Abstract

A new, fast and efficient method, hyphenated microwave-assisted aqueous two-phase extraction (MA-ATPE) was applied in the extraction of α-solanine from Solanum retroflexum. This environmentally friendly extraction method applied water and ethanol as extraction solvents. Central composite design (CCD) was performed which included numerical parameters such as time, mass of plant powder and microwave power. The categorical factors included the chaotrope — NaCl or the kosmotrope — Na2CO3. Fitting the central composite design response surface model to the data generated a quadratic model with a good fit (R2 = 0.920). The statistically significant (p < 0.05) parameters such as time and mass of plant powder were influential in the extraction of α-solanine. Quantification of α-solanine was achieved using a robust and sensitive feature of the ultra-high performance quadrupole time of flight mass spectrometer (UHPLC-qTOF-MS), multiple reaction monitoring (MRM). The optimized condition for the extraction of α-solanine in the presence of NaCl and Na2CO3 was a period of 1 min at a mass of 1.2 g using a microwave power of 40%. Maximal extraction of α-solanine was 93.50 mg kg−1 and 72.16 mg kg−1 for Na2CO3 and NaCl, respectively. The synergistic effect of salting-out and microwave extraction was influential in extraction of α-solanine. Furthermore, the higher negative charge density of the kosmotrope (Na2CO3) was responsible for its greater extraction of α-solanine than chaotrope (NaCl). The shorter optimal extraction times of MA-ATPE make it a potential technique that could meet market demand as it is a quick, green and efficient method for removal of toxic metabolites in nutraceuticals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Solanum retroflexum is one of many species within the Solanaceae family widely distributed and boasting over 3000 species of trees, shrubs and herbs. The consumption of Solanum retroflexum remains controversial in different cultural practices (Averbeke et al. 2007; Managa et al. 2020). In South Africa, Solanum retroflexum is an exclusively produced and consumed vegetable by African people, and due to its high nutrient composition in its leaves, its affordable means to alleviate malnutrition amongst poor rural based South Africans (Averbeke et al. 2007). On the contrary, Solanum retroflexum is an inedible plant and persistent weed in Europe and America, as it is perceived to be toxic (Karabegović et al. 2018).

The edibility or inedibility of Solanum retroflexum is due to its metabolic composition. Some of the classes of secondary metabolites derived from Solanum plants include polyphenols such as flavonoids, widely renowned for its antioxidant activities (Uchida et al. 2017; Mahieddine et al. 2018; Fratianni et al. 2020) and steroidal alkaloids widely reported for its toxic effects. The surge in concentration levels of steroidal alkaloids (glycoalkaloids) is triggered by the exposure of Solanum plants to the sun’s UV light or because of mechanical injury including peeling and slicing (Dao and Friedman 1994; Kasnak and Artik 2018. Some of the toxic effects of glycoalkaloids are due to anticholinesterase effects on the central nervous system (Caprioli et al. 2014; Lelario et al. 2019) and disruption of cell membranes (Blankemeyer et al. 1998; Nepal and Stine 2019. Symptoms of glycoalkaloid poisoning in humans include colic pain in the abdomen and stomach, diarrhoea, vomiting, burning sensation about the lips and mouth, fever, rapid pulse and headache (Uluwaduge et al. 2018; Deng et al. 2021). Other destructive effects of glycoalkaloids include craniofacial malformations in hamsters (Gaffield and Keeler 1996; Ni et al. 2018; Kumar et al. 2019) and a variety of organ malformations in frog embryos and mealworms (Friedman et al. 1991; Chen et al. 2021). Furthermore, the Centre for Food Safety (2015) reported on poisoning of patients after consumption of cooked potatoes, and subsequent investigations revealed that the poisoning was due to the glycoalkaloid α-solanine. As a result, regulatory bodies such as the Commission for Food and Agricultural Organization (FAO) and the World Health Organization (WHO) have established regulations for maximum permissible concentrations of glycoalkaloids, which currently stands at 200 mg kg−1 for fresh potatoes (Solanum lycopersicum) sold in supermarkets.

In view of the toxic potential of glycoalkaloids contained in Solanum vegetables, food toxicology regulating bodies have come-up with maximum allowable limits of these metabolites. Besides these policy frameworks, more still need to be done to improve the nutritional value and safety of some plant foods, especially those consumed by humans. This could come in the form of environmentally friendly extraction techniques that target these poisonous glycoalkaloids in food. A variety of extraction methods have been studied for enrichment of glycoalkaloids from Solanum tuberosum. This includes bisolvent extraction using methanol and chloroform (2:1 v/v) and Soxhlet extraction involving 3% acetic acid in ethanol (Wang et al. 1972; Priedniece et al. 2017; Abedini et al. 2020; Kaunda et al. 2021). However, these methods often apply toxic organic solvents and at time are used in large quantities, making the extraction method user-unfriendly. Furthermore, these techniques require multiple extraction steps from time to time making the process tedious and resulting in huge losses of the analytes of interest. Aqueous two-phase extraction (ATPE) has attracted interest amongst researchers for it’s due to biphasic extraction capacity and selectivity, resulting in the achievement of target constituents that could be extracted either in the top or bottom phase (Xie et al. 2017, 2021). More importantly, it is a green and efficient pre-treatment solution for separation and purification of compounds from natural products (Xie et al. 2017; Li et al. 2020).

In the view that ATPE has potential as a versatile technique, very little is known on the coupling of ATPE to other extraction methods, which could in turn attract interest amongst researchers. Hence, in this study, the one-pot extraction, microwave-assisted aqueous two phase extraction (MA-ATPE) of a toxic metabolite, α-solanine, from Solanum retroflexum was investigated. Additionally, information on multivariate approaches for extraction of toxic compounds from natural food sources is scarce. Therefore, this work also applied optimization based on chemometric tools such as central composite design (CCD) and response surface methodology (RSM) for α-solanine in Solanum retroflexum. The CCD and RSM approach are useful as it reduces the number of experiments, making it less laborious and time efficient (Silva et al. 2019). Application of MA-ATPE could be a fast, environmentally friendly and efficient method for extraction of α-solanine that could be vital by reducing toxicity of a popular vegetable, Solanum retroflexum, making it safe for consumption. Furthermore, this hyphenated environmentally friendly extraction technique could potentially be utilized on a commercial scale.

Materials and Methods

Chemicals and Reagents

The salts NaCl (anhydrous ≥ 99% purity), Na2CO3 (anhydrous ≥ 99% purity) and ethanol (99% CP) were purchased from Associated Chemical Enterprises (Johannesburg, South Africa) and Sigma-Aldrich (Johannesburg, South Africa). Ultra-pure water (0.005 µS, 18 mΩ) using a Direct-Q 5UV distiller (MA, USA) was applied for the preparation of the salt solutions. A modified microwave oven (DM 350, Defy, Polokwane, South Africa) of 28 L capacity, working at a frequency of 2450 MHz, was used for microwave-assisted extraction. Chromatographic separation of the metabolites in the extracts was done using a reverse phase Shim-pack Velox C18, 2.1 × 100 mm, 2.7 µm with a serial number 227–32,009-03 (Columbia, USA). The UPLC was connected to a Shimadzu 9030 LC, qTOF-MS detector (Shimadzu, Kyoto). The solvents used for the chromatographic runs were methanol and formic acid, which were purchased from Romil Pure Chemistry (Cambridge, UK).

Sample Collection and Preparation

The leaves of Solanum retroflexum were obtained from a street vendor within the Thulamela District in Thohoyandou, South Africa. The plants were air dried until a constant weight was obtained, and the leaves were ground into a fine powder with a blender at 2000 rpm and stored in glass containers. The containers were covered in paper bags to prevent light penetration. The MA-ATPE method consisted of powdered leaves placed in a 250-mL round bottomed flask (Fig. 1). Thereafter, saturated salt concentrations (5 mL) of 30% (w/v) involving Na2CO3 (kosmotrope) and NaCl (chaotrope) were prepared by weighing 15 g of salt in 50 mL of water and were added to the powdered leaves in the round bottomed flask. Thereafter, 99% ethanol extraction solvent (5 mL) was added resulting in ATPE (Fig. 1). The spontaneous formation of ATPE under the conditions stated above was also reported by Mokgehle et al. (2021). The ATPE mixture was then placed in a microwave oven (Fig. 1). This was conducted so that the microwaves could enhance extraction in ATPE, MA-ATPE. The volumes of the solvents after the extraction period remained unaltered. The setup of the MA-ATPE systems is shown in the appendix (Fig. 1). The MA-ATPE extracts, top-layer of ATPE system, obtained were then analysed on the UPLC-qTOF-MS for α-solanine.

Chromatographic and Mass Spectrometry Conditions

α-Solanine was separated using the column stated in the “Chemicals and Reagents” section. The column was maintained at 40 °C at a flow rate of 0.4 mL min−1, and the injection volume was 5 µL. Mobile phase A was 0.1% formic acid in ultrahigh purity water (v/v), and mobile phase B was 0.1% (v/v) formic acid in methanol.

The ultra-high performance quadrupole time of flight mass spectrometer (UHPLC-qTOF-MS) 9030 mass spectrometer was equipped with an electrospray interface (ESI) operating in positive mode. The ESI parameters were optimized for α-solanine by direct infusion of standard solutions into the mass spectrometer. The mass spectrometer was operated in the multi reaction monitoring (MRM) mode to confirm the identity of α-solanine. High-purity nitrogen (N2) was used as the nebulizing and drying gas. The optimum parameters were as follows: drying gas temperature, 250 °C; drying gas flow, 10 L min−1; and collision energy, 50–80 V. Lab solutions software was used to run the LC–MS/MS instrument for data acquisition, and the mass range used was m/z 100–1000.

Preparation of Standards and Quantification of Samples

The stock α-solanine standard solution was prepared in methanol at a concentration of 1000 µg L−1. The stock standard solution was stored at 4 °C in amber volumetric flasks. A series of nine working standard solutions at the concentration values of 15 to 1000 µg L−1 were prepared from the stock standard solution by diluting with HPLC grade methanol. The α-solanine standards were quantified based on scheduled multiple reaction monitoring (MRM) where one m/z transition, from the precursor ion to the product ion, for α-solanine (868 → 722) was explored. The regression equation was y = 52.1677x + 624.135, the limit of detection (LOD) and limit of quantification (LOQ) were 0.3169 and 0.9509, respectively. The abovementioned transition was then applied for quantification of α-solanine from the ground leaves of Solanum retroflexum following MA-ATPE extraction. MRM quantification of α-solanine in the 36 samples studied was performed in duplicates (Table 1). The parameters evaluated for optimization of MA-ATPE of α-solanine were time, mass of plant powder, microwave power and the salt type (kosmotrope or chaotrope).

Statistical Analysis

The central composite design response surface model (CCD RSM) was fitted to experimental data to obtain the relationship between factors and optimize the response of Z (α-solanine yield) in relation to A (time), B (plant mass) using Design Expert 11 (Minneapolis, USA). By using CCD, a total of 36 experimental runs, done in duplicate, were designed which included 3 numerical factor levels for time (1 min, 5 min 30 s and 10 min), 3 factor numerical levels for mass of plant powder (0.2, 0.7, 1.2 g), 3 numerical factor levels for power (40, 70, 100%) and 2 categorical factor levels for salts which included the chaotrope (NaCl) and kosmotrope (Na2CO3).

The interaction between the various parameters studied and its resultant effected on the extraction of α-solanine (mg kg−1) was fitted to experimental data by using a statistical multiple regression approach method of least square (MLS) and resulted in the lowest possible residual (Baş and Boyacı 2007). Model parameters and model significance were determined at p < 0.05. The fitness of the model was determined by evaluating the coefficient of regression (R2) obtained from the analysis of variance (ANOVA). The model fit generated the response surface that defined the behaviour of the response variable. By means of these plots, the optimized ranges for each factor that led to the highest response (i.e. concentration of α-solanine) that can be extracted (Baş and Boyacı 2007; Arteaga-Crespo et al. 2020).

Results and Discussion

MRM Quantification of α-Solanine Based on the 868 → 722 Transition

In this study, the extraction of α-solanine was performed of which was reported to be contained in Solanum retroflexum, using a hyphenated MA-ATPE approach (Daji et al. 2018; Mokgehle et al. 2021). The MA-ATPE was modified using different factors as shown in Table 1, on the recovery of target metabolite α-solanine. The presence of α-solanine has been reported in Solanum retroflexum and other species within the Solanum genus (Daji et al. 2018; Mokgehle et al. 2021). Using a sensitive and robust tandem MS approach (UHPLC-qTOF-MS) with settings presented elsewhere (Gbashi et al. 2016; Mokgehle et al. 2021), it was possible to efficiently fingerprint these α-solanine as shown in Fig. 2 based on m/z 722 product ion. Thereafter, based on the 868 → 722 transition within the MRM method, α-solanine was quantified as a function of the various factors shown in Table 1.

Fit Statistics of Experimental and Predicted Data

The model fitted to the data was observed to have a quadratic fit; p values less than 0.001 indicate model terms are significant. The following terms, mass of plant powder, time and power, were found to be significant (p < 0.05), while power2 was found to be insignificant when both the chaotrope and kosmotrope salts were applied during extraction (Fig. 3a and b). This indicated that the linear terms were adequate predictors of the experimental values obtained. The quadratic effect of the terms studied was found to be insignificant for Na2CO3 in particular (Fig. 3b). The linear effect of a variable indicates that the variable correlates in a directly proportional manner to the response variable (α-solanine), whereas the quadratic effect of a variable implies that the response variable is correlated with the square of that variable (Gbashi et al. 2016). In the same work, the authors highlighted that a significant linear effect of a variable (p < 0.05) means that the optimal level of the response falls out of the range of the experimental values for that variable; similarly, this was observed for Na2CO3 (Fig. 3b). The F value was observed to be 0.37 which indicated that it was not significant relative to the absolute error. The non-significant lack of fit was desirable. The goodness of fit between the experimental and the predicted values was R2 = 0.920. Furthermore, the predicted R2 of 0.7936 was in reasonable agreement with the adjusted R2 of 0.8594, i.e. the difference was less than 0.2.

Box Plots Evaluating the Effect of Time, Mass of Plant Powder and Power on α-Solanine Extraction

In Figs. 4 and 5 are the box-and-whiskers plots of the effect of time, mass and power on the MA-ATPE extractability of α-solanine from leaves of Solanum retroflexum. From these plots, a proportional increase in α-solanine was observed with an increase in the mass of plant powder when NaCl and Na2CO3 were applied during extraction (Figs. 4a and 5a). This indicated that the mass of the plant powder played a key role in the recovery α-solanine. The increased enrichment of α-solanine was more notable when Na2CO3 was used compared to NaCl. For instance, the concentration of α-solanine extracted increased from approximately 14.286 mg kg−1 (0.2 g) to 72.16 mg kg−1 (1.2 g) which equated to a fivefold increase (Fig. 5a). The observed enhancement in the yield of α-solanine with an increase in mass can be attributed to the increased mass transfer of metabolites from the plant matrix to the solvent when larger weights of the plant material were used (Doulabi et al. 2020). Additionally, the high α-solanine extractions was most likely due to the low solvent to mass ratio, i.e. 0.12 (m/v) when 1.2 g was used compared to 0.02 (m/v) with 0.2 g in a 10 mL mixture, which generally contributed to high microwave energy absorption of the plant material as the solvent absorbed most of the microwave energy (Doulabi et al. 2020). Conversely, increased solvent volumes have been reported to reduce the heating efficiency in microwave extraction, limit the breakage of solid cell walls and inhibit the driving force for the mass transfer of compounds (Doulabi et al. 2020). Similarly, Alara and Abdurahman (2019) reported that larger volumes of solvent required more energy and time to maximize extraction of analytes from the plant matrix.

It was also observed from Figs. 4b,c and 5b,c that an increase time and power led to a general decrease in the extraction of α-solanine. This highest extraction of α-solanine was observed at 40% microwave power, indicating that power had an influence on extraction. Microwave power was reported by Kuhnert and Danks (2002) and Khan et al. (2018) to cause superheated solvents. Additionally, an increase in microwave power resulted in the superheated extraction by water, resulting in quicker and easier penetration of solvent into the plant matrix. Furthermore, the thermal energy supplied by varying microwave power can overcome cohesive (solute–solute) and adhesive (solute–matrix) forces by reducing the activation energy needed for the desorption process, as seen at 40% power (Vergara-Salinas et al. 2013; Gbashi et al. 2016). However, at microwave powers greater than 40%, a steady decrease was observed due to excessive microwave irradiation energy degrading the α-solanine analyte (Routray and Orsat 2012; Valdés et al. 2015). Therefore, the optimal extraction power was observed at 40%. Moreover, according to the box-and-whiskers plots, the best extraction was generally observed at shorter times; this could probably be due to the synergistic effect of extraction time and microwave energy. A similar observation was reported by Martino et al. (2006) and Kaderides et al. (2019).

Chromatographic Profile of MRM-Based Quantification of α-Solanine

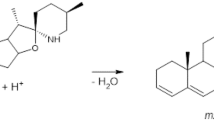

Chromatograms depicting the highest and lowest concentrations of α-solanine (mg kg−1) obtained when NaCl and Na2CO3 was applied is included in Fig. 6a-d. As seen in the chromatogram, the MRM transition of α-solanine 868 → 722 is observed at a retention time of 3.80 min (Fig. 6a,b,c and d). The fragmentation profiles showing the product ions of α-solanine are also included in Fig. 6f. As seen in Fig. 2, α-solanine is composed of the solanidine aglycone unit glycosylated to solatriose. Solatriose is a trisaccharide composed of glucose, rhamnose and galactose monosaccharides. Of interest in this study was the 868 → 722 transition which was due to the loss of rhamnose at collision energy of 65 eV (Figs. 2 and 6f). Other product ions of α-solanine were also observed which included m/z 576, 445 and 414 which were due to losses of glucose, loss of the [Glu + H − H2O − CO]+ adduct (m/z 131) and galactose, respectively (Kuuranne et al. 2000; Yuan et al. 2018).

Response Surface Equations and Corresponding for NaCl and Na2CO3 and the Resultant Optima

Response equations, Eqs. 1 and 2, corresponding to NaCl and Na2CO3, respectively, and the resultant response surfaces evaluating the multivariate interaction between the mass of plant powder, power and time are shown in Figs. 7 and 8. Equations 1–3 and 4–6 represent the response surface equations for NaCl (Fig. 7a-c) and Na2CO3 (Fig. 8a-c), respectively, where A = time; B = mass of plant powder, C = power and Z = extraction yield (mg kg−1).

As the mass of plant powder was increased, in the presence of NaCl and Na2CO3, a proportional increase in the yield of α-solanine was obtained (Figs. 7a and 8a). The observed increment in the concentration of α-solanine with an increase in mass can be attributed to the increased mass transfer of metabolites from the plant matrix to the extraction solvent (Doulabi et al. 2020). This concurs with observations from the Pareto chart, Fig. 3 a and b, which indicates the significant linear effect (p < 0.05) of mass of plant powder on the extraction of α-solanine. In Fig. 9 a and b, the predicted optimal extraction of α-solanine in the presence of Na2CO3 and NaCl was 88.57 mg kg−1 and 73.36 mg kg−1, with a desirability score of 0.804 and 0.868, respectively. The high (> 0.8) desirability score of Na2CO3 and NaCl indicated its closeness to the target requirement of 1 and hence the greater reliability of this optimum for maximal enrichment of α-solanine. Additionally, comparisons of the concentrations of α-solanine obtained in Table 1 and (Figs. 7a-c and 8a-c) indicated that more of α-solanine was extracted for Na2CO3 compared to NaCl. This suggested that, generally, α-solanine extraction was probably favoured by the presence of multiply charged ions (kosmotropes), Na2CO3 in this case, rather than NaCl. The doubly charged carbonate ions from Na2CO3, probably formed stronger hydrogen bonds with the solvation sphere surrounding α-solanine than singly charged chloride ions, enhancing the extent of its precipitation (salting-out) from the hydration sphere and its subsequent extraction by ethanol. This observation is correlated with the Hofmeister series as narrated by Kang et al. (2020), Dogra et al. (2020) and Wang et al. (2021). Similarly, the salting-out effect was also reported by Sazali et al. (2019) and Mokgehle et al. (2021). Hence, α-solanine extraction is better achieved with the divalent Na2CO3 rather than monovalent NaCl.

Comparison of MA-ATPE to MAE and ATPE

Studies evaluating the extraction of glycoalkaloids involving either MAE or ATPE have been reported. For instance, Kondamudi et al. (2017) examined MAE for obtaining glycoalkaloids from Solanum tuberosum. In that study, the concentrations of α-solanine extracted ranged from 15.40 to 28.12 mg kg−1 at an optimal extraction time of 10 min. In another study, Maldonado et al. (2014) examined ATPE systems for extraction of α-solanine from Solanum tuberosum peels and obtained concentrations of 71 mg kg−1. However, this study has shown that hyphenation of microwave extraction and salting out through MA-ATPE, in the presence of kosmotrope-Na2CO3, can significantly reduce the extraction period (1 min) for α-solanine while simultaneously obtaining greater concentrations (93.50 mg kg−1) than what was reported by Kondamudi et al. (2017) and Maldonado et al. (2014). In this view, MA-ATPE is an economical and efficient extraction method for α-solanine.

Conclusions

The application of MA-ATPE, a synergy of microwaves and salting-out, has demonstrated to be an energy efficient and time-saving method for enrichment of α-solanine from Solanum retroflexum. This is evident in the lower times (1 min) and microwave power (40%) required by MA-ATPE for maximal extraction of α-solanine. Furthermore, MA-ATPE is environmentally friendly method due to its non-requirement for toxic organic solvents for extraction. This technique only utilizes water and ethanol, which is a green solvent, for extraction. The maximal amount of α-solanine extracted was 93.50 mg kg−1 and 72.16 mg kg−1 for Na2CO3 and NaCl, respectively. Fitting the central composite design response surface model to the data generated a quadratic model with a good fit (R2 = 0.92). It was statistically deduced that time and mass of plant powder had a significant effect (p < 0.05) on the extraction of α-solanine in MA-ATPE. The effect of microwave power was determined to be insignificant. The application of multiply charged salts such as the kosmotrope-Na2CO3 was shown to be a comparably better extractant of α-solanine than the chaotrope-NaCl and is in agreement with the Hofmeister effect. Therefore, this cost-cutting technique, MA-ATPE, can potentially be escalated to be applied as a reliable means to minimize the concentrations of toxic compounds in other food sources. The MA-ATPE method has some limitations and extraction can be improved by potentially coupling MA-ATPE with minitiarization techniques such as hollow fibre minitiarized extraction (HFME) or the exploration of natural deep eutectic solvents (NADES) as extraction solvents.

Data Availability

All data generated or analysed during this study are included in this published article.

References

Abedini A, Amiri H, Karimi K (2020) Efficient biobutanol production from potato peel wastes by separate and simultaneous inhibitors removal and pretreatment. Renew Energy 160:269–277

Alara OR, Abdurahman NH (2019) Microwave-assisted extraction of phenolics from Hibiscus sabdariffa calyces: Kinetic modelling and process intensification. Ind Crops Prod 137:528–535. https://doi.org/10.1016/j.indcrop.2019.05.053

Arteaga-Crespo Y, Radice M, Bravo-Sanchez LR, García-Quintana Y, Scalvenzi L (2020) Optimisation of ultrasound-assisted extraction of phenolic antioxidants from Ilex guayusa Loes. leaves using response surface methodology. Heliyon 6:1–8. https://doi.org/10.1016/j.heliyon.2019.e03043

Baş D, Boyacı IH (2007) Modeling and optimization I: Usability of response surface methodology. J Food Eng 78:836–845. https://doi.org/10.1016/j.jfoodeng.2005.11.024

Blankemeyer JT, McWilliams ML, Rayburn JR, Weissenberg M, Friedman M (1998) Developmental toxicology of solamargine and solasonine glycoalkaloids in frog embryos. Food Chem Toxicol 36:383–389. https://doi.org/10.1016/S0278-6915(97)00164-6

Caprioli G, Cahill MG, James KJ (2014) Mass fragmentation studies of α-tomatine and validation of a liquid chromatography LTQ orbitrap mass spectrometry method for its quantification in tomatoes. Food Anal Methods 7:1565–1571. https://doi.org/10.1007/s12161-013-9771-9

Chen Z, Li C, Yuan A et al (2021) α-Solanine causes cellular dysfunction of human trophoblast cells via apoptosis and autophagy. Toxins 13:1–12. https://doi.org/10.3390/toxins13010067

Daji G, Steenkamp P, Madala N, Dlamini B (2018) Phytochemical composition of Solanum retroflexum analysed with the aid of ultra-performance liquid chromatography hyphenated to quadrupole-time-of-flight mass spectrometry (UPLC-qTOF-MS). J Food Qual 2018:1–9. https://doi.org/10.1155/2018/3678795

Dao L, Friedman M (1994) Chlorophyll, chlorogenic acid, glycoalkaloid, and protease inhibitor content of fresh and green potatoes. J Agric Food Chem 42:633–639. https://doi.org/10.1021/jf00039a006

Deng Y, He M, Feng F et al (2021) The distribution and changes of glycoalkaloids in potato tubers under different storage time based on MALDI-TOF mass spectrometry imaging. Talanta 221:1–9. https://doi.org/10.1016/j.talanta.2020.121453

Dinarvand M, Rezaee M, Foroughi M (2017) Optimizing culture conditions for production of intra and extracellular inulinase and invertase from Aspergillus niger ATCC 20611 by response surface methodology (RSM). Braz J Microbiol 48:427–441. https://doi.org/10.1016/j.bjm.2016.10.026

Dogra P, Roy SS, Joshi A, Mukhopadhyay S (2020) Hofmeister ions modulate the autocatalytic amyloidogenesis of an intrinsically disordered functional amyloid domain via unusual biphasic kinetics. J Mol Biol 432:6173–6186. https://doi.org/10.1016/j.jmb.2020.10.015

Doulabi M, Golmakani MT, Ansari S (2020) Evaluation and optimization of microwave-assisted extraction of bioactive compounds from eggplant peel by-product. J Food Process Preserv 44:1–13. https://doi.org/10.1111/jfpp.14853

Fratianni F, Cozzolino A, d’Acierno A et al (2020) Qualitative Aspects of Some of Some Traditional Landraces of the Tomato “Piennolo”(Solanum lycopersicum L.) of the campania region, southern Italy. Antioxidants 9:1–14. https://doi.org/10.3390/antiox9070565

Friedman M, Rayburn JR, Bantle JA (1991) Developmental toxicology of potato alkaloids in the frog embryo teratogenesis assay—Xenopus (FETAX). Food Chem Toxicol 29:537–547. https://doi.org/10.1016/0278-6915(91)90046-A

Gaffield W, Keeler RF (1996) Steroidal alkaloid teratogens: Molecular probes for investigation of craniofacial malformations. J Toxicol Toxin Rev 15:303–326

Garfield W, Keeler RF (1994) Structure-activity relations of teratogenic natural products. Pure Appl Chem 66:2407–2410. https://doi.org/10.1351/pac199466102407

Gbashi S, Njobeh P, Steenkamp P, Tutu H, Madala N (2016) The effect of temperature and methanol–water mixture on pressurized hot water extraction (PHWE) of anti-HIV analogues from Bidens pilosa. Chem Cent J 10:1–12. https://doi.org/10.1186/s13065-016-0182-z

Kaderides K, Papaoikonomou L, Serafim M, Goula AM (2019) Microwave-assisted extraction of phenolics from pomegranate peels: Optimization, kinetics, and comparison with ultrasounds extraction. Chem Eng Process 137:1–11. https://doi.org/10.1016/j.cep.2019.01.006

Kang B, Tang H, Zhao Z, Song S (2020) Hofmeister series: Insights of ion specificity from amphiphilic assembly and interface property. ACS Omega 5:6229–6239. https://doi.org/10.1021/acsomega.0c00237

Karabegović I, Mančić D, Nikolić N et al (2018) Total polyphenols from Solanum retroflexum Dun. fruit: extraction and optimization by response surface methodology. J Food Meas Charact 12:1772–1778. https://doi.org/10.1007/s11694-018-9792-6

Kasnak C, Artik N (2018) Change in some glycoalkaloids of potato under different storage regimes. Potato Res 61:183–193. https://doi.org/10.1007/s11540-018-9367-2

Kaunda JS, Qin XJ, Zhu HT, Wang D, Yang CR, Zhang YJ (2021) Previously undescribed pyridyl-steroidal glycoalkaloids and 23S, 26R-hydroxylated spirostanoid saponin from the fruits of Solanum violaceum ortega and their bioactivities. Phytochem 184:112656

Khan A, Wang X, Gul K et al (2018) Microwave-assisted spent black tea leaves as cost-effective and powerful green adsorbent for the efficient removal of Eriochrome black T from aqueous solutions. Egypt J Basic Appl Sci 5:171–182. https://doi.org/10.1016/j.ejbas.2018.04.002

Kondamudi N, Smith JK, McDougal OM (2017) Determination of glycoalkaloids in potatoes and potato products by microwave assisted extraction. Am J Potato Res 94:153–159. https://doi.org/10.1007/s12230-016-9558-9

Kuhnert N, Danks TN (2002) Microwave accelerated synthesis of cyclopentadienyl bis-phosphine ruthenium (II) thiolato complexes using focused microwave irradiation. J Chem Res 2002:66–68. https://doi.org/10.3184/030823402103171294

Kumar R, Khan MI, Prasad M (2019) Solasodine: A Perspective on their roles in Health and Disease. Res J Pharm Technol 12:2571–2576. https://doi.org/10.5958/0974-360X.2019.00432.3

Kuuranne T, Vahermo M, Leinonen A, Kostiainen R (2000) Electrospray and atmospheric pressure chemical ionization tandem mass spectrometric behavior of eight anabolic steroid glucuronides. J Am Soc Mass Spectrom 11:722–730. https://doi.org/10.1016/S1044-0305(00)00135-5

Lelario F, De Maria S, Rivelli AR, Russo D, Milella L, Bufo SA, Scrano L (2019) A complete survey of glycoalkaloids using LC-FTICR-MS and IRMPD in a commercial variety and a local landrace of eggplant (Solanum melongena L.) and their anticholinesterase and antioxidant activities. Toxins 11:1–18. https://doi.org/10.3390/toxins11040230

Li H, Zhang J, Ke H, Fu M, Fang J, Yang B (2020) Nonlinear response surface in the study of aqueous two-phase system and ionic liquid extraction of lignans from Schisandrae chinensis and mechanism clarification. Sep Sci Technol 55:1330–1338

Mahieddine B, Amina B, Faouzi SM, Sana B, Wided D (2018) Effects of microwave heating on the antioxidant activities of tomato (Solanum lycopersicum). Ann Agric Sci 63:135–139. https://doi.org/10.1016/j.aoas.2018.09.001

Maldonado AFS, Mudge E, Gänzle MG, Schieber A (2014) Extraction and fractionation of phenolic acids and glycoalkaloids from potato peels using acidified water/ethanol-based solvents. Food Res Int 65:27–34. https://doi.org/10.1016/j.foodres.2014.06.018

Managa MG, Mpai S, Remize F, Garcia C, Sivakumar D (2020) Impact of moist cooking methods on colour, anti-nutritive compounds and phenolic metabolites in African nightshade (Solanum retroflexum Dun.). Food Chem 325:1–8. https://doi.org/10.1016/j.foodchem.2020.126805

Martino E, Ramaiola I, Urbano M, Bracco F, Collina S (2006) Microwave-assisted extraction of coumarin and related compounds from Melilotus officinalis (L.) Pallas as an alternative to Soxhlet and ultrasound-assisted extraction. J Chromatogr A 1125:147–151. https://doi.org/10.1016/j.chroma.2006.05.032

Mokgehle T, Madala N, Gitari W, Tavengwa N (2021) Deciphering the effects of kosmotrope and chaotrope salts during aqueous two phase extraction (ATPE) of polyphenolic compounds and glycoalkaloids from the leaves of a nutraceutical plant, Solanum retroflexum, with the aid of UPLC-qTOF-MS. Appl Biol Chem 64:1–15. https://doi.org/10.1186/s13765-021-00603-8

Nepal B, Stine KJ (2019) Glycoalkaloids: Structure, Properties, and Interactions with Model Membrane Systems. Processes 7:1–26. https://doi.org/10.3390/pr7080513

Ni W, Tian T, Zhang L et al (2018) Maternal periconceptional consumption of sprouted potato and risks of neural tube defects and orofacial clefts. Nutr J 17:1–8. https://doi.org/10.1186/s12937-018-0420-4

Priedniece V, Spalvins K, Ivanovs K, Pubule J, Blumberga D (2017) Bioproducts from Potatoes. Rev Environ Clim Technol 21:18–27

Routray W, Orsat V (2012) Microwave-assisted extraction of flavonoids: A review. Food Bioproc Tech 5:409–424. https://doi.org/10.1007/s11947-011-0573-z

Sazali YA, Sazali WML, Ibrahim JM et al (2019) Investigation of high temperature, high pressure, scaling and dissolution effects for carbon capture and storage at a high CO2 content carbonate gas field offshore Malaysia. J Petrol Sci Eng 174:599–606. https://doi.org/10.1016/j.petrol.2018.11.060

Silva CL, Perestrelo R, Silva P, Tomás H, Câmara JS (2019) Implementing a central composite design for the optimization of solid phase microextraction to establish the urinary volatomic expression: a first approach for breast cancer. Metabolomics 15:1–13. https://doi.org/10.1007/s11306-019-1525-2

Spochacz M, Chowański S, Szymczak M et al (2018) Sublethal effects of solanum nigrum fruit extract and its pure glycoalkaloids on the physiology of tenebrio molitor (mealworm). Toxins 10:1–21. https://doi.org/10.3390/toxins10120504

Uchida K, Tomita H, Takemori T, Takamura H (2017) Effects of grilling on total polyphenol content and antioxidant capacity of eggplant (Solanum melongena L.). J Food Sci 82:202–207. https://doi.org/10.1111/1750-3841.13567

Uluwaduge DI, Lecturer S, Lanka S (2018) Glycoalkaloids, bitter tasting toxicants in potatoes: A review. Int. J. Food Sci. Nutr. 3, 188–193 https://doi.org/10.22616/foodbalt.2017.002

Valdés A, Vidal L, Beltran A, Canals A, Garrigós MC (2015) Microwave-assisted extraction of phenolic compounds from almond skin byproducts (Prunus amygdalus): A multivariate analysis approach. J Agric Food Chem 63:5395–5402. https://doi.org/10.1021/acs.jafc.5b01011

Van Averbeke W, Tshikalange TE, Juma KA (2007) The commodity systems of Brassica rapa L. subsp. chinensis and Solanum retroflexum Dun. in Vhembe, Limpopo Province. South Africa Water SA 33:349–354. https://doi.org/10.4314/wsa.v33i3.180593

Vergara-Salinas JR, Bulnes P, Zúñiga MC, Pérez-Jiménez J, Torres JL, Mateos-Martín ML, Agosin E, Pérez-Correa JR (2013) Effect of pressurized hot water extraction on antioxidants from grape pomace before and after enological fermentation. J Agric Food Chem 61:6929–6936. https://doi.org/10.1021/jf4010143

Wang SL, Bedford CL, Thompson NR (1972) Determination of glycoalkaloids in potatoes (S. tuberosum) with a bisolvent extraction method. American Potato Journal 49(8):302–308

Wang X, Qiao C, Song K, Jiang S, Yao J (2021) Hofmeister effect on the viscosity properties of gelatin in dilute solutions. Colloids Surf 206:1–7

World Health Organisation. (2008) Media Centre, Traditional Medicine, 20.

Xie X, Zhu D, Zhang W, Huai W, Wang K, Huang X, Zhou L, Fan H (2017) Microwave-assisted aqueous two-phase extraction coupled with high performance liquid chromatography for simultaneous extraction and determination of four flavonoids in Crotalaria sessiliflora L. Ind Crops Prod 95:632–642

Xie L, Chong KY, Stefanova R, Hui JP, Zhang J, Brooks MS (2021) Recovery of chlorogenic acid from haskap leaves (Lonicera caerulea) using aqueous two-phase extraction. Biomass Convers Biorefinery 29:1–10

Yuan B, Byrnes D, Giurleo D, Villani T, Simon JE, Wu Q (2018) Rapid screening of toxic glycoalkaloids and micronutrients in edible nightshades (Solanum spp.). J Food Drug Anal 26(2):751–760

Funding

This study is financially supported by the University of Venda, Sasol Inzalo and the National Research Foundation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Informed consent not applicable.

Consent to Participate

Informed consent not applicable.

Conflict of Interest

Tebogo Mphatlalala Mokgehle declares that he has no conflict of interest. Ntakadzeni Madala declares that he has no conflict of interest. Wilson Mugera Gitari declares that he has no conflict of interest. Nikita Tawanda Tavengwa declares that he has no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Optimization of MA-ATPE resulted in good yields of α-solanine from Solanum retroflexum.

• The kosmotrope-Na2CO3 was a better extractor of α-solanine than the chaotrope-NaCl.

• The mass of plant powder and time had a significant (p < 0.05) effect on extraction.

• MA-ATPE is a green and competitive technique for reducing food toxicity.

• The enriched metabolites from MA-ATPE could potentially be applied in pharmacology.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mokgehle, T.M., Madala, N., Gitari, W.M. et al. Effect of Microwave-Assisted Aqueous Two-Phase Extraction of α-Solanine from S. retroflexum and Analysis on UHPLC-qTOF-MS. Food Anal. Methods 15, 1256–1268 (2022). https://doi.org/10.1007/s12161-021-02224-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-021-02224-9