Abstract

Ergot alkaloids are a group of toxic compounds, formed by fungi on infested grasses. In 2022, the European Commission set into effect maximum levels for the sum of the twelve major ergot alkaloids in multiple foods. To facilitate the laborious and costly individual quantification of the twelve major ergot alkaloids by HPLC–MS/MS or -FLD, we recently reported a sum parameter method (SPM) for ergot alkaloid quantification. Here, derivatization to lysergic acid hydrazide—a derivative of the mutual ergoline backbone in all ergot alkaloids—allowed simplified determination of all ergot alkaloids in flour via HPLC-FLD. For the measurement of more complex matrices like processed foods, we now developed a MS/MS-based SPM. Two internal standards (IS), isotopically labelled at different positions of the molecule, were synthesized and employed in the MS/MS-measurements. Method performance using either the 13CD3-labelled or the 15N2-labelled IS was evaluated on naturally contaminated rye and wheat flour samples as well as on processed food matrices. Employing the 13CD3-labelled IS leads to lower variances and better consistency with the reference data (obtained by the FLD-based SPM) in flour samples compared to the 15N2-labelled IS. The novel method significantly improves the measurement of ergot alkaloids in complex food matrices, due to their increased selectivity and thus lower interferences. Furthermore, the application of isotope labelled IS obviates the need for time-consuming steps like the determination of recovery rate based, matrix specific correction factors as described in the MS/MS-based European standard method for ergot alkaloid quantification (EN 17425).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ergot alkaloids are a group of mycotoxins defined by the ergoline moiety as a mutual structural feature (Komarova and Tolkachev 2001). The alkaloids formed by fungi of Claviceps genus on various grasses, e.g., rye, wheat, or barley, are contained in sclerotia, the wintering body of the fungi. During milling, the sclerotia are broken up, and the toxins spread within the flour (Pitt and Miller 2017). Most of the ergot alkaloid contamination remains even after processing of contaminated flour to bread or other bakery products (Scott and Lawrence Guillaume 1982; Merkel et al. 2012; Bryła et al. 2019). However, continuous consumption of ergot alkaloid containing food can cause two types of an ultimately fatal disease: the gangrenous or convulsive type of ergotism (Hofmann 1978).

To reduce the risk of ergotism, maximum levels for ergot alkaloids in various food matrices were defined in 2021 by the European commission in Commission Regulation 2021/1399. In 2023, this regulation was integrated in the revised version of the commission regulation on maximum levels for contaminants in food (European Commission Regulation 2023/915). The rules refer to the summed-up content of the twelve predominant ergot alkaloids and vary between different grain products. Maximum levels were set to 100 µg/kg for barley, wheat, and oat products. As rye is the most infested grain type, higher maximum levels of 500 µg/kg are allowed. Both maximum contents will be halved by July 2024. The lowest levels of 20 µg/kg were set for infant cereal products, due to the vulnerability of this group (European Commission Regulation 2023/915).

To ensure food safety and compliance with the regulations, performant analytical methods are required. Thus, various methods quantifying each of the major ergot alkaloids individually by high-performance liquid chromatography (HPLC) with either tandem mass-spectrometric (MS/MS) or fluorescence detection (FLD) have been published (Flieger et al. 1997; Scott 2007; Crews 2015; Chung 2021). These classical approaches for ergot alkaloid quantification are costly and laborious, since twelve calibration standards must be purchased and twelve individual signals in the chromatogram evaluated. Furthermore, the employed detectors often suffer from matrix interferences. While the FLD-chromatogram often exhibits signals overlapping with the analytes, matrix effects can be problematic in the MS/MS (Krska et al. 2008). The current European standard method for ergot alkaloid quantification EN 17425 recommends to address these MS/MS-interferences by incorporating correction factors based on recovery rates obtained from analysis of spiked blank matrices (CEN 2021). This laborious procedure is necessary because no isotope labelled ergot alkaloids besides ergometrine (Braun et al. 2017; Chung 2021) are available which could be used in an alternative approach as internal-standards (IS). By applying isotope-labelled IS in the MS/MS-measurement, a primary ratio method, a method of high metrological quality, is obtained, featuring characteristics like increased precision and accuracy (Matschat et al. 2023).

Recently, we reported a method determining a sum parameter as an alternative approach for ergot alkaloid quantification (Kuner et al. 2023). This is accomplished by transferring the ergot alkaloids to one uniform structure, which is subsequently quantified by HPLC-FLD. An optimized hydrazinolysis protocol was employed, converting the ergot alkaloids to lysergic acid hydrazide—a derivative of the ergoline backbone in every ergot alkaloid. Comparing the sum parameter method (SPM) to the official EN 17425 on wheat and rye flour samples showed that similar values were obtained by both methods. Even though we did not observe this for our naturally contaminated reference materials, ergot alkaloids, not included in the current regulation, can potentially contribute to the value obtained by this method, and thus lead to overestimations. Also, information about the distribution between the different ergot alkaloids is lost, due to derivatization to one uniform structure. However, since the current European maximum levels are just defined for the sum and not individual concentrations of the major ergot alkaloids, the SPM provides a cheap and simple screening alternative to the conventional quantification approach. Because just two peaks (the two isomers of lysergic acid hydrazide) must be evaluated, interferences in the FLD-chromatogram were not observed when measuring flour samples with the SPM. However, processed food samples like bread are much more complex and thus often suffer from higher interferences.

To address the problem of interference, we developed in this work a more selective SPM based on HPLC–MS/MS instead of HPLC-FLD, employing isotope-labelled IS. Over the last years, LC–MS/MS has become the method of choice for the quantification of mycotoxins and other contaminants in foods, owing to its high selectivity and sensitivity (Asam and Rychlik 2015). Two IS, labelled at different positions of the lysergic acid hydrazide molecule, were developed. In the first IS, a methyl group in the ergoline system was replaced by 13CD3 (Δ M = + 4). The second IS contained a 15N2-labelled hydrazide group to obtain a mass difference of Δ M = + 2. The new method, employing the respective IS, was applied to six naturally contaminated flour reference materials by two laboratories and the results compared to those obtained by the recently published SPM-FLD. Finally, the methods were tested on multiple processed food samples, spiked with a mix standard solution of the major ergot alkaloids.

Materials and Methods

Chemicals and Equipment

All chemicals were used as purchased without further purification. The twelve ergot alkaloid standards (ergotamine/-inine, ergometrine/-inine, ergosine/-inine, ergocristine/-inine, α-ergocryptine/-inine, ergocornine/-inine) were obtained from RomerLabs Division Holding GmbH (Tulln, Austria). DMSO and acetonitrile (MS- and HPLC-grade) were obtained from Th. Geyer (Renningen, Germany). Ammonium carbonate and hydrazine hydrate (analytical reagent grade) were acquired from Fischer Scientific GmbH (Hampton, NH, USA). Bondesil PSA was purchased from Agilent Technologies Inc. (Waldbronn, Germany). Hydrazinium chloride was purchased from abcr GmbH (Karlsruhe, Germany). 15N2-hydrazine sulfate (isotopic enrichment > 99.7%) was obtained from Cambridge Isotope Laboratories (Andover, MA, USA). All syringe filters were obtained from Macherey Nagel GmbH & Co. KG (Düren, Germany).

Synthesis of lysergic acid hydrazide as native calibration standard and production of the flour reference materials was already described previously (Kuner et al. 2023).

All processed food samples were acquired in local supermarkets. Rye bread was pre-ground in a GM 300 knife mill (Retsch, Haan, Germany); crispbread and infant cereals were ground in a ZM 200 centrifugal mill (< 500 µm) (Retsch, Haan, Germany) and homogenized for 12 h in a Reax 20 overhead shaker (Heidolph, Schwabach, Germany). All bread matrices were analyzed freshly and not dried.

For thermoshaking, a HLC MHR 13 thermoshaker (Hettich, Tübingen, Germany) was used. Centrifugation of the extracts was performed with a 6K15 centrifuge (Sigma, Osterode, Germany). HPLC vials were centrifuged in an RVC 2–25 CDplus speedvac system (Christ, Osterode, Germany). Removal of volatile compounds in a nitrogen stream was performed in a Reacti-Therm 18823 (Thermo Scientific, Waltham, MA, USA).

HPLC-FLD was measured with a 1290 infinity HPLC system, equipped with a G4226A autosampler, G1330B thermostat, G4204A quaternary pump, G1316C TCC, G4212B DAD detector, and a G1321B FLD detector (Agilent, Waldbronn, Germany).

HPLC–MS/MS data were measured on a 1290 infinity II HPLC system equipped with a G7167B autosampler, a G7120A pump, a G7116B thermostat, and a G6495C triple-quadrupole mass spectrometer (Agilent, Waldbronn, Germany).

High-resolution masses were measured with a 1290 infinity II system equipped with a G7167B autosampler, G7104A pump, G7116B MCT, G7117C DAD detector (Agilent, Waldbronn, Germany), and a TripleTOF 6600 mass spectrometer (Sciex, Darmstadt, Germany).

SPM-FLD samples were measured with a Phenomenex Luna Phenyl-Hexyl column (150 × 3 mm, 5 µm). The SPM-13CD3 and SPM-15N2 measurements were performed with a Phenomenex Gemini NX-C18 column (150 × 2 mm, 5 µm).

All samples and calibration curves were produced and evaluated gravimetrically, not volumetrically. Meaning, that whenever a volume (e.g., of a derivatization/ extracting agent or solvent) was added, just the weight of the added substances was measured and used for the final calculation of the analyte content or calibration.

Synthesis of 13CD3-Lysergic Acid Hydrazide

13CD3-lysergic acid hydrazide (V) was synthesized starting from lysergic acid methyl ester (Fig. 1). After a two-step demethylation of I to 6-nor-lysergic acid methyl ester, III was remethylated with 13CD3-labelled methyl iodide. Finally, the 13CD3-labelled methyl ester IV was transferred to the desired product by hydrazinolysis. Formation of V was confirmed by HR-MS and comparison of HPLC-retention times to the native, unlabeled compound. As 13CD3-labelling of the ester has been reported previously (Braun et al. 2017), just the final hydrazinolysis step is described more thoroughly in the following section.

In a 4-mL amber vial, hydrazine hydrate (1 mL) was added to IV (20 mg, 0.070 mmol). The vial was heated in a thermoshaker and shaken at 100 °C, 1100 rpm. After 30 min, the reaction was aborted, and the vial removed from the thermoshaker. Subsequently, all volatile compounds were removed in a nitrogen stream (70 °C, 2 h) and V obtained as a sticky solid. The product was obtained as an isomer mixture and used without further purification.

Synthesis of 15N2-Lysergic Acid Hydrazide

Synthesis of 15N2-lysergic acid hydrazide (VI) was performed by hydrazinolysis of lysergic acid methylester (Fig. 2) in two parallel batches, on respectively 0.5 mmol scale and 0.75 mmol scale. Both crude products thus obtained were subsequently combined for purification and isomer separation.

I (141 mg, 0.5 mmol) and hydrazine sulfate-15N2 (99 mg, 0.75 mmol) were loaded in a microwave vial and suspended in MeOH (4 mL) under argon atmosphere, and triethylamine (0.35 mL, 2.5 mmol) was added at room temperature. The microwave reaction vessel was sealed tightly and the reaction mixture stirred for 25 h at 132 °C. A dark brown suspension was obtained and filtrated, and all volatile filtrate compounds removed under reduced pressure to give 300 mg of crude VI as a brown oil.

Following the same experimental procedure, I (212 mg, 0.75 mmol), hydrazine sulfate-15N2 (149 mg, 1.13 mmol), and triethylamine (0.52 mL, 3.75 mmol) were reacted in MeOH (6 mL) to give 480 mg of crude VI.

Both crude products were combined and purified by medium pressure liquid chromatography. The two isomers were subsequently separated by HPLC. VI was obtained as a light brown solid: R-isomer (44 mg, 0.15 mmol, 12% yield) and S-isomer (28 mg, 0.1 mmol, 8% yield).

Equilibration Test Between R- and S-Lysergic Acid Hydrazide

Solutions containing either the pure R- or S-lysergic acid hydrazide were prepared with two different concentration levels (c = 1 µg/kg and 85 µg/kg). The compounds were dissolved in hydrazine hydrate containing 3% hydrazinium chloride/DMSO (1:1) (solvent composition of the later samples). The obtained solutions were measured every hour by HPLC-FLD (injection volume, 10 µL; HPLC-conditions, ACN:0.02% aq. (NH4)2CO3, 50:50, 0.8 mL/min, 20 min runtime; FLD-conditions, λex = 330 nm, λem = 415 nm).

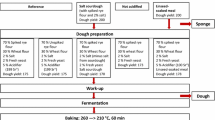

Sum Parameter Method for Ergot Alkaloid Quantification

The first sample preparation steps (extraction, centrifugation and d-SPE) were performed in analogy to EN 17425. A 100-mL centrifugation tube was filled with 10 g sample and 50 mL extracting agent (ACN:0.02% aq. (NH4)2CO3 (84:16)). After 30 min extraction in an orbital shaker, the tubes were centrifuged (3000 rpm, 2900 × g, 5 min). An aliquot (1.5 mL) of the supernatant was added to 75 mg of Bondesil PSA (40 µm) in a 4-mL amber vial and vortexed for 45 s. Subsequently, the slurry was filtered through a syringe filter (PTFE, 25 mm, 0.2 µm) into an amber HPLC vial. In the next step, the sample was evaporated to dryness in a nitrogen stream (40 °C), and 0.5 mL derivatization mixture (3% hydrazinium chloride in hydrazine hydrate) added. After crimping the vials, the samples were shaken in a thermoshaker (100 °C, 1100 rpm) and then quickly removed after 20 min to prevent analyte decomposition. Samples were diluted with DMSO (0.5 mL) and vortexed thoroughly, and the vials centrifuged prior to HPLC measurement. For the HPLC–MS/MS-based determinations, the DMSO used for dilution of the reaction mixture contained ~ 20 µg/kg of the respective IS. HPLC- and MS-conditions are listed in Tables 1, 2 and 3. HPLC-FLD conditions for the SPM-FLD were described previously (Kuner et al. 2023).

For the quantifications via lysergic acid hydrazide, a six-point calibration in the range of 1 µg/kg to 75 µg/kg was employed (calibration solutions produced gravimetrically, given calibration contents refer to the actual concentration in the calibration solution and are not converted to the concentration in the measured materials). The weight of each sample, added reagent, solvent, or extracting agent was measured to calculate the dilution for each sample solution individually, to determine the corresponding analyte concentration in the measured material.

Calibrants were prepared by adding varying amounts of a lysergic acid hydrazide stock solution in iso-propanol to an amber vial, evaporation to dryness in a nitrogen stream, and reconstituting the calibrant in hydrazine hydrate (containing 3% hydrazinium chloride)/DMSO (1:1). For the approaches with IS, the IS was previously dissolved in the DMSO, used for reconstitution of the calibrant after evaporation.

Recovery Rate Determination

Recoveries were determined by spiking the respective matrix with an ergot alkaloid mix solution containing equimolar amounts of each ergot alkaloid to obtain levels of ~ 17 nmol/kg (≙ ~ 10 µg/kg for ergopeptines and ~ 5 µg/kg for ergometrine, due to its much lower molecular weight) for each ergot alkaloid in the doped sample. Thus, an ergot alkaloid contamination of ~ 110 µg/kg in the materials was obtained. The subsequent analysis was performed according to the respective method procedure.

Determination of Limits of Detection and Quantification

Analytical limits were determined by the calibration curve method according to DIN 32645–2008. Triplicates of ten equidistant calibration points over one order of magnitude were measured with a concentration range close to the noise of the respective detector. Subsequently, the obtained data were evaluated with the program DIN-Test and the limit of detection (LOD) and quantification (LOQ) calculated.

Results and Discussion

Analysis Workflow

The SPM involves several sample preparation steps preceding the measurement, which have been thoroughly described previously (Kuner et al. 2023). For an accurate SPM-MS/MS, the IS must be added to the sample prior to measurement. Typically, IS are added to the ground sample before extraction, to not only compensate for matrix effects but also for potential losses during sample preparation. However, in case of the SPM, this would be disadvantageous for two reasons. First, the extraction behavior differs significantly between the analytes and the IS. Lysergic acid hydrazide is less soluble in the applied extraction mixture compared to native ergot alkaloids. Second, lysergic acid hydrazide degrades thermally at high temperatures, as shown in our previous publication. Hence, IS would be lost during the derivatization process. Both effects would lead to significant underestimation of the IS-content in the HPLC–MS/MS measurement and yield in consequence incorrect results. To avoid these problems, the IS was added in the dilution step after derivatization by means of an IS-DMSO-solution. This approach has the additional advantage of keeping the sample preparation workflow consistent with the SPM-FLD method.

Data Evaluation

During derivatization of the ergot alkaloids both stereoisomers of lysergic acid hydrazide are formed. Interconversion between the R- and S-isomer also occurs at room temperature after finishing the reaction, due to the basic conditions caused by hydrazine hydrate. However, because of the high boiling point of hydrazine hydrate, removal of the employed reagent would be too time-consuming for a quick screening method. Since the calibrants are dissolved in the same solvent mixture as the samples, these also isomerize.

In our previous publication to the SPM-FLD this issue was targeted by using just the summed-up areas of both peaks for calibration as well as for further calculations. This approach is enabled, by the equal response of both isomers in the FLD, as shown by similar calibration curve slopes of both isomers in a solvent mixture without occurring isomerization (Kuner et al. 2023). When performing the same test using MS/MS (without IS) instead of FLD, significantly different calibration curve slopes and thus different responses of both isomers were observed (Figure S1 in supplementary material). Upon usage of IS in the MS/MS-measurements, the slope of the calibration curves and thus the response equalizes between both isomers (Figure S2 in supplementary material).

Using the summed-up areas of both isomers is still a viable option for the SPM-MS/MS without IS, as a stable equilibrium between both compounds is formed in the applied solvent mixture. This was demonstrated by preparation of pure solutions of each diastereomer in hydrazine hydrate/DMSO (1:1), which were stored at room temperature and periodically measured by HPLC-FLD (Fig. 3). Regardless of the used starting isomer or concentration of the solution, consistently, the same distribution of 62% R-isomer and 38% S-isomer was obtained over time. Thus, treating the signals of both isomers as a sum during determination of the hydrazide content is valid for both forms (with and without usage of IS) of the SPM-MS/MS.

Fraction of R-isomer and S-isomer of lysergic acid hydrazide dissolved in hydrazine hydrate/DMSO (1:1) against time measured by HPLC-FLD (λex = 330 nm, λem = 415 nm). Two concentration levels (c1 = 1 µg/g, c2 = 85 ng/g) starting with either the pure R- (R1 and R2) or pure S-isomer (S1 and S2) were used and equilibration over time between both diastereomers observed

Method Comparison on Flour Samples

In our previous publication on the SPM-FLD, the method was tested and compared to EN 17425 on six prepared flour (rye/wheat) reference materials with three contamination levels: L1 ~ 50 µg/kg, L2 ~ 150 µg/kg, and L3 ~ 250 µg/kg (sum of 12 major ergot alkaloids). The same materials were employed to test the novel SPM-MS/MS. Since EN 17425 delivered similar values to the SPM-FLD (as shown in our latest article on this topic) (Kuner et al. 2023), just the SPM-FLD values were used as reference data in the following method comparison.

The MS/MS-based method, using either the 13CD3-labelled (SPM-13CD3) or the 15N2-labelled IS (SPM-15N2), was applied as fourfold replicates to each of the reference materials by two participants/laboratories of the method comparison, and all samples measured as a double injection. Obtained data were normalized to the corresponding mean SPM-FLD value of each material (rye/wheat), contamination level (L1-3), and participant (Lab 1/2) to enable data comparison (Fig. 4) (absolute values in Tables S3–S8 in Supplementary Information).

Method comparison of the sum parameter methods (SPM) for ergot alkaloid quantification via lysergic acid hydrazide. The FLD-based SPM (SPM-FLD) was compared to the two novel MS/MS-based SPMs, employing either 13CD3- (SPM-13CD3) or 15N2-labelled (SPM-15N2) lysergic acid hydrazide as IS, on six flour samples. Relative molar fractions are normalized to the median obtained by the SPM-FLD of each material (rye/wheat), contamination level (L1 ~ 50 µg/kg; L2 ~ 150 µg/kg; L3 ~ 250 µg/kg major ergot alkaloid content) and participant (Lab 1/2) of the comparison study. All materials measured in fourfold replicates; each sample was injected twice

Values obtained with SPM-13CD3 were generally consistent with those of the SPM-FLD. Mean values of the SPM-13CD3 ranged from 96 to 104% of the respective SPM-FLD mean. Just for the rye samples measured by Lab 1, 6–8% lower mean values to the corresponding SPM-FLD mean were obtained. All by SPM-13CD3 obtained data points were within 85–119% of the reference value.

Elevated deviations from the reference data were noticed for the SPM-15N2. Mean values of all materials and participants were significantly (4–25%) higher than the respective SPM-FLD mean. Considering all SPM-15N2 data, 52% maximum excess to the corresponding reference was observed. Overall, a total value range of 80–152% of the respective SPM-FLD mean was found. The higher data range of the SPM-15N2 also reflected in the method variances. While the average relative standard deviation (RSD) for the SPM-FLD and SPM-13CD3 (5% vs 6%) were comparably low, increased values were measured for the SPM-15N2 (average RSD 10%). (Explanation for the observed effects in section “IS comparison.”).

LOD and LOQ for the quantification via lysergic acid hydrazide were determined by the calibration curve method in compliance with DIN 32645. Slightly lower limits were determined for the MS/MS-based SPM-13CD3 (LOD 0.064 µg/kg, LOQ 0.212 µg/kg) and SPM-15N2 (LOD 0.056 µg/kg, LOQ 0.187 µg/kg) than for the FLD-based SPM-FLD (LOD 0.185 µg/kg, LOQ 0.655 µg/kg), owing to the increased sensitivity of the MS/MS-detector. Transferred to analytical limits of the ergot alkaloid with the highest molecular weight of all major ergot alkaloids (ergocristine), theoretical values for SPM-13CD3 (LOD 0.138 µg/kg, LOQ 0.458 µg/kg), SPM-15N2 (LOD 0.121 µg/kg, LOQ 0.404 µg/kg), and SPM-FLD (LOD 0.400 µg/kg, LOQ 1.415 µg/kg) would be obtained. However, analytical limits of all tested methods were significantly below the currently active European maximum values for ergot alkaloids in food (European Commission Regulation 2023/915) and are, in this regard, all suitable for the assessment of food safety.

To determine recoveries of the methods, blank rye and wheat flour were spiked with a mixture of the twelve major ergot alkaloids in equimolar amounts. Subsequently, the samples were analyzed by the respective procedure in a fourfold replicate (with double injection) and the recovery rates determined (Fig. 5). The highest mean recovery rates of 113% for rye and 104% for wheat were observed for the SPM-15N2. Similar to the measurement of the naturally contaminated samples, this method also showed the highest variances in the obtained values. Lower and less variable recovery rates were achieved by the two other tested methods. While mean recoveries of 94% in rye and 96% in wheat flour were obtained by SPM-FLD, SPM-13CD3 showed 90% for rye and 91% for wheat. Over all methods and materials, the recovery rates ranged from 88 to 119%. Hence, the common recovery rate limits of 70–120% defined by European Commission Regulation 401/2006 for multiple mycotoxins were fulfilled by all tested methods.

Determined recoveries of the FLD-based sum parameter method (SPM-FLD) and the MS/MS-based SPMs employing either 13CD3- (SPM-13CD3) or 15N2-labelled (SPM-15N2) lysergic acid hydrazide as IS in rye or wheat flour. Matrices were doped with a mix solution containing equimolar amounts of each major ergot alkaloid and analyzed in fourfold replicates with double injection

Measurement of Processed Food Samples

The current European standard method for ergot alkaloid quantification is not just validated for different flour types, but also for various processed foods. Hence, the performance of the different SPMs was tested on some of these more complex matrices. Since certified reference materials were unavailable, crispbread, rye bread, and infant cereals were purchased in a local supermarket. The materials were spiked with the ergot alkaloid mix solution used in the previous section to obtain ergot alkaloid levels of 110 µg/kg in the materials and the recovery rates determined. When checking the blank values of the three acquired products, native ergot alkaloid contamination in the crispbread was observed. In this case, the blank value was subtracted in the subsequently measured recovery rates. Recoveries of the methods are depicted in Fig. 6.

Determined recoveries of the FLD-based sum parameter method (SPM-FLD), and the MS/MS-based SPMs employing either 13CD3- (SPM-13CD3) or 15N2-labelled (SPM-15N2) lysergic acid hydrazide as IS in rye bread, crispbread, and infant cereals. Matrices were doped with a mix solution containing equimolar amounts of each major ergot alkaloid and analyzed in fourfold replicates with double injection. Highly increased SPM-FLD recoveries are due to overlapping matrix signals

Mean recovery rates in a reasonable range of 85–99% for all tested matrices were delivered by SPM-13CD3. However, analog to the prior experiments SPM-15N2 exhibited increased values of 123–126%. Again, this method also showed the highest variances with 10% average RSD (vs 3% SPM-13CD3, 1% SPM-FLD). As expected, the FLD-based method suffered from matrix interferences, which also reflect in the obtained recoveries. While moderate 94% mean recovery rate were achieved in rye bread, highly increased rates were measured in crispbread (110%, after subtraction of the blank value) and infant cereals (192%). This is plausible, as in rye bread, nearly no matrix signals were visible at the corresponding analyte retention times, whereas large peaks are noticeable in the chromatograms of the tested infant cereals (Figure S9–S10 in Supplementary Information). Since the crispbread was already naturally contaminated, no blank matrix chromatogram could be obtained. However, a minor influence of the matrix is visible as a shoulder of the first analyte peak, which complies to the observed small recovery rate increase in this matrix.

In contrast, the MS/MS-based method did not show any matrix signals (Figure S11–S13 in Supplementary Information) and exhibited consistent recovery rates between the different matrices, confirming the high method selectivity. The superior method selectivity is further advantageous for the measurement of infant cereal-based products, as these are subject to the lowest European maximum values and would thus increasingly suffer from the influence of matrix interferences.

Even though the SPM performances in processed food matrices were evaluated just by measuring doped samples, suitability of the method for the determination of naturally contaminated samples can be inferred, as spiking primarily effects the analyte extraction. Since the extraction in our SPMs is the same as in EN 17425, being validated on these matrices, measurement of spiked samples is in this case sufficient.

IS Comparison

Both IS were used for MS/MS-based ergot alkaloid quantification and tested on multiple matrices. Employment of IS for the suppression of matrix effects is indispensable for the MS/MS-based ergot alkaloid determination, as tests without IS revealed. Depending on the matrix 40% matrix suppression, up to 7% matrix enhancement were observed (compared to the respective 13CD3-IS value). Due to the strong matrix effects, application of IS is strongly recommended for the SPM-MS/MS. Overall, the 13CD3-labelled IS performed highly satisfactorily. Values consistent with the SPM-FLD and low variances were observed for the SPM-13CD3.

In contrast, substantially increased contents, and notably larger RSDs, were obtained throughout all experiments, when using the 15N2-labelled IS. However, the discrepancy of the results cannot just be explained by the smaller molecular mass difference of the IS (Δ M = + 2) to the native compound. Even though typically a mass difference of at least three Dalton is favored, to avoid overlap of the naturally occurring isotope distribution with the isotope labelled IS, this cannot explain the observed results, since lysergic acid hydrazide is just a small molecule and does not contain elements with a broad natural isotope distribution (e.g., chlorine or sulfur). Besides, this also does not explain the detected high method variances.

Instead, an increasing analyte- to IS-signal ratio (and thus increased analyte contents) was observed, when measuring duplicates of the same sample or calibrant over time, which was not the case for the solutions containing the 13CD3-labelled IS. Hence, the concentration of the 15N2-labelled IS is gradually decreasing, which can be explained by the different labelling positions in the molecule. Owing to the hydrazine hydrate in the solution, an exchange between the hydrazide-group of the compound and the hydrazine in solution occurs (Fig. 7 & Figure S14 in Supplementary Information). While this exchange is unproblematic for the analyte or when employing the 13CD3-labelled IS, it leads to losses of the 15N2-labelled IS, and thus the witnessed overestimations and highly increased method variances. To avoid these problems with the 15N2-labelled IS, the hydrazine hydrate had to be removed and reconstituted in another solvent. Though, due to its low volatility, this would result in an unfavorable highly increased analysis time.

Conclusion

A novel HPLC–MS/MS-based method quantifying the ergot alkaloids after derivatization to lysergic acid hydrazide was developed. Also, two isotopic labelled compounds were synthesized, being the first time that isotopic-labelled IS are available and employed for the determination of all ergot alkaloids.

All in all, the 13CD3-labelled IS performed significantly better than the 15N2-labelled IS, concerning recovery rates, method variances, and consistency with the data obtained by SPM-FLD in flour matrices. However, due to the higher selectivity of the MS/MS compared to the FLD, the novel MS/MS-method is superior for the analysis of processed food samples. The novel method combines the benefits of the SPM, such as reduced costs for calibrants and simplified determination of the ergot alkaloid content, with the advantages of MS/MS-detection. Compared to the also MS/MS-based EN 17425 for ergot alkaloid quantification, the availability and employment of IS in the measurements is further beneficial, since the laborious and vague determination of matrix specific recovery rate-based correction factors can be omitted.

Thus, especially the SPM-13CD3 is a time and cost-saving alternative to the established EN 17425 for ergot alkaloid screening in complex food matrices.

Data availability

All data generated or analyzed during this study are included in the published article and the corresponding supplementary information.

References

Asam S, Rychlik M (2015) Recent developments in stable isotope dilution assays in mycotoxin analysis with special regard to Alternaria toxins. Anal Bioanal Chem 407(25):7563–7577. https://doi.org/10.1007/s00216-015-8904-y

Braun B, Köppen R, Wedler C, Theil F (2017) Synthesis of M + 4 stable isotopomers of ergometrine and ergometrinine. Nat Prod Commun 12(3):373–376

Bryła M, Ksieniewicz-Woźniak E, Waśkiewicz A, Podolska G, Szymczyk K (2019) Stability of ergot alkaloids during the process of baking rye bread. LWT 110:269–274. https://doi.org/10.1016/j.lwt.2019.04.065

CEN (2021) Foodstuffs - determination of ergot alkaloids in cereals and cereal products by dSPE clean-up and HPLC-MS/MS. Brussels. EN 17425:2021

Chung SWC (2021) A critical review of analytical methods for ergot alkaloids in cereals and feed and in particular suitability of method performance for regulatory monitoring and epimer-specific quantification. Food Addit Contam, Part A 38(6):997–1012. https://doi.org/10.1080/19440049.2021.1898679

Commission Regulation (EU) 2021/1399 of 24 August 2021 amending Regulation (EC) No 1881/2006 as regards maximum levels of ergot sclerotia and ergot alkaloids in certain foodstuffs

Commission Regulation (EU) 2023/915 of 25 April 2023 on maximum levels for certain contaminants in food and repealing Regulation (EC) No 1881/2006

Crews C (2015) Analysis of ergot alkaloids. Toxins 7(6):2024–2050

Flieger M, Wurst M, Shelby R (1997) Ergot alkaloids — sources, structures and analytical methods. Folia Microbiol 42(1):3–30. https://doi.org/10.1007/BF02898641

Hofmann A (1978) Historical view on ergot alkaloids. Pharmacology 16(Suppl 1):1–11. https://doi.org/10.1159/000136803

Komarova EL, Tolkachev ON (2001) The chemistry of peptide ergot alkaloids. Part 1. Classification and chemistry of ergot peptides. Pharm Chem J 35(9):504–513. https://doi.org/10.1023/a:1014050926916

Krska R, Stubbings G, Macarthur R, Crews C (2008) Simultaneous determination of six major ergot alkaloids and their epimers in cereals and foodstuffs by LC-MS-MS. Anal Bioanal Chem 391(2):563–576. https://doi.org/10.1007/s00216-008-2036-6

Kuner M, Lisec J, Mauch T, Konetzki J, Haase H, Koch M (2023) Quantification of Ergot alkaloids via lysergic acid hydrazide: development and comparison of a sum parameter screening method. Molecules 28(9):3701

Matschat R, Richter S, Vogl J, Kipphardt H (2023) On the way to SI traceable primary transfer standards for amount of substance measurements in inorganic chemical analysis. Anal Bioanal Chem. https://doi.org/10.1007/s00216-023-04660-4

Merkel S, Dib B, Maul R, Köppen R, Koch M, Nehls I (2012) Degradation and epimerization of ergot alkaloids after baking and in vitro digestion. Anal Bioanal Chem 404(8):2489–2497. https://doi.org/10.1007/s00216-012-6386-8

Pitt JI, Miller JD (2017) A concise history of mycotoxin research. J Agric Food Chem 65(33):7021–7033. https://doi.org/10.1021/acs.jafc.6b04494

Scott PM (2007) Analysis of ergot alkaloids — a review. Mycotoxin Res 23(3):113–121. https://doi.org/10.1007/BF02951506

Scott PM, Lawrence Guillaume A (1982) Losses of ergot alkaloids during making of bread and pancakes. J Agric Food Chem 30(3):445–450. https://doi.org/10.1021/jf00111a009

Funding

Open Access funding enabled and organized by Projekt DEAL. This research was funded by Zentrales Innovationsprogramm Mittelstand (ZIM) of the German Federal Ministry for Economic Affairs and Climate Action (support code: ZF4044226SB8).

Author information

Authors and Affiliations

Contributions

Conceptualization: M.K. (Maximilian Kuner) and M.K. (Matthias Koch). Formal analysis: J.L. Funding acquisition: M.K. (Matthias Koch). Resources: M.K. (Matthias Koch). Investigation: M.K. (Maximilian Kuner), M.I.P., M.R. and J.K. Supervision: H.H. and M.K. (Matthias Koch). Writing-original draft: M.K. (Maximilian Kuner). Writing-review and editing: J.L., M.I.P., J.K., H.H. and M.K. (Matthias Koch). Visualization: M.K. (Maximilian Kuner) and J.L. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Does not apply since neither humans nor animals were involved in this study.

Informed consent

Not applicable.

Conflict of interest

Maximilian Kuner declares no conflict of interest. Jan Lisec declares no conflict of interest. Marie-Idrissa Picher declares no conflict of interest. Massimo Rigo declares no conflict of interest. Jörg Konetzki declares no conflict of interest. Hajo Haase declares no conflict of interest. Matthias Koch declares no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kuner, M., Lisec, J., Picher, MI. et al. Development and Application of Isotope Labelled Internal Standards in a Sum Parameter Method for Ergot Alkaloid Screening of Food. Food Anal. Methods 17, 119–128 (2024). https://doi.org/10.1007/s12161-023-02553-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-023-02553-x