Abstract

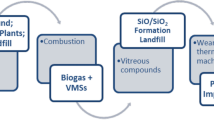

Volatile methyl siloxanes (VMS) are biogas pollutants generated from the metabolism of polydimethylsiloxanes (PDMS) in anaerobic digestion processes. In the past, VMS were considered an issue only for biogas produced in landfills. However, the widespread presence of VMS in different types of biogas has been demonstrated in recent years as a consequence of the intensive use of PDMS in the formulation of personal care products, industrial lubricants, glues, paints, and detergents. Burning biogas (or biomethane) laden with VMS leads the formation of silicate (SiO2) deposits, resulting in abrasion and severe lubrication issues, which finally produce irreversible damage to energy production devices. The present work provides a comprehensive review of the VMS concentrations recently reported in several types of biogas, as well as the physical–chemical technologies available on a commercial scale for the removal of VMS. Alternative biological processes for VMS removal are also described, including the most recent advances in microbial degradation mechanisms, bioreactor configurations, and operation modes. Critical research niches and challenges towards the consolidation of biotechnologies as efficient and cost-effective VMS treatment systems are identified and critically discussed.

Similar content being viewed by others

Abbreviations

- AAC:

-

Adsorption on activated carbon

- BTF:

-

Biotrickling filter

- CCT:

-

Cryogenic condensation technologies

- \({\mathrm C}_{G\;\mathrm{in}}\) :

-

VMS inlet concentration in gas phase (mg m−3)

- \({\mathrm C}_{G\;\mathrm{out}}\) :

-

VMS outlet concentration in gas phase (mg m−3)

- \({\mathrm{C}}_{\mathrm{L}}\) :

-

VMS concentration in liquid phase (mg m−3)

- D3:

-

Hexamethylcyclo-trisiloxane

- D4:

-

Octamethylcyclo-tetrasiloxane

- D5:

-

Decamethylcyclo-pentasiloxane

- EBRT:

-

Empty bed residence time of biogas (min)

- EC:

-

Elimination capacity (g m−3 h−1)

- \({\mathrm{F}}_{\mathrm{G}/\mathrm{L}}\) :

-

Gas–liquid pollutant transfer rate (g m−3 h−1)

- GRT:

-

Gas retention time (min)

- H:

-

Dimensionless Henry’s law constant

- HRT:

-

Hydraulic retention time (day)

- \({\mathrm{K}}_{\mathrm{La}}\) :

-

Overall gas–liquid mass transfer coefficient

- L2:

-

Hexamethyl-disiloxane

- L3:

-

Hexamethyl-trisiloxane

- L4:

-

Decamethyl-tetrasiloxane

- NAP:

-

Non-aqueous phase

- PDMS:

-

Polydimethylsiloxane

- Q:

-

Biogas flow rate (m3 h−1)

- RE:

-

Removal efficiency (%)

- VMS:

-

Volatile methyl siloxanes

- \({\mathrm V}_{\mathrm{packed}\;\mathrm{bed}}\) :

-

Empty volume of the packed bed (m3)

- VOC:

-

Volatile organic compounds

References

Shen M, Zhang Y, Hu D et al (2018) A review on removal of siloxanes from biogas: with a special focus on volatile methylsiloxanes. Environ Sci Pollut Res 25:30847–30862. https://doi.org/10.1007/s11356-018-3000-4

Tabatabaei M, Aghbashlo M, Valijanian E et al (2020) A comprehensive review on recent biological innovations to improve biogas production, Part 1: Upstream strategies. Renew Energy 146:1204–1220. https://doi.org/10.1016/j.renene.2019.07.037

Wąs A, Sulewski P, Krupin V et al (2020) The potential of agricultural biogas production in ukraine—impact on ghg emissions and energy production. Energies 13:1–20. https://doi.org/10.3390/en13215755

Lu J, Gao X (2021) Biogas: potential, challenges, and perspectives in a changing China. Biomass Bioenerg 150:106127. https://doi.org/10.1016/j.biombioe.2021.106127

Atelge MR, Krisa D, Kumar G et al (2020) Biogas production from organic waste: recent progress and perspectives. Waste and Biomass Valorization 11:1019–1040. https://doi.org/10.1007/s12649-018-00546-0

Suhartini S, Nurika I, Paul R, Melville L (2021) Estimation of biogas production and the emission savings from anaerobic digestion of fruit-based agro-industrial waste and agricultural crops residues. Bioenergy Res 14:844–859. https://doi.org/10.1007/s12155-020-10209-5

Bharathiraja B, Sudharsana T, Jayamuthunagai J et al (2018) Biogas production – a review on composition, fuel properties, feed stock and principles of anaerobic digestion. Renew Sustain Energy Rev 90:570–582. https://doi.org/10.1016/j.rser.2018.03.093

Das J, Ravishankar H, Lens PNL (2022) Biological biogas purification: recent developments, challenges and future prospects. J Environ Manage 304:114198. https://doi.org/10.1016/j.jenvman.2021.114198

Garcia NH, Mattioli A, Gil A et al (2019) Evaluation of the methane potential of different agricultural and food processing substrates for improved biogas production in rural areas. Renew Sustain Energy Rev 112:1–10. https://doi.org/10.1016/j.rser.2019.05.040

Hepburn CA (2014) Removal of siloxanes from biogas. Doctoral thesis. Cranfield University, School of Energy. Envrionment and Agrifood Cranfield Water Science Institute.

Noyola A, Morgan-Sagastume JM, López-Hernández JE (2006) Treatment of biogas produced in anaerobic reactors for domestic wastewater: Odor control and energy/resource recovery. Rev Environ Sci Biotechnol 5:93–114. https://doi.org/10.1007/s11157-005-2754-6

del Rodero M, R, Severi CA, Rocher-Rivas R, et al (2020) Long-term influence of high alkalinity on the performance of photosynthetic biogas upgrading. Fuel 281:118804. https://doi.org/10.1016/j.fuel.2020.118804

Baena-Moreno FM, le Saché E, Pastor-Pérez L, Reina TR (2020) Membrane-based technologies for biogas upgrading: a review. Environ Chem Lett 18:1649–1658. https://doi.org/10.1007/s10311-020-01036-3

Khan MU, Lee JTE, Bashir MA et al (2021) Current status of biogas upgrading for direct biomethane use: a review. Renew Sustain Energy Rev 149:111343. https://doi.org/10.1016/j.rser.2021.111343

Adnan AI, Ong MY, Nomanbhay S et al (2019) Technologies for biogas upgrading to biomethane: a review. Bioengineering 6:1–23. https://doi.org/10.3390/bioengineering6040092

Struk M, Kushkevych I, Vítězová M (2020) Biogas upgrading methods: recent advancements and emerging technologies. Rev Environ Sci Biotechnol 19:651–671. https://doi.org/10.1007/s11157-020-09539-9

Scarlat N, Dallemand JF, Fahl F (2018) Biogas: Developments and perspectives in Europe. Renew Energy 129:457–472. https://doi.org/10.1016/j.renene.2018.03.006

Natividad Pérez-Camacho M, Curry R, Cromie T (2019) Life cycle environmental impacts of biogas production and utilisation substituting for grid electricity, natural gas grid and transport fuels. Waste Manag 95:90–101. https://doi.org/10.1016/j.wasman.2019.05.045

Aryal N, Kvist T (2018) Alternative of biogas injection into the Danish gas grid system—a study from demand perspective. ChemEngineering 2:1–11. https://doi.org/10.3390/chemengineering2030043

Elwell AC, Elsayed NH, Kuhn JN, Joseph B (2018) Design and analysis of siloxanes removal by adsorption from landfill gas for waste-to-energy processes. Waste Manag 73:189–196. https://doi.org/10.1016/j.wasman.2017.12.021

Kuhn JN, Elwell AC, Elsayed NH, Joseph B (2017) Requirements, techniques, and costs for contaminant removal from landfill gas. Waste Manag 63:246–256. https://doi.org/10.1016/j.wasman.2017.02.001

Das J, Nolan S, Lens PNL (2022) Simultaneous removal of H2S and NH3 from raw biogas in hollow fibre membrane bioreactors. Environ Technol Innov 28:102777. https://doi.org/10.1016/j.eti.2022.102777

Baena-Moreno FM, Rodríguez-Galán M, Vega F et al (2019) Review: recent advances in biogas purifying technologies. Int J Green Energy 16:401–412. https://doi.org/10.1080/15435075.2019.1572610

Nyamukamba P, Mukumba P, Chikukwa ES, Makaka G (2020) Biogas upgrading approaches with special focus on siloxane removal—a review. Energies 13:1–17. https://doi.org/10.3390/en13226088

Piechota G (2021) Removal of siloxanes from biogas upgraded to biomethane by Cryogenic Temperature Condensation System. J Clean Prod 308:127404. https://doi.org/10.1016/j.jclepro.2021.127404

Popat SC, Deshusses MA (2008) Biological removal of siloxanes from landfill and digester gases: opportunities and challenges. Environ Sci Technol 42:8510–8515. https://doi.org/10.1021/es801320w

Soreanu G, Falletta P, Béland M, et al (2009) Abiotic and biotic mitigation of volatile methyl siloxanes in anaerobic gas-phase biomatrices. Environ Eng Manag J 8:1235–1240. https://doi.org/10.30638/eemj.2009.181

Ruiling G, Shikun C, Zifu L (2017) Research progress of siloxane removal from biogas. Int J Agric Biol Eng 10:30–39. https://doi.org/10.3965/j.ijabe.20171001.3043

De Arespacochaga N, Valderrama C, Raich-Montiu J et al (2015) Understanding the effects of the origin, occurrence, monitoring, control, fate and removal of siloxanes on the energetic valorization of sewage biogas-a review. Renew Sustain Energy Rev 52:366–381. https://doi.org/10.1016/j.rser.2015.07.106

Mazzoni SM, Roy S, Grigoras S (1997) Organosilicon Materials. In: The Handbook of Environmental Chemistry. p 287

Homem V, Ratola N (2020) Volatile methyl siloxanes in the environment. In: Handbook of Environmental Chemistry. p 227–245

Boada E, Santos-Clotas E, Bertran S, et al (2020) Potential use of Methylibium sp. as a biodegradation tool in organosilicon and volatile compounds removal for biogas upgrading. Chemosphere 240:. https://doi.org/10.1016/j.chemosphere.2019.124908

Boada Cahueñas E (2020) Towards the implementation of a biotechnology for biogas upgrading: role of bacteria in siloxane removal. Doctoral thesis. Universitat de Girona.

Wang G, Zhang Z, Hao Z (2019) Recent advances in technologies for the removal of volatile methylsiloxanes: a case in biogas purification process. Crit Rev Environ Sci Technol 49:2257–2313. https://doi.org/10.1080/10643389.2019.1607443

Alves CMAC, Abreu FOMS, Araújo RS, Oliveira MLM (2022) Recent advances in siloxanes removal from biogas and their efficiency: a short review. Chem Pap. https://doi.org/10.1007/s11696-022-02460-1

Ajhar M, Travesset M, Yüce S, Melin T (2010) Siloxane removal from landfill and digester gas - a technology overview. Bioresour Technol 101:2913–2923. https://doi.org/10.1016/j.biortech.2009.12.018

Tran VTL, Gélin P, Ferronato C et al (2019) Siloxane adsorption on activated carbons: role of the surface chemistry on sorption properties in humid atmosphere and regenerability issues. Chem Eng J 371:821–832. https://doi.org/10.1016/j.cej.2019.04.087

Wheless E, Pierce J (2004) Siloxanes in Landfill and Digester Gas Update 27 th Annual SWANA LFG Symposium

Finocchio E, Montanari T, Garuti G et al (2009) Purification of biogases from siloxanes by adsorption: on the regenerability of activated carbon sorbents. Energy Fuels 23:4156–4159. https://doi.org/10.1021/ef900356n

Sigot L, Ducom G, Benadda B, Labouré C (2014) Adsorption of octamethylcyclotetrasiloxane on silica gel for biogas purification. Fuel 135:205–209. https://doi.org/10.1016/j.fuel.2014.06.058

Gaj K (2021) Siloxanes removal from biogas and emerging biological techniques. In: Emerging Technologies and Biological Systems for Biogas Upgrading

San-Valero P, Gabaldón C, Penya-roja JM, Quijano G (2017) Enhanced styrene removal in a two-phase partitioning bioreactor operated as a biotrickling filter: Towards full-scale applications. Chem Eng J 309:588–595. https://doi.org/10.1016/j.cej.2016.10.054

Kapoor R, Ghosh P, Kumar M, Vijay VK (2019) Evaluation of biogas upgrading technologies and future perspectives: a review. In: Environmental Science and Pollution Research. Environmental Science and Pollution Research, pp 11631–11661

Rodero MR, Ángeles R, Marín D, et al (2019) Biogas purification and upgrading technologies. In: Biogas. Biofuel and Biorefinery Technologies. pp 110–127

Pascual C, Cantera S, Lebrero R (2021) Volatile siloxanes emissions: impact and sustainable abatement perspectives. Trends Biotechnol 39:1245–1248. https://doi.org/10.1016/j.tibtech.2021.05.003

Quijano G, Miguel-Romera JA, Bonilla-Morte LM, Figueroa-González I (2017) HC-0B-05: Two-phase partitioning bioreactors for treatment of volatile hydrocarbons

Pascual C, Lebrero R, Cantera S (2022) Toward a sustainable and cost-efficient biological-based platform for siloxanes removal. Crit Rev Environ Sci Technol 0:1–17. https://doi.org/10.1080/10643389.2022.2044254

Wang J, Zhang W, Xu J et al (2014) Octamethylcyclotetrasiloxane removal using an isolated bacterial strain in the biotrickling filter. Biochem Eng J 91:46–52. https://doi.org/10.1016/j.bej.2014.07.003

Mishra A, Kumar M, Bolan NS et al (2021) Multidimensional approaches of biogas production and up-gradation: opportunities and challenges. Bioresour Technol 338:125514. https://doi.org/10.1016/j.biortech.2021.125514

Singh A, Prajapati P, Vyas S et al (2022) A comprehensive review of feedstocks as sustainable substrates for next-generation biofuels. Bioenergy Res. https://doi.org/10.1007/s12155-022-10440-2

Aromolaran A, Sartaj M, Alqaralleh RMZ (2022) Biogas production from sewage scum through anaerobic co-digestion: the effect of organic fraction of municipal solid waste and landfill leachate blend addition. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-02152-y

Xu M, Yang M, Sun H, et al (2022) Role of multistage inoculation on the co-composting of food waste and biogas residue. Bioresour Technol 127681. https://doi.org/10.1016/j.biortech.2022.127681

Mano EM, Naranjo AM, Pecanha VP, Vaz C, do R, (2019) Life cycle assessment of manure biogas production: a review. J Clean Prod 219:411–423. https://doi.org/10.1016/j.jclepro.2019.02.091

Rücker C, Kümmerer K (2014) Environmental Chemistry of Herbicides, Volume 2. 21:312

Companioni-Damas EY, Santos FJ, Galceran MT (2014) Linear and cyclic methylsiloxanes in air by concurrent solvent recondensation-large volume injection-gas chromatography-mass spectrometry. Talanta 118:245–252. https://doi.org/10.1016/j.talanta.2013.10.020

Victor A, Ribeiro J, Araújo F (2019) Study of PDMS characterization and its applications in biomedicine: a review. J Mech Eng Biomech 4:1–9. https://doi.org/10.24243/jmeb/4.1.163

Lassen C, Hansen CL, Mikkelsen SH, Maag J (2005) Siloxanes - consumption , toxicity and alternatives. DANISH Minist Environ Environ Proj No 1031 2005 Miljøprojekt 1–111

Guo W, Dai Y, Chu X et al (2021) Assessment bioaccumulation factor (BAF) of methyl siloxanes in crucian carp (Carassius auratus) around a siloxane production factory. Ecotoxicol Environ Saf 213:111983. https://doi.org/10.1016/j.ecoenv.2021.111983

Surita SC, Tansel B (2014) Emergence and fate of cyclic volatile polydimethylsiloxanes (D4, D5) in municipal waste streams: release mechanisms, partitioning and persistence in air, water, soil and sediments. Sci Total Environ 468–469:46–52. https://doi.org/10.1016/j.scitotenv.2013.08.006

Wang X, Schuster J, Jones KC, Gong P (2018) Occurrence and spatial distribution of neutral perfluoroalkyl substances and cyclic volatile methylsiloxanes in the atmosphere of the Tibetan Plateau. Atmos Chem Phys 18:8745–8755. https://doi.org/10.5194/acp-18-8745-2018

Nu Nguyen HM, Khieu HT, Ta NA et al (2021) Distribution of cyclic volatile methylsiloxanes in drinking water, tap water, surface water, and wastewater in Hanoi. Vietnam Environ Pollut 285:117260. https://doi.org/10.1016/j.envpol.2021.117260

Tran VTL, Gélin P, Ferronato C et al (2019) Adsorption of linear and cyclic siloxanes on activated carbons for biogas purification: Sorbents regenerability. Chem Eng J 378:122152. https://doi.org/10.1016/j.cej.2019.122152

Ortiz-Ardila AE, Díez B, Celis C et al (2021) Microaerobic conditions in anaerobic sludge promote changes in bacterial composition favouring biodegradation of polymeric siloxanes. Environ Sci Process Impacts 23:1182–1197. https://doi.org/10.1039/d1em00143d

Pascual C, Cantera S, Muñoz R, Lebrero R (2021) Siloxanes removal in a two-phase partitioning biotrickling filter: influence of the EBRT and the organic phase. Renew Energy 177:52–60. https://doi.org/10.1016/j.renene.2021.05.144

Laubie B, Bonnafous E, Desjardin V et al (2013) Silicone-based surfactant degradation in aqueous media. Sci Total Environ 454–455:199–205. https://doi.org/10.1016/j.scitotenv.2013.02.022

Sevimoĝlu O, Tansel B (2013) Effect of persistent trace compounds in landfill gas on engine performance during energy recovery: a case study. Waste Manag 33:74–80. https://doi.org/10.1016/j.wasman.2012.08.016

Schweigkofler M, Niessner R (1999) Determination of siloxanes and VOC in landfill gas and sewage gas by canister sampling and GC-MS/AES analysis. Environ Sci Technol 33:3680–3685. https://doi.org/10.1021/es9902569

Gaj K (2020) Adsorptive biogas purification from siloxanes-a critical review. Energies 13:2605. https://doi.org/10.3390/en13102605

Fernandes AS, Azevedo T, Rocha F, et al (2022) Plant uptake potential and soil persistence of volatile methylsiloxanes in sewage sludge amended soils. Chemosphere 308:. https://doi.org/10.1016/j.chemosphere.2022.136314

Torre M, Borin D, Segreto M, et al (2019) Siloxanes concentration and removal in biomethane from sewage sludge. Eur Biomass Conf Exhib Proc 137–138

Rasi S, Läntelä J, Rintala J (2011) Trace compounds affecting biogas energy utilisation - a review. Energy Convers Manag 52:3369–3375. https://doi.org/10.1016/j.enconman.2011.07.005

Raich-Montiu J, Ribas-Font C, de Arespacochaga N et al (2014) Analytical methodology for sampling and analysing eight siloxanes and trimethylsilanol in biogas from different wastewater treatment plants in europe. Anal Chim Acta 812:83–91. https://doi.org/10.1016/j.aca.2013.12.027

López ME, Rene ER, Veiga MC, et al (2012) Environmental chemistry for a sustainable world. In: Environmental Chemistry for a Sustainable World. pp 347–378

Mendiara T, Cabello A, Izquierdo MT et al (2021) Effect of the presence of siloxanes in biogas chemical looping combustion. Energy Fuels 35:14984–14994. https://doi.org/10.1021/acs.energyfuels.1c02031

Álvarez-Flórez J, Egusquiza E (2015) Analysis of damage caused by siloxanes in stationary reciprocating internal combustion engines operating with landfill gas. Eng Fail Anal 50:29–38. https://doi.org/10.1016/j.engfailanal.2015.01.010

Wang N, Tan L, Xie L et al (2020) Investigation of volatile methyl siloxanes in biogas and the ambient environment in a landfill. J Environ Sci (China) 91:54–61. https://doi.org/10.1016/j.jes.2020.01.005

Piechota G (2021) Siloxanes in biogas: approaches of sampling procedure and GC-MS method determination. Molecules 26:. https://doi.org/10.3390/molecules26071953

Amaraibi RJ, Joseph B, Kuhn JN (2022) Techno-economic and sustainability analysis of siloxane removal from landfill gas used for electricity generation. J Environ Manage 314:115070. https://doi.org/10.1016/j.jenvman.2022.115070

Östürk Ö, Sevimoğlu O (2020) Identification of major and minor elements by multiple analysis responsible for deposit formation on engine utilizing landfill gas. Fuel 277:. https://doi.org/10.1016/j.fuel.2020.118125

Konkol I, Cebula J, Bohdziewicz J et al (2020) Mineral deposit formation in gas engines during combustion of biogas from landfills and municipal WWTP. Ecol Chem Eng S 27:347–356. https://doi.org/10.2478/eces-2020-0022

Accettola F, Guebitz GM, Schoeftner R (2008) Siloxane removal from biogas by biofiltration: biodegradation studies. Clean Technol Environ Policy 10:211–218. https://doi.org/10.1007/s10098-007-0141-4

Tansel B, Surita SC (2019) Managing siloxanes in biogas-to-energy facilities: Economic comparison of pre- vs post-combustion practices. Waste Manag 96:121–127. https://doi.org/10.1016/j.wasman.2019.07.019

Soreanu G (2016) Insights into siloxane removal from biogas in biotrickling filters via process mapping-based analysis. Chemosphere 146:539–546. https://doi.org/10.1016/j.chemosphere.2015.11.121

Piechota G (2022) Biogas / biomethane quality and requirements for combined heat and power ( CHP ) units / gas grids with a special focus on siloxanes-a short review. 3:1–10

Cabrera-Codony A, Montes-Morán MA, Sánchez-Polo M et al (2014) Biogas upgrading: optimal activated carbon properties for siloxane removal. Environ Sci Technol 48:7187–7195. https://doi.org/10.1021/es501274a

Gaj K (2017) Applicability of selected methods and sorbents to simultaneous removal of siloxanes and other impurities from biogas. Clean Technol Environ Policy 19:2181–2189. https://doi.org/10.1007/s10098-017-1422-1

Vagenknechtová A, Ciahotný K, Vrbová V (2017) Siloxanes removal from biogas using activated carbon. Acta Polytech 57:131–138. https://doi.org/10.14311/AP.2017.57.0131

Piechota G (2021) Multi-step biogas quality improving by adsorptive packed column system as application to biomethane upgrading. J Environ Chem Eng 9:105944. https://doi.org/10.1016/j.jece.2021.105944

Kajolinna T, Aakko-Saksa P, Roine J, Kåll L (2015) Efficiency testing of three biogas siloxane removal systems in the presence of D5, D6, limonene and toluene. Fuel Process Technol 139:242–247. https://doi.org/10.1016/j.fuproc.2015.06.042

Gong H, Chen Z, Fan Y et al (2015) Surface modification of activated carbon for siloxane adsorption. Renew Energy 83:144–150. https://doi.org/10.1016/j.renene.2015.04.004

Schweigkofler M, Niessner R (2001) Removal of siloxanes in biogases. J Hazard Mater 83:183–196. https://doi.org/10.1016/S0304-3894(00)00318-6

Meng Z, Liu Y, Li X, Ma Z (2020) Removal of siloxane (L2) from biogas using methyl-functionalised silica gel as adsorbent. Chem Eng J 389:124440. https://doi.org/10.1016/j.cej.2020.124440

Liu YH, Meng ZY, Wang JY et al (2019) Removal of siloxanes from biogas using acetylated silica gel as adsorbent. Pet Sci 16:920–928. https://doi.org/10.1007/s12182-019-0336-4

Silva EN, Cantillo-Castrillon M, Dantas TM, et al (2021) Siloxane adsorption by porous silica synthesized from residual sand of wastewater treatment. J Environ Chem Eng 9:. https://doi.org/10.1016/j.jece.2020.104805

Jafari T, Jiang T, Zhong W et al (2016) Modified mesoporous silica for efficient siloxane capture. Langmuir 32:2369–2377. https://doi.org/10.1021/acs.langmuir.5b04357

Bak C, Lim CJ, Lee JG et al (2019) Removal of sulfur compounds and siloxanes by physical and chemical sorption. Sep Purif Technol 209:542–549. https://doi.org/10.1016/j.seppur.2018.07.080

Jiang T, Zhong W, Jafari T et al (2016) Siloxane D4 adsorption by mesoporous aluminosilicates. Chem Eng J 289:356–364. https://doi.org/10.1016/j.cej.2015.12.094

Zhong W, Jiang T, Jafari T et al (2017) Modified inverse micelle synthesis for mesoporous alumina with a high D4 siloxane adsorption capacity. Microporous Mesoporous Mater 239:328–335. https://doi.org/10.1016/j.micromeso.2016.10.028

Cabrera-Codony A, Santos-Clotas E, Ania CO, Martín MJ (2018) Competitive siloxane adsorption in multicomponent gas streams for biogas upgrading. Chem Eng J 344:565–573. https://doi.org/10.1016/j.cej.2018.03.131

Noshadi I, Kanjilal B, Jafari T et al (2016) Hydrophobic mesoporous adsorbent based on cyclic amine-divinylbenzene copolymer for highly efficient siloxane removal. RSC Adv 6:77310–77320. https://doi.org/10.1039/c6ra11382f

Santiago R, Moya C, Palomar J (2020) Siloxanes capture by ionic liquids: solvent selection and process evaluation. Chem Eng J 401:126078. https://doi.org/10.1016/j.cej.2020.126078

National Center for Biotechnology Information PubChem Compound Summary for CID 12389, Tetradecane. In: 2022. https://pubchem.ncbi.nlm.nih.gov/compound/Tetradecane. Accessed 17 Apr 2022

Huppmann R, Lohoff HW, Schröder HF (1996) Cyclic siloxanes in the biological waste water treatment process - determination, quantification and possibilities of elimination. Fresenius J Anal Chem 354:66–71. https://doi.org/10.1007/s002169600011

Muñoz R, Meier L, Diaz I, Jeison D (2015) A review on the state-of-the-art of physical/chemical and biological technologies for biogas upgrading. Rev Environ Sci Biotechnol 14:727–759. https://doi.org/10.1007/s11157-015-9379-1

Yousef AM, El-Maghlany WM, Eldrainy YA, Attia A (2018) New approach for biogas purification using cryogenic separation and distillation process for CO2 capture. Energy 156:328–351. https://doi.org/10.1016/j.energy.2018.05.106

Baena-Moreno FM, Rodríguez-Galán M, Vega F et al (2019) Biogas upgrading by cryogenic techniques. Environ Chem Lett 17:1251–1261. https://doi.org/10.1007/s10311-019-00872-2

Delhoménie MC, Heitz M (2005) Biofiltration of air: a review. Crit Rev Biotechnol 25:53–72. https://doi.org/10.1080/07388550590935814

Stamatelatou K, Tsagarakis KP (2015) Sewage treatment plants : economic evaluation of innovative technologies for energy efficiency

Darvin C, Serageldin M (2015) Using bioreactors to control air pollution. NepisEpaGov 28

Ángeles Torres R, Marín D, Rodero M del R, et al (2020) Biogas treatment for H2S, CO2, and other contaminants removal. From Biofiltration to Promis Options Gaseous Fluxes Biotreat 153–176. https://doi.org/10.1016/b978-0-12-819064-7.00008-x

Quijano G, Huerta-Ochoa S, Gutiérrez-Rojas M (2010) Assessment of the limiting step of mass transfer in n-hexadecane biodegradation in a bubble column reactor. Water Sci Technol 62:906–914. https://doi.org/10.2166/wst.2010.343

Lebrero R, Hernández M, Quijano G, Muñoz R (2014) Hexane biodegradation in two-liquid phase biofilters operated with hydrophobic biomass: effect of the organic phase-packing media ratio and the irrigation rate. Chem Eng J 237:162–168. https://doi.org/10.1016/j.cej.2013.10.016

Muñoz R, Gan E, Hernández M, Quijano G (2013) Hexane biodegradation in two-liquid phase bioreactors: high-performance operation based on the use of hydrophobic biomass. Biochem Eng J 70:9–16. https://doi.org/10.1016/j.bej.2012.09.009

Xu S, Kropscott B (2014) Evaluation of the three-phase equilibrium method for measuring temperature dependence of internally consistent partition coefficients (KOW, KOA, and KAW) for volatile methylsiloxanes and trimethylsilanol. Environ Toxicol Chem 33:2702–2710. https://doi.org/10.1002/etc.2754

Muñoz R, Daugulis AJ, Hernández M, Quijano G (2012) Recent advances in two-phase partitioning bioreactors for the treatment of volatile organic compounds. Biotechnol Adv 30:1707–1720. https://doi.org/10.1016/j.biotechadv.2012.08.009

San-Valero P, Dorado AD, Quijano G et al (2018) Biotrickling filter modeling for styrene abatement. Part 2: Simulating a two-phase partitioning bioreactor. Chemosphere 191:1075–1082. https://doi.org/10.1016/j.chemosphere.2017.10.141

Soreanu G, Dumont É (2020) From biofiltration to promising options in gaseous fluxes biotreatment

Pascual C, Cantera S, Muñoz R, Lebrero R (2020) Comparative assessment of two biotrickling filters for siloxanes removal: effect of the addition of an organic phase. Chemosphere 251:0–7. https://doi.org/10.1016/j.chemosphere.2020.126359

Zhang Y, Oshita K, Kusakabe T et al (2020) Simultaneous removal of siloxanes and H2S from biogas using an aerobic biotrickling filter. J Hazard Mater 391:122187. https://doi.org/10.1016/j.jhazmat.2020.122187

Yang L, Corsolini SI (2019) Online removal of volatile siloxanes in solid-state anaerobic digester biogas using a biofilter and an activated carbon filter. J Environ Chem Eng 7:103284. https://doi.org/10.1016/j.jece.2019.103284

Boada E, Santos-Clotas E, Cabrera-Codony A, et al (2021) The core microbiome is responsible for volatile silicon and organic compounds degradation during anoxic lab scale biotrickling filter performance. Sci Total Environ 798:. https://doi.org/10.1016/j.scitotenv.2021.149162

Bruneel J, Walgraeve C, Mukurarinda J (2018) Biofiltration of hexane, acetone and dimethyl sulphide using wood, compost and silicone. J Chem Technol Biotechnol 93:2234–2243. https://doi.org/10.1002/jctb.5566

Soreanu G, Béland M, Falletta P, et al (2011) Approaches concerning siloxane removal from biogas - a review. Can Biosyst Eng / Le Genie des Biosyst au Canada 53:

Bachmann N (2013) Design and engineering of biogas plants. Biogas Handb Sci Prod Appl 191–211. https://doi.org/10.1533/9780857097415.2.191

Flores-Cortés M, Pérez-Trevilla J, de María C-López F et al (2021) H2S oxidation coupled to nitrate reduction in a two-stage bioreactor: targeting H2S-rich biogas desulfurization. Waste Manag 120:76–84. https://doi.org/10.1016/j.wasman.2020.11.024

Quijano G, Valenzuela EI, Cantero D, et al (2021) Impact of an anoxic desulfurization process on methane content of the purified biogas. Fuel 303:. https://doi.org/10.1016/j.fuel.2021.121256

San-Valero P, Penya-roja JM, Javier Álvarez-Hornos F et al (2019) Fully aerobic bioscrubber for the desulfurization of H2S-rich biogas. Fuel 241:884–891. https://doi.org/10.1016/j.fuel.2018.12.098

Quijano G, Figueroa-González I, Buitrón G (2018) Fully aerobic two-step desulfurization process for purification of highly H2S-laden biogas. J Chem Technol Biotechnol 93:3553–3561. https://doi.org/10.1002/jctb.5732

Han M, Wang C, Fu Y (2018) Treatment of hydrophobic volatile organic compounds using two-liquid phase bio filters. Sci Total Environ 640–641:1447–1454. https://doi.org/10.1016/j.scitotenv.2018.05.400

Nourmohammadi M, Karimi A, Golbabaei F et al (2021) Biodegradation of toluene in a two-phase low-pressure bioscrubber with using silicon oil as organic phase. Int J Environ Anal Chem. https://doi.org/10.1080/03067319.2021.1921763

Wasserbauer R, Zadak Z (1990) Growth of Pseudomonas putida and P . fluorescens on Silicone Oils. 393:384–393

Xu L, Shi Y, Cai Y (2013) Occurrence and fate of volatile siloxanes in a municipal Wastewater Treatment Plant of Beijing, China. Water Res 47:715–724. https://doi.org/10.1016/j.watres.2012.10.046

Li Y, Zhang W, Xu J (2014) Siloxanes removal from biogas by a lab-scale biotrickling filter inoculated with Pseudomonas aeruginosa S240. J Hazard Mater 275:175–184. https://doi.org/10.1016/j.jhazmat.2014.05.008

Huynh H, Le TV, Tran L (2020) Removal of H2S in biogas using biotrickling filter : recent development. Process Saf Environ Prot 144:297–309. https://doi.org/10.1016/j.psep.2020.07.011

Quijano G, Figueroa-gonzález I, Buitrón G (2018) Fully aerobic two-step desulfurization process for purification of highly H2S-laden biogas. 3553–3561. https://doi.org/10.1002/jctb.5732

Brito J, Almenglo F, Ramírez M, Gómez JM (2017). PID control system for biogas desulfurization under anoxic conditions. https://doi.org/10.1002/jctb.5243

Grümping R, Michalke K, Hirner AV, Hensel R (1999) Microbial degradation of octamethylcyclotetrasiloxane. Appl Environ Microbiol 65:2276–2278. https://doi.org/10.1128/aem.65.5.2276-2278.1999

González-Cortés JJ, Almenglo F, Ramírez M, Cantero D (2021) Simultaneous removal of ammonium from landfill leachate and hydrogen sulfide from biogas using a novel two-stage oxic-anoxic system. Sci Total Environ 750:141664. https://doi.org/10.1016/j.scitotenv.2020.141664

Chan-Pacheco CR, Valenzuela EI, Cervantes FJ, Quijano G (2021) Novel biotechnologies for nitrogen removal and their coupling with gas emissions abatement in wastewater treatment facilities. Sci Total Environ 797:149228. https://doi.org/10.1016/j.scitotenv.2021.149228

Santos-Clotas E, Cabrera-Codony A, Comas J, Martín MJ (2020) Biogas purification through membrane bioreactors: experimental study on siloxane separation and biodegradation. Sep Purif Technol 238:116440. https://doi.org/10.1016/j.seppur.2019.116440

Han MF, Wang C, Fu Y (2018) Treatment of hydrophobic volatile organic compounds using two-liquid phase biofilters. Sci Total Environ 640–641:1447–1454. https://doi.org/10.1016/j.scitotenv.2018.05.400

Qu Y, Ma Y, Wan J, Wang Y (2018) Quantitative structure–activity relationship for the partition coefficient of hydrophobic compounds between silicone oil and air. Environ Sci Pollut Res 25:15641–15650. https://doi.org/10.1007/s11356-018-1705-z

Aziz T, Fan H, Khan FU et al (2019) Modified silicone oil types, mechanical properties and applications. Polym Bull 76:2129–2145. https://doi.org/10.1007/s00289-018-2471-2

Funding

This work was supported by the Mexican Council for Science and Technology, CONACYT (Ciencia Básica project A1-S-10079), and DGAPA-UNAM (PAPIIT project TA100123). L.A. Rivera-Montenegro and E.I. Valenzuela acknowledge the support from CONACYT through the grants 869998 and 40872, respectively. The Regional Government of Castilla y León and the EU-FEDER program (grant numbers CLU 2017–09, UIC 315 and CL-EI-2021–07) are also gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

All authors contributed to the writing, review, and editing of the present work. In addition, Raúl Muñoz: funding acquisition; Guillermo Quijano: conceptualization and funding acquisition.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rivera-Montenegro, L., Valenzuela, E.I., González-Sánchez, A. et al. Volatile Methyl Siloxanes as Key Biogas Pollutants: Occurrence, Impacts and Treatment Technologies. Bioenerg. Res. 16, 801–816 (2023). https://doi.org/10.1007/s12155-022-10525-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-022-10525-y