flooding. SPE Reserv Eval Eng. 1999;2(2):205–10. doi:10.2118/55965-PA.

Ren SR, Zhang L, Zhang L. Geological storage of CO2: overseas demonstration projects and their implications for China. J China Univ Pet (Edn Nat Sci). 2010;34(1):93–8 (in Chinese).

Ren SR, Li DX, Zhang L, et al. Leakage pathways and risk analysis of carbon dioxide in geological storage. Acta Pet Sin. 2014;35(3):591–601. doi:10.7623/syxb201403024 (in Chinese).

Seright RS. Reduction of gas and water permeabilities using gels. SPE Prod Facil. 1995;10(2):103–8. doi:10.2118/25855-PA.

Sweatman RE, Parker ME, Crookshank SL. Industry experience with CO2-enhanced oil recovery technology. In: SPE international conference on CO2 capture, storage, and utilization, 2–4 November, San Diego, California, USA; 2009. doi:10.2118/126446-MS.

Sydansk RD, Argabright PA. Conformance improvement in a subterranean hydrocarbon-bearing formation using a polymer gel. U.S. Patent No. 4683949; 1987.

Talebian SH, Masoudi R, Tan IM, et al. Foam assisted CO2-EOR: a review of concept, challenges and future prospects. J Pet Sci Eng. 2014;120:202–15. doi:10.1016/j.petrol.2014.05.013.

Xing DZ, Wei B, Trickett K, et al. CO2-soluble surfactants for improved mobility control. In: SPE improved oil recovery symposium, 24–28 April, Tulsa, Oklahoma, USA; 2010. doi:10.2118/129907-MS.

Xing QY, Pei WW, Xu RQ, et al. Fundamental organic chemistry. Beijing: Higher Education Press; 2005. p. 359 (in Chinese).

Yu JJ, An C, Mo D, et al. Foam mobility control for nanoparticle stabilized CO2 foam. In: SPE improved oil recovery symposium, 14–18 April, Tulsa, Oklahoma, USA; 2012. doi:10.2118/153336-MS.

Zhang L, Ren SR, Wang RH, et al. Feasibility study of associated CO2 geological storage in a saline aquifer for development of Dongfang 1-1 gas field. J China Univ Pet (Edn Nat Sci). 2010;34(3):89–93. doi:10.3969/j.issn.1673-5005.2010.03.019 (in Chinese).

Zhang MS, Yang ZR. Water shut-off technology using polyacrylamide-methenamine-resorcinol gel system. Oil Drill Prod Technol. 1988;7:161–70 (in Chinese).

Zhang SY, She YH, Gu YA. Evaluation of polymers as direct thickeners for CO2 enhanced oil recovery. J Chem Eng Data. 2011;56(4):1069–79. doi:10.1021/je1010449.

Zhang Y, Song H, Li DX, et al. Experiment on high pressure CO2 foam stability of nonionic surfactants. J China Univ Pet (Edn Nat Sci). 2013a;37(4):119–23, 128 (in Chinese).

Zhang YM, Chu ZL, Dreiss CA, et al. Smart wormlike micelles switched by CO2 and air. Soft Matter. 2013b;9:6217–21. doi:10.1039/C3SM50913C.

Zhang YM, Feng YJ, Wang YJ, et al. CO2-switchable viscoelastic fluids based on a pseudogemini surfactant. Langmuir. 2013c;29(13):4187–92. doi:10.1021/la400051a.

Zhu YZ, Liao CH, Wang CQ. Mitigation and recovery of carbon dioxide. Beijing: Chemical Industry Press; 2011. p. 110–6 (in Chinese).

Acknowledgments

The authors would like to acknowledge financial support from the National Basic Research Program of China (2015CB251201), the Fundamental Research Funds for the Central Universities (15CX06024A), and the Program for Changjiang Scholars and Innovative Research Team in University (IRT1294 and IRT1086).

Author information

Authors and Affiliations

Corresponding author

Additional information

Edited by Yan-Hua Sun

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Li, DX., Zhang, L., Liu, YM. et al. CO2-triggered gelation for mobility control and channeling blocking during CO2 flooding processes. Pet. Sci. 13, 247–258 (2016). https://doi.org/10.1007/s12182-016-0090-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12182-016-0090-9