Abstract

The pre-treatment of lignocellulose material towards cellulosic bioethanol production releases microbial inhibitors that severely limit the fermentation ability of Saccharomyces cerevisiae. This study evaluated to what degree robust xylose-capable strains may improve the fermentability of non-detoxified sugarcane bagasse (SCB) slurries derived from steam explosion (StEX) and further compared this to slurries derived from ammonia fibre expansion (AFEX) pre-treatment. Initial screening in separate hydrolyses and co-fermentation processes using StEx-SCB hydrolysates identified S. cerevisiae TP-1 and CelluXTM4 with higher xylose consumption (≥ 88%) and ethanol concentrations (≥ 50 g/L), and ethanol metabolic yields (≥89% relative to theoretical maximum), even in the presence of approximately 8 g/L of acetic acid. Under industrially relevant pre-hydrolysis simultaneous saccharification and co-fermentation (PSSCF) conditions of high solids loading (15%, w/w) and low enzyme dosage (8 mg protein per gram untreated biomass), the fermentation of StEx-treated SCB whole slurry achieved ethanol yields of 208 and 224 L per Mg raw dry SCB using S. cerevisiae TP-1 and CelluXTM4, respectively. Under the same solids loading and enzyme dosages, the PSSCF of ammonia fibre expansion (AFEXTM) pre-treated SCB achieved ethanol yields of 234 and 251 L per Mg raw dry SCB using TP-1 and CelluXTM4, respectively. The study achieved non-detoxified whole-slurry co-fermentation using StEx pre-treated SCB, with higher ethanol yields than previously reported, by utilising robust xylose-capable strains. The results of this work provide insights into the potential use of inhibitor-tolerant S. cerevisiae strains TP-1 and CelluXTM4 as ethanologens for the fermentation of steam-exploded and undetoxified SCB whole slurries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Feedstock or raw material processing is of key importance for 2G biorefineries, as maximising ethanol yields through the efficient conversion of all the available polymeric carbohydrate substrates in the feedstock is essential for improving the economic viability of prospective cellulosic biorefineries [1]. Current technologies for the biologically mediated conversion of lignocelluloses to ethanol commence with a thermochemical pre-treatment step to render the polymeric fractions embedded in the plant cell wall more accessible for enzymatic degradation [2, 3]. However, a majority of these pre-treatment technologies result in the generation of intrinsic biomass- and pre-treatment-derived degradation products, which have inhibitory effects in subsequent enzymatic hydrolysis [4] and fermentation processes [5]. Hence, for maximising ethanol yields, the fermentation of biomass-derived hexoses (i.e., glucose, mannose, and galactose) and pentoses (i.e., xylose, arabinose) in the presence of pre-treatment-derived inhibitors is one of the fundamental bottlenecks for large scale and economical cellulosic ethanol production [6, 7].

Saccharomyces cerevisiae, the most widely used microorganism in industrial sucrose and corn starch ethanol production, remains one of the leading candidate ethanologens for cellulosic ethanol production due to its general robustness and relatively high tolerance to microbial stresses such as pre-treatment inhibitors and fermentation metabolites [5]. Through rational metabolic engineering interventions, pentose (particularly xylose) fermenting capacity in S. cerevisiae has been pursued through the cloning of fungal xylose reductase and xylitol dehydrogenase (XR-XDH) or the cloning of bacterial or fungal xylose isomerase (XI) pathways into S. cerevisiae strains [8]. However, genetically engineered xylose-fermenting yeast strains generally display higher sensitivity phenotypes to stressful conditions (e.g., in the presence of high weak acid, chemical inhibitors, and ethanol concentrations), resulting in lower overall fermentation yields [9].

Steam explosion (StEx) is a mature thermochemical pre-treatment that uses water as the solvent/catalyst to overcome the recalcitrance of a wide array of lignocellulosic feedstocks. However, at industrially relevant pre-treatment conditions, StEx generates weak acids (particularly acetic acid from the deacetylation of O-acetyl groups in hemicellulose), furan aldehydes (derived from the dehydration of glucose and xylose), and phenolic compounds (from the cleavage of acid- and alkali-labile lignin-carbohydrate complexes) that are found in the resultant pre-treated slurry [10]. Among the pre-treated slurry (herein referred to as whole slurry, containing both solids and pre-treatment liquor) processing options available, the use of the whole slurry in downstream enzymatic hydrolysis and co-fermentation (utilisation of both pentoses and hexoses) both is one of the strategies considered for reducing the biorefinery capital expenditure (CAPEX) and operating expenditures (OPEX). Using whole slurries effectively avoids costs associated with solid/liquid separation, washing, reclamation of excess process water, detoxification, and salt disposal [11, 12]. The fermentation of inhibitor-laden StEx whole slurries (without detoxification) by laboratory recombinant strains such as S. cerevisiae 424A (LNH-ST) was, however, significantly limited by the synergistic action of microbial stresses such as pre-treatment-derived inhibitors and fermentation metabolites [6]. In comparison, the same recombinant strain achieved near complete xylose consumption (96%) and high ethanol yields (0.46 g ethanol/g sugars) in hydrolysates derived from pre-treatment technologies, such as ammonia fibre expansion (AFEX), that is known to generate limited amounts of microbial inhibitors [6]. It is clear that robust strains are required to “close the gap” between ethanol yields observed in fermentations utilising harsher StEx pre-treated material and that of fermentations using milder AFEX pre-treated material.

Recently, several works have reported on the successful fermentation of non-detoxified whole slurry hydrolysates derived from autohydrolysis-type pre-treatments by recombinant S. cerevisiae strains [13], demonstrating high xylose consumption (> 80%), ethanol concentrations (> 38 g/L), metabolic yields (> 78%), and overall ethanol productivities (0.57 g/L/h) [14–16]. Furthermore, Brandt et al. [17] overexpressed six genes in industrial recombinant strain S. cerevisiae CelluXTM1 to confer enhanced strain resistance to weak acid, furan aldehyde, and phenolic compound stresses. The resultant transformant strain, S. cerevisiae TP-1, demonstrated higher inhibitor resistance, detoxification, and ethanol production phenotypes relative to the parent strain in non-detoxified spent sulphite liquor [17]. These studies demonstrate the impressive advances in the development of sufficiently hardened yeast strains to support the efficient fermentation of non-detoxified whole slurry hydrolysates obtained from hydrothermal pre-treatments.

In this study, we evaluated the effect of robust yeast on the potential ethanol production from steam-exploded versus AFEX pre-treated sugarcane bagasse (SCB) using industrial S. cerevisiae strains under industrially relevant conditions (i.e., high solid loadings to achieve high ethanol concentrations). First, we evaluated the fermentability of StEx pre-treated SCB whole slurry hydrolysates using S. cerevisiae strains: TP-1, TP-50, E50, and CelluXTM4 in fermentations using separate hydrolysis and co-fermentation (SHCF) process configuration. Successively, the two best-performing yeast strains were selected and used as ethanologens to compare the fermentability of StEx-SCB whole slurry to AFEX-pre-treated SCB in a fed-batch pre-hydrolysis simultaneous saccharification and co-fermentation (PSSCF) configuration operating under industrially relevant solids loadings and enzyme dosages. Finally, mass balances from the PSSCF experiments for both StEx- and AFEX-treated SCB were developed to estimate the overall ethanol yields per tonne of untreated SCB and subsequently compared with literature-reported yields for SCB. The results of this work provide significant insights into the improvements in the overall ethanol yields from steam-exploded non-detoxified sugarcane bagasse slurries versus that of AFEX pre-treated material, facilitated by the use of efficient industrial xylose-fermenting and inhibitor-tolerant ethanologens. Therefore, the limitation of ethanol yields as a consequence of microbial inhibition from StEx-whole slurry fermentations (at the same pre-treatment severity used in this work) can be alleviated by using S. cerevisiae TP-1 and CelluXTM4.

Materials and Methods

Biomass, StEx, and AFEX Pre-Treatment

Fresh sugarcane bagasse (SCB) was collected from two local sugar mills in Malelane (Mpumalanga, South Africa) and Mount Edgecombe (Kwazulu Natal, South Africa) and prepared as previously described by Mokomele et al. [6]. The composition of untreated SCB (g/100 g DM) consisted of 39.5 ± 0.4% glucan, 25.2 ± 0.1% xylan, 1.23 ± 0.38 arabinan, 3.43 ± 0.04 acetyl, 6.02 ± 0.42 extractives, 19.4 ± 0.1% Klason lignin, and 2.9 ± 0.7% ash content. StEx pre-treatment of SCB was conducted in an automated batch pilot-scale unit (IAP GmBH, Graz, Austria) equipped with a 19-L StEx reaction vessel, a 100-L discharge vessel, and a 40-bar steam generator [18]. SCB was pre-treated at 200 °C and 10 min, with three 100 g samples of the pre-treated slurry collected and characterised in terms of the total solids (TS), water-soluble solids (WSS), water-insoluble solids (WIS), and degradation product content in the WSS. The remaining slurry was vacuum packed and stored at −20 °C and used within 7 days. Pilot-scale AFEX pre-treatment of SCB was performed in a pair of 450 L vertical packed-bed reactors at Michigan Biotechnology Institute (Lansing, MI, USA) as described by Mokomele et al. [19]. Pre-treatment conditions included ammonia to biomass loading of 0.7 g NH3/g dry biomass, water loading of 0.6 g H2O/g dry biomass, temperature range of 80–120 °C, and residence time of 60 min.

Enzymes

Commercial fungal enzyme preparations Cellic® CTec2 (138 mg protein/mL), Cellic® HTec2 (138 mg protein/mL), and Pectinex Ultra-SP (31 mg protein/mL) were used in enzymatic hydrolysis and ethanol production experiments. These enzymes were generously donated by Novozymes (Copenhagen, Denmark). The protein content for each cocktail was estimated using Kjeldahl nitrogen analysis (AOAC Method 2001.11). Combinations of CTec2, HTec2, and Pectinex Ultra-SP previously optimised by Mokomele et al. [6] for StEx-treated SCB and AFEX-treated SCB were used during enzymatic hydrolysis and fermentation.

Microbial Strains

Four industrial genetically engineered xylose-fermenting yeast strains were used to ferment StEx pre-treated SCB whole slurry hydrolysates. Recombinant strains S. cerevisiae TP-1, S. cerevisiae TP-50 and S. cerevisiae E-50, and S. cerevisiae CelluXTM4 were kindly provided by Dr. BA Brandt (full description of strains in Brandt et al. [17]) with permission from Leaf by Leasaffre (Leaf Technologies, France). S. cerevisiae TP-1 was derived from recombinant parent strain S. cerevisiae CelluXTM1 and was rationally engineered to overexpress six genes to confer increased resistance to selected weak acids, furan aldehydes, and phenolic compounds. S. cerevisiae TP-50 and S. cerevisiae E-50 are evolutionary engineered variants of S. cerevisiae TP-1 and CelluXTM1, respectively, that have been evolved over ~ 50 generations in repeated batch cultures using increasing concentrations of spent sulphite liquor as a selective pressure. The more recent S. cerevisiae CelluXTM4 is the fourth generation of the CelluXTM commercial strain collection. Stock culture aliquots of each strain were contained in 40% (v/v) glycerol and stored at −80 °C.

Inoculum Preparation

The inoculum for all fermentations was prepared using a two-step protocol to condition the yeast cells for improved fermentation performance upon exposure to inhibitor-stressed conditions [17]. Pre-seed cultures of the four industrial strains used in this work were initially cultivated from the glycerol stock cultures in test tubes containing 10 mL YPDX media (20 g/L glucose, 4 g/L xylose, 10 g/L yeast extract, 20 g/L peptone) and incubated at 30 °C and 150 rpm in a rotary shaker for 24 h. The seed culture was prepared by inoculating 1.5 g CDW/L of the pre-seed cultures into 250 mL Erlenmeyer flasks containing pre-conditioning media that was composed of 75 mL YPDX media and 25 mL of StEx pre-treatment liquor. StEx pre-treatment liquor was derived by filtering the solids from the StEx pre-treatment whole slurry. After inoculating the pre-conditioning media, the seed cultures were incubated at 30 °C and 150 rpm in an orbital shaker for 24 h. The pre-conditioned seed culture was thereafter harvested by centrifuging at 1500 × g for 10 min, and the yeast pellets were used as inoculum for whole slurry hydrolysates fermentation and PSSCF experiments.

Fermentation of StEx SCB Whole Slurry

The fermentation capability of the four selected industrial xylose-fermenting yeast strains was evaluated in two sets of experiments as shown in Fig. 1. In the first set, the fermentation capability of the four selected recombinant strains was evaluated on non-detoxified StEx-SCB whole slurry hydrolysate using a separate hydrolysis and co-fermentation (SHCF) process configuration. The performance of the strains was compared in terms of the ethanol yield, final ethanol concentration, and specific ethanol productivity. In the second set of experiments, two of the best-performing strains from the first set were subsequently used to evaluate their suitability as ethanologens for the PSSCF of non-detoxified StEx-treated SCB whole slurry and AFEX pre-treated SCB.

Experimental approach for evaluating the fermentability of StEx-treated SCB whole slurry and AFEX-treated biomass. Strains were screened using a separate hydrolysis and co-fermentation process configuration (SHCF) whereas the follow-up fermentations used a pre-hydrolysis simultaneous saccharification and co-fermentation process configuration (PSSCF)

Yeast Screening: Preparation and Fermentation of StEx-SCB Whole Slurry Hydrolysate Using Separate Hydrolysis and Co-Fermentation (SHCF) Configuration

The yeast screening used a SHCF fermentation configuration. The StEx-treated SCB whole slurry was enzymatically hydrolysed in 1000 mL baffled Erlenmeyer flasks with a working volume of 400 g at a solids loading of 15% (w/w) and an enzyme dosage of 40 mg protein/g glucan. A relatively high enzyme dosage was used to overcome the impact of the inhibitors and end-product inhibition on the activity of the hydrolytic enzymes. This enabled the production of non-detoxified enzymatic hydrolysates with relatively high sugar concentrations that are anticipated for commercial biorefineries [20]. To avoid mixing issues associated with high solids loading enzymatic hydrolysis, the whole slurry was added using a fed-batch strategy, with half the slurry added at t = 0 h and the remainder at t = 3 h. The enzymatic hydrolysis mixtures were supplemented with 50 mM potassium phosphate buffer to regulate the hydrolysis/ fermentation pH, 50 mg/L chloramphenicol to prevent bacterial contamination, and subsequently incubated at 50 °C and 180 rpm in an orbital shaker. After 72 h of hydrolysis, the hydrolysis slurry was centrifuged at 8000 × g for 30 min. The sugar-rich supernatant was supplemented with 0.5% (w/w) corn steep liquor (CSL) as nitrogen source, pH adjusted to 5.5 using 10 M KOH, before being filter sterilised through a 0.22-μm polyethersulfone filter into a sterile bottle (Millipore Stericup). The sterile whole slurry hydrolysate was refrigerated at 4 °C until use (used within 1 day).

The fermentation of the sterile StEx-SCB whole slurry hydrolysates was performed in 100 mL serum bottles with a working volume of 40 mL and incubated at 30 °C and 150 rpm in an orbital shaker. Each serum bottle was inoculated with the pre-conditioned seed culture at OD600 of 3.0 (~1.8 g CDW/L). After inoculation, serum bottles were capped with sterile butyl rubber stoppers, sealed with an aluminium crimp, and pierced with two hypodermic needles to facilitate CO2 release, sampling, and micro-aerobic fermentation conditions. Samples were withdrawn once every 24 h, and the sugar, ethanol, and furan aldehyde content of the cell-free supernatants was quantified via HPLC analysis. Each hydrolysate fermentation assay was performed in triplicate.

Simultaneous Saccharification and Co-Fermentation with Pre-Saccharification (PSSCF)

Fed-batch PSSCF of both the StEx-treated SCB whole slurry and the AFEX-treated SCB at 15% (w/w) solids loading were carried out in baffled 250 mL Erlenmeyer flasks using an enzyme dosage of 20 mg protein/g glucan and a total mixture weight of 100 g. The biomass was added in two steps half at t = 0 h and the remainder at t = 3 h, and the PSSCF flasks were supplemented with 50 mM phosphate buffer, 0.5% (w/w) CSL, and 50 g/L chloramphenicol (antibiotic), and the pH was adjusted using 10 M KOH or 8 M HCl after biomass addition. The PSSCF runs were conducted with an initial 48-h pre-saccharification step at 50 °C, pH 5.0, and 200 rpm to liquefy the pre-treated biomass and to produce high sugar concentrations prior to yeast inoculation [21]. After pre-saccharification, seed cultures of the recombinant strains were inoculated at to an initial OD600 of 3.0; the incubation temperature and shaking speed were lowered to 35 °C and 180 rpm, respectively; and the PSSCF proceeded for an additional 96 h (144 h total pre-saccharification + SSCF time). For the duration of the PSSCF, samples were withdrawn once every 24 h and quantified by HPLC analysis. Each PSSF assay was performed in triplicate.

Analytical Techniques

Monomeric sugars (glucose, xylose, arabinose), aliphatic acids (acetic acid, formic acid), and furan aldehyde (furfural, 5-HMF) fermentation products (lactate, xylitol, glycerol, and ethanol) were determined by Thermo Separation Product HPLC system on an Aminex HPX-87H ion exchange column equipped with a Bio-Rad H cartridge guard column (Bio-Rad, Hercules, CA, USA). The column temperature was maintained at 65 °C, with 5 mM H2SO4 as the mobile phase at a flow rate of 0.6 mL/min. The peak detection for sugars, fermentation products, and aliphatic acids was performed using a refractive index detector (Shodex, RI-101), whereas the furan aldehydes were detected using a RS Variable Wavelength UV detector set at 280 nm. Phenolic compounds were analysed on Dionex UltiMateTM 3000 HPLC System equipped with an Aminex HPX-87H (7.8×250 mm) and a RS Variable Wavelength UV detector. The mobile phases used for elution were water (A) and acetonitrile (B) at a flow rate of 0.7 mL/min.

Calculations

For hydrolysate fermentation experiments, the ethanol yield (Yp/s) was determined from the amount of ethanol generated relative to the sum of monomeric glucose and xylose at t = 0 h. The ethanol metabolic yield was calculated from the ethanol generated relative to the consumed amounts of glucose and xylose and compared to the stoichiometric maximum. The specific glucose or xylose uptake (qglucose or qxylose) was determined from the amount of substrate consumed whereas the specific ethanol production rates (qethanol) were determined from ethanol produced (g) per cell mass (g). The maximum growth rate (μmax) was calculated during the exponential growth phase by plotting the natural logarithm of the cell OD600 as a function of time. The ethanol yields from PSSCF were estimated based on the weight of ethanol produced relative to the weight of initial polymeric glucan and xylan content input to the flasks. The overall PSSCF productivity was calculated to the amount of ethanol generated relative to the overall processing time, i.e., 144 h.

Statistical Analysis

The experimental data is presented as means ± standard deviation of triplicate experimental runs. The statistical significance of the experimental results was determined through a one-way analysis of variance (ANOVA) in combination with Tukey’s post hoc HSD test for multiple comparisons (Minitab Inc., State College, PA, USA). The null hypothesis was accepted or rejected at a 95% confidence interval (p < 0.05).

Results and Discussion

Chemical Composition of StEx and AFEX Pre-Treated SCB and Whole Slurry Enzymatic Hydrolysate

The chemical composition of the StEx-SCB whole slurry after pre-treatment, the hydrolysate derived from the enzymatic hydrolysis thereof, and the AFEX-treated SCB are presented in Table 1. Post-pretreatment, the total glucan, and xylan recovered in both the pre-treated solids and pre-treatment liquor were 97% and 76%, respectively. Hence, this suggests that an equivalent of 3% and 24% of the glucan and xylan in the untreated biomass were degraded to various undesired products during the pre-treatment of the biomass, respectively. These carbohydrate recoveries for StEx-pre-treated SCB are similar to those achieved elsewhere in literature at similar pre-treatment temperatures of 205 °C and 10 min residence time [6, 19]. The water-insoluble solids of the StEx-SCB whole slurry were enriched in glucan and Klason lignin content, whereas the pre-treatment liquor was composed of predominantly hemicellulose-derived total sugars (34.0 g/L), acetate (5.87 g/L), formate (0.57 g/L), and furan aldehydes (0.958 g/L). Acetate, a product of the hydrolysis of the acetyl groups in hemicellulose during StEx pre-treatment, was present in the highest quantity in the pre-treatment liquor, with concentrations similar to that achieved in literature for hydrolysis of sugarcane bagasse [22, 23]. However, furan derivatives, furfural and 5-hydroxymethyl furfural (5-HMF), concentrations generated were lower than those reported for H2SO4 or SO2-impregnated StEx pre-treatment of SCB at similar pre-treatment temperatures, suggesting that either lower reaction times or temperatures are required for acid-impregnated StEx pre-treatment to limit sugar dehydration [24, 25]. Vanillic acid, ferulic acid, p-coumaric acid, 3,4-dihydrobenzoic acid, syringic acid, vanillin, syringaldehyde, and coniferyl aldehyde were quantified as the predominant phenolic compounds in the pre-treatment liquor, with their cumulative concentration being 232 mg/L. These phenolic compounds typically originate from the acid-catalysed cleavage of ether and ester linkages in lignin macromolecules of monocots [26].

High solids loading enzymatic hydrolysis (at a high enzyme dosage of 40 mg protein/g glucan) of the non-detoxified whole slurry generated a hydrolysate with increased glucose (80.8 g/L), xylose (33.7 g/L) and acetate (8.11 g/L) concentrations due to the enzyme-mediated degradation of the structural carbohydrates and soluble oligosaccharides (p < 0.05). The formate (0.81 g/L) concentration increased slightly whereas, furan aldehyde (0.717 g/L) and phenolic compound concentrations (158 mg/L) were slightly reduced compared to the pre-treatment liquor, primarily due to the addition of water and enzymes during the enzymatic hydrolysis (p < 0.05). Based on the total fermentable sugar (monomeric glucose + xylose) concentration in the whole slurry hydrolysate, a maximum ethanol concentration of 58.4 g/L (based on a theoretical yield of 0.51 g ethanol /g sugar) could be generated from the hydrolysate. This would be significantly higher than the minimum recommended ethanol concentration (40 g/L) from fermentation to minimise energy costs for downstream ethanol recovery. The structural composition of AFEX-treated SCB was adopted from [27].

Screening of Industrial Xylose-Fermenting Yeast Strains for Tolerance of Inhibitors in SCB Whole Slurry Hydrolysate

The SHCF fermentation profiles for converting the hydrolysate obtained from enzymatic hydrolysis of the StEx-treated SCB whole slurry to ethanol are presented in Fig. 2, and the corresponding fermentation performance parameters are presented in Table 2. The non-detoxified hydrolysates were generated from 15% w/w solids loading enzymatic hydrolysis to attain high initial sugar and inhibitor concentrations to simulate the synergistic action of multiple stress conditions on xylose utilisation, including inhibitors and osmotic stress at the beginning of the fermentation and high ethanol stress towards the end of the fermentation [16, 31].

Time profiles for the fermentation of steam exploded and un-detoxified sugarcane bagasse whole slurry hydrolysate. Fermentation used (a) S. cerevisiae TP-1, (b) S. cerevisiae TP-50, (c) S. cerevisiae E50, and (d) S. cerevisiae CelluXTM4 strains. Fermentations were performed with an initial inoculum of 1.5 g CDW/L at pH 5.5, 30 °C, and a shaking speed of 150 rpm for 120 h. All hydrolysates were supplemented with 0.5% (w/w) corn steep liquor

For all four yeast strains, fermentation proceeded well with glucose rapidly consumed to completion within 24 h, resulting in ethanol concentrations greater than 38 g/L even in the presence of acetic acid concentrations of approximately 8.3 g/L. The fast-initial glucose consumption by these strains demonstrated their higher affinity for glucose and their robustness for the rapid utilisation of glucose in the inhibitor-laden whole slurry hydrolysate. Furthermore, all four strains showed slow to no diauxic xylose fermentation traits given the extended time between sampling points, even though xylose was consumed at a slower rate relative to glucose [32]. In literature, S. cerevisiae 424A (LNH-ST) demonstrated a similar trend, with glucose consumed to completion within 24 h and slow xylose fermentation phenotype potentially due to the lack of high-affinity xylose transporters in the presence of glucose [6].

Overall, the highest xylose consumption, ethanol concentration, ethanol metabolic yield, and overall ethanol productivity were achieved by CelluXTM4, reaching 98%, 53.8 g/L, 92% (based on consumed sugars), and 0.75 g/L/h after 72 h of fermentation, respectively (Table 2). Fermentation with the TP-1 strain was also characterised by high xylose consumption (88%) and metabolic yield (89%), with the final ethanol concentration reaching 50 g/L. However, TP-1 required 120 h of fermentation to achieve high xylose consumption and demonstrated a 4.5-fold lower-specific xylose fermentation rate (qxylose) compared to CelluXTM4, suggesting that the TP-1 strain may have lower xylose affinity or lower ethanol and/or inhibitor stress tolerance phenotypes relative to CelluXTM4. The evolved strains (TP-50 and E50) demonstrated lower overall xylose consumption and specific xylose consumption rates compared to CelluXTM4 and TP-1, suggesting that these evolved strains might have lost some part of their xylose utilisation ability during the course of their evolution [15, 33, 34]. As expected, no xylitol formation was detected from the fermentation runs of all four yeast strains, as strains contain XI-xylose pathway.

Figure 3 illustrates the time-based profiles of the furan aldehydes (furfural and 5-HMF) during the fermentation of the non-detoxified hydrolysate (Fig. 3a–d) and the final concentrations of the phenolic compounds quantified at the end of the 120 h of fermentation period (Fig. 3e). As shown in Fig. 3a–d, all four strains demonstrated near complete furfural and 5-HMF detoxification phenotypes within 24h of fermentation, indicating that these strains were effective in detoxifying furan aldehydes [35].

An illustration of the time-based detoxification of furan derivatives (furfural and 5-HMF). (a–d) Furan degradation during the fermentation of steam exploded and un-detoxified sugarcane bagasse whole slurry hydrolysate using S. cerevisiae TP-1, TP-50, E50, and CelluXTM4. (e) A comparison of the phenolic acid and aldehydes before and after fermentation of the steam-exploded and un-detoxified sugarcane bagasse whole slurry hydrolysate

Traditionally, microbial stresses caused by both furfural and 5-HMF inhibit yeast glycolysis, deplete intracellular NAD(P)H and ATP pools, and damage intracellular proteins [5, 36]; hence, their detoxification during the glucose consumption phase mitigates their effect on the xylose fermentation capacity of these four industrial strains. When present at sub-lethal concentrations, Almeida et al. [37] suggested that both furfural and 5-HMF can be reduced by some inhibitor-tolerant yeast strains to form their furan alcohol equivalents (furfuryl alcohol and 2,5-bis-hydroxymethylfuryl alcohol, respectively).

Similarly, lignin-derived phenolic aromatic aldehydes, viz. vanillin, syringaldehyde, and coniferyl aldehyde, were also quantified at significantly lower concentrations after the fermentation period for all four yeast strains relative to the initial hydrolysate (p < 0.05), as seen in Fig. 3e. Although initially present at significantly lower concentrations (0.23 g/L) relative to furan aldehydes (0.95 g/L) and aliphatic acids (> 6.0 g/L), phenolic aldehydes such as coniferyl aldehyde and vanillin have previously demonstrated significantly higher S. cerevisiae toxicity even at low concentrations [22, 26]. Hence, these phenolic aldehyde detoxification traits suggest that microbial stress due to phenolic aldehydes are more limited, allowing these robust strains to exhibit more efficient xylose fermentation capacity.

However, apart from CelluXTM4, there were minor increases in the total phenolic aromatic acid (p-coumaric acid, ferulic acid, syringic acid, vanillic acid, and 3-4-dihydrobenzoic acid) concentration after fermentation relative to the hydrolysate (p < 0.05). The minor increments in p-coumaric acid and ferulic acid were the primary factors for the higher total phenolic aromatic compound concentration. Like the phenolic aldehydes, Larsson et al. [38] found that the inhibitory effect of phenolic acids is significantly stronger than that of aliphatic acids such as acetate and formate. Furthermore, phenolic compounds have been shown to increase the toxicity of aliphatic acids [17, 39]. As such, these inhibitory compounds within the hydrolysate may result in cumulative microbial inhibition, detrimentally affecting the xylose-fermentation capacity of TP-1, TP-50, and E50 in non-detoxified StEx-SCB whole slurry hydrolysate.

Recent research has suggested that hydroquinones (e.g., p-benzoquinone) and small aliphatic aldehydes (e.g., formaldehyde), which both can be found in high-severity steam exploded hydrolysates [40], may have an even more pronounced inhibitory effect on S. cerevisiae relative to some phenolic acids and aliphatic acids such as acetate [10, 41]. Hence, future quantification of the phenolic aldehyde, phenolic acid, hydroquinone, and small aliphatic aldehyde concentrations accumulated in the cells or in the reaction medium as a function of fermentation time could provide valuable insights of the fate of these products in the presence of high ethanol and acetic acid concentrations in the fermentation of inhibitor-laden hydrolysates [42].

Remarkably, the industrial xylose-capable CelluxTM4 and TP-1 strains displayed encouraging SHCF results. Furthermore, the fermentation capacity of the four industrial yeast strains used in this work was compared to some of the most promising xylose-fermenting yeast strains (fermenting non-detoxified hydrolysates) reported in literature [28, 29] (Table 2). Among the most efficient xylose-fermenting yeasts reported in literature, recombinant S. cerevisiae strains RWB218, GS1.11-26, XH7, and LF1 have demonstrated high xylose consumption (> 80%), ethanol concentrations (> 38 g/L), metabolic yields (> 78%), and overall ethanol productivities (0.57 g/L/h) in non-detoxified StEx generated whole slurry hydrolysates derived from various lignocellulosic residues [13, 14, 16]. Despite its low specific xylose uptake rate and therefore low overall volumetric productivity, TP-1 achieved xylose consumption (88%) akin to RWB218, XH7, and LF1 with higher metabolic yields and ethanol concentrations.

The results of this work have demonstrated that CelluXTM4 can produce volumetric ethanol productivities that were 2-fold higher than TP-1, while generating xylose consumption, metabolic yield ethanol concentrations higher than those demonstrated by RWB218, GS1.11-26, XH7, and LF1. Even with a volumetric ethanol productivity only surpassed by S. cerevisiae LF1, the results from this work suggest that CelluXTM4 is one of the more promising industrial xylose-fermenting yeast strains for the efficient conversion of both glucose and xylose in inhibitor-laden hydrolysates derived from autohydrolysis based pre-treatment technologies such as StEx. It must be noted, however, that the direct comparison of the fermentation of non-detoxified hydrolysates of various strains presented in literature is not trivial due to the differences in the source of raw biomass, type of pre-treatment, pre-treatment conditions, the microbial stress tolerance and background of the selected strains, the application of detoxification methods, and ultimately the levels multiple stress factors (e.g., ethanol, sugars, salt content, inhibitors) present in the hydrolysates. Regardless, these results generated using robust xylose-capable strains indicate a promising leap towards using StEx-derived whole slurry material in industrial cellulosic ethanol production processes.

Pre-Hydrolysis and Simultaneous Saccharification and Co-Fermentation of Un-Detoxified Steam Exploded Sugarcane Bagasse

The S. cerevisiae TP-1 and CelluXTM4 strains were selected from the SHCF screening as the two best-performing strains and were subsequently used to evaluate ethanol production from StEx-SCB whole slurry compared to AFEX-SCB biomass in PSSCF runs (Table 3, Fig. 4). This would indicate how robust strains may effectively bridge the performance gap between the lower fermentability of material generated using harsher StEx pre-treatment versus the higher fermentability of the less harsh AFEX pre-treated materials. The PSSCF runs also evaluated whether the presence of un-hydrolysed solids in tandem with the pre-treatment derived inhibitors would impact the xylose fermentation capacity of TP-1 and CelluXTM4 as was previously reported for S. cerevisiae 424A (LNH-ST) [46].

Comparison of PSSCF of AFEX-treated SCB solids and StEx-treated SCB whole slurry using S. cerevisiae TP-1 and S. cerevisiae CelluXTM4. All the PSSCF experiments were carried out with a 48-h pre-saccharification at 50 °C followed by a simultaneous saccharification and co-fermentation period of 96 h at 35 °C using a total solid loading of 15% (w/w), inoculum of 1.8 g CDW/L, and enzyme dosage of 20 mg protein per gram glucan. Arrows illustrate the time when the yeast cells were inoculated

Enzymatic hydrolysis for the PSSCF experiments was performed using a more industrially relevant enzyme dosage of 20 mg/g glucan (~8 mg/g of untreated dry bagasse) using mixtures of CTec2, HTec2, and Pectinex Ultra-SP. The sugar, ethanol, and acetate profiles during PSSCF with TP-1 and CelluXTM4 are shown in Fig. 4. After 48 h of pre-saccharification at the relatively low enzyme loading, the reaction mixtures from both the StEx-SCB whole slurry and the AFEX-treated SCB solids contained glucose and xylose concentrations that were marginally higher than 40 g/L and 20 g/L, respectively (Fig. 4 a, c). Conversely, the acetic acid concentrations in the AFEX reactions flasks were about 3-fold lower than the StEx whole slurry flasks. This was primarily due to the dominant ammonolysis reactions that cleave the ester-linked O-acetyl groups in hemicellulose to form acetamide instead of acetic acid during AFEX pre-treatment [6].

After the inoculation of TP-1, glucose was rapidly consumed within 24 h, with the final ethanol concentration reaching 33 and 36 g/L for the StEx-SCB whole slurry and AFEX-SCB fermentations respectively, after 144 total reaction time (Fig. 4a, c). Xylose was consumed to near completion (< 1.5 g/L residual xylose) after 120 h for both experiments, indicating that most of the monomeric xylose that was simultaneously released by the hemicellulases from the soluble oligomers or the insoluble xylan was consumed the TP-1 strain. Similarly, PSSCF carried out with CelluXTM4 resulted in the near complete glucose and xylose consumptions in both the StEx-SCB and AFEX-SCB whole slurry experiments (Fig. 4 b, d). Moreover, the xylose consumption rate and the final ethanol concentrations from CelluXTM4 were marginally higher than those achieved with TP-1 (p < 0.05), suggesting that the presence of the unhydrolysed solids might not have a significant impact on the xylose fermentation capacity of both TP-1 and CelluXTM4. These results indicate that both strains were able to effectively ferment both StEx and AFEX materials, exhibiting only a 3.0 g/L difference in ethanol titres between the different pre-treated slurries. This demonstrates that using inhibitor-resistant yeasts can overcome the inhibitor issues related to the fermentability of StEx pre-treated material, closing the performance gap between the fermentability of StEx and AFEX pre-treated material.

The robust nature of both the S. cerevisiae TP-1 and CelluxTM4 strains were emphasised by their performances in StEx-SCB slurry PSSCF fermentations containing acetic acid in access of 6.0 g/L (Fig. 4a, b; Table 2) as compared to sugarcane bagasse fermentations in literature [24, 45]. Furthermore, both TP-1 and CelluXTM4 demonstrated strong furfural and 5-HMF detoxification phenotypes in the PSSCF experiments StEx-SCB whole slurry experiments, with both furan aldehydes completely assimilated within 24 h after inoculation (data not shown). These results suggest that the concentrations of these furan aldehydes in SCB that was steam exploded at a pre-treatment severity of 3.94 (200 °C, 10 min) are likely below the inhibition concentrations for the TP-1 and CelluXTM4 strains. This highlights the robust nature of these strains to maintain fermentation ability in the presence of access lignocellulose-derived microbial inhibitors.

The ethanol titres from the PSSCF fermentations (Fig. 4, Table 3), although very promising, remain below the 40 g/L concentration required for economical ethanol distillation [47]. The overall yields from the non-optimised PSSCF strategy used in this work may have been reduced by biomass recalcitrance or inhibition of the hydrolytic enzymes by lignin and pre-treatment-derived inhibitors [4] that are present in the reaction medium [48,49,50]. The optimisation of the PSSCF process may further improve the fermentability of StEx pre-treated material using the S. cerevisiae TP-1 and CelluXTM4 strains, forwarding the development of economical industrial cellulosic bioethanol production processes. Nonetheless, even in the presence of potential enzyme inhibition, the results of this study demonstrated that the use of S. cerevisiae TP-1 and CelluXTM4 resulted in superior StEx-treated whole slurry PSSCF than previously reported.

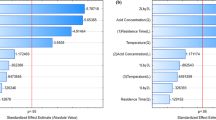

Mass Balances for PSSCF Process

The ethanol yield per tonne of untreated SCB provides a metric for quantifying the combined effect of biomass recalcitrance, enzyme inhibition, and microbial inhibition for various pre-treatment, hydrolysis, and fermentation process combinations. The results from the PSSCF experiments using AFEX- and StEx-treated SCB and the inhibitor-tolerant yeast strains TP-1 and CelluXTM4 were used to generate process mass balances and to estimate the overall ethanol yield per tonne of untreated SCB (Fig. 5). Owing to the absence of significant carbohydrate degradation, AFEX only increased the nitrogen content of the pre-treated biomass by approximately 1.5 kg per 100 kg of untreated SCB. In contrast, StEx resulted in the recovery of 97% and 76% of polymeric glucan and xylan in the whole slurry relative to the glucan and xylan content in the untreated biomass, respectively, demonstrating a 3% and 24% loss of glucan and xylan, respectively, due to sugar degradation during StEx pre-treatment. However, the sugar loss to degradation obtained in this study was lower than that observed in Mokomele et al. [6] primarily due to the lower pre-treatment severity used during StEx pre-treatment in this study.

Under industrially relevant solids loading and limited enzyme loading conditions, the PSSCF of AFEX-treated SCB using TP-1 and CelluXTM4 produced ethanol yields of 50 and 54% relative to the theoretical maximum estimated from the polymeric glucan and xylan input to the PSSCF process, respectively. These ethanol yields correspond to overall process yields of 234 and 251 L of ethanol per tonne of untreated SCB, respectively. These ethanol yields achieved for PSSCF of AFEX-treated SCB using both TP-1 and CelluXTM4 were lower than those reported previously [6]. The lower ethanol yields observed were primarily due to (i) the use of older cellulase and hemicellulase generation (CTec2 & HTec2 vs CTec3 & HTec3), (ii) lower enzyme dosages i.e. 25 mg vs. 20 mg protein per gram glucan, and (iii) the higher AFEX pre-treatment severity used in this study relative to the study presented by Mokomele et al. [6]. Nonetheless, the PSSCF of StEx-treated SCB whole slurry generated ethanol yields of 208 and 224 L of ethanol per tonne using S. cerevisiae TP-1 and CelluXTM4, respectively. The ethanol yields were lower compared to those achieved from the PSSCF of AFEX-SCB, suggesting that carbohydrate loss due to degradation during StEx pre-treatment could be a decisive factor that needs to be further considered to close the gap in yields between AFEX-SCB and StEx-treated SCB whole slurries. The lower process yields for the StEx-treated SCB relative to the AFEX-SCB reveal the effect of carbohydrate loss due to sugar degradation during StEx pre-treatment; therefore, the fermentability of StEx-treated SCB is no longer limited by the formation and detrimental effects of microbial inhibitors on S. cerevisiae.

To establish commercially viable cellulosic biorefineries, a major goal for cellulosic ethanol production is to achieve efficient conversion of both hexose and pentose sugars to ethanol (high yield per unit of untreated feedstock), high ethanol concentrations from fermentation (> 40 g/L), high volumetric productivity, and low enzyme loadings. The ethanol yields for the PSSCF of the StEx-treated SCB whole slurry using CelluXTM4 (224 L/Mg RDM) were higher than those previously reported by Mokomele et al. [6] using the recombinant yeast strain S. cerevisiae 424A (LNH-ST) in SHCF (204 L/Mg RDM). As previously discussed, the degradation products in the StEx-SCB whole slurry and the fermentation metabolites from the glucose-consumption phase limited the xylose uptake by S. cerevisiae 424A (LNH-ST) thus achieving lower ethanol yields even at the higher enzyme loadings used in that study. In contrast, the PSSCF of the StEx-SCB whole slurry using TP-1 achieved ethanol yields that were equivalent to those reported by Mokomele et al. [6] (205 L Mg/RDM) and also higher than those reported by Mesa et al. [44] due to the efficient fermentation of the fermentable glucose and xylose released by the hydrolytic enzymes. Furthermore, higher volumetric ethanol productivities were achieved by the PSSCF experiments relative to the SHCF of StEx-treated SCB whole slurries.

Literature reported ethanol yields for AFEX-treated SCB range from 272 to 324 L/Mg RDM (Table 3). The PSSCF of AFEX-SCB using both CelluXTM4 and TP-1 produced ethanol yields of 234 and 251 L/Mg RDM, which were lower than this literature-reported range. These results suggest that either SHCF is a more efficient process relative to PSSCF for AFEX-treated SCB or that the PSSCF process is limited by biomass recalcitrance at low enzyme loadings.

Conclusions

In this study, we evaluated the glucose and xylose fermentation capability of five XI-pathway industrial recombinant yeast strains on StEx-treated undetoxified SCB whole slurry hydrolysates. The S. cerevisiae TP-1 and CelluxTM4 strains demonstrated high acetate, furan aldehyde, and phenolic detoxification phenotypes, resulting in near complete combined glucose and xylose conversion (> 96%) and high ethanol concentrations (> 50 g /L) from the fermentation of StEx-treated and undetoxified SCB whole slurry hydrolysates. Under industrially relevant PSSCF solid loadings and low enzyme dosages, both S. cerevisiae TP-1 and CelluxTM4 facilitated the consumption of nearly all the glucose and xylose released by the hydrolytic enzymes, from inhibitor-laden StEx-treated SCB whole slurries and inhibitor deficient AFEXTM-treated SCB biomass. This work demonstrates that TP-1 and CelluXTM4 are robust strains that can efficiently convert both glucose and xylose from inhibitor-laden autocatalyzed StEx whole slurries into ethanol.

Data Availability

The data generated during this study is available from the corresponding author upon reasonable request.

References

Jansen MLA, Bracher JM, Papapetridis I et al (2017) Saccharomyces cerevisiae strains for second-generation ethanol production: from academic exploration to industrial implementation. FEMS Yeast Res 17:fox044. https://doi.org/10.1093/femsyr/fox044

van Zyl WH, Chimphango AFA, den Haan R et al (2011) Next-generation cellulosic ethanol technologies and their contribution to a sustainable Africa. Interface Focus 1:196–211. https://doi.org/10.1098/rsfs.2010.0017

Zhang W, Zhang X, Lei F, Jiang J (2020) Co-production bioethanol and xylooligosaccharides from sugarcane bagasse via autohydrolysis pretreatment. Rene Energ 162:2297–2305. https://doi.org/10.1016/j.renene.2020.10.034

Mhlongo SI, den Haan R, Viljoen-Bloom M, van Zyl WH (2015) Lignocellulosic hydrolysate inhibitors selectively inhibit/deactivate cellulase performance. Enzyme Microb Tech 81:16–22. https://doi.org/10.1016/j.enzmictec.2015.07.005

Brandt BA, Jansen T, Görgens JF, van Zyl WH (2019) Overcoming lignocellulose-derived microbial inhibitors: advancing the Saccharomyces cerevisiae resistance toolbox. Biofuel Bioprod Biorefin 13:1520–1536. https://doi.org/10.1002/bbb.2042

Mokomele T, Da Costa SL, Balan V et al (2018) Ethanol production potential from AFEXTM and steam-exploded sugarcane residues for sugarcane biorefineries. Biotechnol Biofuels 11:127. https://doi.org/10.1186/s13068-018-1130-z

Antunes FAF, Thomé LC, Santos JC et al (2021) Multi-scale study of the integrated use of the carbohydrate fractions of sugarcane bagasse for ethanol and xylitol production. Rene Energ 163:1343–1355. https://doi.org/10.1016/j.renene.2020.08.020

Cunha JT, Soares PO, Romaní A et al (2019) Xylose fermentation efficiency of industrial Saccharomyces cerevisiae yeast with separate or combined xylose reductase/xylitol dehydrogenase and xylose isomerase pathways. Biotechnol Biofuels 12:20. https://doi.org/10.1186/s13068-019-1360-8

Deparis Q, Claes A, Foulquié-Moreno MR, Thevelein JM (2017) Engineering tolerance to industrially relevant stress factors in yeast cell factories. FEMS Yeast Res 17:fox036. https://doi.org/10.1093/femsyr/fox036

Martín C, Wu G, Wang Z et al (2018) Formation of microbial inhibitors in steam-explosion pretreatment of softwood impregnated with sulfuric acid and sulfur dioxide. Bioresour Technol 262:242–250. https://doi.org/10.1016/j.biortech.2018.04.074

Teter SA, Sutton KB, Emme B (2014) Enzymatic processes and enzyme development in biorefining. In: Advances in Biorefineries: Biomass and Waste Supply Chain Exploitation. Elsevier, pp 199–233. https://doi.org/10.1533/9780857097385.1.199

Lynd LR, Weimer PJ, van Zyl WH, Pretorius IS (2002) Microbial cellulose utilization: fundamentals and biotechnology. Microbiol Mol Biol R 66:739–739. https://doi.org/10.1128/mmbr.66.4.739.2002

Van Maris AJA, Winkler AA, Kuyper M et al (2007) Development of efficient xylose fermentation in Saccharomyces cerevisiae: xylose isomerase as a key component. Adv Biochem Engin/Biotechnol 108:179–204. https://doi.org/10.1007/10_2007_057

Li H, Shen Y, Wu M et al (2016) Engineering a wild-type diploid Saccharomyces cerevisiae strain for second-generation bioethanol production. Bioresour Bioprocess 3:51. https://doi.org/10.1186/s40643-016-0126-4

Demeke MM, Dietz H, Li Y et al (2013) Development of a D-xylose fermenting and inhibitor tolerant industrial Saccharomyces cerevisiae strain with high performance in lignocellulose hydrolysates using metabolic and evolutionary engineering. Biotechnol Biofuels 6:89. https://doi.org/10.1186/1754-6834-6-89

Demeke MM, Dumortier F, Li Y et al (2013) Combining inhibitor tolerance and D-xylose fermentation in industrial Saccharomyces cerevisiae for efficient lignocellulose-based bioethanol production. Biotechnol Biofuels 6:120. https://doi.org/10.1186/1754-6834-6-120

Brandt BA, García-Aparicio MDP, Görgens JF, van Zyl WH (2021) Rational engineering of Saccharomyces cerevisiae towards improved tolerance to multiple inhibitors in lignocellulose fermentations. Biotechnol Biofuels 14:1–18. https://doi.org/10.1186/s13068-021-02021-w

Agudelo RA, García-Aparicio MP, Görgens JF (2016) Steam explosion pretreatment of triticale (Triticosecale Wittmack) straw for sugar production. N Biotechnol 33:153–163. https://doi.org/10.1016/j.nbt.2015.10.001

Mokomele T, da Costa SL, Bals B et al (2018) Using steam explosion or AFEXTM to produce animal feeds and biofuel feedstocks in a biorefinery based on sugarcane residues. Biofuel Bioprod Biorefin 12:978–996. https://doi.org/10.1002/bbb.1927

Kumar R, Hu F, Sannigrahi P et al (2013) Carbohydrate derived-pseudo-lignin can retard cellulose biological conversion. Biotechnol Bioeng 110:737–753. https://doi.org/10.1002/bit.24744

Sarks C, Bals BD, Wynn J et al (2016) Scaling up and benchmarking of ethanol production from pelletized pilot scale AFEX treated corn stover using Zymomonas mobilis 8b. Biofuels 7:253–262. https://doi.org/10.1080/17597269.2015.1132368

Martín C, Galbe M, Nilvebrant N-OO, Jönsson LJ (2002) Comparison of the fermentability of enzymatic hydrolyzates of sugarcane bagasse pretreated by steam explosion using different impregnating agents. Appl Biochem Biotechnol 98–100:699–716. https://doi.org/10.1385/ABAB:98-100:1-9:699

Amores I, Ballesteros I, Manzanares P et al (2013) Ethanol production from sugarcane bagasse pretreated by steam explosion. Electron J Energy Environ 1:25–36. https://doi.org/10.7770/ejee-v1n1-art519

Benjamin Y, García-Aparicio MP, Görgens JF (2014) Impact of cultivar selection and process optimization on ethanol yield from different varieties of sugarcane. Biotechnol Biofuels 7:60. https://doi.org/10.1186/1754-6834-7-60

Ferreira-Leitão V, Perrone CC, Rodrigues J et al (2010) An approach to the utilisation of CO2 as impregnating agent in steam pretreatment of sugar cane bagasse and leaves for ethanol production. Biotechnol Biofuels 3:7

Jönsson LJ, Martín C (2016) Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour Technol 199:103–112. https://doi.org/10.1016/j.biortech.2015.10.009

Mokomele T, da Costa SL, Balan V et al (2019) Incorporating anaerobic co-digestion of steam exploded or ammonia fiber expansion pretreated sugarcane residues with manure into a sugarcane-based bioenergy-livestock nexus. Bioresour Technol 272:326–336. https://doi.org/10.1016/j.biortech.2018.10.049

Sarks C, Jin M, Sato TK et al (2014) Studying the rapid bioconversion of lignocellulosic sugars into ethanol using high cell density fermentations with cell recycle. Biotechnol Biofuels 7:73. https://doi.org/10.1186/1754-6834-7-73

Costa CE, Romaní A, Cunha JT et al (2017) Integrated approach for selecting efficient Saccharomyces cerevisiae for industrial lignocellulosic fermentations: importance of yeast chassis linked to process conditions. Bioresour Technol 227:24–34. https://doi.org/10.1016/j.biortech.2016.12.016

Karhumaa K, Sanchez RG, Hahn-Hägerdal B, Gorwa-Grauslund MF (2007) Comparison of the xylose reductase-xylitol dehydrogenase and the xylose isomerase pathways for xylose fermentation by recombinant Saccharomyces cerevisiae. Microb Cell Fact 6:5. https://doi.org/10.1186/1475-2859-6-5

Bai FW, Anderson WA, Moo-Young M (2008) Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnol Ad 26:89–105. https://doi.org/10.1016/j.biotechadv.2007.09.002

Moysés DN, Reis VCB, de Almeida JRM et al (2016) Xylose fermentation by Saccharomyces cerevisiae: challenges and prospects. Int J Mol Sci 17:207. https://doi.org/10.3390/ijms17030207

Parreiras LS, Breuer RJ, Narasimhan RA et al (2014) Engineering and two-stage evolution of a lignocellulosic hydrolysate-tolerant Saccharomyces cerevisiae strain for anaerobic fermentation of xylose from AFEX pretreated corn stover. PLoS One 9:e107499. https://doi.org/10.1371/journal.pone.0107499

Koppram R, Albers E, Olsson L (2012) Evolutionary engineering strategies to enhance tolerance of xylose utilizing recombinant yeast to inhibitors derived from spruce biomass. Biotechnol Biofuels 5:1. https://doi.org/10.1186/1754-6834-5-32

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. I: Inhibition and detoxification. Bioresour Technol 74:17–24. https://doi.org/10.1016/S0960-8524(99)00160-1

De Witt RN, Kroukamp H, Volschenk H (2019) Proteome response of two natural strains of Saccharomyces cerevisiae with divergent lignocellulosic inhibitor stress tolerance. FEMS Yeast Res 19:foy116. https://doi.org/10.1093/femsyr/foy116

Almeida JRM, Modig T, Petersson A et al (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349. https://doi.org/10.1002/jctb.1676

Larsson S, Palmqvist E, Hahn-Hägerdal B et al (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme Microb Technol 24:151–159. https://doi.org/10.1016/S0141-0229(98)00101-X

Yang J, Ding M-Z, Li B-Z et al (2012) Integrated phospholipidomics and transcriptomics analysis of Saccharomyces cerevisiae with enhanced tolerance to a mixture of acetic acid, furfural, and phenol. OMICS 16:374–386. https://doi.org/10.1089/omi.2011.0127

Cavka A, Stagge S, Jönsson LJ (2015) Identification of small aliphatic aldehydes in pretreated lignocellulosic feedstocks and evaluation of their inhibitory effects on yeast. J Agric Food Chem 63:9747–9754. https://doi.org/10.1021/acs.jafc.5b04803

Stagge S, Cavka A, Jönsson LJ (2015) Identification of benzoquinones in pretreated lignocellulosic feedstocks and inhibitory effects on yeast. AMB Express 5:62. https://doi.org/10.1186/s13568-015-0149-9

Sarks C, Higbee A, Piotrowski J et al (2016) Quantifying pretreatment degradation compounds in solution and accumulated by cells during solids and yeast recycling in the Rapid Bioconversion with Integrated recycling Technology process using AFEXTM corn stover. Bioresour Technol 205:24–33. https://doi.org/10.1016/j.biortech.2016.01.008

Krishnan C, da Costa SL, Jin M et al (2010) Alkali-based AFEX pretreatment for the conversion of sugarcane bagasse and cane leaf residues to ethanol. Biotechnol Bioeng 107:441–450. https://doi.org/10.1002/bit.22824

Mesa L, González E, Romero I et al (2011) Comparison of process configurations for ethanol production from two-step pretreated sugarcane bagasse. Chem Eng J 175:185–191. https://doi.org/10.1016/j.cej.2011.09.092

You Y, Li P, Lei F et al (2017) Enhancement of ethanol production from green liquor-ethanol-pretreated sugarcane bagasse by glucose-xylose cofermentation at high solid loadings with mixed Saccharomyces cerevisiae strains. Biotechnol Biofuels 10:92. https://doi.org/10.1186/s13068-017-0771-7

Jin M, Lau MW, Balan V, Dale BE (2010) Two-step SSCF to convert AFEX-treated switchgrass to ethanol using commercial enzymes and Saccharomyces cerevisiae 424A(LNH-ST). Bioresour Technol 101:8171–8178. https://doi.org/10.1016/j.biortech.2010.06.026

Park JM, Oh BR, Seo JW et al (2013) Efficient production of ethanol from empty palm fruit bunch fibers by fed-batch simultaneous saccharification and fermentation using Saccharomyces cerevisiae. Appl Biochem Biotechnol 170:1807–1814. https://doi.org/10.1007/s12010-013-0314-z

Shinde SD, Meng X, Kumar R, Ragauskas AJ (2018) Recent advances in understanding the pseudo-lignin formation in a lignocellulosic biorefinery. Green Chem 20:2192–2205. https://doi.org/10.1039/c8gc00353j

Djajadi DT, Jensen MM, Oliveira M et al (2018) Lignin from hydrothermally pretreated grass biomass retards enzymatic cellulose degradation by acting as a physical barrier rather than by inducing nonproductive adsorption of enzymes. Biotechnol Biofuels 11:85. https://doi.org/10.1186/s13068-018-1085-0

Larsson S, Reimann A, Nilvebrant N-O, Jönsson LJ (1999) Comparison of different methods for the detoxification of lignocellulose hydrolyzates of spruce. Appl Biochem Biotechnol 77:91–104. https://doi.org/10.1385/ABAB:77:1-3:91

Acknowledgements

The study wishes to acknowledge Leaf by Lesaffre for providing the S. cerevisiae CelluXTM1 and CelluxTM4 strains, Jaco van Rooyen, and Levine Simmers for assistance with HPLC analysis.

Funding

Open access funding provided by Stellenbosch University. This work was funded by The National Research Foundation (NRF), South Africa.

Author information

Authors and Affiliations

Contributions

Thapelo Mokomele: conceptualization; methodology—design of experiments; investigation, formal analysis, data curation; writing—original draft. Bianca Brandt: methodology—design of experiments, provide yeast strains; data curation, writing—review and editing. Johann F. Görgens: supervision; writing—review and editing.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

There are no ethical issues associated with the study and manuscript, and all the authors consent to participate.

Consent for Publication

All authors consent to the research article for publication.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mokomele, T., Brandt, B.A. & Görgens, J.F. Effective Fermentation of Sugarcane Bagasse Whole Slurries Using Robust Xylose-Capable Saccharomyces cerevisiae. Bioenerg. Res. 16, 2297–2313 (2023). https://doi.org/10.1007/s12155-023-10577-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-023-10577-8