Abstract

This study focused on determining the effect of the inoculum to substrate ratio (ISR) on biogas production efficiency from the anaerobic co-digestion of two substrates: synthetic food waste and common reeds (Phragmites australis) that were ground and pre-treated using sodium hydroxide at a concentration of 2% to increase access to their cellulose. It also studied the role of different mixing ratios of the two substrates in improving the stability of the digestion process and increasing biogas production. A series of batch tests were carried out under mesophilic conditions using three ratios of ISR: 1:4, 1:2, and 1:1, and five substrate mixing ratios (synthetic food waste: pre-treated P. australis): 25:75, 50:50, 75:25, 100:0, and 0:100. The results showed low biogas production at the ISR 1:4 (21.58±0.00–44.46±0.01 mL/g volatile solid (VS) added), and the reactors suffered from acidification at the different substrates mixing ratios, while the biogas production increased at an ISR of 1:2, where the reactors with the substrate mixing ratio of 25:75 presented the highest biogas production (82.17±0.62 mL/g VS added), and the digestion process was stable. However, the reactors with substrate mixing ratios of 50:50, 75:25, and 100:0 suffered from acidification effects at this ISR. In contrast, at ISR of 1:1, the reactors did not expose to acidification inhibition at all the substrates mixing ratios, and the highest biogas production was found at synthetic food waste: pre-treated P. australis mixing ratios of 75:25 and 100:0 (76.15±1.85 and 82.47±1.85 mL/g VS added, respectively).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The ongoing growth of the global demand for energy resources and the associated deterioration in the quality of the environment has become one of the most important concerning issues facing the world’s nations. This has encouraged exploring and utilising alternative renewable energy sources [1]. As an attractive method of combining waste treatment with the production of biogas that can subsequently be used as an energy source, anaerobic digestion has earned unprecedented attention recently [2]. Anaerobic digestion is a biological process occurring in the absence of oxygen, in which microbial consortia are degrading organic substrates into two valuable products, which are biogas (50–75% methane, 25–50% carbon dioxide, and 0–10% other gases) and digestate [3]. Biogas produced from anaerobic digestion can be used as a clean energy source to generate electricity and heat, or it can be integrated into the national gas network after some further processing [4]. Furthermore, the liquid and solid part of the digestate produced from an anaerobic digestion process is usually abundant in nutrients such as nitrogen and phosphorus that can be recycled and exploited as natural fertiliser to improve soil fertility instead of synthetic fertilisers [5]. Moreover, the solid part of digestate can be converted into biochar [6].

A wide range of organic wastes, including municipal solid waste, industrial waste, agricultural residues, and wetland plants, can be harnessed to use as a substrate in anaerobic digestion to produce biogas [7]. However, among these, some agricultural residues and wetland plants such as crop straw, prairie grass, and common reed (Phragmites australis) are characterised by high lignocellulosic content, which makes them recalcitrant for microbial degradation. Thus, before using them in anaerobic digestion processes, it is necessary for them to undergo appropriate pre-treatment, which may be mechanical, thermal, chemical, biological, or a combination of these [8].

The implementation of pre-treatment can assist in promoting the digestion of lignocellulosic substrates and improve the performance of anaerobic digestion systems using these kinds of plant matter [9]. For example, mechanical treatment such as grinding enhances the reduction of cellulose crystallinity and increases the surface area exposed to microbial activity and hydrolysis enzymes [10]. In addition, using chemical treatments such as immersion in an alkaline NaOH solution can increase the solubility of lignin and, thus, its removal. This can increase accessibility to cellulose for hydrolysis enzymes and increase biogas production from the subsequent anaerobic digestion process [11]. Zhu et al. [12] reported that pre-treating of corn stover biomass with various NaOH concentrations (1%, 2.5%, 5.0%, and 7.5%) resulted in an increase in lignin removal ranging from 9.1 to 46.2%. Similarly, Xue et al. [13] demonstrated a reduction in the lignin content of Miscanthus reed biomass by 1.03%, 5.1%, and 12.8% following treatment with 1%, 3%, and 5% NaOH, respectively. No removal was observed for cellulose and hemicellulose content at these NaOH concentrations. However, lignocellulosic substrates have sub-optimally high carbon to nitrogen ratios (C: N). The carbon content is mainly utilised to produce organic acids that are further converted by microorganisms to produce methane, while the nitrogen sources are recruited to form proteins in microbes’ cells [6]. Therefore, high C:N ratios tend to diminish microorganism growth, which negatively impacts on the effectiveness of the anaerobic digestion process and biogas production [14]. This problem can be mitigated by co-digesting with nitrogen-rich substrates such as animal manure and food waste [15].

Food waste constitutes the main fraction of municipal solid waste [16]. The amount of food waste produced globally has reached more than 1.3 billion tons annually [17], and most of this is disposed of in landfills [18]. Because food waste is readily degradable, it leads to emissions of a significant amount of greenhouse gases, most notably methane, from landfill sites [4]. Around 13% of landfill methane emission is estimated to result from food waste degradation [19]. Therefore, this traditional disposal method has become a significant environmental problem, and it has become essential to adopt more sustainable and environmentally considerate methods for the treatment of vast amounts of food waste.

Anaerobic digestion is one of the strategies that can be used as a green alternative to the treatment of food waste [20]. However, digesting food waste in isolation may reduce the efficiency and stability of the anaerobic digestion process due to the accumulation of high volatile fatty acids (VFAs) concentrations (higher than 2.5 g/L) resulting from the rapid degradation of food waste, causing a reduction in the pH of the system and inhibition of microbial consortia [21]. As well as the high nitrogen content of food waste can lead to an accumulation of ammonia nitrogen that can penetrate through the microbial cell wall and causes an imbalance in proton and potassium availability and changing intracellular pH, thus inhibiting methanogenic microorganisms [20]. For this reason, the co-digesting of food waste with other organic wastes that have high C:N ratios, including lignocellulosic substrates such as agricultural crop straw and grasses, has become a popular way of improving the use of food waste in the anaerobic digestion process [22].

However, the appropriate selection of two or more different substrates to be co-digested is crucial for avoiding inhibition effects that can result during the anaerobic digestion process [23]. Furthermore, determining the mixing ratio of the substrates and the inoculum to substrates ratio (ISR) plays an essential role in preventing VFA accumulation and other inhibitors of digestion and controlling the effectiveness of the anaerobic digestion process [24]. Researchers reported different results for the influence of substrate mixing ratios and ISR on biogas and methane production from the co-digestion of various feedstocks. For example, Zhang et al. [25] observed an increase of 8.3% in methane production from co-digestion of rice straw and food waste at a mixing ratio of 1:3, with an optimal methane production of 259.57 mL/g volatile solid (VS). Weerayutsil et al. [26] examined the co-digestion performance of Napier grass and chicken manure in batch digestion assay. They found that the mixing ratio of 1:1 presented the highest biogas and methane production.

As a widespread plant, it does not compete with food and feed and grows naturally without needing arable land and fertilisers; common reed (Phragmites australis) biomass was selected as a substrate for co-digesting with food waste in the present study. Because the use of common reeds in the anaerobic digestion process is relatively novel, the parameters of ISR and mixing ratio still need to be determined for co-digestion of pre-treated P. australis and synthetic food waste. Therefore, this study aimed to determine the optimal ISR and mixing ratio of pre-treated P. australis and synthetic food waste to enhance biogas production from pre-treated P. australis biomass using anaerobic digestion.

Materials and Methods

Substrates and Inoculum

Samples of P. australis reed plants were obtained from a small lake at the Forrest Hills site, Lancaster, UK (54.007° N, 2.772° W). P. australis plants of equal stem lengths (about 2.5 m) were selected and cut at 5–10 cm above ground level. Then, the vegetative parts (leaves and flowering panicles) were removed to retain the stems only, which were packaged in sealed plastic bags and transported to the laboratory. In the laboratory, the P. australis stalks were cut manually using scissors into segments of 3 cm length and then ground with a knife mill to get particle size can pass through a 1-mm sieve and packed in air-tight plastic bags and stored at 4 °C until used. Based on the Waste and Resources Action Programme’s (WRAP) household food waste data [27], synthetic food waste (SFW) was prepared from different compositions (such as bread, vegetable, fruit, meat, fish, eggs, juice, desserts), and stored at −20 °C to prevent biological decomposition, following the procedures outlined by Gandhi et al. [28]. Before the experiment setup, the frozen synthetic food waste is thawed by transferring it to the refrigerator at 4 °C for ~24 h. The inoculum was obtained from an on-farm commercial scale, mesophilic, anaerobic digester (Cockerham Green Energy Limited, UK). The inoculum was sieved with a 1-mm sieve to remove coarse materials. Characterisation of the substrate and inoculum is displayed in Table 1.

The synthetic food waste used in this work was prepared based on the procedures presented by Gandhi et al. [68], and the inoculum was obtained also from the same source. This work did not measure the characteristics of synthetic food waste and inoculum, such as carbohydrates, proteins, lipids, cellulose, lignin, C, and N. It was considered to have similar values to that of the synthetic food waste and inoculum that were used by Gandhi et al. [68]. Per 100 g (% dry basis), the synthetic food waste was reported to contain 56.51 g carbohydrates, 16.25 g proteins, 13.37 g lipids, 4.01 g cellulose, 7.16 g lignin, 47.32 g carbon, and 3.42 g nitrogen. While 100 g (% dry basis) of the inoculum contains 7.29 g carbohydrates, 24.47 g proteins, 10.49 g lipids, 9.27 g cellulose, 12.20 g lignin, 34.27 g carbon, and 4.37 g nitrogen [68]. On the other hand, P. australis’s chemical composition is assumed to fall within the ranges reported in the other studies. As per 100 g of P. australis (% dry basis), the studies have shown the range of cellulose, hemicellulose, lignin, carbon, and nitrogen were 42.80–48.0, 22.70–26.60, 12.50-14.60, 43.25–46.87, and 0.55–1.02, respectively [14, 29, 30].

Pre-treatment

Alkaline pre-treatment was applied to the ground P. australis samples using a 2% NaOH solution. The ground P. australis biomass was placed into a 500-ml bottle and then treated by adding 100 mL of 2% NaOH solution for each 10 g of ground P. australis. The bottles were capped with aluminium foil and kept inside the fume cupboard for 3 days at room temperature (20 ± 2 °C) without agitating. After 3 days of this treatment, the treated P. australis was strained using a 38-micron-diameter sieve to separate the liquid and solid fractions. The solid portion was rinsed with deionised water and drained multiple times until its pH reached 7. These treated P. australis samples were then dried in an oven at 65 °C for 24 h.

Experimental Setup

Three sets of batch experiments were conducted to screen the optimal inoculum to substrate ratio (ISR) and substrate mixing ratio (SMR) for biogas production from two types of substrates—synthetic food waste and pre-treated P. australis. All experiments were performed using microcosm vessels (125 mL) as reactors with working volumes of 80 mL. The ISR of the first set of batch assays was 1:4, calculated using the volatile solid (VS) content of the inoculum and substrates, while the ISRs of the second and third sets of batch assays were 1:2 and 1:1. For each of these ISR values, substrates mixing (synthetic food waste: P. australis) were implemented in various ratios: 25:75, 50:50, 75:25, 100:0 (synthetic food waste control), and 0:100 (P. australis control). These SMRs were calculated based on the VS content of the substrates. Duplicate reactors were prepared for each SMR, and two additional blank reactors were filled with inoculum and deionised water only, serving as controls. Deionised water was used to make up the final volume to 80 ml in each reactor (Table 2). These reactors were then sealed and flushed with nitrogen gas for 1 min to displace the residual oxygen from the mixture and the reactors’ headspace, thus achieving the required anaerobic conditions. All the reactors were then placed in a water bath at mesophilic conditions (37±1 °C), and the anaerobic digestion process was allowed to proceed. The reactors were manually shaken once a day but otherwise were static.

Analytical Methods

Total solids (TS) and volatile solids (VS) for the inoculum and substrates were determined using standard methods [31]. The pH values were determined using a pH metre (Mettler, Switzerland). The partial, intermediate, and total alkalinity were measured at the end of digestion period based on the method presented by Ripley et al. [32] by using an auto titrator analyser (Orion Star T910, Thermo Scientific). The volume of produced biogas was measured by connecting each reactor to a gas counter unit that contained a tipping-bucket mechanism (manufactured by CJC Labs LTD, UK). The tipping buckets were filled with water, such that when the produced biogas entered the counter, it displaced the water in the buckets, tipping it and releasing the biogas, which was then collected in bags attached to the counters. The counter buckets were calibrated to tip and empty when they had collected 6 ml of produced gas. Each tipping of a bucket was recorded using a data acquisition system (DAS) (manufactured by CJC Labs LTD, UK) connected to the counters, and thus indicated a volume of 6 ml of the produced biogas. The total volume of biogas measured in this way was recorded at the same time each day. The cumulative biogas volumes produced from each reactor obtained at ambient temperature and pressure were adjusted to equivalent volumes at standard temperature (273.15 K) and pressure (1 bar) and expressed as ml/g VS added (millilitres of biogas per gram of volatile solids of inoculum + substrate).

Statistical Analyses

Statistical analyses were conducted using IBM SPSS Statistics software v27. One-way analysis of variance (ANOVA) and the Games-Howell post hoc multiple comparisons tests at a confidence level of 95% were conducted on the cumulative biogas production results to determine the significant differences among treatments in cumulative biogas production in each set of batch assays. p value <0.05 was considered statistically significant.

Results and Discussion

Effect of Mixing Ratio of Synthetic Food Waste to P. australis at Inoculum to Substrate Ratio of 1:4 on Biogas Production

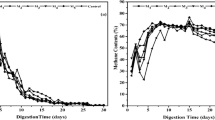

As shown in Fig. 1a, there was variation in the cumulative biogas production among the different SMRs. The reactors at synthetic food waste:P. australis mixing ratios of 75:25, 100:0, and 0:100 showed a bi-phase pattern of biogas production represented by the increase in biogas production at the beginning of digestion, followed by a lag period of biogas production, after which the production of biogas increase again. This may be because the rate of acidogenesis could be higher during the initial phase led to the accumulation of VFAs which could have been consumed in later phase [28], while the reactors at synthetic food waste: P. australis mixing ratios of 50:50 and 25:75 exhibited a one-phase pattern of biogas production where biogas production ceased from the 2nd and 4th day of the digestion process, respectively. This could be attributed to the probability of low abundance or inhibition of methanogens due to the high rate of acidogenesis or VFAs in the system that caused pH drop and acidification thus system failure [16, 28, 33, 34]. This agreed with the results of Xu and Li [21], who found that the solid-state co-digestion of expired dog food and corn stover at ISRs 1:4 and 1:6 with more than 10% of dog food in the substrate led to producing high VFA concentrations (final total VFA ranged 4.9±0.1– 20.0±0.0 g HAc/kg) and caused systems acidification. The study also found that an ISR of 1:2 achieved higher cumulative methane yields than ISRs of 1:4 and 1:6 (p<0.05) for the same dog food to corn stover ratio, as the reduction in methane yield ranged from 11 to 97% when the ISR altered from 1:2 to 1:4. Similarly, the work of Brown and Li [32] revealed that the co-digestion of yard waste with 10% and 20% food waste at an ISR of 1:3 led to producing high VFA concentration and systems acidification. This, in turn, led to the cessation of methane production in these systems at an early stage of the digestion process.

Cumulative biogas production (mL/g VS added) (a) and biogas production rate (mL/g VS added/day) (b) from inoculum control (

) and co-digestion of synthetic food waste and P. australis at different mixing ratios [25:75 (

) and co-digestion of synthetic food waste and P. australis at different mixing ratios [25:75 (

), 50:50 (

), 50:50 (

), 75:25 (

), 75:25 (

), 100:0 (

), 100:0 (

), and 0:100 (

), and 0:100 (

)] and ISR of 1:4, over 30 days digestion period. Data points represent mean ± standard deviation

)] and ISR of 1:4, over 30 days digestion period. Data points represent mean ± standard deviation

The decline in the pH value of the systems with synthetic food waste: P. australis mixing ratios of 50:50 and 25:75 also synchronised with the increase in the intermediate alkalinity to partial alkalinity ratio (IA/PA) to be higher than 0.3 (Table 3), which is considered a robust early indicator of system acidification [32, 35]. Furthermore, the rapid and easy hydrolysis of protein-rich substrates, such as food waste, may lead to the generation of high concentrations of ammonia, which could also inhibit methanogens if it exceeds the threshold level (1.7 g/L for liquid-state or 2.8 g/kg for solid-state digestion), consequently reducing biogas production [36,37,38]. Xu and Li [21] observed an increase in the total ammonia nitrogen concentrations (2.7 ± 0.0–4.9 ± 0.0 g/kg) during the solid-state co-digestion of dog food and corn stover at ISRs of 1:4 and 1:6, in particular in the systems with a higher proportion of dog food due to the protein degradation.

However, the cumulative biogas production from the reactors with a mixing ratio of 0:100 was higher than that from the other mixing ratios (Table 3). This may be attributed to the fact that lignocellulosic substrates such as P. australis are degraded slower than food waste, leading to a relative balance between the production and consumption of intermediate products (such as VFAs) of the degradation process, making the digestion process more stable and thus increasing the amount of biogas produced [21, 24]. This was supported by the value of IA/PA, which was lower than 0.3, which is an indicator that the system was stable at the final stage of digestion period.

On the other hand, the reactors with substrate mixing ratios of 25:75, 50:50, 75:25, and 100:0 exhibited their highest biogas production rates on the first day of digestion. The only exception to this was the mixing ratio of 0:100, which achieved its highest biogas production rate on the second day of the digestion process (Fig. 1b, Table 3). This may be due to the rapid digestion of the synthetic food waste fraction compared to that of the P. australis [39], which made the systems acidified on the first day, and that may have resulted in the conversion of the carbonates to CO2. Similarly, the study conducted by Gandhi et al. [28] found that the digestion of synthetic food waste at ISR of 1:4 resulted in systems acidification and drop in the pH, and this was coincided with an increase of CO2 concentration on the 1st day of digestion.

Effect of Mixing Ratio of Synthetic Food Waste to P. australis at Inoculum to Substrate ratio of 1:2 on Biogas Production

In the cases where ISR = 1:2, the reactors with higher proportions of P. australis (synthetic food waste: P. australis mixing ratios of 25:75 and 0:100) showed higher biogas production and did not suffer from acidification effect, as shown by the pH and IA/PA values (Fig 2a; Table 4). This could be because the slower degradation of P. australis compared to synthetic food waste may provide sufficient time for methanogenic microorganisms to consume VFAs produced in the systems and prevent their accumulation, thus maintaining the stability of the systems. In contrast, the reactors with lesser P. australis proportions and higher synthetic food waste proportions (synthetic food waste: P. australis mixing ratios of 50:50, 75:25, 100:0) appear to have suffered from acidification and produced lower amounts of biogas (Table 4). This may have happened because the rate of acid formation is higher in the case of food waste due to higher concentrations of easily degradable materials such as sugars, resulting in a decline of the pH and methanogens inhibition, consequently, process disruption and/or failure [20, 40]. Panigrahi et al. [41] reported the VFA concentration yielded from the co-digestion of food waste and yard waste mixture (1:3) at ISR 1:1.5 and 1:2 reached 5.51 ± 0.21 and 4.95 ± 0.22 g/L, respectively. However, the systems at synthetic food waste: P. australis mixing ratio of 50:50 showed a reversible acidification pattern, where the biogas production ceased on 2nd day and re-produced at day 15 of digestion, after consumption of accumulated VFAs by the methanogens.

Cumulative biogas production (mL/g VS added) (a) and biogas production rate (mL/g VS added/ day) (b) from inoculum control (

) and co-digestion of synthetic food waste and P. australis at different mixing ratios [25:75 (

) and co-digestion of synthetic food waste and P. australis at different mixing ratios [25:75 (

), 50:50 (

), 50:50 (

), 75:25 (

), 75:25 (

), 100:0 (

), 100:0 (

), and 0:100 (

), and 0:100 (

)] and ISR of 1:2, over 30 days digestion period. Data points represent mean ± standard deviation

)] and ISR of 1:2, over 30 days digestion period. Data points represent mean ± standard deviation

On the other hand, it is observed from Fig. 2b that the maximum daily biogas produced from reactors with mixing ratios of 75:25 and 100:0 was recorded on day one and was significantly higher than the maximum daily biogas produced from reactors with mixing ratios of 25:75, 50:50, and 0:100, which was recorded on 1st and 2nd day respectively. This may be attributed to the high proportion of synthetic food waste in the 75:25 and 100:0 mixing ratios, which resulted in high levels of VFAs, causing a decrease in pH (Table 4), and this might have led to the release of CO2 from carbonates in the liquid phase in the reactors, thus caused high biogas production rate on the first day of the digestion process in reactors using these mixing ratios [28].

Effect of Mixing Ratio of Synthetic Food Waste to P. australis at Inoculum to Substrate Ratio of 1:1 on Biogas Production

The pattern of cumulative biogas production at ISR of 1:1 was similar for all substrate mixing ratios tested, gradually increasing from the beginning of the reaction until reaching its peak value (Fig. 3a). This may indicate that all reactors avoided inhibitive VFA accumulation [42], which may be due to the substrate concentration being optimal at this ISR so that the rate of acid production and consumption was balanced, thus resulting in no accumulation of VFAs, thus preventing drops in pH (Table 5) and acidification of the systems [43]. This was obvious from IA/PA values (Table 5), which were lower than 0.3 in all reactors. Similar results have been found by other researchers, such as Owamah et al. [24] who found better biogas production in their reactors fed with mixtures of food waste and maize husks at ISRs with substrate levels lower than 1:2 with the best performance observed at ISR 1:1. Similarly, Haider et al. [44] reported that biogas production from mixtures of food waste and rice husks increased when substrate portion in the ISR was decreasing below than 1:2. Dixon et al. [45] revealed the co-digestion of food waste, yard waste, and biosolids at an ISR of 1:1 produced the highest cumulative methane yield of 126 mL CH4/g VS added, whereas the ISR of 1:2 and 1:3 resulted in higher VFA release than the ISR of 1:1, caused methanogenesis inhibition, long lag phases (12 days for ISR of 1:2 and 26 days for ISR of 1:3), and lower cumulative methane yields (45.60 and 6.75 mL CH4/g VS added at ISR 1:2 and 1:3, respectively). Borth et al. [46] determined the biochemical methane potential from co-digestion of food waste and garden waste at various inoculum to substrate ratios (1:1 and 2:1). They found that mono-digestion of food waste and co-digestion of food waste with garden waste (80:20%) at ISR of 1:1 produced the highest cumulative biogas production (1082± 60 and 931± 60 mL/g VS, respectively), with methane concentrations reached 43±23 and 48±17%, respectively, and carbon dioxide concentrations were 29 ± 8 and 28 ± 8%, respectively.

Cumulative biogas production (mL/g VS added) (a) and biogas production rate (mL/g VS added/day) (b) from inoculum control (

) and co-digestion of synthetic food waste and P. australis at different mixing ratios [25:75 (

) and co-digestion of synthetic food waste and P. australis at different mixing ratios [25:75 (

), 50:50 (

), 50:50 (

), 75:25 (

), 75:25 (

), 100:0 (

), 100:0 (

), and 0:100 (

), and 0:100 (

)] and ISR of 1:1, over 30 days digestion period. Data points represent mean ± standard deviation

)] and ISR of 1:1, over 30 days digestion period. Data points represent mean ± standard deviation

The reactors with synthetic food waste to P. australis mixing ratios of 100:0 exhibited the highest cumulative biogas production, followed by the reactors with the mixing ratio of 75:25. These were significantly higher (p<0.05) than the cumulative biogas volumes produced from reactors with mixing ratios of 50:50, 25:75, and 0:100 (Table 5). In general, the cumulative biogas production increased significantly (p<0.05) with an increasing proportion of synthetic food waste in the reactors. This is possibly due to the readily biodegradable nature of synthetic food waste and its high nutrient content compared to P. australis [16, 36].

Figure 3b shows that the daily biogas production in reactors with synthetic food waste to P. australis mixing ratios 100:0, 75:25, 50:50, and 25:75 exhibited similar trends, which rose rapidly from the beginning of the digestion process to reach peak rates on the first day. While in reactors with a mixing ratio of 0:100, the daily biogas production peaked on the second day. This is possibly due to the easy degradation of synthetic food waste partition compared to reactors without synthetic food waste [47]. However, the reactors with a mixing ratio of 75:25 showed a higher biogas production rate through the digestion period compared to the reactors with mixing ratios of 50:50 and 25:75 which make it the preferable option for co-digesting of synthetic food waste with P. australis at the ISR of 1:1, to enhance biogas production.

Overall, it is observed that the systems at ISR 1:4 with synthetic food waste: P. australis mixing ratios of 25:75, 50:50, 75:25, and 100:0 suffered from acidification effect and presented the lowest biogas production (Table 6). While at ISR of 1:2, the systems with SMRs of 25:75 were non-acidified, whereas the systems with SMRs of 50:50 showed reversible acidification, and biogas production was recovered after 13 days of cease, and only the systems with SMRs 75:25 and 100:0 undergone to continuous acidification influents (Fig. 4). At an ISR of 1:1, the systems at all SMRs did not show any acidification pattern, and the digestion process was stable. The increase of substrate amount from ISR 1:1 towards ISR 1:4, particularly the synthetic food waste proportion, was the main reason for increasing the acidification effect on systems and decreasing biogas production. However, the systems at ISR of 1:2 with SMRs 25:75 showed higher cumulative biogas production (82.17 ± 0.62 mL/g VS added) than that produced from the systems with SMRs 75:25 at ISR of 1:1 (76.15 ± 1.85 mL/g VS added). This may be due to the doubled amount of substrate added at ISR of 1:2 compared to 1:1, and the highest proportion of substrate at SMRs 25:75 consisted of P. australis, which is characterised by slower degradation compared to synthetic food waste, which led to producing VFAs at concentrations suitable for methanogens consumption capacity, thus enhance biogas production.

Cumulative biogas production (mL/g VS added) from inoculum control (

) and co-digestion of synthetic food waste and P. australis at different mixing ratios [25:75 (

) and co-digestion of synthetic food waste and P. australis at different mixing ratios [25:75 (

), 50:50 (

), 50:50 (

), 75:25 (

), 75:25 (

), 100:0 (

), 100:0 (

), and 0:100 (

), and 0:100 (

)] and ISR of 1:1, 1:2 and 1:4 over 30 days digestion period. Data points represent mean ± standard deviation

)] and ISR of 1:1, 1:2 and 1:4 over 30 days digestion period. Data points represent mean ± standard deviation

Conclusion

The reduction of substrate proportion diminished system acidification and enhanced biogas production. Since the differences in cumulative biogas production were small, and the amount of substrate at ISR of 1:1 was half that at ISR of 1:2, as well as the use of a low P. australis proportion at a 75:25 mixing ratio led to a decrease in the need for additional pre-treatment requirements. The co-digestion of synthetic food waste and P. australis at ISR of 1:1 with a mixing ratio of 75:25 could be practical and more feasible for applying at the pilot or full scale than ISR 1:2.

References

Owamah HI (2020) Biogas yield assessment from the anaerobic co-digestion of food waste and cymbopogon citratus. J Mater Cycles Waste Manag 22:2012–2019. https://doi.org/10.1007/S10163-020-01086-3

Zhang Q, Hu J, Lee DJ (2016) Biogas from anaerobic digestion processes: research updates. Renew Energy 98:108–119. https://doi.org/10.1016/J.RENENE.2016.02.029

Anukam A, Mohammadi A, Naqvi M, Granström K (2019) A review of the chemistry of anaerobic digestion: methods of accelerating and optimizing process efficiency. Processes 7:504. https://doi.org/10.3390/PR7080504

Liu G, Zhang R, El-Mashad HM, Dong R (2009) Effect of feed to inoculum ratios on biogas yields of food and green wastes. Bioresour Technol 100:5103–5108. https://doi.org/10.1016/J.BIORTECH.2009.03.081

Wang M, Sun X, Li P et al (2014) A novel alternate feeding mode for semi-continuous anaerobic co-digestion of food waste with chicken manure. Bioresour Technol 164:309–314. https://doi.org/10.1016/J.BIORTECH.2014.04.077

Pan SY, Tsai CY, Liu CW et al (2021) Anaerobic co-digestion of agricultural wastes toward circular bioeconomy. iScience 24:102704. https://doi.org/10.1016/J.ISCI.2021.102704

Habagil M, Keucken A, Horváth IS (2020) Biogas production from food residues—the role of trace metals and co-digestion with primary sludge. Environments 7:42. https://doi.org/10.3390/ENVIRONMENTS7060042

Adhikari P, Hussain A, Gulati M (2014) Anaerobic co-digestion of lignocellulosic waste co-digested with food waste under mesophillic conditions. J Civ Eng and Environ Technol 4:430–433

Olugbemide AD, Lajide L, Adebayo A, Owolabi BJ (2020) Enhanced biogas production from rice husk through solid-state chemical pretreatments. Waste Biomass Valori 11:2397–2407. https://doi.org/10.1007/S12649-018-00567-9/TABLES/6

Tedesco S, Marrero Barroso T, Olabi AG (2014) Optimization of mechanical pre-treatment of Laminariaceae spp. biomass-derived biogas. Renew Energy 62:527–534. https://doi.org/10.1016/J.RENENE.2013.08.023

Olatunji KO, Ahmed NA, Ogunkunle O (2021) Optimization of biogas yield from lignocellulosic materials with different pretreatment methods: a review. Biotechnology for Biofuels 14:1–34. https://doi.org/10.1186/S13068-021-02012-X

Zhu J, Wan C, Li Y (2010) Enhanced solid-state anaerobic digestion of corn stover by alkaline pretreatment. Bioresour Technol 101:7523–7528. https://doi.org/10.1016/J.BIORTECH.2010.04.060

Xue Y, Li Q, Gu Y et al (2020) Improving biodegradability and biogas production of miscanthus using a combination of hydrothermal and alkaline pretreatment. Ind Crop Prod 144:111985. https://doi.org/10.1016/J.INDCROP.2019.111985

Wang X, Zhang L, Xi B et al (2015) Biogas production improvement and C/N control by natural clinoptilolite addition into anaerobic co-digestion of Phragmites australis, feces and kitchen waste. Bioresour Technol 180:192–199. https://doi.org/10.1016/J.BIORTECH.2014.12.023

Shrestha S, Fonoll X, Khanal SK, Raskin L (2017) Biological strategies for enhanced hydrolysis of lignocellulosic biomass during anaerobic digestion: current status and future perspectives. Bioresour Technol 245:1245–1257. https://doi.org/10.1016/J.BIORTECH.2017.08.089

Brown D, Li Y (2013) Solid state anaerobic co-digestion of yard waste and food waste for biogas production. Bioresour Technol 127:275–280. https://doi.org/10.1016/J.BIORTECH.2012.09.081

van den Bos VM, de Vreede L, Achterbosch T, Rutten MM (2020) Consumers discard a lot more food than widely believed: estimates of global food waste using an energy gap approach and affluence elasticity of food waste. PLoS One 15:e0228369. https://doi.org/10.1371/JOURNAL.PONE.0228369

Aghdam EF, Scheutz C, Kjeldsen P (2019) Impact of meteorological parameters on extracted landfill gas composition and flow. Waste Manag 87:905–914. https://doi.org/10.1016/J.WASMAN.2018.01.045

EPA (2015) Inventory of US greenhouse gas emissions and sinks: 1990–2013. DC, USA, Washington, p 4

Zhang C, Su H, Baeyens J, Tan T (2014) Reviewing the anaerobic digestion of food waste for biogas production. Renew Sust Energ Rev 38:383–392. https://doi.org/10.1016/J.RSER.2014.05.038

Xu F, Li Y (2012) Solid-state co-digestion of expired dog food and corn stover for methane production. Bioresour Technol 118:219–226. https://doi.org/10.1016/J.BIORTECH.2012.04.102

Browne JD, Murphy JD (2013) Assessment of the resource associated with biomethane from food waste. Appl Energy 104:170–177. https://doi.org/10.1016/J.APENERGY.2012.11.017

Klavon KH, Lansing SA, Mulbry W et al (2013) Economic analysis of small-scale agricultural digesters in the United States. Biomass Bioenergy 54:36–45. https://doi.org/10.1016/J.BIOMBIOE.2013.03.009

Owamah HI, Ikpeseni SC, Alfa MI et al (2021) Influence of inoculum/substrate ratio on biogas yield and kinetics from the anaerobic co-digestion of food waste and maize husk. Environ Nanotechnol Monit Manag 16:100558. https://doi.org/10.1016/J.ENMM.2021.100558

Zhang H, Luo L, Li W et al (2018) Optimization of mixing ratio of ammoniated rice straw and food waste co-digestion and impact of trace element supplementation on biogas production. J Mater Cycles Waste Manag 20:745–753. https://doi.org/10.1007/S10163-017-0634-0/TABLES/3

Weerayutsil P, Khoyun U, Khuanmar K (2016) Optimum ratio of chicken manure and Napier grass in single stage anaerobic co-digestion. Energy Procedia 100:22–25. https://doi.org/10.1016/J.EGYPRO.2016.10.141

WRAP (2008) The food we waste. WRAP

Gandhi BP, Otite SV, Fofie EA et al (2022) Kinetic investigations into the effect of inoculum to substrate ratio on batch anaerobic digestion of simulated food waste. Renew Energy 195:311–321. https://doi.org/10.1016/J.RENENE.2022.05.134

Lizasoain J, Rincón M, Theuretzbacher F et al (2016) Biogas production from reed biomass: effect of pretreatment using different steam explosion conditions. Biomass Bioenergy 95:84–91. https://doi.org/10.1016/J.BIOMBIOE.2016.09.021

Scherzinger M, Kaltschmitt M, Thoma M (2021) Effects of vapothermal pretreatment on anaerobic degradability of common reed. Energy Technology 9:2001046. https://doi.org/10.1002/ENTE.202001046

APHA (2005) Standard methods for the examination of water and wastewater. American Public Health Association, Washington, DC, USA, p 21

Ripley LE, Boyle WC, Converse JC (1986) Improved alkalimetric monitoring for anaerobic digestion of high-strength wastes. J Water Pollut Control Fed 58:406–411

Vavilin VA, Fernandez B, Palatsi J, Flotats X (2008) Hydrolysis kinetics in anaerobic degradation of particulate organic material: an overview. Waste Manag 28:939–951. https://doi.org/10.1016/J.WASMAN.2007.03.028

Cheng XY, Zhong C (2014) Effects of feed to inoculum ratio, co-digestion, and pretreatment on biogas production from anaerobic digestion of cotton stalk. Energy Fuel 28:3157–3166. https://doi.org/10.1021/EF402562Z/ASSET/IMAGES/LARGE/EF-2013-02562Z_0003.JPEG

Martín-González L, Font X, Vicent T (2013) Alkalinity ratios to identify process imbalances in anaerobic digesters treating source-sorted organic fraction of municipal wastes. Biochem Eng J 76:1–5. https://doi.org/10.1016/J.BEJ.2013.03.016

Chen X, Yan W, Sheng K, Sanati M (2014) Comparison of high-solids to liquid anaerobic co-digestion of food waste and green waste. Bioresour Technol 154:215–221. https://doi.org/10.1016/J.BIORTECH.2013.12.054

Brown D, Shi J, Li Y (2012) Comparison of solid-state to liquid anaerobic digestion of lignocellulosic feedstocks for biogas production. Bioresour Technol 124:379–386. https://doi.org/10.1016/J.BIORTECH.2012.08.051

Poggi-Varaldo HM, Rodríguez-Vázquez R, Fernández-Villagómez G, Esparza-García F (1997) Inhibition of mesophilic solid-substrate anaerobic digestion by ammonia nitrogen. Appl Microbiol Biotechnol 47:284–291. https://doi.org/10.1007/S002530050928/METRICS

Yong Z, Dong Y, Zhang X, Tan T (2015) Anaerobic co-digestion of food waste and straw for biogas production. Renew Energy 78:527–530. https://doi.org/10.1016/J.RENENE.2015.01.033

Ziaee F, Mokhtarani N, Pourrostami Niavol K (2021) Solid-state anaerobic co-digestion of organic fraction of municipal waste and sawdust: impact of co-digestion ratio, inoculum-to-substrate ratio, and total solids. Biodegradation 32:299–312. https://doi.org/10.1007/S10532-021-09937-Y/FIGURES/12

Panigrahi S, Sharma HB, Dubey BK (2020) Anaerobic co-digestion of food waste with pretreated yard waste: a comparative study of methane production, kinetic modeling and energy balance. J Clean Prod 243:118480. https://doi.org/10.1016/J.JCLEPRO.2019.118480

Ye J, Li D, Sun Y et al (2013) Improved biogas production from rice straw by co-digestion with kitchen waste and pig manure. Waste Manag 33:2653–2658. https://doi.org/10.1016/J.WASMAN.2013.05.014

Boulanger A, Pinet E, Bouix M et al (2012) Effect of inoculum to substrate ratio (I/S) on municipal solid waste anaerobic degradation kinetics and potential. Waste Manag 32:2258–2265. https://doi.org/10.1016/J.WASMAN.2012.07.024

Haider MR, Zeshan YS et al (2015) Effect of mixing ratio of food waste and rice husk co-digestion and substrate to inoculum ratio on biogas production. Bioresour Technol 190:451–457. https://doi.org/10.1016/J.BIORTECH.2015.02.105

Dixon PJ, Ergas SJ, Mihelcic JR, Hobbs SR (2019) Effect of substrate to inoculum ratio on bioenergy recovery from food waste, yard waste, and biosolids by high solids anaerobic digestion. Environ Eng Sci 36:1459–1465. https://doi.org/10.1089/EES.2019.0078/ASSET/IMAGES/LARGE/EES.2019.0078_FIGURE6.JPEG

Borth PLB, Perin JKH, Torrecilhas AR et al (2021) Biochemical methane potential of food and garden waste co-digestion with variation in solid content and inoculum:substrate ratio. J Mater Cycles Waste Manag 23:1974–1983. https://doi.org/10.1007/S10163-021-01270-Z/TABLES/9

Li Y, Zhang R, Liu X et al (2013) Evaluating methane production from anaerobic mono- and co-digestion of kitchen waste, corn stover, and chicken manure. Energy Fuel 27:2085–2091. https://doi.org/10.1021/EF400117F/ASSET/IMAGES/LARGE/EF-2013-00117F_0004.JPEG

Acknowledgements

The authors thank Mr. Christopher James Parry, the Director of Cockerham Green Energy, in the UK, for his invaluable support and assistance to obtain inoculum/digestates. We extend our thanks to Mr. Tim Gregson and Dr. Clare Benskin, from Lancaster University in the UK for providing technical support.

Funding

This work was sponsored and supported by the Iraqi Ministry of Higher Education and Scientific Research and Mosul University, Iraq.

Author information

Authors and Affiliations

Contributions

ARA-I: conceptualisation, methodology, investigation, physio-chemical analysis, formal analysis, visualisation, writing—original draft, writing—review and editing. KTS: conceptualisation, methodology, investigation, formal analysis, validation, visualisation, resources, supervision, writing—review and editing. AMF: conceptualisation, methodology, resources, visualisation, supervision, writing—review and editing. PAB: conceptualisation, resources, visualisation, supervision, writing—review and editing. BPG: formal analysis, writing—review and editing.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Al-Iraqi, A.R., Gandhi, B.P., Folkard, A.M. et al. Influence of Inoculum to Substrate Ratio and Substrates Mixing Ratio on Biogas Production from the Anaerobic Co-digestion of Phragmites australis and Food Waste. Bioenerg. Res. 17, 1277–1287 (2024). https://doi.org/10.1007/s12155-023-10689-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-023-10689-1