Abstract

The paper presents the kinetics of two-step ellagitannin (ET) extraction with an aqueous acetone solution from two technological types of pomace from selected berry fruits of the Rosaceae family. ETs were identified and quantified using HPLC–MS and HPLC–DAD. The results revealed the extraction kinetics of total ETs, their high and low molecular weight fractions (≤ 1569 Da and > 1569 Da), and individual ETs characteristic of the examined fruits. ET extraction proceeded at a faster rate in the first step, regardless of the tested pomace. For all pomace variants, the mean extraction half time t1/2 was 48 min in the first step and 70 min in the second step. The fruit species and the technological type of pomace were not found to exert a definite effect on the kinetics of ET extraction. Statistical analysis demonstrated that the molecular weight of ETs did not influence the kinetics of their extraction, either. It was shown that the technological type of pomace had a significant impact on the extraction rate of both low molecular weight (LMW) and high molecular weight (HMW) ETs in the first extraction step, with the mean t1/2 being 44 min for pomace from juice production and 63 min for pomace from puree production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ellagitannins (ETs) are secondary plant metabolites belonging to the group of hydrolysable tannins (Feldman et al. 2003; Dai and Mumper 2010). They exhibit beneficial health properties, including antioxidant, antibacterial, antiviral, and anti-inflammatory activity (Sangiovanni et al. 2013; Kahkonen et al. 2012; Larrosa et al. 2010; Puljula et al. 2020; Marquez - Lopez et al. 2020). The health-promoting activity of ETs has been demonstrated both in vitro and in vivo. ET extracts from wild strawberry leaves have an inhibitory effect on HepG2 hepatocellular carcinoma cells (Liberal et al. 2019). ET extracts from red raspberry show a strong geno- and cytotoxic effect against colorectal cancer cells Caco-2. In the Nowak et al. (2017) study, ETs in total, in the amount of 2.5–160 μM, induced DNA damage in the range of 7–57%. In a cellular model of UV-induced dermatitis, two ETs—strictinin and casuarictin—demonstrated anti-inflammatory activity by inhibiting interleukin-8 mRNA expression (Takayama et al. 2021). Studies on cell lines have confirmed the anti-inflammatory and anti-carcinogenic effects of ETs obtained from pomegranate leaves (Toda et al. 2020). The in vitro antiviral activity of three ETs was tested—antiviral activity has been demonstrated against three viruses infecting animals (Vilhelmova - Ilieva et al. 2020).

ETs are predominantly oligomeric but also include some monomers. The molecular weight of ETs is in the range of 500–3,000 Da (Lekha and Lonsane 1997; Rao and Snyder 2010; Feldman et al. 2003). Plants containing significant amounts of ETs in their fruits include members of the Rosaceae family, e.g., raspberries and blackberries in the genus Rubus, as well as strawberries and wild strawberries in the genus Fragaria (Hager et al. 2008; Gasperotti et al. 2010; Kahkonen et al. 2012). ET content ranges from 500 mg/kg of strawberry fruits to 4,000 mg/kg fresh weight of blackberry fruits (Sójka et al. 2016; Klimczak et al. 2011; Gasperotti et al. 2010; Hager et al. 2010). The main characteristics of ETs in the studied fruits are the oligomeric compounds lambertianin C, agrimoniin, and sanguiin H-6 (Fig. 1) (Sójka et al. 2016; Kahkonen et al. 2012; Hager et al. 2008; Salminen 2003; Vrhovsek et al. 2012).

Fragaria and Rubus fruits are highly perishable and are processed into more stable forms such as juices, purees, concentrates, and jams, giving rise to by-products in the form of pomace, which largely consists of dietary fiber and retains a mixture of polyphenols, ETs included (Sójka et al. 2016; Siriwoharn and Wrolstad 2004; Hager et al. 2010). ETs tend to bind to plant cell walls and can form bonds with pigment compounds, metal ions, and proteins (Puech et al. 1996; Okuda et al. 1992), which is probably attributable to the size and specific structure of ETs and especially the fact that they contain large numbers of hydroxyl groups. It has been found that up to 90% of the ETs (and in particular high molecular weight ETs) contained in raspberries and blackberries are retained in the pomace after fruit processing (Sójka et al. 2016; Hager et al. 2010).

The literature indicates that acetone is the most effective solvent for the extraction of ETs (Salminen 2003; Klimczak and Król 2010). The concentration of acetone at the level of 60–80% allows to obtain a much higher concentration of ETs in the extract (Salminen 2003; Milczarek et al. 2020). Oligomeric ETs have been shown to be the most stable at pH 2–4; therefore, formic acid is additionally used for the extraction (Sójka et al. 2019).

Fruit pomace may be further extracted to produce preparations rich in biologically active compounds, i.e., polyphenols. Many studies have shown that ET extracts significantly inhibit the development of undesirable microorganisms, such as Escherichia coli, Salmonella enteritidis, and Geotrichum candidum (Klewicka et al. 2016; Navarro et al. 1996; Al-Zoreky 2009). ET extracts obtained from by-products may be used in a variety of industrial applications, e.g., as food additives to inhibit the growth of pathogenic microorganisms or to fortify the end products, as well as in the production of dietary supplements and cosmetics (Klewicka et al. 2016; Dai and Mumper 2010).

Several kinetic models have been presented in the literature to describe the rate of extraction of polyphenolic compounds from plant material into liquids (Khan et al. 2010; Torun et al. 2015; Goula 2013; Bucic-Kojic et al. 2007; Garcia-Estevez et al. 2015; Sant’Anna et al. 2012; Dincer et al. 2002). The transfer of polyphenols from a fruit matrix to a solvent occurs in a heterogeneous environment, which means that they may be extracted at different rates (Diaz-Reinoso et al. 2006). The choice of the right kinetic model mainly depends on the plant matrix. To date, researchers have mainly focused on the kinetics of ET extraction from two sources—blackberry biomass and oak chips (Quirós et al. 2019; Puech et al. 1996; Garcia-Estevez et al. 2015; Psarra et al. 2015). The kinetics of polyphenolic extraction from a fruit matrix have been described using a first-order model (Quiros et al. 2019; Khan et al. 2010) with modifications (Bucic-Kojic et al. 2013; Sant’Anna et al. 2012). In a study on the kinetics of polyphenolic extraction from a blackberry matrix, the first-order model was characterized by a high R2 coefficient (0.860 for ETs, 0.994 for anthocyanins) with a low estimation error (Quirós et al. 2019). A second-order model has been applied to ET extraction from wood (Lazar et al. 2016; Puech et al. 1996). However, little is still known about the detailed mechanisms of ET transfer from pomace to solvents.

Understanding the extraction kinetics of ET from berry fruit pomace is a key aspect in further research on their effective isolation and further use. Extraction is the first step in successfully extracting the ETs from the pomace. Determining the optimal time to extract these compounds from different waste matrices is useful for the economy of the entire process. The effective isolation of ETs from waste products is in line with the green chemistry strategy and the clean label trend. Isolating ETs will allow for further research on their health-promoting effects and chemical and biological properties. Purified ET extracts may be an alternative to food preservatives and anti-inflammatory compounds and may be additives influencing specific health-promoting properties of food.

The aim of the current study was to characterize the kinetics of ET extraction from pomace from two processing technologies. The pomace was a residue after pressing juices and producing purees from the fruits of four plant species of the Rosaceae family. Extraction kinetics were studied not only for total ETs, but also separately for the low molecular weight (LMW) and high molecular weight (HMW) fractions as well as for some individual ETs. Research may help to increase knowledge of acetone extraction of ETs from a complex matrix such as fruit pomace. This study will allow to effectively obtain ETs from by-products.

Materials and Methods

Fruits

The research material consisted of selected berry fruits of the Rosaceae family: raspberry (Rubus idaeus L.), blackberry (Rubus fruticosus L.), strawberry (Fragaria grandiflora), and wild strawberry (Fragaria vesca). Deep-frozen fruit came from the Cajdex warehouse (Lodz, Poland). The material (in the amount of 4 kg for each fruit) was stored at − 21 °C until processing. The fruit was packed in tightly closed polyethylene bags.

Chemicals

Acetone for extraction (99.8% purity) was purchased from Chempur (Piekary Śląskie, Poland). Reagents for HPLC and LC–MS were characterized by HPLC grade. Acetonitrile (LC–MS grade) and orthophosphoric acid (85% concentration) were from the company J.T.Baker (Deventer, Netherlands), while formic acid for HPLC and standard ellagic acid (> 95% purity) were purchased from Extrasynthese (Genay, France). The ET standards that were used to prepare standard curves were obtained and purified (Sójka et al. 2016) at the Institute of Food Technology and Analysis, Lodz University of Technology. The standards were characterized by HPLC (210 nm). The purity of the standards was higher than 90%.

Fruit Processing and ET Extraction

For each fruit species, ETs were extracted from two technological types of pomace: the by-products of unclarified juice and puree manufacture. Juices and purees were produced in accordance with the methodology described in the previous publication (Milczarek et al. 2021). First, approx. 4 kg of fruits was thawed (4 °C, 24 h) and ground using a Zelmer grinder (Rzeszów, Poland). The pulp was incubated (1 h, 45 °C) with the pectinolytic enzyme Rohapect Classic (Novozymes, Bagsvaerd, Denmark) at a dose of 0.2 mL/kg (its enzyme activity was 1906 U/mL). During enzymatic maceration, the sample was stirred manually every 10 min. Subsequently, the pulp was divided into two parts: one for pressing juice (100 bar, 5 min) with a laboratory basket press and the other one for making puree with a strainer—with a mesh of less than 1 mm (Orion, Katowice, Poland). The pomaces obtained from juice and puree production were used for ET extraction. Immediately after processing, the pomace was intended for further analysis.

The pomace (in the amount of above 200 g), which was frozen under liquid nitrogen, was milled with an IKA basic cryogenic mill (Staufen, Germany) and sieved through a 1 mm mesh to obtain a uniform grain size. Extraction was carried out in two identical steps according to the methodology described by Klewicka et al. (2016). The pomace was placed in polypropylene containers with a capacity of 2 L. The pomace was immersed in a 60% aqueous acetone solution with 0.1% formic acid in a 1:5 ratio and shaken for 6 h at ambient temperature in an orbital shaker (Elmi DOS-10L, Aizkraukles, Latvia) at 150 rpm. After that time, the extract was separated from solids using a cotton filter cloth. The pomace was then subjected to another analogous extraction step. Throughout the entire extraction process, 1 mL samples of the extract were taken every hour for HPLC/MS analysis. Two repetitions of extractions were made from each type of pomace. For each time, 3 parallel samples were taken for analysis. A total of 6 repetitions were performed for each hour.

Identification of Ellagitannins

ETs were identified according to the methodology described by Sójka et al. (2016) using a liquid chromatograph coupled to a DAD detector and a Q Exactive Orbitrap mass spectrometer (Thermo Fisher Scientific, Waltham, MA, USA). Separation was done on a Luna C18 100 Å column (250 mm × 4.6 mm, 5 μm) (Phenomenex, Torrance, CA, USA). The separation temperature was 35 °C, and the flow rate was 1 mL/min at an injection volume of 20 μL. Separation took place in a gradient system using two phases: A (1% formic acid in water) and B (80:20 acetonitrile/water solution). The gradient program was as follows: 0–6.5 min—5% B, 95% A; 6.5–12.5 min—5–15% B, 95–85% A; 12.5–44 min—15–45% B, 85–55% A; 44–45 min—45–75% B, 55–25% A; 45–50 min—75% B, 25% A; 50–52 min—75–5% B, 25–95% A; and 52–65.5 min—5% B, 95% A. The mass spectrometer recorded spectra in negative mode (H-ESI source). The capillary temperature was 400 °C, and the vaporizer temperature was set to 500 °C. The auxiliary and sheath gas flow rates amounted to 72 and 20 units, respectively. The ion spray voltage was 4 kV. In full MS/dd-MS2 scanning mode, the mass range was set at m/z 200–2000 and collision energy at 20. Data were collected using Xcalibur 3.0.63 (Thermo Fisher Scientific Inc.) software.

Quantitative Analysis of Ellagitannins by HPLC

Quantitative analysis of ETs was carried out in accordance with the methodology described by Sójka et al. (2016). The content of ETs in the tested extracts was analyzed using a Smartline Knauer liquid chromatograph (Berlin, Germany). The HPLC set consisted of a degasser (Manager 2000), a thermostat, two pumps (P1000), and an autosampler (3950). A PDA detector (2800) was used with the wavelength set to 250 nm. The separation was carried out in accordance with the methodology described by Sójka et al. (2016). The ETs were separated on a Gemini C18 110 Å column thermostated in 35 °C (Phenomenex, Torrance, CA, USA). The dimensions of the column were 250 mm × 4.6 mm, 5 μm. The flow rate was set to 1.25 mL/min. The injection volume was 20 μL. Separation of ETs was carried out in a gradient system, with two phases: A—0.05% aqueous solution of phosphoric acid and B—83% aqueous solution of acetonitrile acidified with 0.05% phosphoric acid. The share of phases in the gradient during analysis was as follows: 0–5 min—5% of phase B, 95% of phase A; 5–10 min—5–15% of phase B, 95–85 of phase A; 10–35 min—15–40% of phase B, 85–60 of phase A; 35–40 min—40–73% of phase B, 60–27% of phase A; 40–44 min—73% of phase B, 27% of phase A; 44–46 min—73–5% of phase B, 27–95% of phase A; and 46–54 min—5% of phase B, 95% of phase A. To quantify individual ETs, standard curves were made in the concentration range: lambertianin C—0.5–225 mg/L, sanguiin H-6—0.5–200 mg/L, agrimoniin—0.5–100 mg/L. The concentrations of lambertianin D, lambertianin C isomers, and unknown ETs were calculated from the lambertianin C standard curve. The concentrations of ellagic acid conjugates were calculated using the ellagic acid standard curve. The main validation parameters, i.e., LOD (limit of detection), LOQ (limit of quantification), recovery, repeatability, and coefficient of variance, were determined on the basis of standard curve equations. The LOD was adopted as the b factor from the respective standard curve equations. LOQ was calculated by multiplying the LOD by three (Table 1).

Immediately before injection of the extract onto the column, the samples were diluted 1:1 with phase A. Data were collected by the ClarityChrom v. 3.0.5.505 program (Berlin, Germany).

Kinetics of Ellagitannin Extraction

The parameters that are typically used to evaluate the fit of extraction kinetics models are the p-value, the determination coefficient R2, and the standard error of estimation (SEE) (Quirós et al. 2019). In a study on the kinetics of blackberry ET and anthocyanin extraction by Quirós et al. (2019), a first-order kinetics model revealed a slightly better fit as compared to a modified pseudo-first-order model (the latter was marginally better in the case of total polyphenolic extraction) (Sant’Anna et al. 2012). Also other studies on the kinetics of polyphenolic extraction from plant matrices indicate a good fit of first-order kinetic models (Spiro and Pui-Lang 1995; Torun et al. 2015; Bucic-Kojic et al. 2013). Therefore, in the present work, that model was selected for describing the kinetics of ET extraction from the tested pomaces.

ET extraction took place in two steps, with each being described separately by the following first-order model kinetic equations:

This model defines the final concentration of ETs \({(C}_{\infty })\) extracted from pomace \({C}_{eq}\)(mg/100 g fresh weight). The linearized equation takes the following form:

where \({c}_{0}\) is the concentration of ETs extracted from pomace at time t (min). In order to determine extraction rate constants (s−1) for ETs, time was plotted as the function ln(\(\frac{{c}_{\infty }}{{c}_{\infty -}{c}_{0}}\)).

Another important parameter is extraction half time or the time after which half of the content of the compounds is extracted – \({t}_\frac{1}{2}\)(min).

The correlation between the theoretical calculations and experimental results was assessed based on the value of the determination coefficient R2, defined as:

where \({y}_{t}\) is the value of ET concentration over time, \({\widehat{y}}_{t}\) is the theoretical value of ET concentration, and \(\overline{y }\) is the arithmetic mean of experimentally obtained ET concentrations. The correlation coefficient value is in the range of 0–1. The higher the R2 value, the better the fit of the model.

The measurement precision for ETs concentration after the first and second extraction step was also determined based on repeatable center points. The CV (coefficient of variance) was determined from the formula:

where SD is standard deviation and X is the average value for repeatable center points.

In addition, the standard error of the mean (SEM) was also determined based on the formula:

where S is standard deviation and n is the number of repetitions.

Statistical analysis of the extraction kinetics results was conducted using StatSoft Statistica software v. 7.0.61.0 EN (CA, USA). The effect of the extraction step, technological type of pomace, fruit species, and molecular weight of ETs on t1/2 was tested using Duncan’s post-hoc test. The effect of individual parameters on the rate constant k was not studied, as this value was closely correlated with the value of t1/2 (R2 = 0.99).

Results and Discussion

The kinetics of ET extraction (for the compounds identified in Table 2) from two technological types of pomace obtained from four species of fruit were divided into two steps, according to the steps of the extraction process. Extraction kinetics were presented as the amount of ET extracted from 100 g of pomace as a function of time and studied in relation to the total concentration of ETs (c∞) obtained after each of the two 6-h steps. In addition, kinetic parameters were determined for the HMW ET fraction (> 1569 Da) and the LMW fraction (≤ 1569 Da). An important element of the work was the determination of extraction kinetics for individual ETs characteristic of the examined fruits.

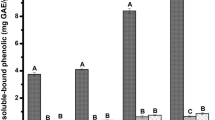

Extraction Kinetics of Total ETs

Table 3 shows the final concentrations of ETs (c∞) as well as the rate constant (k) and extraction half time (t1/2) values for the two extraction steps (Fig. 2). In each case, extraction proceeded until reaching equilibrium. In all tested extracts, total ET content was higher in the first than in the second step. Three to four times more ETs were obtained from Rubus (raspberry and blackberry) pomaces in the first extraction step; e.g., 100 g of blackberry pomace from juice production yielded 830 mg of ETs in the first step vs. 260 mg in the second step (Table 3). In the case of Fragaria (strawberry and wild strawberry) pomaces, the extraction yields obtained in the first step were up to eight times higher than in the second step. For instance, 100 g of pomace derived from the production of strawberry puree yielded 47 mg of ETs after 6 h of extraction as compared to approx. 6 mg in the second step.

Kinetics of two-step ellagitannin extraction from pomace derived from selected fruits of plants in the Rosaceae family (by-products of juice and puree production): 1, juice: raspberry and blackberry; 2, puree: raspberry and blackberry; 3, juice: strawberry and wild strawberry; 4, puree: strawberry and wild strawberry

For the tested pomace variants, the extraction rate constants were on average 40% higher in the first step (0.012 to 0.021 min−1) than in the second step (0.0068 to 0.013 min−1), except for pomace from the production of wild strawberry puree (0.010 min−1 vs. 0.012 min−1). In a study on the kinetics of ET extraction from blackberry by-products, Quirós et al. (2019) obtained an extraction rate constant of 0.079 min−1, which is in line with the present findings (the extraction rate constant for blackberry pomace in the first step was 0.012–0.021 min−1). In terms of the kinetics of total polyphenolic extraction from fruit material, Khan et al. (2010) reported a rate constant of 0.03 min−1 for orange peels (also using a first-order model). Similar polyphenolic extraction constants have been reported from studies involving blackberry biomass (0.023 min−1, Quirós et al. 2019) and grapes (0.040 min−1, Sant’Anna et al. 2012).

In the present study, the extraction half time t1/2 did not exceed 1 h for any of the tested raspberry and blackberry pomace variants (in the first step), with a significant slowdown in the ET extraction rate after that time. The same was true for strawberry and wild strawberry pomaces except for the variant from the production of wild strawberry puree, where t1/2 in the first step was 68 min. In the second step, t1/2 ranged from 55 to 91 min. Regardless of the fruit species and technological pomace type, extraction kinetics were clearly characterized by a two-step course, with a fast first step and a slower second one, in which an equilibrium was reached. Statistical analysis (ANOVA) revealed a significant difference in the mean t1/2 between the first and second extraction steps at 48 ± 11 min and 70 ± 11 min, respectively (p-value < 0.006548 at the adopted significance level of 0.05) (Table 4). For comparison, in the study of Quirós et al. (2019) on the extraction kinetics of total polyphenols from blackberry biomass, equilibrium was reached after 120 min. A clear two-step mechanism of polyphenolic transfer from plant matrices has been reported in the literature, with a dynamic first step involving the transfer of compounds present on the surface of solids and a slower second one involving diffusion transfer from within solids into a liquid solvent (Coulson et al. 1991; Garcia-Estevez et al. 2015). In the present study, statistical analysis showed that the extraction of total ETs did not depend on the technological type of pomace or fruit species. The mean t1/2 values for pomaces from juice and puree production were 47 and 49 min in the first step and 72 and 68 min in the second step, respectively. The mean t1/2 values obtained for different fruit species did not differ statistically, ranging from 43 to 57 min in the first step and from 66 to 79 min in the second step.

Extraction Kinetics Depending on ET Molecular Weight

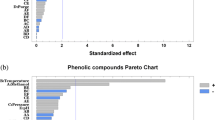

The identified ETs were divided into LMW (≤ 1569 Da) and HMW (> 1569 Da) fractions. The kinetics of their extraction were analyzed based on the amount of ETs extracted from the pomace in each of the two steps (Fig. 3). In addition, mean t1/2 values were analyzed statistically in terms of ET molecular weight, extraction step, technological type of pomace (derived from juice or puree production), and fruit species.

In most cases, the extraction rate constant was higher in the first step for both LMW and oligomeric ETs, except for ETs extracted from pomace derived from the production of wild strawberry puree, for which it was higher by 0.1 (10−4 s−1) in the second step, regardless of ET molecular weight. In the first step, the extraction rate of HMW ETs ranged from 1.26 to 4.06 (10−4 s−1) (Table 5). The second step of ET extraction was generally characterized by lower rate constants as compared to the first step, and the half time of ET extraction was shorter in the first step regardless of ET molecular weight. In the first step of ET extraction from all kinds of pomaces, t1/2 values ranged from 37.5 to 80.2 min for LMW ETs and from 48 to 69 min for HMW ETs. Statistical analysis did not indicate any significant differences in extraction rates between LMW and HMW ETs in either step (Table 6).

However, some significant differences in the first extraction step were observed depending on the product from which the pomace was derived. Regardless of molecular weight, ETs were extracted faster from pomaces obtained from juice production as compared to those from puree production. Interestingly, in the case of raspberries and blackberries, the extraction rates of ETs with a molecular weight of ≤ 1569 Da were two times higher for pomaces from juice production than for those from puree production.

Thus, the time after which half of ETs were extracted was on average half as much for pomace from juice production; t1/2 for raspberry pomace from juice production was about 47 min as compared to over 80 min for raspberry pomace from puree production. This may be due to the greater proportion of seeds in pomaces from puree production, with the hard outer seed shells being a natural barrier likely to impede the extraction of polyphenolic compounds (Siriwoharn and Wrolstad 2004). In the second extraction step, no statistically significant differences were observed in the extraction of ETs depending on molecular weight. For example, the average t1/2 values for LMW and HMW ETs were 86 and 89 min, respectively.

As can be seen, under the tested conditions of shaking-assisted extraction with 60% aqueous acetone solution (20 °C, t = 6 h, shaking – 150 cycles/min), the molecular weight of ETs did not have a clear effect on their extraction kinetics. This may be attributed to the specific polyphenolic profiles of the fruits, as well as the presence of other compounds impeding ET extraction from the matrix. In this context, Puech et al. (1996) also mentioned differences in the solubility of individual ETs and the varying degrees of their affinity for cell walls.

Extraction Kinetics of Individual Ellagitannins

The extraction kinetics of individual ETs were analyzed in two stages. First, extraction rates and t1/2 values were determined for ETs characteristic of pomaces from the various fruits (Table 7). At the second stage, statistical analysis was performed to examine the impact of extraction step, technological type of pomace, and fruit species on the obtained results.

The ETs characteristic of Rubus pomaces are sanguiin H-6 and lambertianin C, which account for up to 90% of total ETs in raspberries and blackberries (Sójka et al. 2016; Gasperotti et al. 2010; Kahkonen et al. 2012). In the case of the genus Fragaria, the main ETs are agrimoniin and an ellagic acid trimer derivative of unspecified structure (Bubba et al. 2012; Vrhovsek et al. 2012). In addition, ellagic acid was determined in all pomace variants.

In the first extraction step, t1/2 values for individual ETs were up to 81 min, with the extraction rates of sanguiin H-6 being 1.47–1.59 (10−4 s−1) for two types of raspberry pomace and 2.06–2.17 (10−4 s−1) for blackberry pomaces. The ET with the highest extraction rate in the first step was trimeric lambertianin C, with t1/2 values ranging from 32 to 73 min, depending on the pomace variant.

Statistical analysis (Table 8) revealed a significant difference in the extraction rates of lambertianin C and sanguiin H-6 from raspberry pomace, with mean t1/2 values in the first step being 38 min for the former and 76 min for the latter. This difference was not observed in the second extraction step or in either step in the case of blackberry pomace. In contrast to the study of Puech et al. (1996), where ellagic acid exhibited the fastest rate of extraction from oak wood, in the present experiments, the t1/2 values for ellagic acid ranged from 43 to 81 min in the first extraction step, depending on the pomace variant, and did not differ significantly from those of other ETs. This may be attributable to a different extraction matrix: Puech et al. (1996) suggested that differences in the extraction kinetics of individual ETs may result from differences in ET solubility and wood permeability. Agrimoniin and the unknown ellagic acid trimer derivative were extracted at comparable rates from all the tested matrices, with t1/2 values being 41–62 min for agrimoniin and 55–71 min for the trimer.

The second step of extraction was slower. The t1/2 value for lambertianin C extraction from raspberry pomace derived from puree production was 138 min. Longer t1/2 values in the second step were also found for ellagic acid (up to 114 min), agrimoniin (up to 114 min), and an unknown ellagic acid trimer derivative (up to 100 min). This may be associated with a solvent sorption mechanism in the first step followed by desorption in the next step (Garcia-Estevez et al. 2015; Coulson et al. 1991).

To date, the extraction kinetics of individual ETs have been studied mainly for wood chips and bark. Due to the complexity of the extraction process, Garcia-Estevez et al. (2015) developed an original “Washing & Two-rates” kinetic model. They indicated that in the case of ET leaching, an additional step can be distinguished, that is, pre-moistening of oak chip surface with the extractant. Only after this step is proper ET extraction followed by diffusion from the innermost chip layers. Garcia-Estevez et al. (2015) also noted that in the second step, the extraction rate constants for castalagin, vescalagin, grandinin, and roburin E were lower by one to two orders of magnitude. The authors attributed that to the differential distribution of ETs in chips. The outermost layers of the chips contained less vescalagin, so the time required to extract half the maximum amount was correspondingly longer. In turn, Puech et al. (1996), who extracted vescalagin and castalagin (934 Da) from oak barrels, observed that they were less available than other ETs, probably due to their greater affinity for oak cell walls. The literature has also indicated that ETs may bind to other compounds, e.g., polyphenols (Jourdes et al. 2009; Okuda et al. 1992). In the case of vescalagin and castalagin epimers, the tendency to form bonds with other polyphenols depends on the orientation of the hydroxyl group at the first carbon atom of the glucose moiety. Unlike castalagin, vescalagin has the ability to bind to pigments (Jourdes et al. 2009; Quideau et al. 2004). Castalagin and vescalagin also differ significantly in reactivity due to the specific structure of their epimers. The position of the β-OH exo-bond at the first glucose carbon atom in the vescalagin structure offers a greater ability to form hydrogen bonds with the solvent (Jourdes et al. 2009). Therefore, compound properties may influence the extraction kinetics of individual ETs. In addition, extraction kinetics are also affected by the composition of the plant matrix and ET distribution within it (Garcia-Estevez et al. 2015; Puech et al. 1996; Jourdes et al. 2009).

The two main ETs in both raspberry and blackberry pomaces are lambertianin C (2806 Da) and sanguiin H-6 (1871 Da). Interestingly, while in the case of raspberry pomace, trimeric lambertianin C was extracted faster than dimeric sanguiin H-6, and the two ETs were extracted at similar rates from blackberry pomace. This may indicate that the extraction of these compounds is affected by the fruit matrix. In the case of pomaces from Fragaria fruits, the characteristic ETs were extracted at similar rates, without significant statistical differences.

Conclusions

This is the first publication to comprehensively describe the kinetics of ET extraction from eight different variants of fruit pomace. Extraction was carried out in two steps with shaking. Two-step ET extraction was analyzed using a first-order kinetic model. The proposed model has been found to describe well the extraction of ETs from the selected Rosaceae fruit pomaces. ET extraction proceeded faster in the first step regardless of the pomace tested. The molecular weight of ETs had no effect on the extraction rate under the conditions presented. The extraction kinetics were affected by the technological type of pomace and fruit matrix. In the case of raspberry pomace, the highest extraction rate was found for trimeric lambertianin C and the slowest for dimeric sanguiin H-6, but the two compounds were extracted at similar rates from blackberry pomace.

In-depth knowledge of extraction kinetics affords a better understanding of ET isolation from pomaces obtained as by-products from the processing of selected fruits of Rosaceae plants. Isolated and purified ET extracts can be used in the food industry for f.e. food enrichment. Moreover, ET extracts can be an alternative to preservatives (due to their anti-microbial properties). ET-rich extracts can also be used in the pharmaceutical and cosmetics industries. However, more research is needed on the interactions of ETs with other food and cosmetics ingredients.

Change history

24 February 2022

A Correction to this paper has been published: https://doi.org/10.1007/s12161-022-02228-z

References

Al-Zoreky NS (2009) Antimicrobial activity of pomegranate (Punica granatum L.) fruit peels. Int J Food Microbiol 134(3):244–248. https://doi.org/10.1016/j.ijfoodmicro.2009.07.002

Bubba M, Checchini L, Chiuminatto U, Doumett S, Fibbi D, Giordani E (2012) Liquid chromatographic/electrospray ionization tandem mass spectrometric study of polyphenolic composition of four cultivars of Fragaria vesca L. berries and their comparative evaluation. J Mass Spectrom 47:1207–1220. https://doi.org/10.1002/jms.3030

Bucic-Kojic A, Planinic M, Srecko T, Bilic M, Velic D (2007) Study of solid–liquid extraction kinetics of total polyphenols from grape seeds. J Food Eng 81:236–242. https://doi.org/10.1016/jjfoodeng.2006.10.027

Bucic-Kojic A, Sonova H, Planinic M, Srecko T (2013) Temperature-dependent kinetics of grape seed phenolic compounds extraction: experiment and model. Food Chem 136:1136–1140. https://doi.org/10.1016/j.foodchem.2012.09.087

Coulson JM, Richardson JF, Backhurst JR, Harker JH (1991) Chemical engineering particle technology and separation processes, 4 2. Pergamon, Oxford

Dai J, Mumper RJ (2010) Plant phenolics: extraction, analysis and their antioxidant and anticancer properties. Molecules 15:7313–7352. https://doi.org/10.3390/molecules15107313

Díaz-Reinoso B, Moure A, Domínguez H, Parajó JC (2006) Supercritical CO2 extraction and purification of compounds with antioxidant activity. J Agric Food Chem 54:2441–2469. https://doi.org/10.1021/jf052858j

Dincer I, Hussain MM, Sahin AZ, Yilbas BS (2002) Development of a new moisture transfer (Bi–Re) correlation for food drying applications. Int J Heat Mass Transf 45:1749–1755. https://doi.org/10.1016/S0017-9310(01)00272-1

Feldman KS, Iyer MR, Liu Y (2003) Ellagitannin chemistry. Studies on the Stability and Reactivity of 2,4-HHDP-Containing Glucopyranose Systems. J Org Chem 68:7433–7438

García-Estevez I, Alcalde-Eon C, Le Grottaglie L, Rivas-Gonzalo JC, Escribano-Bailon MT (2015) Understanding the ellagitannin extraction process from oak wood. Tetrahedron 71(20):3089–3094. https://doi.org/10.1016/j.tet.2014.10.047

Gasperotti M, Masuero D, Vrhovsek U, Guell G, Mattivi F (2010) Profiling and accurate quantification of Rubus ellagitannins and ellagic acid conjugates using direct UPLC-Q-TOF HDMS and HPLC-DAD analysis. J Agric Food Chem 58:4602–4616. https://doi.org/10.1021/jf904543w

Goula AM (2013) Ultrasound-assisted extraction of pomegranate seed oil – kinetic modeling. J Food Eng 117(4):492–498. https://doi.org/10.1016/j.jfoodeng.2012.10.009

Hager TJ, Howard LR, Liyanage R, Lay JO, Prior RL (2008) Ellagitannin composition of blackberry as determined by HPLC-ESIMS and MALDI-TOF-MS. J Agric Food Chem 56:661–669. https://doi.org/10.1111/j.1750-3841.2008.00855.x

Hager TJ, Howard LR, Prior RL (2010) Processing and storage effects on the ellagitannin composition of processed blackberry products. J Agric Food Chem 58:11749–11754. https://doi.org/10.1021/jf102964b

Jourdes M, Lefeuvre D, Quideau S (2009) C-Glycosidic ellagitannins and their influence on wine chemistry, Chemistry and Biology of Ellagitannins, pp 320–365. https://doi.org/10.1142/9789812797414_0009

Kahkonen M, Kylli P, Ollilainen V, Salminen JP, Heinonen M (2012) Antioxidant activity of isolated ellagitannins from red raspberries and cloudberries. J Agric Food Chem 60:1167–1174. https://doi.org/10.1021/jf203431g

Khan MK, Abert-Vian M, Fabiano-Tixier AS, Dangles O, Chemat F (2010) Ultrasound-assisted extraction of polyphenols (flavanone glycosides) from orange (Citrus sinensis L.) peel. Food Chem 119(2):851–858. https://doi.org/10.1016/j.foodchem.2009.08.046

Klewicka E, Sójka M, Klewicki R, Kołodziejczyk K, Lipińska L, Nowak A (2016) Ellagitannins from raspberry (Rubus idaeus L.) fruit as natural inhibitors of Geotrichum candidum. Molecules 21:908. https://doi.org/10.3390/molecules21070908

Klimczak E, Król B (2010) Determination of different forms of ellagic acid acid in by-products of strawberry processing. Oznaczanie zawartości różnych form kwasu elagowego w ubocznych produktach przerobu truskawek. ŻYWNOŚĆ Nauka Technologia Jakość 4(71):81–94

Klimczak E, Rozpara E, Król B (2011) Distribution of ellagitannins in juice, flesh and achenes as additional criterion for optimal utilization of strawberries Rozmieszczenie elagotanin w soku, miąższu i nasionach jako dodatkowe kryterium optymalnego zagospodarowania truskawek. ŻYWNOŚĆ Nauka Technologia Jakość 6 (79):142– 54. https://doi.org/10.15193/zntj/2011/79/142-154

Larrosa M, Garcia-Conesa MT, Espin JC, Tomas-Barberan FA (2010) Ellagitannins, ellagic acid and vascular health. Mol Aspects Med 31:513–539. https://doi.org/10.1016/j.mam.2010.09.005

Lazar L, Talmaciu AI, Volf I, Popa VI (2016) Kinetic modeling of the ultrasound-assisted extraction of polyphenols from Picea abies bark. Ultrason Sonochem 32:191–197. https://doi.org/10.1016/j.ultsonch.2016.03.009

Lekha PK, Lonsane BK (1997) Production and application of tannin acyl hydrolase: State of the art. Adv Appl Microbiol 44:215–260. https://doi.org/10.1016/s0065-2164(08)70463-5

Liberal J, Costa G, Carmo A, Vitorino R, Marquesf C, Domingues MR, Domingues P, Goncalves AC, Alves R, Sarmento-Ribeiro AB, Girao H, Cruz MT, Batista MT (2019) Chemical characterization and cytotoxic potential of an ellagitannin-enriched fraction from Fragaria vesca leaves. Arab J Chem 12:3652–3666

Marquez-Lopez A, Flores FA, Macias-Pureco S, Chavez-Parga MC, Flores DCV, Maya-Yescas R, Gonzales-Hernandez JC (2020) Extract of Ellagitannins starting with Strawberries (Fragaria sp.) and Blackberries (Rubus sp.). Food Sci Technol 40(2):430–439

Milczarek A, Sójka M, Klewicki R (2020) Selection of conditions of ultrasound-assisted, three-step extraction of ellagitannins from selected berry fruit of the Rosaceae family using the Response Surface Methodology. Food Anal Methods 13(4)

Milczarek A, Sójka M, Klewicki R (2021) Transfer of ellagitannins to unclarified juices and purees in the processing of selected fruits of the Rosaceae family. Food Chem 344:128684. https://doi.org/10.1016/j.foodchem.2020.128684

Mullen W, McGinn J, Lean MEJ, MacLean MR, Gardner P, Duthie GG, Crozier A (2002) Ellagitannins, flavonoids and other phenolics in red raspberries and their contribution to antioxidant capacity and vasorelaxation properties. J Agric Food Chem 50:5191–5196. https://doi.org/10.1021/jf020140n

Navarro V, Villarreal ML, Rojas G, Lozoya X (1996) Antimicrobial evaluation of some plants used in Mexican traditional medicine for the treatment of infectious diseases. J Ethnopharmacol 53:143–147. https://doi.org/10.1016/0378-8741(96)01429-8

Nowak A, Sójka M, Klewicka E, Lipińska L, Klewicki R, Kołodziejczyk K (2017) Ellagitannins from Rubus idaeus L. exert geno- and cytotoxic effects against the human colon adenocarcinoma cell line Caco-2. J Agric Food Chem 65(14):2947–2955

Okuda T, Yoshida T, Hatano T, Iwasaki M, Kubo M, Orime T, Yoshizaki M, Naruhashi N (1992) Hydrolysable tannins as chemotaxonomic markers in the Rosaceae. Phytochemistry 31(9):3091–3096. https://doi.org/10.1016/0031-9422(92)83451-4

Psarra C, Gortzi O, Makris DP (2015) Kinetics of polyphenol extraction from wood chips in wine model solutions: effect of chip amount and botanical species. J Inst Brew 121(2):207–212. https://doi.org/10.1002/jib.212,10.1002/jib.212

Puech JL, Feuillat F, Mosedale JR, Puech C (1996) Extraction of ellagitannins from oak wood of model casks. Vitis 35(4):211–214. https://doi.org/10.5073/vitis.1996.35.211-214

Puljula E, Walton G, Woodward MJ, Karone M (2020) Antimicrobial Activities of Ellagitannins against Clostridiales perfringens, Escherichia coli Lactobacillus plantarum and Staphylococcus aureus. Molecules 25:3714

Quideau S, Varadinova T, Karagiozova D, Jourdes M, Pardon P, Baudry C, Genova P, Diakov T, Petrova R (2004) Main structural and stereochemical aspects of the antiherpetic activity of nonahydroxyterphenoyl-containing C-glycosidic ellagitannins. Chem Biodivers 1(2):247–258. https://doi.org/10.1002/cbdv.200490021

Quirós AM, Acosta OG, Thompson E, Soto M (2019) Effect of ethanolic extraction, thermal vacuum concentration, ultrafiltration, and spray drying on polyphenolic compounds of tropical highland blackberry (Rubus adenotrichos Schltdl) by-product. J Food Process Eng 42(4):13051. https://doi.org/10.1111/jfpe.13051

Rao AV, Snyder DM (2010) Raspberries and human health: a review. J Agric Food Chem 58:3871–3883. https://doi.org/10.1021/jf903484g

Salminen JP (2003) Effects of sample drying and storage, and choice of extraction solvent and analysis method on the yield of birch leaf hydrolysable tannins. J Chem Ecol 29:1289–1305. https://doi.org/10.1023/A:1024249016741

Sangiovanni E, Vrhovsek U, Rossoni G, Colombo E, Brunelli C, Brembati L, Trivulzio S, Gasperotti M, Mattivi F, Bosisio E, Dell’Agli M (2013) Ellagitannins from Rubus berries for the control of gastric inflammation: in vitro and in vivo studies. Plos One 8(8):71762. https://doi.org/10.1371/journal.pone.0071762

Sant’Anna V, Brandelli A, Damasceno L, Marczak F, Tessaro IC (2012) Kinetic modeling of total polyphenol extraction from grape marc and characterization of the extracts. Sep Purif Technol 100:82–87. https://doi.org/10.1016/j.seppur.2012.09.004

Siriwoharn T, Wrolstad RE (2004) Polyphenolic composition of Marion and Evergreen blackberries. J Food Sci 69(4):233–240

Sójka M, Macierzyński J, Zaweracz W, Buczek M (2016) Transfer and mass balance of ellagitannins, anthocyanins, flavan-3- ols, and flavonols during the processing of red raspberries (Rubus idaeus L.) to juice. J Agric Food Chem 64:5549–5563. https://doi.org/10.1021/acs.jafc.6b01590

Sójka M, Janowski M, Grzelak-Błaszczyk K (2019) Stability and transformations of raspberry (Rubus idaeus L.) ellagitannins in aqueous solutions. Eur Food Res Technol 245:1113–1122. https://doi.org/10.1007/s00217-018-3212-3

Spiro M, Pui-Lang LL (1995) Kinetics and equilibria of tea infusion-Part 12. Equilibrium and kinetic study of mineral ion extraction from black Assam Bukial and green Chun Mee teas. Food Chem 54(4):393–396. https://doi.org/10.1016/0308-8146(95)00085-W

Takayama S, Kawanishi M, Yamauchi K, Tokumitsu D, Kojima H, Masutani T, Iddamalgoda A, Mitsunaga T, Tanaka H (2021) Ellagitannins from Rosa roxburghii suppress poly(I:C)-induced IL-8 production in human keratinocytes. J Nat Med 75:623–632. https://doi.org/10.1007/s11418-021-01509-x

Toda K, Ueyama M, Tanaka S, Tsukayama I, Mega T, Konoike Y, Tamenobu A, Bastian F, Akai I, Ito H, Kawakami Y, Takahashi Y, Suzuki-Yamamoto T (2020) Ellagitannins from Punica granatum leaves suppress microsomal prostaglandin E synthase-1 expression and induce lung cancer cells to undergo apoptosis. Biosci Biotechnol Biochem 84(4):757–763

Torun M, Dincer C, Topuz A, Sahin-Nadeem H, Ozdemir F (2015) Aqueous extraction kinetics of soluble solids, phenolics and flavonoids from sage (Salvia fruticosa Miller) leaves. J Food Sci Technol 52(5):2797–2805. https://doi.org/10.1007/s13197-014-1308-8

Vilhelmova-Ilieva N, Sirakov I, Jacquet R, Quideau S, Galabov AS (2020) Antiviral activities of ellagitannins against bovine herpesvirus-1, suid alphaherpesvirus-1 and caprine herpesvirus-1. J Vet Med Anim Health 12(4):139–143

Vrhovsek U, Guella G, Gasperotti M, Pojer E, Zancato M, Mattivi F (2012) Clarifying the identity of the main ellagitannin in the fruit of the strawberry, Fragaria vesca and Fragaria ananassa Duch. J Agric Food Chem 60:2507–2516. https://doi.org/10.1021/jf2052256

Funding

The work was financed by the statutory funds of the Institute of Food Technology and Analysis, Faculty of Biotechnology and Food Sciences, Lodz University of Technology, Poland.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable.

Conflict of Interest

Agnieszka Milczarek declares that she has no conflict of interest. Michał Sójka declares that he has no conflict of interest. Robert Klewicki declares that he has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Effective extraction is an important stage to obtain natural compounds of a potential pro-health nature, so knowledge of the ETs extraction kinetics is crucial.

• Two-step ET extraction was analyzed using a first-order kinetic model.

• For all pomace variants, the mean extraction half time t1/2 was 48 min in the first step.

• In the second step, t1/2 ranged from 55 to 91 min.

• The highest extraction rate was found for lambertianin C and the slowest for sanguiin H-6 (for raspberry pomace).

• The extraction kinetics were affected by the technological type of pomace and the fruit matrix.

The original online version of this article was revised: In this article the wrong figure appeared as Fig. 2.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Milczarek, A., Sójka, M. & Klewicki, R. The Kinetics of Two-Step Ellagitannin Extraction from the By-products of Selected Processed Fruits of the family Rosaceae. Food Anal. Methods 15, 1171–1184 (2022). https://doi.org/10.1007/s12161-021-02121-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-021-02121-1