Abstract

The dynamic model of the biogas project was created with changing parameter values over time and compared to the static model of the same project based on constant values of the same parameters. For the dynamic model, the same methods were used to evaluate the biogas project as for the static model to calculate substrate mix volumes, costs, farm production volumes, number of biogas plant equipment, driers, and other numerical characteristics of the farm. Project risks were evaluated by the sensitivity analysis and Monte Carlo simulation. The study was conducted for four scenarios regarding the substrate mix structure and the possibility of selling electricity on the market. In the scenarios, the scale of the project was determined by the size and structure of agricultural and biogas production. The results have shown that when only wastes are used as substrates, net present values (NPVs) of the project are equal to 29.45 and 56.50 M RUB in dependence on the possibility to sell electricity on the market. At the same time, when the substrate mix is diversified, the project NPVs are equal to 89.17 and 186.68 M RUB depending on the ability to sell all the produced electricity to the common power grid. The results of the sensitivity analysis defined that the values of elasticity coefficients are less than 3.14%. Results of the Monte Carlo simulation have shown a probability distribution of positive NPVs for each scenario. This study was conducted to make recommendations for business and municipalities.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biogas production increases the economic efficiency of agricultural organizations, reduces environmental risks associated with energy production, and has positive social effects on the territories where the biogas projects are realized. AD projects make it possible to diversify farm production by using agricultural products not only for their usual use, but also for the production of energy and biofertilizers. This makes production more flexible and allows to increase the profitability of agriculture and rural economies. Each kilowatt of “green” energy produced is able to replace each kilowatt of energy produced by fossil fuels, reducing harmful emissions into the environment. Biogas production allows to improve the infrastructure and create jobs. Therefore, biogas production effectively supports sustainable development in the territories where AD projects are realized.

Nevertheless, the development of biogas production in the Russian Federation is quite unpredictable, and the ability to integrate renewable energy into the Russian economy has not been investigated so far. Electricity production is monopolized and the energy industry is mainly based on fossil energy sources in the country. Farm production structures and hence specializations of farms are often not flexible enough to be adapted to biogas production as unprofitable farms are often subsidized by the state. In spite of attempts of the Russian government to make the economy of the country more stable and predictable, farmers often lack confidence in long-term investment projects. Despite the fact that the Russian state has been declaring programs, special laws, and other statutes to improve the ecological policy and to diversify energy sources inside the country, in reality, the situation is still not changing for the better [1].

Despite many statutes drawn up by the Russian government [2,3,4,5,6,7,8,9,10,11,12,13,14], progress in the field of renewable energies in the Russian Federation is not significant. Furthermore, in spite of the fact that biogas production is a popular solution of sustainable development in many countries [15,16,17,18,19], unfortunately in the Russian Federation, biogas is almost not used, and the Federal State Statistical Service does not collect any data on biogas production inside the country.

In contrast to the lack of knowledge in the field of biogas production in Russia, the authors of this article have developed a simulation model to maximize the profitability of a biogas project, taking into account the peculiarities of the Russian economy and agriculture and applying WFM, SM, LPM, PEM, and scenario analysis [20]. In that work, the biogas production project was evaluated and the farm production plan was calculated using constant input parameters. The results can be used as rather precise “guide values” to assist in biogas production planning.

However, after more careful observation, it turns out that the project plan is based on parameters dependent on time. The values of these parameters, especially the key rate, inflation rate, production outputs, prices, and others, are described by corresponding data series in reality. Therefore, each time-variable parameter corresponds to a separate time-dependent function with its tendency, its trend, and deviations from the trend.

The biogas project is a “multi-project,” which means that if the project is effective, it is usually replicated in countries with the same or similar conditions. On the other side, the implementation of each project is connected with uncertainties, which in turn are connected with risks. The level of risks can vary considerably depending on various factors such as crop yields, animal productivity, soil parameters, market prices of production, and resources. The ability to measure these features and hence to measure the risks connected with them generates the need to investigate these risks by corresponding tools. Thus, the importance of this paper is based on the existence and measurability of the risks of biogas projects, as well as the possibility of studying and avoiding them in advance, which can be of great benefit to farmers and municipalities that can support new biogas projects in the region.

Based on the necessity of this work, the purpose of this paper is to evaluate the profitability of the biogas project using the simulation model based on dynamic parameters and their trends as well as to reveal and evaluate risks associated with each input parameter. Since the possibility of selling electricity on the market and the structure of the substrate mix determine the scope of the project and significantly affect its profitability, the objective of this work is also to identify and assess the risks associated with these circumstances. The numerical assessment of risks is one of the most challenging tasks of risk modeling. The application of a risk analysis (RA) including sensitivity analysis (SA) and Monte Carlo simulation (MCS) methods for renewable energy projects is reported in several papers.

Among others, Di Lorenzo et al. presented the soft-based model based on MCS to assess the investments in a modern low-carbon power plant [21]. The developed program was created to calculate the main discounted cash flow indices (NPV, IRR, and PBP), which provides the opportunity to define the investment potential of the project based on criteria related to the electricity market. MCM made it possible to quantify and analyze the uncertainty connected with predicting the costs of new relevant technologies as well as with the feasibility of investing in these new technologies [21].

Pereira et al. presented the MCS-based method that gives the ability to analyze risks connected with renewable energy production [22]. The elaborated MCS approach was applied to explore the energy production model behavior, which provides the decision-making process referring to risks connected with the sustainability within the Grid-Connected Photovoltaic System in Brazil. The approach has shown that the application of MCM in the power generation systems is more effective than the common methods like SA. Among others, MCM gives an ability to get results of the analysis faster in case of changing variables [22].

Schade and Wiesenthal based their analysis of biofuel policy on a model that takes into account the continuing uncertainty of conditions [23]. To this end, the RA was realized to the corresponding biofuel project model using the MCM. In the model, numerous values of the most important parameters were taken randomly within their probability distribution and set to the model to simulate the system behavior. This approach makes it possible to model the impact of different biofuel support strategies on both production and consumption [23].

Arnold and Yildiz presented RA for decentralized infrastructures of renewable energy projects realized by the MCS approach [24]. This article addresses the problem by introducing the MCM for RA, taking into account the project life cycles. In this work, significant advantages in terms of content and methodology over conventional NPV assessments or SA have been found. The presented analysis in combination with the MCS application helps to optimize the conception of investment projects in terms of return on capital and risk [24].

These and other scientific works consider methods of risk analysis in relation to various renewable energy problems. However, there are no works that consider the use of WFM, SM, LPM, PEM, SA, MCS, and scenario analysis in combination to evaluate biogas projects and assess biogas production risks using dynamic input parameters. The novelty of this study is based on combining methods of applied mathematics, agricultural sciences, and economics to improve and optimize production in the agriculture and energy sectors of the economy. The present work, as a logical continuation of the work presented in [20], is therefore intended to fill this gap and claims to be innovative in the corresponding field of knowledge.

Materials and Methods

Static Model

Due to the lack of information and scientific papers on the profitability of biogas projects in Russia, as well as works that would evaluate a biogas project using a combination of WFM, SM, LPM, PEM, and scenario analysis, the authors of this paper first proposed the methodology for evaluating a biogas project applying these methods using constant values of project parameters [20]. The target of that study was to find the most advantageous substrate mixture for AD production in a typical farm in the Tambov region of the Russian Federation using numerical characteristics of typical biogas production equipment. The key parameters from the point of view of biogas production were outputs of biogas (and hence energies) and in-digestate N, P2O5, and K2O of various substrates as well as the parameters of the farm.

The structure of the farm consists of several interconnected industries, which in turn produce not only the main products for sale, but also intermediate products that can be produced in one industry and used in another; e.g., fodders are produced in crop production of the farm and then used to feed animals in farm animal husbandry; manure produced in animal husbandry and biogas digestate produced by AD are used to fertilize plants. Therefore, the most challenging part of that work was to interconnect crop production, animal husbandry, and biogas production by the system of linear and simulation models.

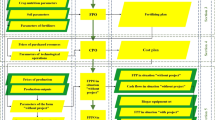

The key target was the project’s NPV maximization. To maximize the project NPV, the direct search method was used to find the most effective substrate mix for biogas production on the farm. For this purpose, a combination of simulation and linear models was constructed and integrated into a calculation procedure that consistently computes the models for the situations when the farm has no AD production and when the farm produces biogas.

To achieve this goal, first, for each available substrate mixture, their numerical characteristics including biogas output and digestate output as well as their N, P2O5 and K2O contents were calculated.

Then, the numerical characteristics of the fertilizers, including the calculated digestate outputs, crop nutrition requirements, soil, and other factors, were included in the calculation procedure as a separate LP model. This LP model was to calculate the application rates for each crop and for each variant of digestate output caused by each available substrate mix. The LP solution of this model was to minimize fertilizer costs.

After that, for both situations, the numerical characteristics of the technical operations in crop, animal, and biogas production as well as the prices of the corresponding resources such as fuel prices and labor costs were entered into the calculation procedure as a separate simulation model to calculate the operating costs of crop, animal, and biogas production.

And finally, for each situation separately, the calculated AD outputs and calculated operational costs together with numerical characteristics of the AD equipment, lands, livestock, crop production, and prices of the corresponding commodity products were used as a separate LP model in the calculation procedure. This model was to optimize the farm production plan by LPM. In the situation when the farm does not have AD production, the farm production plan was optimized by providing the highest total operational income. In turn, in the second situation, the farm production plan for each available substrate mix was optimized by providing the highest NPV value. It was guaranteed by comparing this situation with the one in which the farm does not have AD production by using PEM.

The probe with the substrate mix that provides the maximal NPV of the biogas project was selected as the most effective one. This approach was used for those cases where the farm can sell all of the produced electricity to the net or where the farm can only use the produced electricity for its own needs. The results have shown that in both cases, a positive NPV was achieved, and for the case where the farm can sell all the produced electricity on the market, the project NPV value is higher than in the case where the farm can use the produced electricity only for its own needs by 2.66 times [20].

Dynamic Model

After closer examination, it turns out that in reality, the project plan is based on time-dependent parameters. The “Behavior” of the values of these parameters was described by corresponding data series. Each parameter a constitutes a corresponding function a(t) with its data series \({a}_{t}\):

where A is the set of the project parameters, t is the of the project year, and T is the set of the years the input data series were collected for.

Data series for each parameter were collected in the retrospective for 10 years, and the prediction was realized for the perspective of 20 years. The dynamic model takes into account the prediction of the values of each parameter. For each parameter \(a\) and its values \({a}_{t}\), the corresponding linear, logarithmic, or power trend \({a}_{trend}\left(t\right)\) represented by the data series \({a}_{t,trend}\) and providing the highest coefficient of determination \({R}_{{a}_{t}{a}_{t,trend}}^{2}\) (or R2) was found by the direct search method. Thus, each forecasted parameter \({a}_{trend}\) with its trend data series \({a}_{t,trend} \mathrm{}\) forms the corresponding trend function \({a}_{trend}\left(t\right)\):

where Atrend is the set of the forecasted project parameters.

Typical groups of parameters in accordance with their trend functions and trend function coefficients \(({ k}_{a,trend}\) and \({b}_{a,trend}\)) were identified as the corresponding parameter subsets A1, A2, A3, A4, A5, and A6.

Such parameters as the risk adjustment coefficient, numerical characteristics of technological operations, biogas equipment, lands, and others are assumed to remain unchanged throughout the project period. They were described by the corresponding horizontal linear trends with \({R}_{{a}_{t}{a}_{t,trend}}^{2}\) equal to 1; e.g., the data series of the volume of a fermenter and the corresponding linear trend are shown in Fig. 1. Parameters described by horizontal linear trends with \({R}_{{a}_{t}{a}_{t,trend}}^{2}\) equal to 1 were defined as a subset of parameters A1, and their trends are described by the formula:

where \({k}_{a,trend}=0\).

Other parameter values have fluctuations of different amplitude regardless of the type of trend chosen for them. Since such parameters as AD outputs of substrates as biogas outputs, digestate outputs, in-digestate chemical outputs, and others remain unchanged for the complete project period but have fluctuations, they were described by the corresponding horizontal linear trends but with \({R}_{{a}_{t}{a}_{t,trend}}^{2}<1\); e.g., the data series of biogas output of manure with their trends are presented in Fig. 1. These parameters were defined as a subset of parameters A2. Trends of these parameters are described by the formula:

where \({k}_{a,trend}=0\)

At the same time, it can be seen that most of the values of the parameters related to crop yields, outputs of animal products, and prices show a relatively uniform growth, despite the fluctuations caused by specific factors (s. Table A2, supplementary material). While these small fluctuations of amplitude are caused by random factors, the relatively intensive fluctuations usually occur simultaneously and are connected with sudden force majeure circumstances affecting agriculture as a whole, e.g., the heat wave, drought, and fires that occurred in Russia in the summer of 2010 that caused a considerable decrease in yields of all agricultural crops in that year [25]. Nevertheless, most of the numerical characteristics of yields as well as prices can be described using a linear or logarithmic trend with middle or high \({R}_{{a}_{t}{a}_{t,trend}}^{2}\) (s. Table A2, supplementary material); e.g., the data series of electricity price with its linear trend and winter wheat price with its logarithmic trend are presented in Fig. 1.

Parameters with data series described by linear trends with \({k}_{a,trend}>0\) are defined as parameter subset A3, and their trends are described by the formula:

where \({k}_{a,trend}>0\)

Parameters with data series described by logarithmic trends with \({k}_{a,trend}>0\) and \({R}_{{a}_{t}{a}_{t,trend}}^{2}<1\) are defined as parameter subset A4, and their trends are estimated as:

where \({k}_{a,trend}>0\).

However, the most contradictory parameters are the inflation and key rates. These parameters do not directly affect production, and their values “behave” less predictably if looking back over the last 10 years. On one hand, the more long-term the forecast perspective, the less accurate the forecast, while on the other hand, the more long-term the forecast retrospective, the more accurate the prediction. In practice, the ideal comprehensive forecasting for the economy of a region or country meets such barriers as possible sudden political and economic crises, wars, droughts, changes in political leadership, environmental disasters, disappearance of important resources (e.g., fertilizers or crop protection agent) from the market, and other force majeures. However, based on the smooth evolutionary development of agricultural production, it can be assumed that, relying on linear, logarithmic, and power trends, minimizing the impact of “artificial” factors and/or force majeures, it is still possible to make a forecast that offers orientation to the farmers and municipalities for the situations when serious crises in farm production are not expected. Since the fluctuations of the inflation and key rates are largely related to the economic and political situation in the country, as well as the political decisions made by officials, it can be assumed that these parameters have a largely artificial origin. Thus, the forecasting accuracy for these parameters can be improved by matching the taken retrospective with political changes in the country. The 10-year retrospective does not reflect the political changes and the fluctuations connected with them. However, since the new political team replaced the previous one in 2000 and has been implementing its plans since that year, it is useful to look back since then. It allowed obtaining higher \({R}_{{a}_{t}{a}_{t,trend}}^{2}\) within trend constructing for these parameters (s. Fig A1, supplementary material).

Therefore, it is assumed to apply the logarithmic trend for the inflation rate forecasting (Fig. 1), and its \({a}_{trend}\left(t\right)\) is estimated as the following:

where \({k}_{a,trend}<0\).

As well it is assumed to apply the power trend for the key rate forecasting (Fig. 1), and its \({a}_{trend}\left(t\right)\) is estimated as the following:

where \({k}_{a,trend}>0\) and \({c}_{a,trend}<0\).

Thus, this study assumes an evolutionary development of the farm production and economy, as also taking into account the economy of the region and the country. In order to “bypass” any sudden critical impacts of numerous factors, as well as force majeures that may affect the project, it is proposed to use linear, logarithmic, and power trends for predicting parameter values to reflect the assumed evolutionary development of the farm. Examples of the project parameters with the typical trends are presented in Fig. 1.

Input parameters sorted by their subsets are presented in Table 1 with corresponding references, in particular, to the tables in the supplementary material (SI) of this paper and SI of [20]. The a priori dynamic simulation model for biogas project efficiency maximization was calculated using the forecasted values of the described parameters according to the method described in [20].

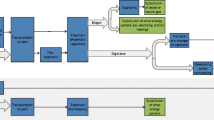

Risk Analysis

In reality, most of the parameter value fluctuations can be monitored and registered only when the year production cycle is finished and all the farm production results are summed up — at the end of each year. Moreover, no farmer would change the whole production structure during the year because of not considerable fluctuations. The only cases that require such radical solutions are force majeure events such as strong drought, fires, or other disasters. Since this study considers the evolutionary development of the farm production and neglects existing severe crises in farm production and regional economy, the posterior dynamic model was used to reveal and assess the risks of the biogas project. Posterior dynamic modeling allows to simulate the changes and fluctuations that can be monitored and registered only at the end of each year and to model standard behavior of the farm taking into account these fluctuations. Therefore, the farm production structure was calculated within the a priori modeling by SM and LPM to evaluate the biogas project itself. Then, SA and MCS were conducted within the posterior modeling by SM methods only.

The posterior analysis implies modeling a “compensatory mechanism” reflecting the behavior of the farm when the value of an input parameter changes; e.g., if the yield of a commodity crop increases, this crop should be sold on the market, which increases the revenue of the farm proportionally, with all the consequences for the project. Or, if yields of fodder crops decrease, the missing fodder crop should be purchased on the market to feed animals in accordance with the farm standards. Or, if a price of a resource changes, it should affect the project cash flows, etc.

Thus, considering the time factor, the project described by a static model in [20] turned into a project described by a flexible dynamic simulation model “reacting” to any changes in parameter values. Improving the accuracy of the farm production plan by means of forecasting input parameters, the dynamic model provides not only better planning of biogas production but takes into account the specifics of Russian farming more realistically.

Parameters of the dynamic model change over time and have fluctuations, which offers the possibility to conduct both SA and the MCS.

Some parameters like prices or capacities of biogas production equipment, energy prices, and other factors influence the project directly. Also, some parameters like prices of common products and application rates of mineral fertilizers influence the farm in general — they change the NPV value of the project but do not reflect the sensitivity of the biogas project. Thus, SA was realized for the parameters influencing the project directly to investigate the sensitivity of the biogas project itself.

The MCS allows to define the “behavior” of the project and the value of its indicators in accordance with the “behavior” of all parameters that change and fluctuate over time. Therefore, MCS was carried out for all the parameters that show variations and affect the farm and the biogas project, in order to investigate the “behavior” of the project NPV value, taking into account all the influencing factors.

Sensitivity Analysis

SA allows to estimate the influence of each parameter and shows how the value of the result indicator will change if each parameter changes separately by a definite value.

To evaluate the influence of each factor (i.e., parameter) influencing the project directly, the corresponding parameters were selected (Table 1) and SA was realized. Elasticity coefficients \({E}_{{ b}_{a,trend}}\) were calculated for \({b}_{a,trend}\) for each parameter by the formula:

where \({NPV}_{0}\) is the base value of NPV, and \({NPV}_{{ b}_{a,trend}}\) is the value of NPV when \({b}_{a,trend}\) changes by ± 1% from its base value.

Monte Carlo Simulation

To evaluate risks connected with fluctuations of all the parameters having \({R}_{{a}_{t}{a}_{t,trend}}^{2}<1\), the corresponding parameters were selected (Table 1) and MCS was realized. The dynamics of values of each project parameter can be described by a trend and each parameter value has its difference from its trend value. Difference of the project parameter value from its trend value \(\Delta {a}_{t}\) in year t is estimated as:

Differences between the factual parameter values and its trend values are assumed to be random within the normal distribution:

To realize MCS, 1000 sets of each project input parameter \({a}_{t}\) were generated through \(\overline{\Delta {a }_{t}}\) and \({\sigma }_{\Delta {a}_{t}}^{2}\) by the random number generator within normal distribution, and each set of input parameters was used in the dynamic posterior model to calculate the corresponding NPV. The set of calculated NPV was described by the corresponding probability distribution function (PDF).

\(\Delta {a}_{t}\) and \(\overline{\Delta {a }_{t}}\) were calculated using factual data series of each parameter having fluctuations.

Parameters from the subset A1 have no fluctuations; therefore, they are assumed to be constant. For each parameter from the subset A2, minimal and maximal values are known. The standard deviation of differences between the factual parameter values and their trend values was calculated by the formula [24]:

where q(p) is the quantile value for probability p equal to 5% with \(\Delta {a}_{t}\) < q, and \(\phi_{sn}^{-1}\left(p\right)\) is the inverse function of f(x) for the standard normal distribution. The formula to calculate σ through quantile q(p) was taken from [24] and adapted to the tasks of this paper.

The inverse function of f(x) is as follows [24]:

For each parameter from the subsets A3 and A4, the standard deviation of differences between the factual parameter values and its trend values was calculated by the formula:

where qT is the number of years the input data series were collected for.

Input parameters used for MCS as having fluctuations are presented in Table 1.

Input Parameters

Scenarios

During the consultations and interviews with the farmer and his assistants, it was revealed that the farmers are not always ready to use fodder and commodity crops to produce biogas due to the risks connected with the application of the new technology.

The novelty of the unproven AD technology, high capital costs, and a typical agricultural inertia make farmers wary of innovations related to biogas projects and fear losing existing sales channels for conventional crops. Furthermore, because biogas production may require the farmer or municipalities to use food products or fodders (e.g., wheat or maize silage) that are not for their intended purpose, the farmer or municipalities should align the idea of biogas production with the federal or regional food security strategy.

One the other side, despite discussions in political circles to introduce and the use of a “green tariff” for green energy producers, in practice, such a tariff is not used, and the amount of electricity generated using renewable energy sources (except of hydroelectric power plants) is not considered significant. Moreover, doubts about the profitability of “green” energy production make discussions about biogas projects less popular. The widespread inability to sell the generated electricity to the common power grid in Russia makes such projects questionable among potential beneficiaries. In addition, the lack of confirmation of the profitability of such projects does not motivate municipalities to support biogas projects.

The variety of substrates in the substrate blend, as well as the ability to sell electricity to the common power grid, affects volumes of AD products including energies and biofertilizers. Also, the more “freedom” the optimization model has, the more profitable the AD production that can be achieved by optimization, and the larger the scale that the project achieves. Thus, the scale of the project in this study is determined on one side by the size and structure of AD production and on the other by the project profitability of the biogas project (and hence NPV value). Therefore, to investigate the effects of the biogas project and its risks connected with these questions, it was decided to calculate and describe the project within 4 scenarios. Two of the scenarios were investigated in [20]: (a) there is no possibility to sell the produced electricity to the power grid, so the demand for the produced electricity is limited by the needs of the farm and equals 885 MWh and (b) the production and selling of electricity produced by AD are not limited by the demand — the produced electricity can be completely sold to the power grid. These scenarios were analyzed in this study through the perspective of two substrate combinations: (1) wastes only (cattle manure + cereal straw) and (2) wastes with maize silage and cereal grain. Therefore:

-

In Scenario 1a, only cattle manure and cereal straw are used as substrates, and electricity production is limited by the farmer’s needs

-

In Scenario 1b, only cattle manure and cereal straw are used as substrates, and electricity production is not limited

-

In Scenario 2a, cattle manure, cereal straw, maize silage, and cereal grains are used as substrates, and electricity production is limited by the farmer’s needs

-

In Scenario 2b, cattle manure, cereal straw, maize silage, and cereal grain are used as substrates, and electricity production is not limited

To solve linear models for all the scenarios, the engine COIN-OR CBC (linear solver) of Open Solver for Excel described in [26, 27] was used.

Results

Project Efficiency Maximization Procedure

The a priori dynamic simulation model for biogas project efficiency maximization was calculated using the LP method and the input parameters presented by the corresponding trends. The calculated variables are presented by corresponding data series described by the corresponding linear, logarithmic, and power trends with their coefficients \({k}_{x,trend}^{opt}\), \({b}_{x,trend}^{opt}\), and \({c}_{x,trend}^{opt}\). Approaches to evaluating the biogas project with constant parameters in the static model and with non-constant parameters in the dynamic model were compared. The comparison of these two approaches to evaluate the project has shown that the dynamic model provides much more positive results. As the dynamic model takes into account not only constant parameters but also their dynamic and general tendencies, it is assumed that from this point of view, the dynamic approach is closer to reality. The NPV values calculated for Scenarios 2a and 2b in this study were equal to 89.17 and 186.68 M RUB, which is much better than the values for the same indicators in the Scenarios A and B calculated for the static model (36.22 M RUB in Scenario A and 96.36 M RUB in Scenario B accordingly [20]).

In this study, the comparison of the NPV values of the scenarios shows that the variety of substrates and the ability to sell all the electricity produced to the common power grid have a positive effect on the project efficiency. Moreover, the results show that using cereal grain as a substrate makes the project much more profitable because of the more effective use of grain. The NPV of the project in Scenario 2a, where grain is used as a substrate, is 3.03 times higher than the NPV of the project in Scenario 1a where grain is not used as a substrate (Table 2) while the amount of energy produced in these scenarios is the same (Table 3).

The values of the project indicators, volumes of biogas production, and energy production and substrate blend inputs and outputs are presented below (Tables 2, 3, and 4).

The volume and structure of the substrate blend are constant for each year of the project; therefore, the volumes of biogas and energy produced by the farm are also stable for each year of the project and described by linear trends with \({k}_{x,trend}^{opt}=0\) in each scenario. Therefore, coefficients \({b}_{x,trend}^{opt}\) of the linear trends describing the production of energy are presented in Table 3.

The optimal substrate blend structure was defined by the simulation model for substrate blend optimization within the project efficiency maximization procedure. It is also assumed that the structure of the substrate blend is stable for the project in each year. Thus, it is described by linear trends with \({k}_{x,trend}^{opt}=0\) in each scenario as well. Therefore, coefficients \({b}_{x,trend}^{opt}\) of the linear trends describing substrate blend inputs and outputs in corresponding units per t of substrate blend are presented in Table 4.

The fertilizing plan, cost plan, and farm production plan were optimized by the simulation model for biogas project efficiency maximization. The fertilizing plan for each year was calculated by the LP model for fertilizing plan optimization in dependence on the fertilizing plan of the previous year. The prices of mineral fertilizers have their own dynamics. Moreover, the model takes into account quantities of N, P2O5, and K2O not only from mineral fertilizers but also from organic fertilizers produced by the AD. Trend values of each crop yield were set to the simulation models with trends of mineral fertilizer application rates needed to meet the crop nutritional requirements. The application rates of organic fertilizers for hoed crops (maize and sunflower) are the same each year of the project, as the maximum application rates are fixed. The cost plan depends directly on the prices of all the resources used for crop and animal production as well as on the fertilizing plan. The substrate mixture structure, in turn, influences the fertilizing plan by the content of N, P2O5, and K2O in the digestate. Therefore, trends of costs have stable positive dynamics for all the period of the project.

Risk Analysis

Sensitivity Analysis

The parameters are divided into 3 conditional groups: parameters influencing the capital costs of the project such as prices of equipment and installation work (group 1), parameters influencing operational incomes and costs such as biogas outputs, in-digestate outputs of chemicals, prices of producing energy, and capacities of biogas equipment (group 2), and parameters of the project environment such as risk adjustment coefficient, key rate, and inflation rate (group 3).

Moreover, in accordance with the results of optimization, each scenario has its own combination of CHPPs (s. Table A4, supplementary material), and each scenario has its own substrate mix (Table 4). This fact should be taken into account while comparing the elasticity coefficient values of the parameters connected with these CHPPs and substrates in SA — zero value of elasticity coefficients connected with biogas equipment and substrates can be connected to the absence of one or more specific CHPPs or substrates in a scenario.

For each group, the parameters with elasticity coefficient values (≥ 0.01%) were ranked for Scenario 1a in descending order. The elasticity coefficient values of the same parameters for the other scenarios were compared with those of Scenario 1a by “tornado” graphs (Fig. 2). The full set of elasticity coefficient values for all scenarios in numerical values is presented in the supplementary material (s. Table A5).

SA has shown that the larger the project scale the less sensitive is the project to the influence of factors, and the thinner is the “tornado” graph in general.

In scenarios with lower NPV values, the project is more susceptible to the capital costs of the biogas equipment. This can be judged by the values of elasticity coefficients of parameters that are strongly connected with the capital costs of equipment that is used in all scenarios. These parameters are as follows: price of plant and equipment for one additional fermenter, price of building for one BGP without fermenters, price of plant and equipment for one BGP without fermenters, price of building for one additional fermenter, and prices of CHPP.

Thus, the parameters associated with the capital costs of a biogas project have a significant impact on the project itself when it is implemented on a small scale, and, therefore, this impact should be taken into account when choosing equipment for the implementation of such a project.

At the same time in scenarios with higher NPV values (Table 2), the project has a larger scale of production. This makes the project more susceptible to parameters connected to operating incomes and costs such as biogas consumption of CHPPs, nominal electricity power of CHPs, biogas outputs of substrates, in-digestate contents of chemicals, and capacities of equipment; e.g., if the price of electricity increases/decreases by 1%, the NPV value of the project increases/decreases by 0.44% in Scenario 1a and by 0.35% in Scenario 1b. Therefore, when the scale of the project is relatively small, the influence of this parameter is considerable in comparison with other parameters. In addition, when comparing Scenarios 1a and 1b, the influence of this parameter decreases but not as much as the influence of other parameters — the larger the project scale, the greater the impact of parameters related to operating incomes and costs on the project compared to other parameters. Thus, when the scale of the project is relatively large, the NPV value of the project increases/decreases by 0.15% and 0.20% accordingly, if the value of electricity price increases/decreases by 1% in Scenarios 2a and 2b. The influence of this parameter became considerably smaller in Scenarios 2a and 2b compared to Scenarios 1a and 1b but increases in Scenario 2b compared to Scenario 2a. The same tendencies are revealed for the content of chemicals in the digestate of manure, biogas output of winter wheat, and others.

Nevertheless, from scenario to scenario, the scale of the project increases so significantly that the influence of those parameters related to the operating costs and revenues becomes less and less noticeable compared to the influence of other factors, especially if these parameters are not very influential in general (e.g., price of heat).

Therefore, since the project turns out to be more sensitive to parameters related to operating costs and revenues, it is important to take this into account when choosing substrates for the implementation of large-scale projects.

SA has shown that the most influential factors are those that influence the discount factor of the project: risk adjustment coefficient, key rate, and inflation rate. However, the larger scale the project has, the less it is influenced by these factors compared to other scenarios. At the same time, the influence of these factors is relatively strong compared to other factors in each scenario. Discount factor affects the cash flows of the project regardless of other factors like outputs of products or capital costs. Therefore, the risk adjustment coefficient, key rate, and inflation rate influence the project crucially. Since these factors are closely related to regional peculiarities and to the peculiarities of agriculture in different regions and countries, the fact that they have a strong influence on the project should be taken into account when planning the production of biogas in different locations.

Monte Carlo Simulation

The MCS was realized by using 1000 statistical probes to simulate the “behavior” of the project within each probe. PDF curves of NPV are presented in Fig. 3. Measures of NPV variability calculated by MCS are presented in the supplementary material (Table A3).

The main factors influencing the project in different scenarios are the variety of substrates and the ability to sell electricity to the common power grid. The fewer constraints on these factors the project has, the more profitable it is and the more the NPV probability distribution function curve moves to the right.

The results of MCS have shown that Scenarios 1b and 2b, where the farm has the ability to sell all of the produced energy to the common power grid, are generally more attractive than Scenarios 1a and 2a correspondingly. In particular, the value of the most probable NPV (mean value) is higher in Scenarios 1b and 2b (55.03 and 185.75 M RUB accordingly) than in Scenarios 1a and 2a (28.43 and 90.53 M RUB respectively), and the curves are located more to the right of the graph. Besides, most of the values are located on the right side from the y-axis in all scenarios but the probability to get a higher NPV in Scenarios 1b and 2b is much higher than in Scenarios 1a and 2a. However, the factor of substrate blend diversification is much stronger than the factor of being able to sell electricity to the common power grid. It is caused by using cereal grain to produce biogas and other AD products that make cereal grain more profitable.

In Scenarios 1b and 2b, the probability to get a maximum NPV is higher than in Scenarios 1a and 2a because the maximal available NPV is equal to 88.36 and 240.18 M RUB in Scenarios 1b and 2b correspondingly, while in Scenarios 1a and 2a, the maximal available NPV is equal only to 50.42 and 111.22 M RUB, accordingly. Moreover, as the ranges and dispersions in Scenarios 1b and 2b are higher, the PDF curves are more “stretched” there than in Scenarios 1a and 2a. Referring to the range and dispersions, the following distribution among the scenarios exists: the ranges and dispersions in Scenarios 1b and 2b have higher values than in Scenarios 1a and 2a, respectively. However, the more factors that influence the project and the more variability they have, the more “stretched” PDF curve is and the less predictable is the NPV.

On one hand, the Monte Carlo analysis indicates a high probability of a profitable project with a high NPV. The more “freedom” the farmer has regarding the variety of substrates for AD and the ability to sell electricity on the market, the more stable and profitable the biogas project is. On the other hand, the main economic risks associated with the biogas project in this study referring to MCS are associated with the probability of an unprofitable project. The AD project is closely linked to biogas and digestate outputs, which means that pre-project AD experiments must be conducted with various substrates that can be produced at the exact location of the future biogas project. Simulation modeling gives “guide values” for the whole project; however, the lack of practical data referring to the biogas and digestate outputs of specific substrates in a specific region can be a reason for high project risks.

In this regard, the biogas and digestate outputs are not high, the graphs in Fig. 3 will “shift” to the left, and overall risks connected with fluctuations of non-constant parameters will be considerable, especially for Scenario 1a, particularly from the view of sustainable development. If the probability of a negative project NPV value is above zero, there will be a risk of losing investments that could be used to extend the production of the farm. This poses the risk that people will not find work due to the lack of production expansion. In addition, there is the risk that the project is not profitable and the implementation is suddenly terminated. There is therefore a risk that customers with whom corresponding contracts could have been concluded in advance will not be supplied with electricity. Areas that could be fertilized with slurry used for AD production are not fertilized with biofertilizer, or this biofertilizer has to be purchased from outside, resulting in economic losses for the farmer. The crop rotation system and the herd structure will be disrupted and their restoration may take a significant period of time, which may also be associated with economic losses.

Furthermore, this project was designed for a long enough period and a sudden force majeure can occur in any year of the project. Being a sudden event for a Russian farmer with a large number of obligations to banks and the state, any force majeure may be critical. Therefore, the results of MCS can be used by farmers and municipalities as a “guide” within the assumption that critical force majeures are not expected and numerous pre-project experiments should have been fulfilled.

Discussion

Despite the fact that risk analysis in relation to renewable energy sources is a popular topic for research and the Monte Carlo analysis is used in relation to the study of renewable energy production [21,22,23,24], scientific works describing the application of WFM, SM, LPM, PEM, SA, MCS, and a scenario analysis in combination to evaluate biogas projects and risks connected with AD production is scarce in scientific databases. The authors of this study propose an approach to solve this problem by “bypassing” the problems associated with nonlinearity and the approach in this work is based on the research in [20] including linear programming for optimization.

The approach presented in the study used linear optimization methods; however, some relationships within the project itself are nonlinear; e.g., the NPV calculation formula uses a nonlinear dependence on the discount rate, which in turn has a nonlinear dependence on the inflation and key rate. In addition, despite the fact that the design of this model assumes the use of corresponding trends in describing the behavior of the main parameters, it should also be taken into account that such parameters like inflation rate, key rate, and risk adjustment coefficient, being an instrument of the state regulation of the economy, may largely have an artificial origin. Therefore, in order to exclude the sudden influence of largely artificial factors from the study, the authors considered corresponding trends in relation to the dynamics of these parameters. In addition, the sensitivity analysis shows that the parameters governing the project environment, which directly affect the discount rate, have a significant impact on the profitability of the project. Therefore, it must be taken into account that the differences in these indicators at different locations can be crucial for the profitability of the AD project. Using corresponding trends for forecasting allows balancing between the necessity to neutralize random and sudden changes in the economy, as well as the influence of those factors that are mostly of “artificial” origin. Nevertheless, at the same time, this approach makes it possible to simulate the evolutionary development of the economy in the most accessible way. In addition, forecasting makes it possible to use MCS for risk assessment. MCS, in turn, offers significant substantive and methodological advantages over the conventional NPV assessment or SA application, confirming the assumption stated in [24] that the MCS application helps to optimize the investment project evaluation approaches in terms of return on capital and risk. However, both SA and MCS were realized in this study. On the one hand, SA allowed to define that the price of plant and equipment of one additional fermenter is the most impactful parameter among those other parameters influencing the capital costs of the project. Results of SA also have shown that the biogas output of the main substrate (i.e., of manure) influences the NPV of the project mostly in comparison with other parameters that are connected with operational costs and incomes. The key rate was revealed as the most influential factor of the project environment by SA as well. Thus, SA gives an ability to investigate project parameters separately. On the other hand, MCS allows to assess the risks that are connected with the project input parameter value dynamics through the prism of PDF of NPV values and by comparison of the scenarios that were set for the modeling. Thus, SA and MCS are considered to be effective methods of RA when they are used in complex and when the project is evaluated within several scenarios.

AD projects are closely connected with the sustainable development of the regions where biogas production is initiated. Biogas projects can have a positive influence on the economy and ecology of rural areas; it also has a positive social impact in those locations where biogas projects are implemented. Although in many countries biogas production is used as a comprehensive solution to problems related to the sustainable development of regions [15,16,17,18,19], Russian authorities and municipalities have so far ignored these advantages of biogas project implementation. Despite numerous laws issued by the Russian authorities [2,3,4,5,6,7,8,9,10,11,12,13,14], biogas and other renewable energy sources (except hydroelectric power plants) are not used as a tool to solve the problems of sustainable development in the regions [1]. However, this study is both to increase the interest of potential beneficiaries in biogas production and to offer the approach to reveal and assess the risks connected with biogas projects.

Conclusion

The dynamic model of the biogas project was elaborated and its attractiveness was measured by standard PEM. Comparing the dynamic and static models using PEM indicators, it has been shown that the dynamic model gives better results and the project modeled according to the dynamic approach is more attractive for potential beneficiaries.

The simulation model to maximize the efficiency of the biogas project described in [20] was applied to solve the problem within the dynamic model. Project NPV was taken as the objective function for maximization. Despite the non-LP elements connected with calculating the discount rate inside the project design itself, the mathematical problems were solved by LP methods. The parameters of the project were classified by their “behavior” and predictability. They were divided into six groups in accordance with their dynamics and fluctuations. On the basis of this classification, RA including SA and MCS was realized. To realize SA, the elasticity coefficients for the selected input project parameters were calculated, ranked, and placed on the “tornado” graphs in accordance with their values. MCS was performed to define the PDF of the project NPV values based on 1000 probes.

Results were calculated for four scenarios. In Scenario 1a, only cattle manure and cereal straw are used as substrates, and electricity production is limited by the farmer’s needs. In Scenario 1b, only cattle manure and cereal straw are used as substrates, and electricity production is not limited. In Scenario 2a, cattle manure, cereal straw, maize silage, and cereal grain are used as substrates, and electricity production is limited by the farmer’s needs. In Scenario 2b, cattle manure, cereal straw, maize silage, and cereal grain are used as substrates, and electricity production is not limited. Opportunities to sell electricity on the market diversification of the substrate mixtures determined the project scale, profitability, and risks associated with the production of biogas in these scenarios. NPV values of the project are equal to 29.45, 56.50, 89.17, and 186.68 M RUB in Scenarios 1a, 1b, 2a, and 2b, correspondingly. Although the values of the variables are meant as a “guideline,” the dynamic model is assumed to be more precise and allows for a more realistic description. All of this depends on the precision of the input data and the trends used to describe the input data. The results show that the larger the project scale, the more economically attractive it is for investments.

For SA, parameters influencing the project itself were selected as other parameters affect the project indirectly and also may change the NPV value without influencing the project itself (e.g., the price of milk may have a nonzero elasticity coefficient but does not make sense for the project sensitivity analysis). SA results have shown that the project has a set of parameters that influence it considerably. The higher the profitability of the project, the larger its scale, and the less sensitive the biogas project is to changes in each single parameter value. The parameters influencing capital costs affect a small-scale biogas project more, while the parameters that affect operating costs and revenues have a significant impact on a large-scale biogas project compared to other parameters. However, their impact also decreases in general with an increase in the project scale. The parameters associated with the project environment have a significant impact on the project as a whole but also decrease in importance as the size of the project increases.

The MCS approach perfectly shows the risks associated with the fluctuations of the parameter values. This method provides calculating the probability of obtaining a project with an NPV value below zero, equal to zero, and above zero. In this study, MCS has shown that there is no probability of obtaining a NPV value below zero. However, SA and MCS cannot assess the risks associated with the project scale. To solve this problem, the scenario analysis was used, which made it possible to assess the risks connected with the size and structure (and hence the scale) of the farm production. MCS shows that the probability to get a positive project result is quite high. The probability to get a higher NPV value increases when the project scale becomes larger. However, the farmers should also consider the factors that may affect the project and reduce the likelihood that the project will be profitable. Risks that may be related to force majeure should also be considered outside the framework of SA and MCS.

The proposed methodology is universal and can be applied to any agricultural organization and has no serious limitations. Nevertheless, the application of dynamic modeling of the biogas project challenges the users of SA and MCS methods to obtain complete and sufficiently accurate data on the parameters set in the model.

The innovativeness of this work is due to the application of WFM, SM, LPM, PEM, SA, MCS, and scenario analysis in combination. Despite the large number of published scientific papers in Russia and in the world concerning biogas production, evaluating the effectiveness of biogas projects, different methods are used separately. In this paper, the authors propose to combine all of the above methods into a single approach for a comprehensive study of biogas projects and their risks.

However, as the authors of this study are faced with numerous issues associated with the dynamic modeling of farm production in the context of evaluating the biogas project, other issues connected with the related problems have also been raised and represent targets for further research.

The different specializations of farms indicate the necessity to investigate the possibility of biogas production using various substrates in connection with the federal production security strategy. This problem, which is closely related to the issue of the use of first- and second-generation biofuels, is the target for the further studies in the scenario analysis. From the point of view of the parameters of the project environment, it is also advisable to analyze scenarios in terms of different values of the risk adjustment coefficient, inflation rate, and key interest rate for different locations and through the prism of the most likely political scenarios.

Many farms trade with other organizations and production chains connected with the AD production play an important role in the farm’s profitability. Thus, biogas multi-projects and their risks for several farms acting as beneficiaries are also the target for the future studies.

And finally, the factors influencing biogas projects are closely connected with fluctuating and dynamic parameters. The precision of parameter forecasting plays an important role within the dynamic modeling of the biogas project. Therefore, the uncertainty due to fluctuations in parameter values is also the object of further investigations.

Data Availability

All data generated or analyzed in the study is included in this published article.

Code Availability

Not applicable.

Abbreviations

- AD:

-

Anaerobic digestion

- CHPP:

-

Combined heat and power plant

- DF:

-

Distribution function

- IRR:

-

Internal rate of return

- LP:

-

Linear programing

- LPM:

-

Linear programing model/modeling

- MCM:

-

Monte Carlo method

- MCS:

-

Monte Carlo simulation

- NPV:

-

Net present value

- PBP:

-

Payback period

- PDF:

-

Probability distribution function

- PEM:

-

Project evaluation methods

- PI:

-

Profitability index

- RA:

-

Risk analysis

- SA:

-

Sensitivity analysis

- SI:

-

Supplementary information/material

- SM:

-

Simulation model/modeling

- WFM:

-

Whole farm modeling

References

Pristupa AO, Mol APJ (2015) Renewable energy in Russia: the take off in solid bioenergy? Renew Sustain Energy Rev 50:315–324. https://doi.org/10.1016/J.RSER.2015.04.183

Russian Government (2014) Decree No. 321 on approval of the State Program on Energy Efficiency and Energy Development (in Russian). http://www.rg.ru/2014/04/24/energetika-site-dok.html. Accessed 10 Oct 2019

Russian Government (2012) Decree No. 1839-p on approval of range of measures stimulation electricity production by generator operating with renewable energy (in Russian). http://www.consultant.ru/document/cons_doc_LAW_136181/. Accessed 10 Oct 2019

Russian Government (2007) Federal Law No. 250-FZ on amendments in certain legislative acts of the Russian Federation in connection with implementation of reform measures of the Unified Energy System (in Russian). http://www.consultant.ru/document/cons_doc_LAW_200559/. Accessed 10 Oct 2019

Russian Government (2003) Order No. 187 on procedure of roster management of issue and repayment of certificates confirming volumes of electricity production on the qualified generators operating with renewable energy (in Russian). https://minenergo.gov.ru/node/10373. Accessed 10 Oct 2019

Russian Government (2003) Federal Law No. 35-FZ on electric power industry (in Russian). http://www.rg.ru/2008/08/26/elektroenergetika-dok.html#maindocs. Accessed 10 Oct 2019

Russian Government (2012) Decree No. 1853p-P8 on approval of the Integrated Program of biotechnology development in the Russian Federation for the period up to 2020 (in Russian). http://www.rg.ru/pril/83/76/16/1247_plan.pdf. Accessed 10 Oct 2019

Russian Government (2011) Decree No. 2227-p on Innovation Development Strategy (in Russian). https://rg.ru/2012/01/03/innov-razvitie-site-dok.html. Accessed 10 Oct 2019

Russian Government (2010) Decree No. 2446-r on approval of the State Program of the Russian Federation for energy saving and energy efficiency (in Russian). http://www.rg.ru/2011/01/25/energosberejenie-site-dok.html. Accessed 10 Oct 2019

Russian Government (2009) Decree No. 1715-r on approval of the Energy Strategy of Russia for the period up to 2030 (in Russian). http://www.rg.ru/2011/10/17/ural-site-dok.html. Accessed 10 Oct 2019

Russian Government (2009) Decree No. 1-p on main directions of the state policy in sphere of energy efficiency increasing on the basement of renewables for the period until 2020 (in Russian). http://www.consultant.ru/document/cons_doc_LAW_83805/. Accessed 10 Oct 2019

Russian Government (2009) Energy Strategy of Russia for the period up to 2030. Approved by the Governmental provision No. 1234 -p. on 28 August 2003 (in Russian). https://minenergo.gov.ru/node/1026. Accessed 10 Oct 2019

Russian Government (2009) Federal Law No. 261-FZ on energy saving and increasing energy efficiency (in Russian). http://www.rg.ru/2009/11/27/energo-dok.html. Accessed 10 Oct 2019

Russian Government (2008) Decree No. 426 on qualification of generator operating with renewable energy (in Russian). http://www.consultant.ru/document/cons_doc_LAW_77391/. Accessed 10 Oct 2019

Ebadollahi M, Amidpour M, Pourali O, Ghaebi H (2022) Flexibility concept in design of advanced multi-energy carrier systems driven by biogas fuel for sustainable development. Sustain Cities Soc 86:104121. https://doi.org/10.1016/J.SCS.2022.104121

Aggarwal RK, Chandel SS, Yadav P, Khosla A (2021) Perspective of new innovative biogas technology policy implementation for sustainable development in India. Energy Policy 159:112666. https://doi.org/10.1016/J.ENPOL.2021.112666

Cudjoe D, Zhu B, Wang H (2022) Towards the realization of sustainable development goals: benefits of hydrogen from biogas using food waste in China. J Clean Prod 360:132. https://doi.org/10.1016/J.JCLEPRO.2022.132161

Obaideen K, Abdelkareem MA, Wilberforce T et al (2022) Biogas role in achievement of the sustainable development goals: evaluation, challenges, and guidelines. J Taiwan Inst Chem Eng 131:104. https://doi.org/10.1016/J.JTICE.2022.104207

Ahmad M, Wu Y (2022) Household-based factors affecting uptake of biogas plants in Bangladesh: implications for sustainable development. Renew Energy 194:858–867. https://doi.org/10.1016/J.RENENE.2022.05.135

Nurgaliev T, Koshelev V, Müller J (2022) Simulation model for biogas project efficiency maximization. BioEnergy Research. https://doi.org/10.1007/s12155-022-10484-4

Di Lorenzo G, Pilidis P, Witton J, Probert D (2012) Monte-Carlo simulation of investment integrity and value for power-plants with carbon-capture. Appl Energy 98:467–478. https://doi.org/10.1016/J.APENERGY.2012.04.010

da Silva Pereira EJ, Pinho JT, Galhardo MAB, Macêdo WN (2014) Methodology of risk analysis by Monte Carlo Method applied to power generation with renewable energy. Renew Energy 69:347–355. https://doi.org/10.1016/J.RENENE.2014.03.054

Schade B, Wiesenthal T (2011) Biofuels: a model based assessment under uncertainty applying the Monte Carlo method. J Policy Model 33:92–126. https://doi.org/10.1016/j.jpolmod.2010.10.008

Arnold U, Yildiz Ö (2015) Economic risk analysis of decentralized renewable energy infrastructures – a Monte Carlo Simulation approach. Renew Energy 77:227–239. https://doi.org/10.1016/j.renene.2014.11.059

RIA (2010) Abnormally hot summer of 2010 in Russia (in Russian). https://ria.ru/20101126/297098566.html. Accessed 29 Dec 2022

Mason A (2020) About OpenSolver. https://opensolver.org/. Accessed 5 May 2020

Mason A (2012) OpenSolver - an open source add-in to solve linear and integer progammes in Excel. In: Klatte D, Lüthi H-J, Schmedders K (eds) Operations Research Proceedings 2011. Springer, Berlin, Heidelberg, Germany, pp 401–406. http://link.springer.com/10.1007/978-3-64

Acknowledgements

The authors greatly acknowledge the scholarship awarded by the EU-Program Erasmus Mundus Partnerships (Action 2) via the project IAMONET-RU, the organizational support of the program coordinators at Universität Hohenheim, and Dr. h.c. Jochem Gieraths, Dr. Angelika Thomas, and Mrs. Sabine Nugent, members of the Institute of Agricultural Engineering at the University of Hohenheim, for language editing.

Funding

Open Access funding enabled and organized by Projekt DEAL. International Academic Mobility Network with Russia (EM ECW—IAMONET-RU).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Data collection and analysis were performed by Timur Nurgaliev. The first draft of the manuscript was written by Timur Nurgaliev, and all authors commented on previous versions of the manuscript. All authors approved the final manuscript and agreed to its publication.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

No experiments with humans or animals were performed in the study. Ethical clearance was not required.

Consent for Publication

All authors agreed to publication.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nurgaliev, T., Koshelev, V. & Müller, J. Risk Analysis of the Biogas Project. Bioenerg. Res. 16, 2574–2589 (2023). https://doi.org/10.1007/s12155-023-10583-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-023-10583-w