Abstract

The aim of the research was to compare the possibility of distinguishing the cultivars of processed beetroots using image analysis technique and sensory evaluation. The differentiation of processed samples was tested for freeze-dried beetroot ‘Czerwona Kula’ and ‘Cylindra’, lacto-fermented beetroot ‘Czerwona Kula’ and ‘Cylindra’, freeze-dried lacto-fermented beetroot ‘Czerwona Kula’ and ‘Cylindra’. The textures from the images of quarters of root slices, as well as sensory attributes evaluated by expert sensory assessors, were determined. The differences in the means of selected textures from color spaces Lab, RGB and XYZ for different cultivars of raw and processed beetroots were observed. The raw beetroots ‘Czerwona Kula’ and ‘Cylindra’ were discriminated with the accuracy of up to 94.5% for models built based on selected texture from color space RGB. In the case of processed beetroots ‘Czerwona Kula’ and ‘Cylindra’, the accuracy reached 96% (color space Lab) for freeze-dried beetroots, 99% (color space Lab) for lacto-fermented beetroots, 98.5% (color space Lab) for freeze-dried lacto-fermented beetroots. In the case of sensory attributes, no statistically significant differences were observed between the beetroot samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The beetroot (Beta vulgaris L. var. esculenta) is a very popular vegetable, not only in Eastern Europe but also all over the world (Sawicki et al., 2016). The beetroots have many uses in human nutrition. Particularly, it can be used in various forms, like a boiled in soup (traditionally borsch), fermented products especially juice and natural red colorants, e.g. to improve the color of sauces, tomato paste, desserts, jellies, jams, ice cream, cereals, sweets (Kaur and Singh 2014), as well as in dried forms like chips, powder in bakery and food supplements. In last year, the root of Beta vulgaris L. plant was considered as a functional health-promoting food (Chhikara et al. 2019; Clifford et al. 2015). The beetroot has active compounds such as betalains, carotenoids, polyphenols and flavonoids, and saponins (Kaur and Singh, 2014; Kowalski and Łechtańska 2015).

Freeze-drying is one of the methods of food preservation, the main goal of which is to inhibit the growth of microorganisms and significantly reduce any changes at the cellular level. It is extremely important to choose the right method of drying food products. In order to maintain high sensory properties of dried products, attention should be paid to the process conditions, i.e. temperature, humidity, air flow velocity, and the properties of the dried products (thermal resistance, structural and mechanical properties) and water diffusion capacity (Jayaraman and Das Gupta 2007; Figiel 2010; Kowalski and Szadzinska 2014). According to many authors, relatively the smallest losses of substances responsible for the sensory quality of the product, in particular aromatic compounds, both in terms of aroma typical and intensity, occur during freeze-drying (Rząca and Witrowa-Rajchert 2007; Kondratowicz and Burczyk 2010). Hoffmann (2007) used the high temperature of drying selected species of spice vegetables using the conventional method, and, through their freeze-drying, both methods caused undesirable changes in the sensory profile, including oxidation of aromatic compounds and the formation of foreign smell notes referred to as ‘hay, dust’.

Freeze-drying is mainly used for processing fruit and vegetables due to the much better quality of the product compared to convection drying of these raw materials. On an industrial scale, this technique has found application in the production of instant coffee and spices. The main obstacles to its dissemination in the industry are economic reasons (high costs and long process time) (Piotrowski et al. 2008; Rząca and Witrowa-Rajchert 2007). In numerous publications, the authors inform about the laboratory use of freeze-drying, among others for drying strawberries (Hammami and Rene 1997; Piotrowski et al. 2008), apples (Hammami et al. 1999), tomatoes (Georgé et al. 2011) or celery (Kozak and Lis 1999). Freeze-dried products are used as flavor additives and ingredients of such dishes as sweets, yogurts, sauces, dressings, instant soups. Color and flavor in the case of dried red beetroot are very attributes of quality affecting the degree of the product acceptability by the consumers (Sorour and El-Mesery 2014).

The aim of this study was to compare the possibility of distinguishing the cultivars of processed beetroots using objective image analysis technique and descriptive sensory evaluation. The study was carried out to determine the presence of textures from the images of quarters of root slices, which allow for cultivar discrimination of beetroot. The sensor attributes that differentiate beetroot cultivars were assessed.

Material and Methods

Material

The beetroots belonging to cultivars ‘Czerwona Kula’ and ‘Cylindra’ were used in the experiments. The beetroots were purchased from the manufacturer in central Poland. The beetroots ‘Czerwona Kula’ were characterized by the round shape, whereas the beetroots ‘Cylindra’ were cylindrical and elongated.

The raw, freeze-dried, lacto-fermented and freeze-dried lacto-fermented beetroots were tested. In the case of tests involving the raw and freeze-dried samples, the roots were washed and peeled and then were cut into slices about 5 mm thick. Additionally, each slice was cut into quarters. The one hundred samples of each cultivar prepared in this way were immediately subjected to the research using image analysis. And part of the material was intended for freeze-drying. Firstly, the quarters of root slices were frozen in the laboratory freezer at a temperature of − 29 ± 2 °C for 3 days. The freeze-drying was carried out for 53 h including 24 h without heating, 24 h at a temperature of 0 °C and 5 h at a temperature of 30 °C. The final pressure was 0.030 mBar.

The other part of beetroots was subjected to lacto-fermentation. The beetroots were washed, peeled and then cut into slices and put into 1300-ml sterile glass jars with standard spices used in fermentation (garlic, horseradish, dill). The jars were filled with potable water. The table salt was added to the final concentration of NaCl in 3.5% brine. The lactic fermentation process was carried out in agreement with the current standard procedures. Elkner (2004) reported that a temperature of about 20 °C was recommended for the initial phase of fermentation. At this temperature, bacteria peptize (protein breakdown), and bacteria of the genus Aerogenes develop, and then lactic acid bacteria acidify the environment. The fermentation process may be slowed down by gradual lowering of temperature—the temperature of 11 °C ± 1 °C is recommended for this stage. The carbon dioxide can dissolve more easily in the brine at this temperature. The fermentation process should proceed slowly, to be correct, and the lactic acid content in products should reach 0.7% after 30–40 days. To fulfill these requirements, in the experiment, fermentation was conducted for 3 days at a temperature of 20 °C, then for the next 10 days at 13.5 °C ± 1.5 °C and finally at 5 °C for 30 days. After stopping fermentation, part of the samples was subjected to tests, and others were used for freeze-drying using the parameters which were applied for the raw material.

Image Analysis

The quarters of slices of raw, freeze-dried, lacto-fermented and freeze-dried lacto-fermented beetroots belonging to different cultivars ‘Czerwona Kula’ and ‘Cylindra’ were imaged using a flatbed scanner. Before placing on the scanner scene, the samples were drained of excess water using a paper towel, if necessary. The scans were obtained on the black background at a resolution of 800 dpi and saved in TIFF format. The tests were performed in one hundred repetitions for each cultivar (800 samples in total). These were acquired:

-

one hundred images of quarters of slices of raw beetroot ‘Czerwona Kula’,

-

one hundred images of quarters of slices of raw beetroot ‘Cylindra’,

-

one hundred images of quarters of slices of freeze-dried beetroot ‘Czerwona Kula’,

-

one hundred images of quarters of slices of freeze-dried beetroot ‘Cylindra’,

-

one hundred images of quarters of slices of lacto-fermented beetroot ‘Czerwona Kula’,

-

one hundred images of quarters of slices of lacto-fermented beetroot ‘Cylindra’,

-

one hundred images of quarters of slices of freeze-dried lacto-fermented beetroot ‘Czerwona Kula’,

-

one hundred images of quarters of slices of freeze-dried lacto-fermented beetroot ‘Cylindra’.

The images of beetroot samples were analyzed using the Mazda software (Łódź University of Technology, Institute of Electronics, Poland) (Szczypiński et al. 2009). The color conversion of images to channels L, a, b, R, G, B, X, Y and Z was performed. Afterward, the region of interest (ROI) including the surface of the quarter of the slice for each sample was determined. Then, approximately two hundred texture parameters of the outer surface of the quarter of the slice based on the run-length matrix, co-occurrence matrix, histogram, autoregressive model and gradient map were calculated for each ROI (Szczypiński et al. 2009).

Sensory Evaluation

Sensory assessment of freeze-dried, lacto-fermented and freeze-dried lacto-fermented beetroots was carried out in the sensory laboratory, which met all the requirements set out in the standard PN-ISO 8589 (Sensory analysis—General guidelines for designing a laboratory for sensory analysis). At all stages of the sensory analysis, the individual evaluation stations were used equipped with the specialized software—program ANALSENS designed for preparing tests, recording individual scores and statistical processing of the results. The sensory evaluation is performed by a 10-person panelist whose members have obtained a certificate of completion of training in the field of sensory sensitivity verification and methods used in the sensory analysis of food products. The certificate was issued by a company dealing with training in the field of sensory analysis of food and water products—J.S. Hamilton Ltd. using the quantitative description analysis (QDA), conducted in accordance with the procedure included in the standard Sensory Profiling ISO 13299:2016. Due to the sensory properties of raw samples of tested beetroot cultivars, which were unacceptable to consumers, the sensory evaluation for raw beetroots was not performed. The sensory quality of products was evaluated for odor, color, texture and taste. Firstly, the brainstorming sessions were run to select attributes for the beetroot products. The assessments for each descriptor were marked on unanchored lines, with anchoring points (low–high intensity of impression). Results were presented in numerical values (0–10), where the starting point of the line was assigned the value zero and the ten centimeters (end of the line) (Table 1). Each analysis was carried out in two sessions, so the results represent the mean of these sessions.

Statistical Analysis

The statistical analysis for texture parameters was performed with the use of the STATISTICA (StatSoft Inc., Tulsa, USA) software and the WEKA (University of Waikato) (Bouckaert et al. 2016). The STATISTICA (StatSoft Inc., Tulsa, USA) software was used to visualize differences in selected textures between beetroot cultivars. The graphs including the means with standard error of each mean (SEM) were prepared. The discriminant analysis was performed using the WEKA application to develop the models for the cultivar differentiation of beetroots. The analyses were performed separately for (i) raw beetroot ‘Czerwona Kula’ and ‘Cylindra’, (ii) freeze-dried beetroot ‘Czerwona Kula’ and ‘Cylindra’, (iii) lacto-fermented beetroot ‘Czerwona Kula’ and ‘Cylindra’, (iv) freeze-dried lacto-fermented beetroot ‘Czerwona Kula’ and ‘Cylindra’. The models including the sets of selected textures from color spaces Lab, RGB and XYZ were developed. Firstly, the attribute selection using the Best First with the CFS subset evaluator was carried out separately for individual color spaces. Due to this step, the texture parameters with the highest discriminative power were selected for building the discrimination models. The beetroots belonging to cultivars ‘Czerwona Kula’ and ‘Cylindra’ were discriminated using tenfold cross-validation mode and the Random Forest classifier from the group of Decision Trees, Logistic from Functions and PART from Rules (Witten and Frank 2005). The average accuracies and accuracies for each cultivar were determined. Additionally, TP Rate (True Positive Rate), F-Measure, ROC Area (Receiver Operating Characteristic Area), PRC Area (Precision-Recall Area) were calculated using the WEKA application.

The ANALSENS software was used to analyze the results of the sensory evaluation. The significance of differences between results was estimated using a nonparametric Mann–Whitney U test (p = 0.05). The medians were calculated.

Results and Discussion

Raw Beetroot

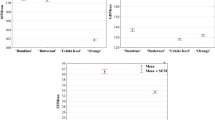

The mean with SEM (standard error of the mean) was determined for selected textures from color spaces Lab, RGB and XYZ. The results are presented in the form of graphs comparing the values for two beetroot cultivars. Only exemplary texture parameters were included in the figures, but the differences in the means were determined for many other textures. The means with SEM for selected textures from each color channel from the color space Lab are shown in Fig. 1. The cultivar differentiation is noticeable for each presented texture. The samples of raw beetroot ‘Czerwona Kula’ were characterized by the lower values of texture LHMean from color channel L (Fig. 1a), aHMean from color channel a (Fig. 1b) and bHMean from color channel b (Fig. 1c), whereas the higher values were observed for beetroot ‘Cylindra’. In the case of images of quarters of slices of raw beetroot ‘Czerwona Kula’, the lower means of selected textures from color space RGB including texture RHMean from color channel R (Fig. 2a), GHMean from color channel G (Fig. 2b) and BHMean from color channel B (Fig. 2c) were noted. Figure 3a) The raw beetroot ‘Czerwona Kula’ was also characterized by the lower means that ‘Cylindra’ of selected textures from color space XYZ: texture XHMean from color channel X (Fig. 3a), YHMean from color channel Y (Fig. 3b) and ZHMean from color channel Z (Fig. 3c).

The differences in texture parameters between beetroot cultivars allowed for the discrimination of ‘Czerwona Kula’ and ‘Cylindra’ with very satisfactory accuracies. In the case of raw beetroot for all developed models, the average accuracies were above 90% (Table 2). The highest correctness equal to 94.5% was observed for the model built based on textures from color space RGB for the PART classifier. The images of quarters of slices of beetroot ‘Czerwona Kula’ were correctly classified in 96% and ‘Cylindra’—93%. It indicated that 96 from 100 cases (quarters of slices) ‘Czerwona Kula’ were included in the class ‘Czerwona Kula’ and 4 cases in the class ‘Cylindra’, whereas 93 cases of ‘Cylindra’ were classified as ‘Cylindra’ and 7 cases—as ‘Czerwona Kula’. The values of TP Rate, Precision, F-Measure, ROC Area and PRC Area were also very high and were above 0.9. In the case of color space RGB, the high results were also obtained for the Random Forest. The average accuracy was equal to 94% and accuracies for individual cultivar 96% for ‘Czerwona Kula’ and 92% for ‘Cylindra’. The average accuracy of 94% was also determined for the model built based on textures selected from color space Lab for the Random Forest. In this case, the accuracy for ‘Czerwona Kula’ was equal to 97% and for ‘Cylindra’ was 91%. The lowest average accuracies of up to 93% (95% for ‘Czerwona Kula’, 91% for ‘Cylindra’) were observed in the case of models built for color space XYZ.

Freeze-Dried Beetroot

The means of one selected texture for each color space are presented in Fig. 4. The differences between cultivars of freeze-dried beetroot were determined. Freeze-dried beetroot ‘Czerwona Kula’ had the lower values of texture LHMean from color channel L from color space Lab (Fig. 4a), texture RHMean from color channel R from color space RGB (Fig. 4b) and texture XHMean from color channel X from color space XYZ (Fig. 4c). The freeze-dried beetroot ‘Cylindra’ was characterized by the higher means of these textures. Data not presented in the graphs indicated that also there were differences between the cultivars for other textures.

The presence of textures with different means between freeze-dried beetroot ‘Czerwona Kula’ and ‘Cylindra’ resulted in high accuracies of cultivar discrimination. The average accuracies were very high and reached 96% for color space Lab and the Random Forest classifier (Table 3). The freeze-dried beetroot ‘Czerwona Kula’ was correctly classified in 97%, and ‘Cylindra’ was correctly included in class ‘Cylindra’ in 95%. Also, the values of TP Rate, Precision, F-Measure, ROC Area and PRC Area were the discrimination performed using the selected textures from color space Lab and Random Forest. Slightly lower results were obtained for the models built based on textures from color spaces RGB and XYZ. In the case of color space RGB, the average accuracy reached 93% for Random Forest (95% for ‘Czerwona Kula’, 91% for ‘Cylindra’) and 93% for Logistic (93% for ‘Czerwona Kula’, 93% for ‘Cylindra’). For color spaces XYZ, the average accuracy was equal up to 94% for Random Forest (96% for ‘Czerwona Kula’, 92% for ‘Cylindra’).

The sensory profiling (0–10) based on beetroot smell, sweet smell, off-odor, beetroot color, color attractiveness, hardness, crunchiness, beetroot taste, sweet taste, bitter taste, off-flavor, taste and overall quality of freeze-dried beetroot ‘Czerwona Kula’ and ‘Cylindra’ were determined (Fig. 5, Table 4). The differences in all attributes between the cultivars were not significant.

Lacto-Fermented Beetroot

The means of textures of images of quarters of slices were different between lacto-fermented beetroot ‘Czerwona Kula’ and ‘Cylindra’, for example, for LHMean from color space Lab (Fig. 6a), RHMean from color space RGB (Fig. 6b) and XHMean from color space XYZ (Fig. 6c). The values of these textures were lower for ‘Czerwona Kula’ than for ‘Cylindra’.

The discriminant analysis of the lacto-fermented beetroot revealed very high accuracies. The cases of beetroot ‘Czerwona Kula’ and ‘Cylindra’ were distinguished with the correctness of up to 99% in the case of models built based on textures selected from color space Lab for the Random Forest and Logistic classifiers (Table 5). In the case of the Random Forest, the lacto-fermented beetroot ‘Czerwona Kula’ was discriminated with an accuracy of 100%. It means that all cases of beetroot ‘Czerwona Kula’ were correctly classified as ‘Czerwona Kula’. The accuracy for beetroot ‘Cylindra’ was equal to 98%. The values of TP Rate for ‘Czerwona Kula’, Precision for ‘Cylindra’, as well as ROC Area and PRC Area for ‘Czerwona Kula’ and ‘Cylindra’ reached 1.000. In the case of the Logistic classifier, both cultivars were classified with accuracies of 99%. It means that 99% of cases of ‘Czerwona Kula’ were included in class ‘Czerwona Kula’ and 1% in class ‘Cylindra’, and 99% of cases of ‘Cylindra’ were classified as ‘Cylindra’ and 1% as ‘Czerwona Kula’. The values of the ROC Area and PRC Area were equal to 1.000. The average accuracies for color spaces RGB and XYZ were slightly lower and reached 95% (Random Forest, PART) and 93% (Random Forest, PART), respectively.

The results of the sensory quality of the lacto-fermented beetroot ‘Czerwona Kula’ and ‘Cylindra’ are presented in Fig. 7 and Table 6. The beetroot smell, beetroot fermented smell, sweet smell, off-odor, beetroot color, color attractiveness, hardness, crunchiness, beetroot taste, fermented beetroot taste, sweet taste, bitter taste, off-flavor taste and overall quality were evaluated. There were no significant differences between samples.

Freeze-Dried Lacto-Fermented Beetroot

The values of selected textures from color spaces Lab, RGB and XYZ were different between freeze-dried lacto-fermented beetroot ‘Czerwona Kula’ and ‘Cylindra’. The means of LHMean from color space Lab (Fig. 8a), RHMean from color space RGB (Fig. 8b) and XHMean from color space XYZ (Fig. 6c) were lower for ‘Czerwona Kula’. The freeze-dried lacto-fermented beetroot ‘Cylindra’ was characterized by the higher values of these texture parameters.

The samples of freeze-dried lacto-fermented beetroot ‘Czerwona Kula’ and ‘Cylindra’ were distinguished with an average accuracy of up to 98.5% in the case of textures of images of quarters of slices from color space Lab for the Random Forest and Logistic (Table 7). In the case of both classifiers, the accuracies for individual cultivars were equal to 99% for ‘Czerwona Kula’ and 98% for ‘Cylindra’. The average accuracy for the models built based on textures selected from color space RGB reached 93.5% for the Random Forest classifier. In the case of color space XYZ, the quarters of slices of freeze-dried lacto-fermented beetroot ‘Czerwona Kula’ and ‘Cylindra’ discriminated with the correctness of up to 93% for the Random Forest.

The sensory profiling based on beetroot smell, beetroot fermented smell, sweet smell, off-odor, beetroot color, color attractiveness, hardness, crunchiness, beetroot taste, fermented beetroot taste, sweet taste, bitter taste, off-flavor taste and overall quality of freeze-dried lacto-fermented beetroot ‘Czerwona Kula’ and ‘Cylindra’ is shown in Fig. 9 and presented in Table 6. The sensory assessment of beetroot showed no significant differences between cultivars and treatments.

The consumer’s visual sensory perception of food can influence other sensory perceptions such as taste, smell and texture. Literature data confirm that when assessing the taste and smell of a product, the consumer is suggested by its appearance, e.g. color, and its loss or unfavorable change is associated with the deterioration of other sensory features (Walkowiak-Tomczak and Czapski 2007; Walkowiak-Tomczak et al. 2016; Herbach et al. 2007). Several factors directly determine the appearance of the product—the raw material, the used technology and the storage conditions. The effect of processing on the physicochemical and sensory properties of beetroot was reported by Nistor et al. (2017) and Tomic et al. (2020). In our study, the effect of cultivar on raw and processed beetroots was evaluated. The different processing techniques may affect beetroots differently depending on the cultivar. Cultivar differentiation may be more or less evident in different parameters of beetroots. Therefore, the appropriate technique for distinguishing the cultivars of beetroots should be chosen. The image analysis based on textures was useful for the discrimination of cultivars of raw and processed beetroots with a high probability. The sensory evaluation provided only small differences in attributes of processed beetroots. Therefore, the objective procedure, for example, using image analysis may be more desirable for distinguishing the cultivars of processed beetroots than descriptive sensory evaluation.

Conclusions

The cultivar differentiation of beetroots was studied using image analysis and descriptive sensory evaluation. The possibility of distinguishing the beetroot cultivars based on texture parameters of images of raw and processed samples and sensory attributes of processed beetroots was compared. The presence of textures from the images of quarters of root slices allowing for cultivar discrimination of beetroot was proved. The models built based on selected textures provided a very high discrimination accuracy of up to 99%. The differences in sensory attributes were very small, and their usefulness for distinguishing the beetroot cultivars may be minimal. Therefore, the objective techniques may be more useful in practice for the cultivar discrimination of raw and processed beetroots.

Data Availability

Not applicable.

Code Availability

Not applicable.

References

Bouckaert RR, Frank E, Hall M, Kirkby R, Reutemann P, Seewald A, Scuse D (2016) WEKA manual for version 3-9-1. University of Waikato, Hamilton, New Zealand

Chhikara N, Kushwaha K, Sharma P, Gat Y, Panghal A (2019) Bioactive compounds of beetroot and utilization in food processing industry: a critical review. Food Chem 272:192–200

Clifford T, Howatson G, Daniel J, West DJ, Stevenson EJ (2015) The potential benefits of red beetroot supplementation in health and disease. Nutrients 7:2801–2822

Elkner K (2004) Jakość ogórków kiszonych II [Quality of pickled cucumbers]. Hasło Ogrodnicze 9:80–82 ([in Polish])

Figiel A (2010) Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum-microwave methods. J Food Eng 98(4):461–470

Georgé S, Tourniaire F, Gautier H, Goupy P, Rock E, Caris-Veyrat C (2011) Changes in the contents of carotenoids, phenolic compounds and vitamin C during technical processing and lyophilisation of red and yellow tomatoes. Food Chem 124:1603–1611

Hammami C, Rene F (1997) Determination of freeze-drying process variables for strawberries. J Food Engin 32:133–154

Hammami Ch, René F, Marin M (1999) Process-quality optimization of the vacuum freeze-drying of apple slices by the response surface method. Int J Food Sci Technol 34(2):145–160

Herbach K, Maier Ch, Stintzing F, Carle R (2007) Effects of processing and storage on juice colour and betacyanin stability of purple pitaya (Hylocereus polyrhizus) juice. Eur Food Res Technol 224(5):649–658

Hoffmann M (2007) Jakość sensoryczna wybranych warzyw przyprawowych liofilizowanych i suszonych konwencjonalnie [Sensory quality of frozen-dried and air-dried seasoning vegetables]. ŻYWNOŚĆ Nauka Technologia Jakość 2(51):91–97

Jayaraman KS, Das Gupta DK (2007) Drying of fruits and vegetables. In: Mujumdar AS (ed) W: Handbook of industrial drying. CRC Press Taylor&Francis Group, New York S, pp 611–631

Kaur K, Singh AK (2014) Drying kinetics and quality characteristics of beetroot slices under hot air followed by microwave finish drying. Afr J Agric Res 9(12):1036–1044

Kondratowicz J, Burczyk E (2010) Technologiczne aspekty procesu liofilizacji [Technological aspects of freeze-drying process]. Chłodnictwo 45(4):54–59

Kowalski SJ, Łechtańska JM (2015) Drying of red beetroot after osmotic pretreatment: kinetics and quality considerations. Chem Process Eng 36(3):345–354

Kowalski SJ, Szadzinska J (2014) Kinetics and quality aspects of beetroots dried in non-stationary conditions. Drying Technol 32:1310–1318

Kozak P, Lis T (1999) Wpływ temperatury płyt grzejnych liofilizatora na cechy jakościowe suszu z selera [The influence of the temperature of the freeze dryer heating plates on the quality characteristics of dried celery]. Zesz Nauk Polit Łódz 821:63–68

Nistor OV, Seremet L, Andronoiu DG, Rudi L, Botez E (2017) Influence of different drying methods on the physicochemical properties of red beetroot (Beta vulgaris L. var. Cylindra). Food Chem 236:59–67

Piotrowski D, Biront J, Lenart A (2008) Barwa i właściwości fizyczne odwadnianych osmotycznie i suszonych sublimacyjnie truskawek [Colour and physical proprieties of osmotically dehydrated and freeze-dried strawberries]. Żywność Nauka Technologia Jakość 4(49):216–226

Rząca M, Witrowa-Rajchert D (2007) Suszenie żywności w niskiej temperaturze [Food drying at low temperature.]. Przemysł Spożywczy 4:30–35

Sawicki T, Baczek N, Wiczkowski W (2016) Betalain profile, content and antioxidant capacity of red beetroot dependent on the genotype and root part. J Funct Foods 27:249–261

Szczypiński PM, Strzelecki M, Materka A, Klepaczko A (2009) MaZda—a software package for image texture analysis. Comput Methods Programs Biomed 94(1):66–76

Sorour H, El-Mesery H (2014) Effect of microwave and infrared radiation on drying of onion slices. Int J Res Appl 2(5):119–130

Tomic N, Djekic I, Hofland G, Smigic N, Udovicki B, Rajkovic A (2020) Comparison of supercritical CO2-drying, freeze-drying and frying on sensory properties of beetroot. Foods 9(9):1201

Walkowiak-Tomczak D, Czapski J (2007) Colour changes of a preparation from red cabbage during storage in a model system. Food Chem 104(2):709–714

Walkowiak-Tomczak D, Czapski J, Młynarczyk K (2016) Assessment of colour changes during storage of elderberry juice concentrate solutions using the optimization method. Acta Sci Pol Technol Aliment 15(3):299–309

Witten IH, Frank E (2005). Data mining. In: Practical machine learning tools and techniques (525, 2nd ed.). San Francisco, CA: Elsevier.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics Approval

All procedures performed in studies involving human participants were in accordance with the ethical standards of the institutional and national research committee and with the 1964 Helsinki Declaration and its later amendments or comparable ethical standards.

Consent to Participate

Informed consent was obtained from all individual participants included in the study.

Conflict of Interest

Ewa Ropelewska declares that she has no conflict of interest. Anna Wrzodak declares that she has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ropelewska, E., Wrzodak, A. The Use of Image Analysis and Sensory Analysis for the Evaluation of Cultivar Differentiation of Freeze-Dried and Lacto-Fermented Beetroot (Beta vulgaris L.). Food Anal. Methods 15, 1026–1041 (2022). https://doi.org/10.1007/s12161-021-02187-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-021-02187-x