Abstract

This study focuses on the determination of the chemical profile of 24 non-aged Brazilian artisanal sugarcane spirits (cachaça) samples through chromatographic quantification and chemometric treatment via principal component analysis (PCA) and Kohonen’s neural network. In total, forty-seven (47) chemical compounds were identified in the samples of non-aged artisanal cachaça, in addition to determining alcohol content, volatile acidity, and copper. For the PCA of the chemical compounds’ profile, it could be observed that the samples were grouped into seven groups. On the other hand, the variables’ bearings were grouped together, making it difficult to separate the components in relation to the sample groups and reducing the chances of obtaining all the necessary information. However, by using a Kohonen’s neural network, samples were grouped into eight groups. This tool proved to be more accurate in the groups’ formation. Among the chemical classes of the compounds observed, esters stood out, followed by alcohols, acids, aldehydes, ketones, phenol, and copper. The abundance of esters in these samples may suggest that these compounds would be part of the regional standard for cachaças produced in the region of Salinas, Minas Gerais.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cachaça is the typical and exclusive name for the sugarcane spirit produced in Brazil, with specific identity profiles established by the identity and quality standard of cachaça (Brasil 2005). However, this standard alone is not enough to establish a chemical profile capable of discriminating the cachaça complex matrix. The expansion of cachaça’s market share has been encouraging improvements, in order to implement stricter controls and more detailed studies regarding the beverage’s production process, as well as in improving its chemical and sensory qualities (Serafim and Lanças 2019).

The municipality of Salinas, Minas Gerais, in Brazil has been recognized as the national capital of cachaça, where the most coveted cachaça brands in the country are produced. Salinas has the highest concentration of artisanal cachaça brands in Brazil with more than sixty brands and an estimated production of five million liters per harvest. The harvest moves dozens of alembics, generating income, and jobs for the local populace (Brasil 2018).

Artisanal cachaça is highly appreciated due to its characteristic aroma and flavor, which are conferred by the presence of several compounds of the fermentative process of freshly extracted sugarcane juice (de Souza et al. 2009). In addition to ethanol and water, sugarcane sprits contain a lower concentration of many organic compounds, which are incorporated throughout the production process and are known as congeners. According to Serafim et al. (2016), cachaça can be described as a complex aqueous solution, consisting of water, ethanol, higher alcohols, ethyl esters, aldehydes, ketones, and organic acids. These substances represent less than 1% of the total compounds and are responsible for cachaça’s typical sensory properties. The present compounds and their respective concentrations are formed, at different levels, due to the type of substrate, yeast strain used and fermentation conditions, distillation, and aging. According to Serafim and Lanças (2019), the demand for chemical analysis of beverages has been increasing, mainly due to the need to improve the quality standards and industrial control.

Chemical profiles of artisanal cachaça could provide relevant information to improve their traceability, sugarcane cultivation practices, the yeasts used during the fermentation process (“industrial” or “natural”), and even the alembic apparatus (copper or stainless steel) used in the distillation process (Serafim et al. 2016). Determination of specific compounds that may aid in tracking a product’s origin through fingerprint studies are in demand due to several marketing and economic reasons. These studies allow for a greater knowledge of a traditional Brazilian product, where its quality is paramount, according to Brazilian producers of artisanal cachaça, especially those from the Minas Gerais State (de Souza et al. 2009). Thus, by using data related to the cachaça’s geographical origin, it is possible to ensure their authenticity; it helps with the product’s traceability in order to guarantee their quality (Serafim et al. 2016) and to support the adoption of certification criteria proposed by the Instituto Nacional da Propriedade Industrial (INPI) (INPI — Selo de identificação geográfica para cachaças).

In order for a data set to be relevant, and potentially used in further studies, chemical analysis results are traditionally treated via chemometric analysis, such as principal component analysis (PCA) or, more recently, Kohonen’s artificial neural networks (Ferreira et al. 2020; Novaes et al. 2017; Silva et al. 2019). Principal component analysis essentially consists of rewriting the coordinates of the samples in a more convenient and simplified axis system for data analysis, where the main objective is to represent the variance present in the many variables by using a small number of factors (Novaes et al. 2017). However, interpretation of PCA results can be difficult, mainly due to the variability of the results found. Therefore, new data treatment approaches, such as Kohonen’s neural network, may be more advantageous due to its ease of interpretation and visualization. A Kohonen’s neural network allows visualizing the sample’s similarities and differences through the formation of groups according to the similarities present. An algorithm groups samples considered similar according to the evaluated components, while separating or distancing samples with little in common following to the same evaluation criteria (Silva et al. 2019).

In light of these observations, the hypothesis of our work follows that specific compounds could determine the product’s origin through fingerprint studies in order to improve knowledge of high-quality artisanal cachaça. In addition, Kohonen’s neural network, an easy to understand tool with a friendly interface, was used to substantiate this claim. Thus this study aims to establish a chemical profile for cachaças from the region of Salinas, Minas Gerais, Brazil, via chromatographic quantification of data using principal component analysis and Kohonen’s neural network.

Material and Methods

Chemicals

The analytical standards 5-methylfurfural (99%), propionaldehyde (97%), benzaldehyde (99%), acetaldehyde (99%), isovaleraldehyde (99%), furfuraldehyde (99.6%), 2,3-butanedione (97%), hydroxymethylfurfural (99%), ethyl hexanoate (99%), ethyl lactate (98%), ethyl octanoate (99%), ethyl decanoate (99%), ethyl carbamate (99%), 1-pentanol (99%), 1-butanol (99.8%), 2-butanol (99%), isoamyl alcohol (99%), 1-propanol (99.5%), dichloromethane (> 99.8%) chromatographic grade, 2,4-dinitrophenylhydrazine (99%) (2,4-DNPH), and deuterated anthracene (D10) all from Sigma-Aldrich (St. Luis, MO, USA) were used in the chromatographic analyses. All solutions were prepared using analytical grade reagents and ultrapure water (Milli-Q, Millipore, Bedford, MA, USA).

Samples

For this study, 24 samples of non-aged artisanal cachaça were collected in Salinas, MG, Brazil, at plants belonging to the Association of Artisanal Producers of Cachaça from Salinas (APACS). The samples were collected immediately after distillation in sterile glass bottles, suitable for cachaça storage, with a capacity of 700 mL, coded with random numbers from 1 to 24. The samples were then transported and stored in an appropriate place, at room temperature, until the moment of analysis.

Analysis of Alcohol Content and Volatile Acidity

The alcohol content was determined through densitometry, with measurements performed at 20 °C, using a digital densimeter DensiMat (Gibertini, MI, Italy). The result was expressed as percentage by volume (%, v/v), also known as Gay-Lussac grade (°GL) (Brasil 2005).

Volatile acids were extracted from the samples by distillation, using an Enochimic Electronic Distiller (mod. DDE, Gibertini, MI, Italy), with the extract being titrated with 0.1 mol L−1 sodium hydroxide. The results obtained were expressed in milligrams of acetic acid per 100 mL of anhydrous alcohol (ethanol) (Brasil 2005).

Determination of Volatile Organic Compounds in Cachaça by GC-MS

Liquid-Liquid Extraction

The liquid-liquid extraction method (LLE) was adapted from Cardoso et al. (2003), using 0.500 g of sodium chloride, 1.0 mL of anthracene (D10), 1.0 mL of dichloromethane, and 8.0 mL of sample or standard solution. Reagents were added to a 15 mL glass vial, and the solution was vortexed for 10 min at 2400 rpm and then left to stand in order to separate the phases (10 min). Then, 1 µL of the organic phase was injected into a GC-MS system. The profiles of the volatile compounds were obtained through the “analyte area/internal standard area” relationships.

Gas Chromatography Coupled to Mass Spectrometry Conditions

A gas chromatograph coupled with mass spectrometry detection (GC-MS) model QP2010S Plus (Shimadzu, Kyoto, Japan) was used during the experiments. The apparatus was equipped with automatic sampler (AOC-20i), electronic flow control, source of impact ionization electron with 70 eV energy, and quadrupole type mass analyzer. The GC-MS chromatographic conditions were the following: injector temperature 240 °C, splitless injection mode for 0.75 min and split 1:15, temperature ramp of the column oven starting at 50 °C, increasing to 240 °C with a heating rate of 5 °C min−1, maintaining the final temperature for 5 min. Helium was used as carrier gas at a flow rate of 3.08 mL min−1, and the solvent cutting time was 7 min. The column used was made of polyethylene glycol, 60-m long × 0.25-mm internal diameter × 0.25-µm film thickness (DB-Wax-Agilent J&W Scientific, USA). The interface temperature was 240 °C and the ion source was kept at 200 °C. In order to identify the compounds present in the cachaça samples, the GC-MS operated in full scan mode, scanning mode (m/z from 40 to 400), with single ion monitoring mode (SIM) being used to identify anthracene (D10) (m/z = 188) and ethyl carbamate (m/z = 62). The retention times of the compounds were obtained from confirming the spectra of the various analytes using the scanning mode and by comparison with the National Institute of Standards and Technology (NIST) and Shimadzu libraries. Chromatograms and mass spectra were obtained with the aid of the GCMS Real Time Analysis software, v.2.50 SU3, and the data was evaluated using GC-MS solutions software (Shimadzu Corporation, Kyoto, Japan).

Determination of Alcohols, Total Esters, and Total Aldehydes by GC-FID

The analyses for the determination of methanol, n-propanol, isobutanol, isoamyl alcohol, ethyl acetate, 2-butanol, 1-butanol, and acetaldehyde in non-aged artisanal cachaças were carried out in a gas chromatograph with flame ionization detector GC-FID (Varian, model CP-3380). The volume of standard solution or sample injected was 2 µL. A 2.5% (v/v) solution of 1-pentanol was used as an internal standard (PI) and prepared by adding 25.0 µL of 1-pentanol in 975 µL of a hydroalcoholic solution (40%, v/v). The chromatographic conditions employed were as follows: injector in split mode 1:25 at 225 °C, FID detector at 280 °C, column initially at 50 °C for 6 min, then at 100 °C with a heating rate of 15 °C min−1 and remaining at 100 °C for 6 min, then at 240 °C with a heating rate of 20 °C min−1 for 7.7 min. A DB-Wax column (polyethylene glycol, 60-m long × 0.25-mm internal diameter × 0.25-µm film thickness, Agilent Scientific, USA) was used, and the total running time was 30 min. Hydrogen was used as carrier gas at a rate of 0.87 mL min−1. For the FID, synthetic air and hydrogen were used at a rate of 300 mL min−1 and 30 mL min−1, respectively. The runs were managed by the Varian Star Workstation software.

Determination of Aldehydes and Ketones by HPLC-DAD-MS

Derivatization

For the determination of aldehydes and ketones in the samples, 50.0 µL of formic acid and 1.0 mL of a 2,4-DNPHo solution (200 mg of 2,4-DNPHo in 100 mL of hydroalcoholic solution (40 %, v/v)) were added to 4.0 mL of cachaça sample. The resulting solution was left to stand for 2 h for the derivatization reaction to be completed. After that, a 40 µL aliquot was transferred to a vial and used for analysis in the HPLC-DAD-MS system. The analytical curves used in the quantification of aldehydes and ketones in the samples of non-aged artisanal cachaças were built from successive dilutions of derivatized solutions with a concentration of 100 mg L−1 of the aldehyde and ketone standards, in a range between 0.25 and 7.50 mg L−1.

High-Performance Liquid Chromatography (HPLC) and Detection by UV-vis Spectrophotometry with Diode Array (DAD) and Mass Spectrometry (MS)

The chromatographic system used was an HPLC-DAD-MS (Shimadzu model LC-20AD) equipped with two high-pressure pumps, a diode array detector (DAD) model SPD-M20A, degasser model DGU-20A3, controller module CBM-20A, SIL-20AC self-sampler, and an ion trap (IT) time of flight (TOF) mass analyzer.

The separations were performed using a Phenomenex 100A Kinetex PFP (pentafluorophenyl) column (50 mm in length × 2.10 mm in diameter × 2.6 µm in particle diameter). Ultrapure water (A) and acetonitrile and methanol (55:45, v / v) (B) were the solvents used as mobile phase. The injection volume was 10 μL. The elution gradient used was B 40% for 13 min, linearly increasing to B 75% for 7 min, changing to B 100% for 5 min. This mobile phase was maintained for 3 min, returning to B 40% for 2 min with a stabilization period of 5 min. A flow rate of 0.2 mL min−1 was employed during the analysis. The analysis total time was 35 min. Quantification was performed by external standardization, and, to detect the analytes in the DAD, a wavelength equal to 350 nm was used. For MS detection, the conditions of the mass spectrometer were as follows: curved dissolvation line interface temperature of 200 °C, nebulization gas volume (N2) of 1.5 L min−1, detector voltage of 1.7 kV, 10-ms ion acquisition time, and 80 to 500 Da (Dalton) mass/charge monitoring range. The runs were managed by the LCMS Solutions software.

Copper Determination by AAS

For the determination of copper concentrations in the cachaça samples, an AA50 atomic absorption spectrophotometer (AAS) was used, with a wavelength of 324.7nm, a gap of 0.5nm, acetylene gas/air, and an oxidizing flame (hollow cathode lamp for Cu with 4mA current and D2 lamp for background correction). The copper content was determined by comparing the readings observed in the cachaça samples, with reading values referring to an analytical curve previously constructed in hydroalcoholic solution (40% v/v) in the range 0.1 to 10.0 mg L−1. The copper content was expressed in milligrams of copper per liter of the sample.

Chemometric Treatment

Principal component analysis was used to evaluate the original data obtained from the determination of 50 elements in 24 samples, totaling a data matrix of 24 × 50 (Novaes et al. 2017). Kohonen’s neural networks were also used to verify the cachaça samples’ profiles by using the Marquardt-Levenberg algorithm, as recommended by Ferreira et al. (2020). The optimization of Kohonen’s neural network architecture, that is, to obtain the best number of neurons that allows for the adequate distribution of the samples, resulted in the selection of an architecture of 49 neurons, arranged in a 7×7 square. This configuration was achieved after training several network architectures with 5 to 9 neurons. The normalization of the data was carried out to guarantee the same weight or significance level of the signals, regardless of the absolute value, and for the proper functioning of the algorithm. Experimental data were processed using the software MatLab 6.5 (MathWorks, Natick, MA).

Results and Discussion

Analysis of Alcohol Content and Volatile Acidity

Due to the importance of the constituents of cachaça for its classification, some physical and chemical parameters were evaluated. The alcoholic degree for the non-aged artisanal cachaça samples showed values varying from 37.8 to 48.0% (v/v) and can be seen in Fig. S1a. In the present study, all samples were below the maximum limit established (48%, v/v) by Brazilian cachaça legislation. Small variations in alcoholic content may be related to the beverage’s storage conditions, such as humidity, temperature, and incorrect cutting during the distillation stage or in the dilution of the product (de Miranda et al. 2007).

The evaluated samples showed a volatile acidity ranging from between 35 and 120 mg (100 mL anhydrous alcohol−1), and out of the 24 samples analyzed, only one was outside this range, that is, 225.98 mg 100 mL anhydrous alcohol−1 (Fig. S1b). Low volatile acidity values indicate a controlled production process, with adequate hygiene practices, and low levels of bacterial contamination. Sensorially, cachaças with lower acidity levels receive better evaluations from consumers. Analyzing 94 cachaças and commercial distilled spirits according to their identity and quality standards, maximum values for volatile acidity were found to be 247.4 mg 100 mL anhydrous alcohol−1, with a minimum of 6.06 mg 100 mL anhydrous alcohol−1 indicating that cachaça do possess a great variability of chemical compositions among the analyzed brands, with volatile acidity being among the components with greater variation (de Miranda et al. 2007), coinciding with the similar results found in this study.

Chemical Profile of Non-aged Artisanal Cachaça Samples

The concentrations of acetaldehyde, ethyl acetate, methanol, 2-butanol, n-butanol, and the sum of higher alcohols (n-propanol, isobutanol, and isoamyl alcohol) and congeners found in the 24 samples of non-aged artisanal cachaças are shown in Table 1. Meanwhile, the concentrations of formaldehyde, acrolein, 2,3-butanedione, furfuraldehyde, acetone, propionaldehyde, and benzaldehyde are described in Table 2. The chemical profile of the volatiles present in the samples was analyzed through gas chromatography coupled to a mass spectrometer. Figure S2 shows the chromatographic profile of a sample of non-aged artisanal cachaça (A12) obtained by GC-MS in scanning mode, in which 15 compounds belonging to different classes of chemical compounds were identified. Among the esters, ethyl hexanoate, ethyl lactate, ethyl decanoate, and ethyl carbamate were quantified using GC-MS. The concentrations of these esters are shown in Table 3.

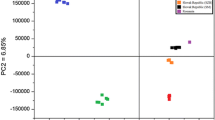

Based on these observations, a total of forty-seven (47) chemical compounds were identified in non-aged artisanal cachaça samples. Table 4 lists alcohol content, volatile acidity, the 47 chemical compounds, and copper found in the samples, identified by all analytical methods with their respective chemical structures. In order to verify if there were similarities between the samples and the components listed in Table 4, a data matrix containing alcohol content, volatile acidity, all identified chemical compounds, and copper was made for PCA in all 24 samples. For the PCA of the chemical compounds profile (self-scaled data), it was found that eighteen main components (PC) were necessary to explain 97.69% of the data variability. Figure S3 represents the score graphs, that is, the distribution of samples (A) and bearings, the distribution of variables (B) in the PCA for data on alcohol content, volatile acidity, chemical compounds, and copper from the non-aged artisanal cachaças. It could be observed through the analysis of Fig. S3, in the score graph, the formation of seven groups of samples and in the variables’ bearings were grouped in a single group, making it difficult to separate the components in relation to the groups formed. It was also possible to verify that the sum variance percentages remain around 25% (PC1 + PC2), which would be considered very low. This implies that in order to be able to fully interpret the data, combinations of at most three main components would have to be plotted. This process would make data interpretation difficult, with few chances of obtaining all the necessary information, as this procedure can be quite time-consuming. In order to solve this problem, other chemometric tools can be used, such as Kohonen’s neural network, which allows for a very friendly assessment, since it works with only two axes in space (two-dimensional space).

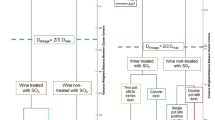

Figure 1 shows the distribution profile of the 24 samples of non-aged artisanal cachaça after treatment with the Kohonen’s neural network algorithm. In this case, the evaluated parameters were alcohol content, volatile acidity, copper; but also chemical compounds from samples with chromatographic peaks that were identified according to the NIST library with probabilities above 98% were considered (Table 4); signals that were confused with instrumental noise were discarded. The data was normalized, and the neural network distributed the samples into eight groups (Fig. 1). In order to identify which components influenced the distribution of the samples, the individual distribution map of the variables employed in the treatment by Kohonen’s network was used. The numerical index indicates the components listed in Table 4. The distribution map of the variables is shown in Fig. 2. Through the joint observation of the samples’ map (Figure 1) and the identification of the components that make up the map of variables (Figure 2), we can corroborate the similarities and differences between the cachaças pointed out by Kohonen’s map.

Distribution maps of individual variables used in the treatment by Kohonen’s network. The numerical index indicates the evaluated components, which are listed in Table 4

Based on the component analysis of Kohonen’s neural network, it was possible to visualize the identification of several types of substances such as alcohols, esters, aldehydes, ketones, and organic acids as the main responsible for the groups established in Fig. 2. To assess the neural network, it is necessary to observe the position of the neuron in the map of the variables (Fig. 2) and contrast with the position of the sample in the group (Fig. 1). The same positioning in the network indicates the presence or absence of the component or compound under study, which is given by the intensity indicated by the sidebar. The greater intensity of each component is indicated by the higher value of the sidebar, identified by the red color on the maps. Thus, cachaça samples can be combined into sets, which can be characterized in terms of composition and similarities.

In the sample distribution profile (Fig. 1), group I consists of sample A24, which presented specific compounds, which influenced this sample only (Fig. 2), thus contributing to it being distinguished from the others: ethyl octanoate (10), diethyl succinate (19), ethyl hexanoate (33), isoamyl alcohol (42), and acrolein (44). The octanoate (10) and ethyl hexanoate (33) have odors described as “fruity” and “apple peel,” respectively. In addition, after distillation, the freshly distilled beverage undergoes a state of equilibrium in its components, characterized by a decrease in diethyl succinate (19), which is associated with the balsamic aroma (Madrera et al. 2011).

Isoamyl alcohol (3-methyl-1-butanol) (42), a constituent of higher alcohols, is relatively common in alcoholic beverages, being dominant in beverages such as cachaça (Moreira et al. 2012). Nonato et al. (2001) describe that in terms of odor, 3-methyl-1-butanol can be characterized as an odor of “whiskey” and “malt,” in addition to “alcoholic,” “wine,” “banana,” and “sweet.” However, acrolein was also found in this group, which impairs the drink’s quality. Acrolein (2-propenal) (44) is formed during cachaça’s fermentation process and, in wines, can also be associated with the presence of thermofermentative bacteria (Bacillus amaracrylus and Lactobacillus colinoides) (de Azevêdo et al. 2007). Acrolein has stood out among the aldehydes, because in addition to the toxic effects associated with its presence, it also influences the aroma of cachaça, which is usually described as an unpleasant “rancid” odor. Its presence is also associated, in beverages, with the smell of pepper, its strong pungent, its penetrating odor, as well as its bitter taste (Zacaroni et al. 2011).

Despite being more intense in sample A24 (group I), analytes 1-hexanol (9), hexanoic acid (22), octanoic acid (25), decanoic acid (29), and isobutanol (40) were decisive for the approximation with group IV. Octanoic (25) and hexanoic (22) acids are present in the formation of their respective ethyl octanoate esters (derived from octanoic acid and ethanol) and ethyl hexanoate (hexanoic acid and ethanol). In cachaças from different regions of Brazil, it was found that among the volatile acids present in greater quantities in cachaças, octanoic and acetic acids were the most prominent (do Nascimento et al. 1998). Nóbrega (2003) found amounts of hexanoic acid in various types of cachaça that could justify the high concentration of it. Hexanoic acid is responsible for an unpleasant “pungent” odor that resembles cheese.

Alcohols appear both among the striking compounds and those that have little influence on group I. Sugarcane spirits manufactured in alembics have high amounts of higher alcohols, which can be used as a quality indicator for spirits. Isobutanol (2-methyl propanol) (40), isoamyl, and n-propyl alcohols constitute higher alcohols, the largest group among the aromatic components, which have a significant effect on the sensory characteristics of beverages. Also, 1-hexanol (9) is reported in literature as a compound that produces important aromatic responses in alcoholic beverages, such as cachaça and rum (Pino et al. 2012). Soares et al. (2011) reported that this compound is produced by yeasts, but the amount produced varies with the fermentation conditions, the genus, species, and, probably, with the strain used.

Regarding the compounds that determine this sample’s allocation (A24) and unique characteristics, the presence of three esters, three acids, and the same number of alcohols can be noted, all of which are important compounds for cachaça’s sensory quality. On the other hand, acrolein is also in this group which impairs the product’s quality. It is important to highlight that most of this study’s identified esters were found in sample 24, while the acids were more well distributed among the sample groups. It was possible to observe for sample 24 that the compounds related to it, apart from acrolein, are highly desirable as they produce essential and desirable aromatic responses in alcoholic beverages, which qualified the cachaça positively.

Sample A12 was located close to the network’s center in Fig. 1, and alone constitutes group II. The compounds 3-methyl-3-buten-1-ol (4), ethyl tetradecanoate (24), hexadecanol (30), butyl butyrate (32), formaldehyde (43), and propionaldehyde (48) were responsible for its distinction in regarding the other samples (Fig. 2). 3-Methyl-3-buten-1-ol (4) alcohol is reported as a minor aromatic component in several alcoholic beverages produced by fermentation (Madrera et al., 2011), but its sensory descriptor does not appear in the literature. Hexadecanol (30) present in spirits and cachaças is a minor compound that can be formed during the fermentation and distillation processes and has an important role in the beverage’s sensory characteristics, that is, aroma, taste, and flavor (Penteado and Masini 2009). Among the minor alcohols found, hexadecanol has obtained a prominent place in the composition of cachaças due to its high concentration (Moreira et al. 2012).

The presence of two esters in group II was also observed, one acts as a marker while the other is influenced by its closeness to group I. Ethyl tetradecanoate (24) was found in relatively low concentrations in brandy in the work of Nóbrega (2003) and was described as important for its aromatic composition. Meanwhile, butyl butyrate (32) contributes as an important “pineapple” flavor and aroma for the food and beverage industries (Varma and Madras 2008). In the literature, it is described as an important volatile compound of alcoholic beverages such as apple wine (Wang et al. 2004), but there are no reports regarding cachaça. However, due to its sensory description, the presence of this compound became irrelevant.

Group II was marked by the presence of two aldehydes, critical in differentiating the sample. Aldehydes are compounds that, depending on their concentration, can contribute positively or negatively to the sensory quality of cachaça. Formaldehyde (43) and propionaldehyde (48) are aldehydes known to decrease the quality of cachaças, as they modify the product’s flavor and aroma (Capobiango et al. 2013). Formaldehyde is noteworthy due the toxic effects associated with the aldehyde class and its influence on the beverage’s aroma, being associated with a “pungent” and “suffocating” odor (Moreira et al. 2012).

Sample 12, which forms group II (Fig. 1), despite containing aldehydes considered to be undesirable at high intensities, has other compounds associated with a pleasant aroma. Thus, it is possible to infer that the balance between the substances that compose a sample is essential for its characterization, not just the compounds themselves, which allowed it to be positively qualified. In addition, the presence of two determinant alcohols in this group allowed the approximation with group III, hexadecanol (30), and with groups I, IV, and V, 3-methyl-3-buten-1-ol (4).

In group III, samples A1 and A5 showed a similar chemical profile (Fig. 1) and were distinguished from the others due to the presence of 3-(methyl) 1-pentanol (7), ethyl lactate (8), methyl 2-hydroxy-4-methylvalerate (13), lactic acid (14), caprylic alcohol (15), ethyl decanoate (18), ethyl carbamate (34), acetaldehyde (35), methanol (37), 2-butanol (38), acetone (47), and copper (50) (Fig. 2). Literature describes 3-(methyl)-1-pentanol (7) as an important compound on the aroma of a cashew-based alcoholic beverages (Garruti et al. 2003), and 2-hydroxy-4-methylvalerate of methyl (13) is an important volatile component of soursop (Pino et al. 2002). In addition, trace amounts of ethyl decanoate (18) can be found in fermented beverages such as wine, beer, French cognac, and Scotch whisky, but they are identified as strong contributors to the aroma and flavor of these beverages (da Silva et al. 2008). Its presence in several beverages comes mainly as the result of the yeast metabolism during the fermentation process, which is also applied to cachaça, creating ester compounds associated with pleasant fruit notes. The specific odor of ethyl decanoate has been reported as “grape.” Thus, the composition of methyl 3-(methyl)-1-pentanol (7), 2-hydroxy-4-methylvalerate (13), and ethyl decanoate (18) in samples A1 and A5 may be related to the aromatic fruit characteristics in these samples.

Lactic acid (14), a non-volatile, odorless, mild-tasting organic acid, is present in many foods, either naturally or as a fermentation by-product, and is one of the main intermediates of metabolism in several organisms. Lactic acid is usually associated with contamination by lactic acid bacteria in beverages such as cachaça (Serafim et al. 2011). Meanwhile, ethyl lactate (8) has been associated with contamination by Lactobacillus spp. which is responsible for lactic fermentation. The most likely sources of contamination would be raw materials (e.g., sugarcane, yeast, water) or the distillation apparatus itself (Moreira et al. 2012). It is possible that ethyl lactate has some positive contribution to the taste and aroma of alcoholic beverages and will contribute positively to the aroma of cachaça; however, at relatively high levels, along with its low sensation threshold, it can certainly mask other aromas present in the beverages (Nascimento et al. 2009).

The presence of acetaldehyde (35), the main aldehyde associated with alcoholic fermentation, originates from distillation processes in which the “head” fraction of the beverage is not adequately separated. It has a pungent odor when concentrated and fruit notes when diluted. Its content can be minimized by avoiding aeration at the end of the fermentation (Moreira et al. 2012). In addition, ethyl carbamate (34) present in this group of samples has been the target of frequent concern for cachaça producers due to its carcinogenic potential. In recent years, several studies have been conducted, focusing on the causes of the formation of ethyl carbamate. They have found that its production occurs naturally in distilled beverages, before, during, and after the distillation stage via the reaction of ethanol with some nitrogen compounds (Serafim and Lanças 2019).

In this group (III), it is also important to highlight the presence of 13 compounds, out of which 11 are specific and did not influence the other groups. The presence of copper (50) is more accentuated in sample A15 of group VI, and while isoamyl octanoate (16) was also detected in this group, its greatest intensity is related to group V. Regarding the chemical classes, a great diversity was observed among the compounds that influence this group (III), with five esters, four alcohols, an aldehyde, a ketone, a metal, and an organic acid. It is important to note that group III (Fig. 1) stood out for bringing together the largest number of compounds with high intensities associated with it, despite containing only two samples. Among the compounds, the presence of ethyl carbamate, acetaldehyde, and methanol with relevant intensity in relation to the other groups may indicate loss of quality of these samples in relation to the others, since higher levels of these compounds are considered undesirable.

In group IV, samples A3, A4, and A6 were in the same neuron (Fig. 1), which indicates that they have an analogous profile. The compounds responsible for this formation correspond to ethyl dodecanoate (21), phenylethyl alcohol (23), and furfuraldehyde (46) and ester, an alcohol, and an aldehyde, respectively. These compounds stood out in relation to the others, due to their accentuated presence in these samples, which allowed them to be distinguished from the others. Ethyl dodecanoate (21) has had its contribution to alcoholic beverages supposedly due to its texture (oiliness) rather than the “plant leaf” aroma as has been described. Phenylethyl alcohol (23) is a product of yeast metabolism and used as an indicator of the fermentation process, in addition to being identified as one of the minor alcohols in cachaça (Boscolo et al. 2000). In addition, Coelho (2010) reported that floral nuances in an alcoholic beverage may come from derivatives of phenyl compounds, such as phenylethyl alcohol, more than from other compounds, and that the concentration of this alcohol may increase during distillation. Meanwhile, furfuraldehyde (46), a product of the degradation of pentoses from thermal dehydration of glycides, tends to have penetrating odors, which are generally nauseating and can negatively impact the taste of alcoholic beverages. They are considered toxic to humans and are associated with the unpleasant effects of excessive consumption of alcoholic beverages (symptoms of intoxication). Among these symptoms, nausea, vomiting, agitation, sweating, confusion, and headaches can be highlighted (Moreira et al. 2012). It is worth noting that the compounds 3-methyl-3-buten-1-ol (4), 1-hexanol (9), hexanoic acid (22), octanoic acid (25), decanoic acid (29), and isobutanol (40) were important for the group’s location and proximity to group I (Fig. 2).

Group V of Fig. 1 contains samples A2, A7, A8, A9, A11, A18, A20, A22, A23, A14, and A19, the last two samples having very similar chemical profiles and allocated in the same neuron. The group’s distribution was marked by the presence of 5-hydroxy-2-methyl-3-hexanone (3), propanoic acid (12), isoamyl octanoate (16), succinic acid (19), 3 (methyl-thio)-1-propanol (20), 2-methoxy-4-vinylphenol (26), and benzaldehyde (49) (Fig. 2). 5-Hydroxy-2-methyl-3-hexanone (3) is a ketone that has been identified as an aromatic compound in bananas, while propanoic acid (12) is responsible for the characteristic smell of Swiss cheese (Selli et al. 2012). Propanoic and succinic acids are among organic acids, secondary compounds that are formed during the wort fermentation stage. These exert a strong influence on the quality and sensory properties of beverages and on the stability during the fermentation stage (Serafim et al. 2011).

Isoamyl octanoate (16) or 3-methyl-1-butyl is an ester easily found in cachaça, however, in small concentrations (Moreira et al. 2012). Meanwhile, Simões et al. (2009) describe 3 (methyl-thio)-1-propanol (20) as being present in the aroma of apple ciders. Vinylguaiacol, also known as 2-methoxy-4-vinylphenol (26), is a compound normally observed in several types of wines, beer, whisky, and non-alcoholic beverages, such as fruit juices and coffee, and is sensorially described as a “condiment.” De Souza et al. (2006) were able to identify vinylguaiacol in cachaça samples and described the compound as having an active odor. The presence of benzaldehyde (49) and formaldehyde (43) in beverage may be related to the type of sugarcane, fermentation process, distillation method, and aging (Vilela et al. 2007). In general, these compounds have penetrating odors, usually nauseating, which are considered undesirable for cachaças (Moreira et al. 2012).

Despite being samples from different producers, it was observed that this group represents 45.83% of the samples studied in the present work, indicating great similarity between the samples produced in the region. It is also important to note that a small number of compounds were related to the group and that among them, there is no recognized positive aroma markers of cachaça such as major esters and higher alcohols. Thus, group V was marked by the presence of two acids, a phenol, an alcohol, an aldehyde, and a ketone, crucial in the differentiation of the samples; two esters, one of which is a group marker and the other influenced the approximation to group I.

Sample A15 formed group VI (Fig. 1) and was marked by the presence of isopropyl myristate (5), 4-trifluoroacetoxyoctane (28), N-propanol (39), 2,3-butanedione (45), and copper (50) (Fig. 2). Isopropyl myristate (5) has been referred to as a characterization compound of wine volatiles and is described as having a mild oily aroma, being reported as a solvent for fragrances (Welke et al. 2012). 2,3-Butanedione (45), an important compound for the taste of alcoholic beverages, makes an important contribution to the taste of beer, red wines, and distilled beverages such as whiskey and rum (Janzantti, 2004), giving the beverage an aroma similar to “butter.” In general, ketones are not considered harmful. However, prolonged inhalation of these compounds can cause irritation of the mucous membranes, headaches, confusion, and narcotic effects and can also lead to a coma. In studies on ketones of sugarcane spirits, 2,3-butanedione was the major ketone, followed by acetone (Cardoso et al. 2003).

This group was strongly influenced by copper (50) which assumes great importance in the final quality of artisanal cachaça, since it is generally produced in copper alembics, which gives the product better quality when compared to alembics made with other materials (Lima et al. 2009). According to Odello et al. (2009), the improved sensory characteristics of cachaça produced in copper alembics come from the reduced amount of volatile sulfur compounds in the distillate and, therefore, the unpleasant typical odor sulfides. Lima et al. (2009) reported that copper excess can be reduced with the appropriate cleaning of the alembic or through the removal of the head and tail fraction of the beverage, without affecting the ethanol yield and the quality of the beverage. In addition, the presence of copper made it possible to approximate this group with group III and group VIII, with its presence being highlighted in the samples located to the right of the neural network (Fig. 1). Thus, group VI was marked by the presence of two esters, a ketone, an alcohol, and copper, all determinants in the differentiation of the sample.

Samples A21 and A17 presented similar chemical profiles and formed group VII (Fig. 1). It can be observed that this group had many compounds with lower intensities, indicated by the lower value of the sidebar and identified by the blue color on the maps (Fig. 2). The compounds identified in these samples were only related to this group (VII) and are represented by volatile acidity (2), acetic acid (11), and ethyl acetate (36), which are considered very important components for the quality of cachaça (Nascimento et al. 2008). Volatile acidity expresses the content of organic acids while acetic acid is found in alcoholic beverages in greater concentrations than other acids. Regarding volatile acidity (2), studies indicate that cachaças with lower acidity levels are better accepted by consumers. Acetic acid is also an extremely important compound for the quality of sugarcane spirits, since it is the major acid found in this type of beverage, with a concentration ranging from 90 to 93% of the total acid content, having a great influence on the taste and aroma, and also being related to a penetrating and irritating odor, more commonly described as vinegar odor (Moreira et al. 2012). Ethyl acetate (36), which also differentiates this group, is identified as the most present ester in cachaça samples. This ester is derived from ethanol and acetic acid and, like most esters, is correlated with freshness and fruity notes (Nascimento et al. 2008).

Group VIII in Fig. 1 consists of samples A6, A10, and A13, which have the same equivalent profile. The parameters responsible for this formation were alcohol content (1), 2-heptanol (6), 2,3-butanedione (17), ethyl hexadecanoate (27), and methyl octadecanoate (31) (Fig. 2). 2-Heptanol (6) is part of the alcohols described as minor in the literature regarding the composition of volatile compounds found in spirits such as rum and cachaça, being described as the aroma of “cheese” (Duarte et al. 2011). Meanwhile, 2,3-butanedione (17) is the product of the reduction of diacetyl (2,3-butanedione) under normal conditions during the maturation of alcoholic beverages (Biazon 2008). On the other hand, ethyl hexadecanoate (27) is a minor ester described in cachaça (Nóbrega 2003) characterized by a strong fruity aroma. Copper (50) also influenced the differentiation of this group (Fig. 2).

In light of these observations, quantitative and qualitative variations between cachaça samples were observed. Among the chemical classes of the evaluated compounds, esters stood out, followed by alcohols, acids, aldehydes, ketones, phenols, and copper. This behavior differs from the work of Janzantti (2004), where alcohols were considered the most abundant chemical class in most commercial cachaças. The abundance of esters in the samples analyzed in the present study may suggest that these compounds could be a differential of the samples produced in this region and could be considered as quality markers for non-aged artisanal cachaças from the region of Salinas, MG, Brazil.

Finally, no analytical signals of the 5-methylfurfural, 5-hydroxymethylfurfural (HMF), and isovaleraldehyde compounds were found in any of the 24 analyzed samples. The appearance of HMF and furfural has been associated to sugarcane burning during the distillation, predominantly appearing at trace levels in alembics, depending on the type of heating used in the process (Faria et al. 2003). The absence of these compounds in the samples evaluated by this study may indicate that such practices have not been performed in the region where the samples were produced, which probably gives them superior quality, considering that higher concentrations of these analytes in alcoholic beverages are undesirable.

Conclusion

With what is known about cachaça composition, it will be possible to propose better techniques to control and inspect the beverage. In addition, it will be possible to guarantee to the consumer that the product they are buying is free from contaminants and adulterations. Among the chemical classes of the observed compounds, esters stood out, followed by alcohols, acids, aldehydes, ketones, phenol, and copper. The abundance of esters in these samples may suggest that these compounds play a role in conferring them the traditional characteristics of cachaças produced in the region of Salinas, Minas Gerais. However, this can only be proven with similar studies in other regions.

Still, this study was able to show that cachaças produced in the Salinas region have different composition components, and the differences found are possibly due to small changes in the production process, influenced by sugarcane type used, the sugarcane’s ripeness, type of yeast (wild/selected), conduction of the fermentation process, distillation, cachaça cutoff point, and regional culture.

References

Biazon CL (2008) Utilização de adsorventes durante o processo de microextração em fase sólida de flavours de cerveja. Dissertation, Universidade Federal do Rio Grande do Sul

Boscolo M, Bezerra CWB, Cardoso DR, Lima Neto BS, Franco DW (2000) Identification and dosage by HRGC of minor alcohols and esters in Brazilian sugar-cane spirit. J Braz Chem Soc 11(1):86–90. https://doi.org/10.1590/S0103-50532000000100015

Brasil (2005) Ministério da Agricultura, Pecuária e Abastecimento. Instrução Normativa nº. 13, de 29 de junho de 2005. Regulamento Técnico para Fixação dos padrões de identidade e qualidade para aguardente de cana e para cachaça. Diário Oficial da União [República Federativa do Brasil], Brasília, 30 jun. 2005

Brasil (2018) Senado Federal. Lei nº 13.773, de 19 de dezembro de 2018. Confere ao Município de Salinas, no Estado de Minas Gerais, o título de Capital Nacional da Cachaça. Diário Oficial da União [República Federativa do Brasil], Brasília, 19 dez. 2018

Capobiango M, Oliveira ES, Cardeal ZL (2013) Evaluation of methods used for the analysis of volatile organic compounds of sugarcane (cachaça) and fruit spirits. Food Anal Methods 6:678–988. https://doi.org/10.1007/s12161-012-9550-z

Cardoso DR, Bettin SM, Rech RV, Lima-Neto BS, Franco DW (2003) HPLC-DAD analysis of ketones as their 2,4-dinitrophenylhydrazones in Brazilian sugar-cane spirits and rum. J Food Compos Anal 16(5):563–573. https://doi.org/10.1016/S0889-1575(03)00061-9

Coelho EVM (2010) Relação do aroma e da espuma dos vinhos espumantes com o potencial enológico das uvas e dos vinhos (PhD thesis). Univerdsidade de Aveiro, Portugal

da Silva GA, Augusto F, Poppi RJ (2008) Exploratory analysis of the volatile profile of beers by HS-SPME-GC. Food Chem 111(4):1057–1063. https://doi.org/10.1016/j.foodchem.2008.05.022

de Azevêdo LC, Reis MM, da Silva LA, de Andrade JB (2007) Efeito da presença e concentração de compostos carbonílicos na qualidade de vinhos. Quim Nova 30(8):1968–1975. https://doi.org/10.1590/S0100-40422007000800032

de Miranda MB, Martins NGS, Belluco AEDS, Horii J, Alcarde AR (2007) Chemical quality of Brazilian sugarcane spirits. Ciencia Tecnol Alimentos 27(4):897–901. https://doi.org/10.1590/S0101-20612007000400034

de Souza MDCA, Vásquez P, Del Mastro NL, Acree TE, Lavin EH (2006) Characterization of cachaça and rum aroma. J Agric Food Chem 54(2):485–488. https://doi.org/10.1021/jf0511190

de Souza PP, de Oliveira LCA, Catharino RR, Eberlin MN, Augusti DV, Siebald HGL, Augusti R (2009) Brazilian cachaça: “single shot” typification of fresh alembic and industrial samples via electrospray ionization mass spectrometry fingerprinting. Food Chem 115(3):1064–1068. https://doi.org/10.1016/j.foodchem.2008.12.026

do Nascimento RF, Cardoso DR, LimaNeto BS, Franco DW (1998) Determination of acids in Brazilian sugar cane spirits and other alcoholic beverages by HRGC-SPE. Chromatographia 48(11–12):751–757. https://doi.org/10.1007/BF02467643

Duarte WF, Sousa MVF, Dias DR, Schwan RF (2011) Effect of co-inoculation of Saccharomyces cerevisiae and Lactobacillus fermentum on the quality of the distilled sugar cane beverage cachaça. J Food Sci 76(9):C1307. https://doi.org/10.1111/j.1750-3841.2011.02412.x

Faria JB, Cardello HMAB, Boscolo M, Isique WD, Odello L, Franco DW (2003) Evaluation of Brazilian woods as an alternative to oak for cachaças aging. Eur Food Res Technol 218(1):83–87. https://doi.org/10.1007/s00217-003-0795-z

Ferreira RJ, Rosa TR, Ribeiro J, Barthus RC (2020) Simultaneous metal determination in artisanal cachaça by using voltammetry and multivariate calibration. Food Chem 314(February 2019):26126. https://doi.org/10.1016/j.foodchem.2019.126126

Garruti DS, Franco MRB, Da Silva MAAP, Janzantti NS, Alves GL (2003) Evaluation of volatile flavour compounds from cashew apple (Anacardium occidentale L) juice by the Osme gas chromatography/olfactometry technique. J Sci Food Agric 83(14):1455–1462. https://doi.org/10.1002/jsfa.1560

Janzantti NS (2004) Compostos voláteis e qualidade de sabor da cachaça. In Compostos Voláteis e qualidade de sabor de cachaça (PhD thesis). Universidade Estadual de Campinas, Brazil

Lima AJB, Cardoso MG, Guimarães LGL (2009) Efeito de substâncias empregadas para remoção de cobre sobre o teor decompostos secundários da cachaça. Quim Nova 32(4):845–848. https://doi.org/10.1590/S0100-40422009000400004

Madrera RR, Valles BS, Lobo AP (2011) Chemical and sensory changes in fresh cider spirits during maturation in inert containers. J Sci Food Agric 91(5):797–804. https://doi.org/10.1002/jsfa.4249

Moreira RFA, Netto CC, de Maria CAB (2012) A fração volátil das aguardentes de cana produzidas no Brasil. Quim Nova 35(9):1819–1826. https://doi.org/10.1590/S0100-40422012000900022

Nascimento ESP, Cardoso DR, Franco DW (2008) Quantitative ester analysis in cachaça and distilled spirits by gas chromatography-mass spectrometry (GC-MS). J Agric Food Chem 56(14):5488–5493. https://doi.org/10.1021/jf800551d

Nascimento ESP, Cardoso DR, Franco DW (2009) Comparação de técnicas de determinação de ésteres em cachaça. Quim Nova 32(9):2323–2327. https://doi.org/10.1590/S0100-40422009000900016

Nóbrega ICC (2003) Análise dos compostos voláteis da aguardente de cana por concentração dinâmica do “headspace” e cromatografia gasosa-espectrometria de massas. Ciênc Tecnol Aliment 23(2):210–216. https://doi.org/10.1590/s0101-20612003000200019

Nonato EA, Carazza F, Silva FC, Carvalho CR, De Cardeal ZL (2001) A headspace solid-phase microextraction method for the determination of some secondary compounds of Brazilian sugar cane spirits by gas chromatography. J Agric Food Chem 49(8):3533–3539. https://doi.org/10.1021/jf000896r

Novaes CG, Romão ILdaS, Santos BG, Ribeiro JP, Bezerra MA, da Silva EGP (2017) Screening of Passiflora L. mineral content using principal component analysis and Kohonen self-organizing maps. Food Chem 233:507–513. https://doi.org/10.1016/j.foodchem.2017.04.111

Odello L, Braceschi GP, Seixas FRF, Silva AA, Galinaro CA, Franco DW (2009) Avaliação sensorial de cachaça. Química Nova 32(7):1839–1844. https://doi.org/10.1590/S0100-40422009000700029

Penteado JCP, Masini JC (2009) Heterogeneity of secondary alcohols in brazilian sugar cane spirits from diverse origins and processes of manufacture. Quim Nova 32(5):1212–1215. https://doi.org/10.1590/S0100-40422009000500024

Pino JA, Tolle S, Gök R, Winterhalter P (2012) Characterisation of odour-active compounds in aged rum. Food Chem 132(3):1436–1441. https://doi.org/10.1016/j.foodchem.2011.11.133

Pino J, Martí MP, Mestres M, Pérez J, Busto O, Guasch J (2002) Headspace solid-phase microextraction of higher fatty acid ethyl esters in white rum aroma. J Chromatogr A 954(1–2):51–57. https://doi.org/10.1016/S0021-9673(02)00167-X

Selli S, Gubbuk H, Kafkas E, Gunes E (2012) Comparison of aroma compounds in Dwarf Cavendish banana (Musa spp. AAA) grown from open-field and protected cultivation area. Sci Hortic 141:76–82. https://doi.org/10.1016/j.scienta.2012.04.008

Serafim FAT, Buchviser SF, Galinaro CA, Franco DW (2011) Ácidos orgânicos em aguardentes produzidas em alambique e em coluna. Quim Nova 34(1):28–32. https://doi.org/10.1590/S0100-40422011000100006

Serafim FAT, Lanças FM (2019) Sugarcane spirits (cachaça) quality assurance and traceability: an analytical perspective. In Production and Management of Beverages. Elsevier Inc. https://doi.org/10.1016/b978-0-12-815260-7.00011-0

Serafim FAT, Pereira-Filho ER, Franco DW (2016) Chemical data as markers of the geographical origins of sugarcane spirits. Food Chem 196:196–203. https://doi.org/10.1016/j.foodchem.2015.09.040

Silva EdosS, da Silva EGP, Silva Ddos, Novaes CG, Amorim FAC, dos Santos MJS, Bezerra MA (2019) Evaluation of macro and micronutrient elements content from soft drinks using principal component analysis and Kohonen self-organizing maps. Food Chem 273:9–14. https://doi.org/10.1016/j.foodchem.2018.06.021

Simões DRS, Waszczynskyj N, Wosiacki G (2009) Aromas em maçãs, suco e sidra: revisão. Boletim Centro Pesquisa Processamento Alimentos 27(1):153–172

Soares TL, Silva CF, Schwan RF (2011) Acompanhamento do processo de fermentação para produção de cachaça através de métodos microbiológicos e físico-químicos com diferentes isolados de Saccharomyces cerevisiae. Ciencia Tecnol Alimentos 31(1):184–187. https://doi.org/10.1590/S0101-20612011000100027

Varma MN, Madras G (2008) Wastewater treatment for production of H2S-free biogas. J Chem Technol Biotechnol 83(May):1135–1144. https://doi.org/10.1002/jctb

Vilela FJ, Cardoso MdasG, Masson J, dos Anjos JP (2007) Determinação das composições físico-químicas de cachaças do sul de minas gerais e de suas misturas. Ciência Agrotecnologia 31(4):1089–1094. https://doi.org/10.1590/s1413-70542007000400022

Wang L, Xu Y, Zhao G, Li J (2004) Rapid analysis of flavor volatiles in apple wine using headspace solid-phase microextraction. J Inst Brew 110(1):57–65. https://doi.org/10.1002/j.2050-0416.2004.tb00181.x

Welke JE, Manfroi V, Zanus M, Lazarotto M, Zini CA (2012) Characterization of the volatile profile of Brazilian Merlot wines through comprehensive two dimensional gas chromatography time-of-flight mass spectrometric detection. J Chromatogr A 1226:124–139. https://doi.org/10.1016/j.chroma.2012.01.002

Zacaroni LM, Cardoso MDG, Saczk AA, Santiago WD, Dos Anjos JP, Masson J, Duarte FC, Nelson DL (2011) Caracterização e quantificação de contaminantes em aguardentes de cana. Quim Nova 34(2):320–324. https://doi.org/10.1590/S0100-40422011000200026

Acknowledgements

The authors would like to thank the Coordination for the Improvement of Higher Education Personnel - CAPES (finance code 001).

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature by Universidade de Vigo/CISUG.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Conflict of Interest

Daniela Caetano declares that she has no conflict of interest. Clara Mariana Gonçalves Lima declares that she has no conflict of interest. Ananda Lima Sanson declares that she has no conflict of interest. Debora Faria Silva declares that she has no conflict of interest. Guilherme de Souza Hassemer declares that he has no conflict of interest. Silvani Verruck declares that she has no conflict of interest. Sandra Regina Gregorio declares that she has no conflict of interest. Gilmare Antonia da Silva declares that she has no conflict of interest. Robson Jose de Cassia Franco Afonso declares that he has no conflict of interest. Mauricio Xavier Coutrim declares that he has no conflict of interest. Gaber El-Saber Batiha declares that he has no conflict of interest. Jesus Simal-Gandara declares that he has no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Caetano, D., Gonçalves Lima, C.M., Lima Sanson, A. et al. Chemical Fingerprint of Non-aged Artisanal Sugarcane Spirits Using Kohonen Artificial Neural Network. Food Anal. Methods 15, 890–907 (2022). https://doi.org/10.1007/s12161-021-02160-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-021-02160-8