Abstract

Sugars are a near-ubiquitous ingredient in food products, yet rising rates of obesity and related illnesses have prompted a drive to reduce their content. The use of amorphous sugars in confectionery may be one way of achieving this by providing a similarly sweet sensation due to increased dissolution rate. However, accurate amorphous and crystalline form characterisation and quantification of complex foodstuffs can be difficult. In this study, a method for the quantification of crystalline and amorphous sugars in chocolate precursors, using powder X-ray powder diffraction, is presented. The method was first validated by the use of known compositions of mixtures of amorphous and crystalline sugars, then employed in assessing two chocolate crumb samples. The results show that the method can reliably determine the absolute quantity of amorphous and crystalline components in a confectionery sample, whilst maintaining sample integrity, apart from the addition of an inert internal standard. As such, it is a valuable addition to other techniques currently used.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Gradual changes in human lifestyle and behaviour over the past 100 years have led to a dramatic rise in the incidence of diabetes, obesity and related illnesses (coined “diabesity”) across the globe (Amos et al. 1997; Astrup and Finer 2000; King et al. 1998). Consequently, governments have responded by introducing regulations (such as required information on the fat and sugar content of foodstuffs) and taxations (for example, the recently announced Soft Drinks Industry Levy in the UK) which are likely to become more restrictive on the food industry over the coming decades (Zimmet et al. 2001). As a result, there is heightened interest in research and development of food products that contain reduced sugar and fat content.

There are many options available to confectionery manufacturers to reduce the total quantity of sugars in foods. Perhaps the most widely used approach in the market is the use of sugar replacements (such as sugar alcohols) in chewing gums and carbonated soft drinks. However, these ingredients are more costly, do not necessarily provide the same taste profile and may produce undesirable gastric effects in some consumers (Nabors 2011). Another option is the use of sugars in their amorphous forms; the lack of long-range order in amorphous solids allows for increased dissolution rate within the mouth, providing a sweet sensation at reduced gross sugar content (Hartel et al. 2011).

However, achieving the amorphisation of the sugars in products is not as straightforward as simply replacing previously crystalline powders with their amorphous counterparts. For example, in chocolate manufacture, the product is exposed to a range of physical manipulations, including several heating and cooling steps, mixing within a conch, and the tempering process (Beckett 1994; Beckett 2008). Consequently, components of the mixture that were amorphous at the outset of processing may have been given enough molecular mobility to recrystallise during processing, nullifying the intended impact on the final product. Hence, modifications to the manufacturing process may be required, and prior to this, a method of characterisation and quantification of the amorphous and crystalline components within a product at each stage of preparation is potentially advantageous in ensuring the desired final product is achieved. Quantitative phase analysis using powder X-ray diffraction (PXRD) is one method that can be employed for this purpose; other commonly used methods for quantification of amorphous content include DSC, DVS and solution calorimetry.

PXRD has been used extensively as an analytical technique since its initial application by Debye and Scherrer a century ago (Debye and Scherrer 1916). In recent years, there has been great interest in the application of the Rietveld method (Rietveld 1969) to determine the relative quantities of crystalline components in a powder mixture, a process known as quantitative phase analysis (QPA). Though QPA has been extensively utilised within the cements, mining and ceramics industry, and to some extent within the pharmaceutical industry, its application in other areas is much less common (Aranda et al. 2012). Typically, QPA reports the percentage abundance of each crystalline phase present in a mixture, giving the sum of crystalline phases as 100% of the powder that is irradiated in the X-ray beam. However, by use of an appropriate internal standard, the contribution of non-crystallineFootnote 1 content can also be calculated (De La Torre et al. 2001). This is done by scaling each crystalline phase’s contribution using a scale factor determined by the calculated and known concentrations of the standard, as shown in Eq. 1:

where Wα(abs) is the absolute weight fraction of phase α, Wα(calc) is the calculated relative weight fraction of phase α obtained from the QPA, Ws(calc) is the calculated relative weight fraction of the standard material obtained from the QPA and Ws(known) is the known weight fraction of the standard material.

In order to apply QPA to a mixture, prior knowledge of the crystallographic form of each crystalline component is required. In the case of chocolate and chocolate precursors, these components include (but are not limited to) sucrose, α-lactose monohydrate and β-lactose (see Electronic Supplementary Material for sample PXRD patterns). Furthermore, a well-characterised and highly crystalline internal standard, with an elemental composition comparable to the samples of interest, is also required.

Here, the accuracy and precision of QPA, as applied to known compositions of crystalline and amorphous sugars using synthetic diamond powder as an internal standard, is assessed and the resultant methodology applied to two chocolate crumb samples.

Materials and Methods

Obtaining Pure Phases

Crystalline sucrose (CAS 57-70-1), α-lactose monohydrate (CAS 5989-81-1) and synthetic crystalline diamond powder (CAS 7782-40-3) were obtained from Sigma Aldrich, UK. Amorphous lactose was prepared by dissolving α-lactose monohydrate in water and freeze-drying small individual aliquots of the resultant 10% w/v aqueous solution as follows: pre-freezing at − 80 °C, a primary drying step of 72 h at − 50 °C under a vacuum pressure of 0.06 mbar, then finally a secondary drying step over P2O5 for 48 h at 25 °C. For more information on this process, see Jawad (2012). The resultant powders, which were sealed and stored in desiccators, exhibited no Bragg diffraction peaks when PXRD data were collected on a laboratory diffractometer.

Preparation of Powder Mixtures of Known Composition

Five mixtures comprising varying proportions of sucrose, amorphous lactose (checked by PXRD to ensure it was X-ray amorphous) and diamond were prepared by manually mixing accurately weighed quantities of the aforementioned powders using a pestle and mortar. The composition of each mixture is shown in Table 1. Mixtures were immediately loaded into capillaries (see the “Crystallographic Phase Information” section) and the capillaries sealed with wax to prevent ingress of water from the atmosphere.

Chocolate Crumbs

Two generic chocolate crumbsFootnote 2 (henceforth referred to as crumb A and crumb B) of notionally identical composition, but made using different drying methods (roller drying under vacuum or vacuum oven drying), were supplied for analysis by QPA by Mondelez UK R&D Ltd. An amount of crumb was first weighed accurately, and then spiked with a known mass of diamond powder. Each mixture was then mixed manually using a pestle and mortar to ensure an even distribution of the diamond powder within the sample. The composition of each mixture is shown in Table 2.

Crystallographic Phase Information

Relevant crystallographic information for all phases present in the mixtures and likely to be present in the crumbs was sourced from the literature and is given in Table 3.

Powder X-Ray Diffraction Data Collection and Analysis

Each sample was loaded into a 0.7-mm borosilicate capillary. For the mixtures of known sugar composition, three capillaries of each mixture were prepared, whilst subsequently, a single capillary of each of the crumb mixtures was prepared. Diffraction data were collected under ambient conditions on a Bruker D8 ADVANCE powder diffractometer configured in capillary-transmission geometry using monochromatic Cu Kα1 radiation and a LynxEye detector. Data were collected in the range 3.5–80° 2θ, with a 0.017° step for 10 s per step, which equates to a total time data collection time of approximately 12.5 h per dataset. As the focus of this study was the accurate quantification of crystalline and amorphous sugars, crumb A was also collected at 47 °CFootnote 3 in order to melt the cocoa butter present and remove its crystalline contribution to the pattern. The six known crystalline forms of cocoa butter all have relatively large unit cells, of relatively low symmetry. As a result, these crystalline phases produce a large number of Bragg diffraction peaks that can overlap with those produced by the sugar phases in crumb and chocolate samples, potentially reducing the accuracy and precision of the composition values determined by QPA. As such, this simple heating procedure provides a convenient method for removing the crystalline cocoa butter contribution to the diffraction pattern. Heated samples of crumb A were subsequently cooled to ambient temperature and re-measured after ca. 16 h to observe whether or not the cocoa butter had recrystallised to its original form(s). All PXRD data analysis was performed using TOPAS (Coelho 2003), and a sample TOPAS QPA input file is available as electronic supplementary information. For a brief and effective introduction to QPA as a technique in PXRD, please see Madsen and Scarlett (2008).

Results

QPA of Sugar Mixtures of Known Composition

The results of the QPA conducted on the mixtures of known sugar composition are shown in Table 4, and a representative fit to a PXRD dataset (mixture 1) is shown in Fig. 1.

The Rietveld fit obtained for PXRD data collected from mixture 1 in the 2θ ranges 3.5–40° (upper plot) and 40–80° (lower plot). Observed data (points), calculated data (solid black line) and the difference profile (solid grey line) are shown. Diffraction from the diamond internal standard is clearly visible in the form of the very strong peaks at ca. 44° and ca. 75° 2θ

QPA of Crumb Samples

The results of the QPA conducted on the crumb samples are shown in Table 5, and a representative fit to a PXRD dataset (crumb B) is shown in Fig. 2.

The Rietveld fit obtained for PXRD data collected from crumb B in the 2θ ranges 3.5–40° (upper plot) and 40–80° (lower plot). Observed data (points), calculated data (solid black line) and the difference profile (solid grey line) are shown. Diffraction from the diamond internal standard is clearly visible in the form of the very strong peaks at ca. 44° and ca. 75° 2θ

Discussion

QPA of Known Mixtures

There is very good agreement between the percentage composition values returned by QPA and the known composition across all samples, with the greatest difference occurring in mixture 5 (∆QPA-measured = 1.57%). The proportion of diamond internal standard in the analysed mixture affects the accuracy of the technique, with mixtures containing smaller diamond concentrations (mixtures 3 and 5) displaying poorer agreement with the measured quantities than those containing higher diamond concentrations (mixtures 1, 2 and 4). It also affects precision, as evidenced by the higher standard deviations obtained for mixtures 3 and 5 compared to mixtures 1, 2 and 4. As the determination of the absolute content of each phase within a mixture relies heavily on the scaling of the internal standard, small changes in the QPA-determined diamond percentages can have a significant impact on the final determined percentages of each phase. Obtaining a perfectly homogenous dispersion of the diamond standard throughout each mixture is difficult, subject as it is to inconsistencies in user technique, potential loss of powders during mixing or differences in adhesion of each phase to the pestle and mortar during mixing. Introducing a larger percentage of diamond powder in the final mix helps to reduce the relative impact of the aforementioned factors on the resultant powder pattern. The results suggest a diamond concentration of at least 10% w/w is important in QPA accuracy when dealing with samples of this nature. It is likely that the use of 0.9-mm capillaries, exposing a larger volume of the sample in the incident X-ray beam, would also help mitigate any mixing issues, at relatively small cost to the resolution of the collected PXRD pattern.

Results are precise within a sample set, with the largest standard deviation values occurring in mixtures with low diamond concentrations: mixtures 3 and 5 have a standard deviation of 1.4 and 1.3% respectively). The repeatability coefficient is defined as

where M is the total number of measurements, n is the number of mixtures analysed, degrees of freedom is the number of repeat analyses minus one and sd is the standard deviation for a set of repeats.

For the QPA measurements performed on the sugar mixtures, the coefficient was calculated to be 0.78 (M = 15, n = 5, degrees of freedom = 2), indicating that for two repeat measurements on the same mixture, there is a 95% probability that the results of the QPA will differ by less than 0.78%. The results suggest that multiple repeat measurements of a mixture are not necessary to obtain quantitative data within 1% accuracy.

The goodness of fit between calculated and measured diffraction patterns is indicated by Rwp (Young 1993). In all cases, the fits to the data are good, with low Rwp values and difference plots (see, for example, Fig. 1) consistent with the input crystalline phases providing a very good description of the observed PXRD data. It is important to consider not only the Rwp values when evaluating fits but also the visual fit to the data—samples containing large amounts of amorphous material will have systematically lower Rwp values than those containing smaller amounts (e.g. mixture 4 has 78.29% amorphous lactose and Rwp = 3.18 whilst mixture 3 has 87.64% crystalline sucrose and Rwp = 5.56) as a consequence of the way in which Rwp is calculated. Whilst the background-subtracted Rwp′ could be used to eliminate this systematic difference, the combination of Rwp plus close visual inspection of the difference plot is an effective way of ensuring that a good fit has been obtained. Furthermore, when dealing with samples where the exact compositions are not known a priori, this method allows the identification of unfitted features that may indicate the presence of additional crystalline phases that are not currently included in the Rietveld fit, or reveal inadequacies in the existing models.

QPA of Chocolate Crumb

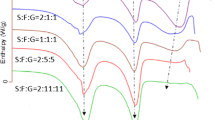

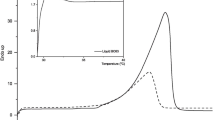

The results shown in Table 5 illustrate the power and the flexibility of PXRD for QPA of phase mixtures, such as the chocolate crumbs examined in this work. The method is able to quantify the crystalline sugars and form V cocoa butter at ambient temperatures, and Fig. 3 shows that upon heating to 47 °C, the diffraction peak at 19.4° 2θ (corresponding to the strongest diffraction peak of form V cocoa butter) disappears, indicative of cocoa butter melting and the removal of its crystalline contribution to the diffraction pattern. The slight lateral shifting of peaks, also clearly visible in Fig. 3, is attributable to unit cell expansion of the crystalline phases at elevated temperature.

Upon cooling of the heated sample back to ambient conditions, the peak at 19.4° 2θ does not immediately reappear, and there are no additional visible diffraction features, even after ca. 16 h at ambient conditions, which cannot be accounted for by the crystalline sugars. This suggests that, owing to the uncontrolled nature of the cooling back to ambient temperature, the cocoa butter may have recrystallised into several polymorphs whose relatively low abundance makes their quantification impractical or has solidified as an amorphous or nanocrystalline solid. QPA performed on the heated and cooled sample reported 0.12% of form V cocoa butter, a negligible amount that reflects correlations between phases included in the calculation as opposed to an accurate value; the same Rwp for the QPA can be achieved when the form V contribution is excluded. Furthermore, the heated and cooled sample showed an increased percentage of crystalline sucrose within the mixture, suggesting that the increased molecular mobility introduced by the heating stage has allowed some amorphous sucrose to recrystallise.

Chocolate crumb B displays a much different pattern to that of crumb A. Firstly, no crystalline alpha-lactose monohydrate was observed in this pattern; rather, there is an increased quantity of the beta anomer. Furthermore, a much higher quantity of crystalline sucrose, and reduced total amorphous content, is present.

It is important to remember that QPA cannot distinguish between different amorphous components within the crumb mixture. Therefore, whilst it is possible to state with good accuracy what percentage of the mixture is amorphous, it is not possible to directly determine the amorphous percentage of each individual phase within the crumb, be it lactose, sucrose, cocoa butter, non-fat cocoa solids or various milk solids. However, evaluation of the amorphous percentages of each phase is possible if the crumb recipe is known. For example, if the recipe states 60% sucrose and QPA returns a crystalline value of 50%, then 10% of the crumb is amorphous sucrose. In this work, Mondelez has confirmed that the results obtained make compositional sense for the chocolate crumbs (whose recipes were not disclosed to us) that they supplied.

This clearly demonstrates the value of QPA in this context: evaluating changes in crystalline composition as a function of sample processing can help to explain differences that may be detected in taste, texture and manufacturability.

Internal Standard and Diffraction Geometry

In developing a QPA method, it is important that a suitable internal standard is chosen. For molecular organic materials, widely used QPA internal standards such as Al2O3 and ZnO are not suitable as microabsorption (Klug and Alexander 1974) becomes an issue. The choice of diamond powder as an internal standard aimed to minimise microabsorption whilst providing sharp diffraction peaks that did not markedly interfere with the regions of strong diffraction observed from the crystalline components of the samples under examination. Both synthetic and naturally sourced diamond powders were tested. It was found that the naturally sourced diamond powder contained trace quantities of zirconia, which produced significant contributions to the diffraction patterns of the spiked mixtures. Whilst these contributions are easily modelled, microabsorption and incidental peak overlap are complications that are best avoided and so synthetic diamond powder was chosen as the internal standard. The internal standard method assumes that the percentage crystallinity of the standard is known; in this work, based on laboratory PXRD and using a hard wearing standard, 100% crystallinity is assumed. The validity of this assumption is illustrated by the excellent agreement between measured and calculated phase percentages in the known mixtures. Whilst relatively expensive as a standard,Footnote 4 the amount of diamond powder required for each individual analysis is sufficiently small that the cost per sample prepared is small. The internal standard method avoids the need for additional corrections to account for scattering from the capillary.

This QPA work has been carried out using a laboratory-based Bruker D8 diffractometer operating in capillary-transmission geometry; the monochromatic incident X-ray beam passes through the sample, contained in a thin-walled borosilicate glass capillary, and diffracted X-rays are collected using a position-sensitive detector. The sample is rotated along the axis of the diffractometer to reduce the detrimental effects of preferred orientation of crystallites within the sample. The use of reflection-based PXRDFootnote 5 for QPA of molecular materials is not recommended; sample presentation issues frequently lead to preferred orientation and sample transparency effects, and these will significantly affect the accuracy of values returned by QPA analysis.

Conclusions

Rietveld-based QPA, with a suitable internal standard, allows quick and easy identification and quantification of crystalline phases in samples related to chocolate manufacture. Furthermore, it allows for accurate quantification of total amorphous content by difference. The presence or absence of detectable amounts of a crystalline phase can be easily determined by incorporation of that phase into the Rietveld calculation and assessing the impact upon the Rwp of the resultant fit to the data.

Temperature control of the sample allows for the removal of crystalline cocoa butter contributions to the pattern, if desired. The method, whilst straightforward, does require the use of a diffractometer operating in capillary-transmission X-ray diffraction geometry to ensure that good quality diffraction data, largely free from the effects of preferred orientation, are obtained. Suitable software for QPA is also required; in this work, TOPAS has been used, but many other alternatives are available and are equally suitable.

Notes

This includes X-ray amorphous solids (solids that do not contribute any visible Bragg diffraction to the PXRD pattern) and any liquid phases present, e.g. liquid fats. For simplicity, these non-crystalline entities are henceforth referred to as the amorphous content of the samples.

Information on the general composition of chocolate crumb, and its role in chocolate manufacture, can be found in the following links: http://bit.ly/2rke10t and http://bit.ly/2smT1Vo

Temperature control was achieved using an Oxford Cryosystems Cryostream Compact device, mounted co-axially with the capillary.

Approximately £160 for 5 g, at the time of writing

Within industry, reflection-based PXRD is commonly used, as it lends itself to rapid sample preparation and presentation, rapid data collection and automated sample changing.

References

Amos AF, McCarty DJ, Zimmet P (1997) The rising global burden of diabetes and its complications: estimates and projections to the year 2010. Diabet Med 14 Suppl 5:S1–85

Aranda MAG, De la Torre ÁG, León-Reina L (2012) Rietveld quantitative phase analysis of OPC clinkers, cements and hydration. Products. Rev Mineral Geochem 74:169–209. https://doi.org/10.2138/rmg.2012.74.5

Astrup A, Finer N (2000) Redefining type 2 diabetes: ‘diabesity’ or ‘obesity dependent diabetes mellitus’? Obes Rev 1:57–59

Beckett S (1994) Industrial chocolate manufacture and use. Springer US

Beckett S (2008) The science of chocolate. Royal Society of Chemistry, UK

Coelho A (2003) TOPAS user manual. Bruker AXS GmbH, Karlsruhe, Germany

De La Torre AG, Bruque S, Aranda MAG (2001) Rietveld quantitative amorphous content analysis. J Appl Crystallogr 34:196–202. https://doi.org/10.1107/S0021889801002485

Debye P, Scherrer P (1916) X-ray interference by disorder particles. Physik Z 17:277–283

Fayos J (1999) Possible 3D carbon structures as progressive intermediates in graphite to diamond phase transition. J Solid State Chem 148:278–285. https://doi.org/10.1006/jssc.1999.8448

Fries DC, Rao ST, Sundaralingam M (1971) Structural chemistry of carbohydrates. III. Crystal and molecular structure of 4-O-[beta]-d-galactopyranosyl-[alpha]-d-glucopyranose monohydrate ([alpha]-lactose monohydrate). Acta Crystallogr B 27:994–1005. https://doi.org/10.1107/S0567740871003364

Hartel RW, Ergun R, Vogel S (2011) Phase/state transitions of confectionery sweeteners: thermodynamic and kinetic aspects. Compr Rev Food Sci Food Saf 10:17–32. https://doi.org/10.1111/j.1541-4337.2010.00136.x

Hynes RC, Le Page Y (1991) Sucrose, a convenient test crystal for absolute structures. J Appl Crystallogr 24:352–354. https://doi.org/10.1107/S0021889891002492

Jawad R (2012) A study of phase transitions of chocolate sugars during manufacture. PhD thesis. In: King's College London

Ken H, Akira S (1974) The crystal and molecular structure of β-lactose. Bull Chem Soc Jpn 47:1872–1879. https://doi.org/10.1246/bcsj.47.1872

King H, Aubert RE, Herman WH (1998) Global burden of diabetes, 1995-2025: prevalence, numerical estimates, and projections. Diabetes Care 21:1414–1431

Klug H, Alexander LE (1974) X-ray diffraction procedures: for polycrystalline and amorphous materials, 2nd edn. Wiley-Interscience, USA

Madsen IC, Scarlett NVY (2008) Quantitative phase analysis. In: Dinnabier RE (ed) Powder diffraction: theory and practice. Royal Society of Chemistry

Nabors LB (2011) Alternative sweeteners. In: Alternative sweeteners, fourth edition. CRC Press, pp 1–10. https://doi.org/10.1201/b11242-2

Rietveld H (1969) A profile refinement method for nuclear and magnetic structures. J Appl Crystallogr 2:65–71. https://doi.org/10.1107/S0021889869006558

van Mechelen JB, Peschar R, Schenk H (2006) Structures of mono-unsaturated triacylglycerols. II. The [beta]2 polymorph. Acta Crystallogr B 62:1131–1138. https://doi.org/10.1107/S0108768106037086

Young R (1993) The Rietveld method. Oxford University Press, UK

Zimmet P, Alberti KGMM, Shaw J (2001) Global and societal implications of the diabetes epidemic. Nature 414:782–787

Acknowledgements

KS and CE gratefully acknowledge the Biotechnology and Biological Sciences Research Council and Mondelez UK R&D Ltd. for funding for DN through the iCASE scheme. MJS is grateful to the Defence Academy of the United Kingdom for allocating time for continued collaboration and academic development.

Funding

This study was funded by the Biotechnology and Biological Sciences Research Council (grant number BB/L015730/1) and Mondelez UK R&D Ltd.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Daniel Nicholls declares that he has no conflict of interest.

Kenneth Shankland declares that he has no conflict of interest.

Mark Spillman declares that he has no conflict of interest.

Carole Elleman declares that she has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Nicholls, D., Shankland, K., Spillman, M. et al. Rietveld-Based Quantitative Phase Analysis of Sugars in Confectionery. Food Anal. Methods 11, 2673–2681 (2018). https://doi.org/10.1007/s12161-018-1243-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-018-1243-9