Abstract

Industry 5.0 (I5.0) is the next industrial revolution that will leverage human intervention in collaboration with intelligent, logical, and smart machines to attain even more user-preferred and resource-efficient manufacturing and supply chain solutions. The main aim of this article is to study I5.0 technologies in supply chains when these are affected by disruptive phenomena such as those created by wars, climate change or pandemics. A systematic literature review methodology was conducted to understand the present knowledge connected with this theme. This study summarises 194 research articles from the period 2009 to 2022 to understand the present knowledge connected with this theme. The research findings show a significant gap related to the adoption of I5.0 technologies to prevent or overcome supply chain disruptions. 194 articles, including journal and review articles, were identified in the literature. The study provides a novel and insightful concept related to I5.0 within the context of supply chain disruptions. The potential applications of I5.0 and Industry 4.0 are elaborately discussed in three areas, namely: (1) disruptions in supply chains due to pandemics; (2) disruptions in supply chains due to war; and (3) disruptions in supply chains due to climate change. Finally, this study highlights research implications and proposes future research avenues that will contribute to further exploring the adoption of I5.0 technologies to prevent, manage and overcome disruptions in supply chains.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The contemporary world has become more volatile and unprecedented due to dynamic technological development (e.g., the fourth and fifth industrial revolutions) and robust global changes (e.g., coronavirus pandemic, climate crisis, wars, great changes in consumer preference and geopolitical disruption) (Free and Hecimovic 2021). Global supply chains, humans, industries, and investors face various adversities emerging from sociological, economical, and political phenomena (Grzybowska and Stachowiak 2022). In the recent era, the manufacturing industries are experiencing an expeditious transformation because of the augmented use of digital technologies, big data, and Artificial Intelligence (AI)-based solutions (Kusiak 2018). Manufacturers from small and large-scale industries are facing the complicated challenge of enhancing productivity while considering humans (Leitão et al. 2016). This ongoing challenge has become even tougher after the presence and crucial role of robots in the manufacturing sector through brain-machine interference and advancement in AI. Such various challenges can take forward by the succeeding industrial revolution, known as Industry 5.0 (I5.0) (Doyle-Kent and Kopacek 2020). In simple terms, I5.0 refers to a combination of humans and machines working as collaborators instead of as competitors (Nahavandi 2019).

The word “Industry 5.0” was invented by Rada (2015). The major features of I5.0 entail the usage of robots to prevent and mitigate risk. It is considered that robots can understand, observe and feel human operators along with the expectation and purpose for the given tasks and actions being accomplished. The motivation is that these robots will understand and implement how a human executes a task and help individual operators in performing the tasks. Moreover, I5.0 enables the perception of human life with AI to maximise man's capacity. I5.0 technologies like the internet of things (IoT), robots, advanced information and technology (IT), artificial intelligence (AI), virtual reality (VR) and augmented reality (AR) are continuously used for the benefit of human workers and their well-being (Brahmi et al. 2022).

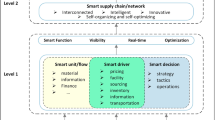

I5.0 identifies the strength of the industry to fulfil their social goals beyond development and employment to create sustainable ways of growth by prioritizing employee health first. Individuals seek satisfaction with their job and healthy career. Thus, Industry (I4.0) contributes to the advanced technologies upgrade that is needed by industries (Agrawal et al. 2021). It strengthens employees and polishes their skill improvements and training practices. To summarise, I5.0 is a revolution which aims to make industries more compatible, sustainable, human critical thinking-centric and resilient. For many researchers, it is an evolution and advancement to those that are an addition to the concepts and practices of I4.0, or we can say that I5.0 complements the paradigm of I4.0. In Fig. 1, the objectives, systematic approaches, and human factors of I4.0 and I5.0 are presented.

Furthermore, the fifth industrial revolution is highly potential to optimise the supply chain (SC) in the most strategic way (Frederico 2021). The system of humans and institutions that are working together to shift goods and services from the raw stage to final consumption is known as SC and any unprecedented situation that cause to disrupts the SC and its working is known as SC disruption. For any enterprise, SC is the heart of its business, and the occurrences of any critical global event may risk the SC. Recently, COVID-19-induced SC disruption has manifested that both domestic and global businesses at any scale and sectors are vulnerable to breakdown. (Khan et al. 2022c) concluded that the COVID-19 pandemic has negatively influenced the sustainability of SCs, mitigation strategies and green spaces and thus harmed such technologies.

Numerous external and internal factors disturb the network of SC. The breakdown in one entity has a direct and negative impact on other entities and this is known as the ripple effect. The forward (supplier-to-customer) and backward (customer-to-supplier) disruption trigger the entire supply chain process that led to a ripple effect. A sustainable supply chain is essential to make the SC less harmful to the environment while also benefiting the environmental, social, and economic performance of industries (Rehman Khan et al. 2022). Sustainable supply chain practices positively impact SCs and encourage I4.0 and I5.0 technologies to be implemented by organisations (Khan et al. 2023). In past, it can be noticed that it is not just the pandemic that can be shrugged off the SC but various unprecedented episodes in the past, i.e., huge flooding in Thailand, flooding of Queensland in Australia, hurricane Katrina disrupting gasoline supply in some parts of the US has severely affected the coal supply chain. The very recent Russia-Ukraine war disturbs SC of the food, energy and natural resources and is a reminder to the world to convert future SC immune to such unpredicted disruptions.

In the history of SC, many technologies have been invented to reconcile traditional practices and enhance their efficiency (Fawcett et al. 2011). The major aim of these technologies is to build a resilient and transparent network of the supply chain by adopting some techniques like keeping additional stock, doing business with multiple suppliers, optimizing the structure of a network, and having high visibility of data and product flow over the SC (Ivanov et al. 2019). Additionally, in the past decade, industries have started commencing on the “I4.0” technologies that denote the advanced computing, digital, AI, big data, cloud computing, machine learning, blockchain, automation and robotics that owe a high potential in modernizing the existing traditional SC to digitally owned and connected infrastructure. After I4.0, an advanced wave of the industrial revolution, I5.0 is emerging that focus on human interference with machines (Schiele et al. 2022). Therefore, to manage the SC effectively and reduce related risks, a holistic approach to digitalizing and re-examining present operational procedures is needed.

Apart from the I4.0 technologies, regarding I5.0, there is a wide gap present concerning what and how this I5.0 revolution will mitigate SC disruptions (Nayeri et al. 2023). However, (Grzybowska and Stachowiak 2022) identified the challenges of SC disruption, from the economic, political and sociological dimensions, which majorly affect economies and industries. They highlighted various characteristics of SC disruption and developed evolving strategies to minimize such disruptions. (Karmaker et al. 2023) highlights the various issues in employing I5.0 to manage the disruption of SCs during the COVID-19 pandemic in emerging economies and focused on the adoption of I5.0 technologies in the post-COVID-19 era to increase SC sustainability through financial support and funding. For environmental protection, green venture capital helps industries to channelize their fund to cleantech, green innovation and technological innovation (Dhayal et al. 2023). While there is a growing body of available literature on the implementation of I4.0, there are certain gaps in terms of practical and theoretical implementation of I5.0 technologies in the SC context. Besides the lack of available literature in I5.0 in a SC disruption context, the gap addressed by the present research is related to how fifth industrial revolution plays a signifcnat role for enhancng the knowledge of SC managers to improve the SC process by mitigating disruptions and the study also provides the future research directions in this context. Therefore, certain knowledge concerning the relationship between SC and I5.0 becomes significantly important.

Hence, the purpose of the present study is to introduce and highlight a novel view of the various I5.0 technologies from SC perspectives and to evaluate how these technologies can be cumulatively applied to solve global and future events at the time of war, pandemic and climate change through the systematic literature review (SLR). The present study is aimed to answer the following identified research questions?

RQ.1: How do the technologies of I5.0 can mitigate global disruptive events to prevent disruption in supply chains during wars, climate change and pandemics?

RQ.2: What are the future opportunities for adopting and integrating the technologies of I5.0 within supply chains?

To address these research questions, this study aimed to present an SLR of disruptions in SC at the time of war, climate change and pandemics and investigate how I4.0 and I5.0 technologies may prevent such disruption. For this study, only the SCOPUS database was selected for identifying all the related articles. By selecting the relevant keywords and manual screening of articles, we shortlisted 194 articles for review. A detailed explanation for collecting, selecting, screening and shortlisting documents is presented in the research methodology section.

The novelty of the presented work is manyfold. Firstly, this review includes an integrated approach of bibliometric study and systematic literature review. Secondly, the article considers the three major causes of disruptions in SC, namely: war, pandemic, and climate change, which have not been discussed previously in the literature. Thirdly, this work proposes some future research questions related to three causes of disruptions in SCs. The study will be helpful to researchers, policymakers and practitioners to understand whether, and how, I5.0 technologies could help to overcome SC disruptions in times of pandemics, war and climate change. The present research also provides light into potential future research directions in this research area.

The remaining section of the article is divided as follows; Section 2 presents a research methodology used in the study. A review and discussion of supply chain disruptions and I5.0 technologies are shown in Section 3. Section 4 highlights a detailed discussion of the study and Section 5 shows the conclusion of the study.

2 Research methodology

The present work focuses on exploring how the technologies of I4.0 and I5.0 ensure SC in the different industries during the three major disruptions: war, pandemic, and climate change. For this, a critical review of the existing literature has been performed segregating it into three major events. The knowledge of the technologies of I4.0 and I5.0 helps in the planning of suitable strategies for industries to prevent SC disruption. Thus, the present study offers an informative insight into the literature by collecting and analysing related research findings. Furthermore, to conduct this analysis, the present study has used a hybrid method combining SLR and bibliometric analysis. The study by (Meredith 1993) SLR enables “integrating several different works on the same topic, summarizing the common elements, contrasting the differences, and extending the work in some fashion”. Moreover, the bibliometric analysis provides a summary of bibliography data of the existing literature that helps to identify the emerging trends and state of the intellectual structure of the given research area (Dervis 2019). Thus, a hybrid approach of SLR and bibliometric analysis is used to conduct the review work by performing the following steps: (1) identifying the research objective(s), (2) finalising the database, (3) applying an exclusion and inclusion criteria for screening the relevant research papers, (4) conducting a bibliometric analysis, and (5) performing a detailed review of shortlisted articles based on identified attributes.

Firstly, the keywords for the study were identified by conducting an academic discussion among the authors of this work. The applied search string used in the database is presented in Table 1.

After the keyword criteria, various exclusion and inclusion criteria were applied to extract the most appropriate articles in accordance with our research theme. The first article was identified in the year 2009, and articles from 2011 were considered as the concept of I4.0 arise in 2011. Only the English language is considered since it is a universal language and is widely accepted. Finally, 194 articles were considered for final review. A bibliometric analysis of the final articles is also performed through the R software package. Figure 2 shows the flowchart of the data extraction.

3 Bibliometric analysis

3.1 Trend of yearly publication

The publication frequency can be seen in Fig. 3 from 2009 to 2022. Since 2009, very few articles have been published till 2019. A sudden increase in publications can be seen in the year 2020 and then onwards the number of articles has increased year-wise. Until December 2022, the number of publications is 101 which is the highest among all the year-wise publications. The figure represents a growing interest among academicians and researchers in the related field and the I4.0 should be credited for such an enormous increase in publications.

3.2 Most productive journals and authors

In Table 2, the analysis of the top ten journals along with the total number of documents published in these journals is shown. “Sustainability Switzerland” tops this list followed by “Annals of Operations Research” and “International Journal of Production Research”. The analysis of the top ten cited authors with their global citations and subsequently, local top ten cited authors and their number of articles is shown in Table 3. The global citations mean the total number of citations cited in an document that is reported in online databases i.e., within and after the research domain, although local citations mean the number of citations of a document only from the publications within the related network (194 articles here) (Boyack and Klavans 2010).

3.3 Top keywords and co-occurrence of keywords

Table 4 shows the top ten keywords used by the authors in their articles. It was found that I4.0 is the majorly used keyword with a total occurrence of 64 followed by Artificial Intelligence and Sustainability. The visual presentation of keywords network analysis of the most occurring keywords is shown in Fig. 4.

4 Literature review on shortlisted articles

This section addresses the first research question RQ1. The authors have performed a detailed review that aims to identify, select, and assess the existing literature to acknowledge the identified research questions and to fulfil research objectives (Xiao and Watson 2019). The review is being conducted in three dimensions, namely, the impact of I4.0 and I5.0 technologies to act as an enabler to prevent disruptions in SCs during (i) pandemics, (ii) wars and (iii) climate change.

4.1 Disruption in supply change due to pandemics

The COVID-19 pandemic has gravely disrupted the manufacturing industries globally. It affects the production patterns and consumption behaviours of society and guides the adoption of sustainability in consumption and production. The pandemic has also expedited the I4.0 technologies and their adaption in promoting sustainable SC development. Piyathanavong et al. (2022) have identified the role of I4.0 technologies in promoting SCs during pandemics by conducting a case study on small, medium, and large-scale industries. They have investigated the impact of pandemics on the operations of Thai metals companies. Companies have adopted the automated technologies, data analytics, cloud technology, and simulation technologies of I4.0 and it resulted in the effective work performance of their employees. Project management, I4.0 and the adoption of circular economy (CE) are the contributing factors in sustainable SCs. They suggested companies to shift towards lower competitive markets and prioritise product customisation as a possible solution.

Dadash Pour et al. (2022) suggest that technologies of I4.0 such as cyber-physical systems, big data, additive manufacturing and IoT are helpful to overcome pandemic challenges. The significance of I4.0 in the identification of raw material provenance, business continuity, and collaboration, the agility of manufacturing, crisis simulation and related variables are studied. They developed a self-assessment readiness model that helps manufacturing companies decide their readiness level. Ivanov and Dolgui (2020) theorise an idea of digital SC through an automated model that shows a network state at a period. The amalgamation of data-driven factors and model-based approaches permits the relation of data, disruption modelling and performance assessment. The SC shock during the times of pandemic and post-pandemic retrieval prepares indubitable evidence for the serious need of mapping SC and its visibility through digital twins.

Spieske and Birkel (2021) have done a holistic literature review of enablers of I4.0 and SC resilience antecedents. They have proposed a conceptual framework representing the relationship between I4.0 resilience and SC disruption. To verify the proposed model, the authors have used the framework in the COVID-19-affected automotive industry. The study revealed that big data analytics is suitable to improve SC resilience whereas additive manufacturing and CPS, enablers of I4.0 are still less effective. The technologies of I4.0 maintains the pre-disruption resilience measures and enable industries for taking proactive risk management. Kumar et al. (2020) highlighted the epidemic outbreak and SC for daily essentials and the operational challenges faced by retail industries to provide efficient services. The study has identified various operational barriers in the retail sectors and concluded that I4.0 is a driver for minimizing the effect of challenges during pandemics. The barriers are non-flexible SC, lack of government support and incentives, trust among SC players, lack of coordination and communication, poor infrastructure, delay in supply essentials, less manpower, imbalance in demand and supply, the safety of staff, and consumer behaviour.

Jayashree et al. (2021) identified the core I4.0 technologies, their role and their impact on preventing the disruption of COVID-19 to strengthen SC resilience by using “Preferred Reporting Items for Systematic Review and Meta-Analysis” (PRISMA) on 1482 articles. The findings of the study suggest the importance of digitalisation of SC management in large industries. Technologies such as big data, cloud computing, IoT, additive manufacturing and blockchain are important variables to maintain SC resilience during a pandemic. Galanakis et al. (2021) investigated the innovations in the food industry that are directly affected by the outbreak pandemic including food safety, food security, bioactive food compounds and sustainability during the era of COVID-19. The anticipation of foreseen innovations that disturbed the food sector and SC of the food industry was also discussed. The findings of the study suggest Internet and Communication Technologies (ICT), blockchain in the SC of food and other applications of I4.0 has redefined the consumption pattern of society. This includes lab-grown meat, valorisation of bio-resources and plant-based alternatives of meat are the recent advances with the highest emerging scope in the evolving new era. The need to understand society’s attitude, understanding and barriers affects the behavioural pattern of consumers and the agriculture-based food industry.

Ambrogio et al. (2022) analysed the impact of the COVID-19 pandemic on employees and SC resilience in a comprehensive manner. The authors have proposed I4.0-driven solutions to increase workforce resilience namely, the remote operator, the prophetical well-being of operational staff, and plug-and-play workers. The technologies of Digital and Unconventional Sourcing and Product Innovation are being investigated from an integration perspective. Forward-looking industries should convert the disruption events into a chance for technical innovation in the organization. Reyes et al. (2023) studied lean SC a set of organisations connected with upstream and downstream values between processes that work efficiently to lessen costs and waste. In the study, a detailed investigation of constructs and multi-structural variables is considered to propose a conceptual reference model. They merge the digital technologies of I4.0 and lean manufacturing factors that aim to minimize waste and minimise costs during implementing lean supply chain planning (LSCP). Narayanamurthy and Tortorella (2021) have examined the impact of the pandemic on the work performance of employees in terms of quality and delivery. Secondly, they verified the moderating role of I4.0 on employee participation and performance by surveying 106 employees of different service organisations. The study revealed that work implications such as a work-from-home culture, fear of loss of job and virtual connection have a severe impact on employees’ performance at a different pace.

The digitalization of service organisations has pushed new ways of working in the post-pandemic era. Madhavan et al. (2022) in their study identified the characteristics of I4.0 and I5.0 in small and medium enterprise (SME) research by using the PRISMA approach. The findings of the study suggest a behavioural shift among academicians in exploring the I4.0 technologies in SMEs during the pre-pandemic and during the pandemic time. During the pandemic, the studies inclined toward human-centric approaches, adoption models, cost-effective solutions, AI, innovation industry and COVID-19 effects and resilience. The revolution of I5.0 emerged and supplemented I4.0. The study has proposed a conceptual model for evaluating the adoption of I4.0 and the digital transformation of SMEs in a global value chain. Kasinathan et al. (2022) discussed the potential of technologies to accomplish Sustainable Development Goals (SDGs). They analysed the outcomes of disruptive technologies on product development, healthcare transformation, nature-inclusive models and pandemic case study. The investigation of disruptive technologies highlighted the importance of I5.0 and Society 5.0 to achieve the SDGs. The study proposed an integrated framework to include recent technologies and bring forth the concepts of I5.0 and society 5.0 in smart cities and villages.

Maddikunta et al. (2022) discussed the survey-based examples of potential technologies and applications of I5.0 in intelligent healthcare, cloud manufacturing, manufacturing production and SC management during the post-pandemic era. They highlighted the supported technologies of I5.0 technologies i.e., digital twin, edge computing, blockchain and 6G and beyond to deal with the disruption in SC during the pandemic times. Romero and Stahre (2021) introduced the concept of “The Resilient Operator 5.0” concept. It is based on a human–machine system and human-operator resilience to provide a vision for the future in a resilient manufacturing system in the period of I5.0. The study suggests achieving a smart manufacturing industry through a human-centric perspective along with technical solutions.

4.2 Disruption in supply change due to climate change

The ecosystem of SC in the modern era has become difficult and fragile because of modern complexities and its interconnected functions from planning to production to distribution to final sales. Nowadays, industrial organisations have adopted the I4.0 technologies i.e., Big Data Analytics, Automation, robotics and IoT to take efficient decisions. Optimise current practices and end-to-end transparency which makes an ‘Intelligent supply chain”. Fluctuations in climate change make the SC functioning vulnerable to regional issues, product customisation, changes in consumer preferences and price competitiveness. To deal with such condition, IoT acts as an enabler for structured and flexible SC management and thus motivate the ecosystem of I4.0. Global events such as climate change consider traditional forecasting patterns as an inefficient parameter that escort to disruption in SC (Santhi and Muthuswamy 2022). Ben Youssef and Zeqiri (2022) have investigated the conditions under which I4.0 could support fighting climate change in the hospitality sector. The authors have proposed five conditions of technologies of I4.0 that can help to prevent climate change namely, enhance energy efficiency and reduce GHG, reduce water consumption, reduce food waste, promote circular hospitality 4.0 and reduction in transport cost. Moreover, the I4.0 offers various opportunities to enhance sustainable development and prevent SC disruptions in the hospitality sector.

Mastrocinque et al. (2022) in their study applied a “multi-criteria decision-making” intelligent approach to identify the Triple Bottom Line principles for sustainable SC development in the renewable energy sector by using I4.0 technologies. A case study of solar photovoltaic energy SC was conducted encompassing an energy production method from supply to disposal. Quantitative and qualitative data are analysed to identify the effect of I4.0 on three pillars of sustainability, economic, social and environmental. A novel sustainability index is proposed to analyse the sustainability of photovoltaic energy for seven European countries. According to Agrawal et al. (2022) integrated implementations of I4.0 technologies are required to design the product-service system to reduce the wastage of material, energy and ecosystems. To face the challenge of climate change in society, circular economy (CE) and I4.0 together can progress towards sustainable societies and prevent the SC disruption. The practices of CE will help individuals to understand the importance of reusing the products or to return the product after their efficient consumption. While performing the cluster analysis, five emerging themes were identified, namely, smart and circular supply chain (CSC), business models of I4.0 and the CE, sustainable practices and CE, digital CE and smart dissemble. An integrated framework of I4.0 and CE was developed to ensure effective decision-making to advance the efficient resource, premium quality o products, logistics and reduction in fossil-fuel carbon footprints.

Kumar et al. (2023) have evaluated the major success factors of I4.0 and CSC to achieve sustainable SC operations. Factors like climate change and scarcity of resources are the major components that force industries to examine their commitment towards society. The study has proposed a three-phase study framework of critical success factors (CSF) for the integration between I4.0 and CSC. It suggests that the adoption of CSFs with I4.0 technologies is a key component to achieving sustainability in SC operations followed by “knowledge of CSC” and “top management commitment”. Khan et al. (2022a, b, c, d) considered reverse logistics (RL) as an essential element in recent SC with various industries investing in CE. The linear models have various adverse environmental effects like, climate change, loss of biodiversity, ocean pollution, land refill and land degradation. The authors proposed to link RL with CE in the view of I4.0 and I5.0 technologies and developed a hierarchal structure among them by applying the Delphi method and Interpretive Structural based model. The findings of the study determine the I4.0 technologies as a successful enabler for sustainable inter-firm collaboration. The role of cyber-physical systems along with human interference coexist and learn from each other. In the case of logistic SCs, there are numerous stakeholders and partners even despite of automation and AI technologies make the tasks repetitive and manual. The findings suggested by (Foster and Rhoden 2020) explain that SC and logistics stakeholders are raising awareness and gradually integrating AI and automation into their operations.

Bunn et al. (2015) have projected the climate sustainability for coffee production at a world level by applying machine learning algorithms. These algorithms help to procure climate sustainability by using the database of geo-refereed production locations. The study examined the results of the change in climate on coffee production. It results indicate that climate change has a severe impact on coffee production, especially in Brazil. Thus, it leads to global losses in suitability for the production industry. The study suggests the in future Robusta production may help to reduce the losses in Arabica production. In the long span, the adaption of I4.0 technologies will be in high demand across the entire SC. Talari et al. (2022) reviewed the articles focused on big data and web-based technologies for food safety with special reference to climate change influences. Technologies are developed to handle complex and large data from diverse sources, thus big data and decision support systems (DSS) support the modern data-driven approaches to recognize the problems and provide solutions to enable improved decision-making processes. All the related information in food SCs is scattered and contains heterogeneity in data, scale, format and geographical origin. The interactions among food combinations, foodborne diseases and environmental factors are challenging and complex to predict. The study reveals the issues in implementing big data technology in food safety. It suggested a web-based DSS framework that helps in decision-making systems that are evolved with agri-food data sources. The study concluded that climate change affects food safety, and climate change projection data is helpful to assess DSS tools to improve efficiency, consumer confidence and health. It improves SC transparency and discourages illegal activities. The integration of SC with blockchain makes the process of SC more transparent.

De Bernardi et al. (2020) analyse the new paradigms of industrial technologies that impact the food industry in the long run. In the recent era, industries are known to resolve the big challenges of the new paradigm. In this view, the food sector plays a significant role during times of poverty, hunger, climate change, malnutrition, and social inequalities. To cope-up with such challenges, industries are adopting a digital transformation in terms of new ways of thinking, creating, and working with updated technology-driven machinery and methods to provide value to consumers and producers without disturbing the food SC. The authors suggest that digitalisation, big data, spatial applications, and the development of online applications are the contributing factors in food product transformation that aligns with sustainability and physical well-being challenges. Industries can renew or innovate their existing business models by direct connecting the consumers to producers or vice-versa through digital techniques by setting up innovation in marketing channels and enhancing logistics. Blockchain for SC traceability and auditability, AI for smart farming and urban farming, and data management for waste-less, and these are just a few of the disruptive technologies that an increasing number of industries have been adopting, redefining their business models.

Ghose et al. (2009) examined that IT plays a crucial debate in climate change. The vital role of IT as an enabler of the climate change issue is still unrecognised. In the massive inter-connect planet system, IT supplies a wide scope of tools and techniques to manage, model and optimise the SC. “The University of Wollongong Carbon-Centric Computing Initiative” (CCCI) addressed the issues of climate change with a range of computing technologies including optimisation technologies, SC management technologies, grid computing, business process improvement technologies and virtualisation technologies. The outline of the development of industrial technologies is aligned with climate change. The report suggests a web infrastructure that could leverage web optimisation to reduce the global carbon footprint. The shift towards simulation promotes green manufacturing and environment-inclined system in the industry. The role of IT-based technologies supports the SC optimisation audits to determine the best value obtained from the sound use of technology. Information and Communication Technology (ICT)-enabled collaboration techniques help in reducing carbon footprints. The report suggests a Decision Systems Lab in the area of business process management, industrial optimisation, software engineering and service-oriented computing. Lenny Koh et al. (2013) discussed the DSS for carbon emissions accounting and management for product SC. The study has proposed an SC framework that provides a business with a holistic knowledge of their SC and ensures the collaborative networks of SC. They designed and developed a DSS framework known as the “supply chain environmental analysis tool” (SCEnAT). It is an innovative and unique framework with various features as compared to existing tools namely, SC carbon accounting, and particular techniques of SC mapping, SC interventions and SC interventions evaluation. The SCEnAT framework is vital to reduce carbon emissions and promoting SC with open innovation. The framework contemplates the SC as a whole to take co-decision for reducing carbon with the most robust technology of life cycle assessment.

Sivarethinamohan and Sujatha (2021) focused on the role of blockchain technology that imparts hope to the most sensitive issue of environment and climate change facing the planet. Blockchain is a known promising technology attaining traction in many different fields. The technology of blockchain uncovers its capacities as a decentralised ledger of all progress across peer-to-peer networking and compiles everything of value in addition to financial transactions. It ensures a transition to cleaner and resource-conserving decentralised solutions to empower communities and natural capital. The adoption of blockchain in industries will ensure to preservation and support of the global environment at different levels including climate change, biodiversity conservation, life on land, life below the earth and healthy water bodies.

4.3 Disruption in supply change due to war

The earth is currently suffering from unrivalled interlinked environmental, social, political and economic challenges due to the outburst of a pandemic, war, climate change and others. The global dilemmas have posed a direct impact on food security and justify an urgent requirement for scientific innovation, solutions, and technological approaches. The alarming events such as war among countries create the response of agri-food industries and SC of their products in a major loss. The study by Hassoun et al. (2022) is a review of the two megatrends of agriculture and food industries. A sudden inclination to green vegetable diets and digital innovation in the production and consumption patterns of food. Several innovative technologies are correlated with the sustainable food system and nutrition quality. AI, big data, IoT and blockchain are being implemented in smart farms and smart food industries to enhance food production outcomes. The study suggests that the implementation of vegetal innovation and adopting I4.0 technologies with food SC have great potential that enables digital and ecological transitions. In the past decade, American agriculture has been beset by various outliers such as natural disasters, trade wars, cyber-attack and pandemics. These unpredictable black swans create uncertainties in the food SC from the level of agriculture production to the consumption at the household level and global trade flows. The major drivers beyond agriculture productivity are weather-related disruption, transport disruption, shipping delays and policy reforms. The study proposed an AI-enabled framework that can measure uncertainties while evaluating cause-effect factors in agriculture production. Deployment of deep learning (DL) model can forecast the impact of crop yield during extreme cyber-attack and weather events. The study suggests that the adaption of deep farm technology is effective in forecasting and quantifying the effects of war and outlier events on crop yield in the regions of the United States (Wang et al. 2022).

Zhang et al. (2020) examined the past and future of operation management research from 1997–2018 by using a machine learning approach motivated by the three major events, namely, the US-China war, the COVID-19 pandemic and material, information and financial flows of operation management. The study concludes that to achieve operational efficiency, sustainability and resilience in I4.0, industries should accept three capabilities, namely; continuity, clarity and connectivity. Allam et al. (2022) explore the impact of the Russia-Ukraine war with a focus on the role of climate finance to achieve equitable and sustainable mechanisms that are motivated by the decarbonisation agenda. The agenda was highlighted in COP 26 debates in the Glasgow Climate Pact. The study concludes that the unprecedented event of the Russia-Ukraine war has had a direct impact on the prices of commodities, supply and pricing of labour, availability of resources and knock-on impacts on global SCs. The impact of SC disruption during a war is relatively high on the cost of final products, long transportation time, less access to raw materials and an increase in inequality in SCs. To cope-up with such disruptions, industries are encouraged to adopt green technologies in their production.

5 Discussion

This section addresses the second research question RQ2. To address the complexities of global SCs, I5.0 technologies can be an advancement and a transition that can impart immense benefits. Traditional SC management along with its various complications requires modern data-driven technologies to provide key insights into the dataset that encourage the decision-making power of functional managers. For example, the demand and supply of products need new-fangled data analytics and machine learning-based technologies, real-time inventory management, the tracking of assets using IoT, AI and visibility in the value chain by using end-to-end optimisation of products compelling AI and the generation of an agile SC to meet the needs of consumers by combining robotics, human brain, automation and additive manufacturing.

The present study shows how the technologies of I5.0 helps to prevent the disruption in SC and implementing the I5.0. During the SLR it has been discovered that the freedom of customisation in the products cannot be achieved completely through I4.0 (Huang et al. 2021). The perfection to mass-customise and include various products is indeed a great advantage to industries and societies. Thus, it enables the scope of extensive personalisation of products that are close to customer satisfaction. As a result, the level of resistance that must be enforced becomes considerably more acceptable. Furthermore, customisation has an indirect but relevant effect on various factors. Although machines are designed to execute numerous tasks and work with humans to show a practical image of the version of I5.0 (Liu et al. 2021). This is also directly correlated to the goals of sustainability, societal value creation, and bioeconomy, which involve working with robots and on analogues that provide advantages to humans. Khan et al. (2022d) investigated the role of advanced digital technologies in the post-pandemic time to indicate that gross fixed capital and knowledge spillover is positively correlated with international trade.

Traditional SC planning in a business is segregated into the prediction of demand, supply, production and sales and operations planning. Because it is dependent on internal data, the data that is shared among these functions is not entirely transparent. Additionally, they are not impervious to unpredicted external circumstances like the COVID-19 epidemic, wars, natural disasters, and so on. Moreover, external data can be utilised dynamically by data-driven planning using AI, machine learning, and data analytics to prevent disruption shocks. However, these techniques can be utilised in safety concerns and mitigating labour supply by enabling process optimisation, remote working and machine utilisation that improves productivity and quality enhances operational efficiency and reduces cyclical time. Automation and Robotics and Robotic Process Automation have the potential to dramatically reduce the dependency on unskilled manual labour. Logistics provided by the IoT, and drones allowed for automation and contactless delivery of commodities. Technologies like route optimisation, carrier analytics and digital fleet management can assist in enhancing operative resilience to lessen the impact of such unplanned external catastrophes. Khan et al. (2022b) examined the role of technological innovation on CE and suggested integrating CE with digital technologies to achieve long-term financial stability. However, in the recent era, many I4.0 technologies pretend as a major driving force in SC management such as supply planning, logistics, order management, stakeholder relationship, performance management, and strategic SC. Multidirectional communication across the SC network brings a modification in service, cost, capital, and agility to a traditional SC.

Human–machine collaboration is the next core focus of I5.0 because of robots, governing software and integrating IoT with AI (Naveed et al. 2018) and other factors (Aslam et al. 2020). The creation of these cooperative robots and virtual helpers will facilitate human work systems and guarantee the efficient operation of repetitive procedures (Demir et al. 2019). Additionally, this would address the eighth and ninth Sustainability Goals (Decent Work and Economic Growth) and (industry, innovation, and infrastructure). Bioeconomy integrated with customisation and human–machine collaboration will have a high individual influence as it integrates two sides of technologies, i.e. “biology and economy”, where biology will focus on the bioproducts, e.g., agriculture (Lioutas et al. 2021), sea products, animal products, food products and forest products along with the services, products and medicine and surgery aspects products and, correspondingly, they have a positive impact on the environment, business growth and financial aspects and, thus creating a clean, green, resilient, bio-oriented, sustainable economy. Bionics has a huge application in the field of medicine and surgery including pharmaceuticals and drugs (Kucirkova 2017). After learning from the COVID-19 pandemic's catastrophic effects on every sector of the global economy and in every country, the creation of essential medications and vaccinations has taken precedence over all other efforts to avoid sickness. To produce resilient outputs and promote social well-being, knowledge and technology must be improved and properly applied. Furthermore, the other technologies of bionics are mechanical replacements for physical disability and hence it relates to the third SDG (good health and well-being). Consequently, bionics is a crucial component of healthcare technologies. IoT-enabled systems can help companies to expand their operations. Manufacturing industries can improve communication with their global collaborative machines and hence, through automation and availability, it plays a significant role in attaining resilience (Naveed et al. 2018). Advanced simulations help to achieve the ninth sustainability goal through industry innovation. By enhancing manufacturing quality and taking into account existing levels of resilience, it uses better and more efficient approaches to take into account and process the simulation components. Big data is another by-product of I4.0. In recent developments of I5.0, big data provides various better application opportunities, specifically on social grounds. It feeds the information for AI systems that significantly improve performance, service and resiliency (Özdemir and Hekim 2018). Big data can be used to deliver the most convenient, necessary, and realistically required services because it holds the secrets to client needs and preferences. The proposed framework for the technologies of I4.0 and I5.0 as an enabler to the disruption in SCs during pandemics, war and climate change is shown in Fig. 5.

6 Implications of the study

6.1 Theoretical and research implications

This study presents a systematic review of the application of I5.0 technologies to mitigate disruptions in SC during pandemics, wars, and climate change. Industry 5.0 technologies have emerged as a promising solution to overcome supply chain disruptions caused by pandemics, war, and climate change. Most of the articles available in the investigating field are conceptual and discussed the benefits and challenges of implementing I4.0 and I5.0 technologies in SC. The present study adopted two review techniques namely bibliometric analysis and SLR methodology. Bibliometric analysis is an attempt to identify the statistics in terms of highly cited articles, prolific researchers, important keywords and top publishing journals in the investigating field. The second technique i.e., SLR methodology helps in providing an answer to the proposed research questions. This article proposed a framework that guides how I4.0 and I5.0 technologies can enable the mitigation of SC disruptions during pandemics, wars, and climate change.

From a theoretical perspective, these technologies offer several implications for SC management and sustainability. For instance, the adoption of Industry 5.0 technologies can help companies achieve greater supply chain resilience. By leveraging predictive analytics, blockchain, IoT, and AI, companies can monitor their supply chain in real-time, identify potential disruptions, and take proactive measures to mitigate them.

6.2 Practical implications

The COVID-19 pandemic, climate change, and geopolitical conflicts have caused significant disruptions to global supply chains. However, Industry 5.0 technologies such as artificial intelligence, blockchain, and the Internet of Things (IoT) offer practical solutions to overcome these challenges. The proposed article has significant implications for industrial practitioners and SC managers. SC managers should understand the relevancy of disruptive technologies and their applications in SCs. SC managers should develop mixed strategies for adopting disruptive technologies to mitigate disruptions in SCs. On the other hand, policymakers also play a significant role in developing strategies such as tax rebates and subsidies in adopting environmentally conscious technologies and support for sustainable development.

A joint effort of academia, government, and industries is needed to design more resilient and robust SCs that can mitigate disruptions during pandemics, wars, and climate change. Proposed future research questions were also developed in the area of disruptions in SCs due to pandemics, war, and climate change as presented in Table 5.

6.3 Proposed research questions

The study conducted an exhaustive SLR and bibliometric analysis that resulted in the potential future research agenda presented in Table 5. This future research agenda may impart the foundation to future researchers and policymakers in the field of I5.0 and SC as there is still an abundance of untapped research opportunities left to be studied.

7 Conclusion

I5.0 is considered the next industrial revolution that leverages the creativity of the human brain in collaboration with intelligent, efficient, and accurate machines. It aims to achieve resource-efficient and user-favoured manufacturing solutions. As compared to I4.0, the main focus of I5.0 is to deliver life-increased products and services to society. Moreover, various factors were not considered and reached in I4.0 such as co-working robots, personalisation, AI systems, bioeconomy and sustainable practices. Now is the right time to look at the alarming disturbances around the globe due to the COVID-19 pandemic, war, climate crisis and human activities. To change such practices, more resilient and sustainable alternatives are implemented into both our industry and daily lives.

In the past decades, SC has seen many challenges that emerged in the invention of novel strategies to transform its functions. During extreme events like the pandemic, war, and natural calamities, even effective SC methods such as sourcing and moving the manufacturing system to a developing country, minimum stock management, and just-in-time production have failed. However, the implementation of I5.0 technologies such as human–machine collaboration, digital drug, cobots, additive manufacturing digital twin, IoT, Big Data Analytics, blockchain, automation and robotics provides opportunities for organisations to achieve agility, operational efficiency, customer service and innovation that transforms it into a digital SC. In this paper, we have discussed the enablers of I5.0 and how the enabling technologies of I5.0 can prevent disruptions in global SCs. In summary, I5.0 is a concept designed to constantly align the maximum productivity of humans and machines in the workplace. Considering various emerging applications and technologies, I5.0 ensures an increase in production and customer satisfaction. Additionally, this review indicates that although the benefits of adapting I5.0 technologies in SC management are well recognised, the related research, its applications and real-life examples are still scarce. If the pandemic, climate crisis or war has exposed bottlenecks in global SC practices, advanced technologies of I5.0 may be the solution.

7.1 Limitations

This present article has various limitations that require to be considered. In the article, book chapters, conference proceeding articles, editorials, erratum and notes have been excluded via the exclusion criteria to maintain the quality of the research sources. Furthermore, only research articles in English were considered. Thus, the mentioned sample bias selection of articles may influence the results of the study. Moreover, the findings are generalized to I4.0, I5.0 and SC disruption during the time of pandemics, war and climate change research domains and not on other related disruptive situations.

Data availability

The data that support the findings of this study are openly available in the SCOPUS database and are available from the corresponding author on request.

References

Agrawal S, Sharma N, Bhatnagar S (2021) Education 4.0 to Industry 4.0 Vision: Current Trends and Overview. Lecture Notes in Mechanical Engineering 475–485. https://doi.org/10.1007/978-981-16-3033-0_45

Agrawal R, Wankhede VA, Kumar A et al (2022) Progress and trends in integrating Industry 4.0 within Circular Economy: A comprehensive literature review and future research propositions. Bus Strategy Environ 31:559–579

Allam Z, Bibri SE, Sharpe SA (2022) The Rising Impacts of the COVID-19 Pandemic and the Russia-Ukraine War: Energy Transition, Climate Justice, Global Inequality, and Supply Chain Disruption. Resources-Basel 11:99. https://doi.org/10.3390/RESOURCES11110099

Ambrogio G, Filice L, Longo F, Padovano A (2022) Workforce and supply chain disruption as a digital and technological innovation opportunity for resilient manufacturing systems in the COVID-19 pandemic. Comput Ind Eng 169:108158

Aslam F, Aimin W, Li M, Rehman KU (2020) Innovation in the Era of IoT and Industry 5.0: Absolute Innovation Management (AIM) Framework. Information 2020, 11:124.

Ben Youssef A, Zeqiri A (2022) Hospitality Industry 4.0 and Climate Change. Circular Economy and Sustainability 2021 2:1043–1063.

Boyack KW, Klavans R (2010) Co-citation analysis, bibliographic coupling, and direct citation: Which citation approach represents the research front most accurately? J Am Soc Inform Sci Technol 61:2389–2404

Brahmi M, Aldieri L, Dhayal KS, Agrawal S (2022) Education 4.0: can it be a component of the sustainable well-being of students? Sustainable development of human resources in a globalization period. IGI Global, pp 215–230. https://doi.org/10.4018/978-1-6684-4981-3.ch014

Bunn C, Läderach P, Ovalle Rivera O, Kirschke D (2015) A bitter cup: climate change profile of global production of Arabica and Robusta coffee. Clim Change 129:89–101

Dadash Pour P, Nazzal MA, Darras BM (2022) The role of industry 4.0 technologies in overcoming pandemic challenges for the manufacturing sector. Concurr Eng 30:190–205. https://doi.org/10.1177/1063293X221082681

De Bernardi P, Azucar D, Forliano C, Franco M (2020) Innovative and sustainable food business models. Contributions to Management Science 189–221. https://doi.org/10.1007/978-3-030-33502-1_7

Demir KA, Döven G, Sezen B (2019) Industry 5.0 and human-robot co-working. Procedia Comput Sci 158:688–695. https://doi.org/10.1016/j.procs.2019.09.104

Dervis H (2019) Bibliometric analysis using bibliometrix an R package. Journal of Scientometric Research 8:156–160

Dhayal KS, Giri AK, Esposito L, Agrawal S (2023) Mapping the significance of green venture capital for sustainable development: A systematic review and future research agenda. J Clean Prod 396:136489

Doyle-Kent M, Kopacek P (2020) Industry 5.0: is the manufacturing industry on the cusp of a new revolution? In: Durakbasa N, Gençyılmaz M (eds) Proceedings of the international symposium for production research 2019. ISPR 2019. Lecture notes in mechanical engineering. Springer, Cham, pp 432–441. https://doi.org/10.1007/978-3-030-31343-2_38

Fawcett SE, Wallin C, Allred C et al (2011) Information technology as an enabler of supply chain collaboration: a dynamic-capabilities perspective. J Supply Chain Manag 47:38–59

Foster MN, Rhoden SLNH (2020) The integration of automation and artificial intelligence into the logistics sector: A Caribbean perspective. Worldwide Hospitality and Tourism Themes 12:56–68

Frederico GF (2021) From Supply Chain 4.0 to Supply Chain 5.0: Findings from a Systematic Literature Review and Research Directions. Logistics 5:49.

Free C, Hecimovic A (2021) Global supply chains after COVID-19: the end of the road for neoliberal globalisation? Accounting, Auditing & Accountability Journal 34:58–84

Galanakis CM, Rizou M, Aldawoud TMS et al (2021) Innovations and technology disruptions in the food sector within the COVID-19 pandemic and post-lockdown era. Trends Food Sci Technol 110:193–200

Ghose A, Hasan H, Spedding T (2009) Carbon-centric computing - It solutions for climate change: A report prepared by the university of wollongong working group on the carbon-centric computing initiative. Telecommunications Journal of Australia 59:1 9.1–9.12. https://doi.org/10.2104/TJA09009

Grzybowska K, Stachowiak A (2022) Global Changes and Disruptions in Supply Chains—Preliminary Research to Sustainable Resilience of Supply Chains. Energies (basel) 15:4579. https://doi.org/10.3390/en15134579

Hassoun A, Boukid F, Pasqualone A et al (2022) Emerging trends in the agri-food sector: Digitalisation and shift to plant-based diets. Curr Res Food Sci 5:2261–2269

Huang H, Yang L, Wang Y et al (2021) Digital Twin-driven online anomaly detection for an automation system based on edge intelligence. J Manuf Syst 59:138–150

Ivanov D, Dolgui A (2021) A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod Plan Control 32:775–788. https://doi.org/10.1080/09537287.2020.1768450

Ivanov D, Dolgui A, Das A, Sokolov B (2019) Digital Supply Chain Twins: Managing the Ripple Effect, Resilience, and Disruption Risks by Data-Driven Optimization, Simulation, and Visibility. Handbook of Ripple Effects in the Supply Chain. Internat Ser Oper Res Management Sci 276:309–332. https://doi.org/10.1007/978-3-030-14302-2_15

Jayashree S, Reza MNH, Malarvizhi CAN, et al (2021) The implications of Industry 4.0 on supply chains amid the COVID-19 pandemic: a systematic review. F1000Res 10:1008. https://doi.org/10.12688/F1000RESEARCH.73138.2

Karmaker CL, Bari ABMM, Anam MdZ, et al (2023) Industry 5.0 challenges for post-pandemic supply chain sustainability in an emerging economy. Int J Prod Econ 258:108806.

Kasinathan P, Pugazhendhi R, Elavarasan RM, et al (2022) Realization of Sustainable Development Goals with Disruptive Technologies by Integrating Industry 5.0, Society 5.0, Smart Cities and Villages. Sustainability 2022, Vol 14, Page 15258 14:15258.

Khan SA, Laalaoui W, Hokal F, et al (2022a) Connecting reverse logistics with circular economy in the context of Industry 4.0. Kybernetes. https://doi.org/10.1108/K-03-2022-0468

Khan SAR, Piprani AZ, Yu Z (2022b) Digital technology and circular economy practices: future of supply chains. Oper Manag Res 15:676–688

Khan SAR, Waqas M, Honggang X et al (2022c) Adoption of innovative strategies to mitigate supply chain disruption: COVID-19 pandemic. Oper Manag Res 15:1115–1133

Khan SAR, Yu Z, Umar M et al (2022d) Tackling post-pandemic challenges with digital technologies: an empirical study. J Enterp Inf Manag 35:36–57

Khan SAR, Tabish M, Zhang Y (2023) Embracement of industry 4.0 and sustainable supply chain practices under the shadow of practice-based view theory: Ensuring environmental sustainability in corporate sector. J Clean Prod 398:136609.

Kucirkova N (2017) An integrative framework for studying, designing and conceptualising interactivity in children’s digital books. Br Educ Res J 43:1168–1185

Kumar A, Choudhary S, Garza-Reyes JA et al (2023) Analysis of critical success factors for implementing Industry 4.0 integrated circular supply chain – moving towards sustainable operations. Prod Plan Control 34:984–998. https://doi.org/10.1080/09537287.2021.1980905

Kumar MS, Raut DRD, Narwane DVS, Narkhede DBE (2020) Applications of industry 4.0 to overcome the COVID-19 operational challenges. Diabetes Metab Syndr 14:1283–1289

Kusiak A (2018) Smart manufacturing. Int J Prod Res 56:508–517

Leitão P, Colombo AW, Karnouskos S (2016) Industrial automation based on cyber-physical systems technologies: Prototype implementations and challenges. Comput Ind 81:11–25

Lenny Koh SC, Genovese A, Acquaye AA et al (2013) Decarbonising product supply chains: design and development of an integrated evidence-based decision support system – the supply chain environmental analysis tool (SCEnAT). Int J Prod Res 51:2092–2109

Lioutas ED, Charatsari C, De Rosa M (2021) Digitalization of agriculture: A way to solve the food problem or a trolley dilemma? Technol Soc 67:101744

Liu P, Rani P, Mishra AR (2021) A novel Pythagorean fuzzy combined compromise solution framework for the assessment of medical waste treatment technology. J Clean Prod 292:126047

Maddikunta PKR, Pham QV, B P, et al (2022) Industry 5.0: a survey on enabling technologies and potential applications. J Ind Inf Integr 26:100257

Madhavan M, Wangtueai S, Sharafuddin MA, Chaichana T (2022) The precipitative effects of pandemic on open innovation of SMEs: a scientometrics and systematic review of industry 4.0 and industry 5.0. Journal of Open Innovation: Technology, Market, and Complexity 8:152.

Mastrocinque E, Ramírez FJ, Honrubia-Escribano A, Pham DT (2022) Industry 4.0 enabling sustainable supply chain development in the renewable energy sector: a multi-criteria intelligent approach. Technol Forecast Soc Change 182:121813

Meredith J (1993) Theory Building through Conceptual Methods. Int J Oper Prod Manag 13:3–11

Nahavandi S (2019) Industry 5.0—A Human-Centric Solution. Sustainability 11:4371.

Narayanamurthy G, Tortorella G (2021) Impact of COVID-19 outbreak on employee performance – moderating role of industry 4.0 base technologies. Int J Prod Econ 234:108075

Naveed K, Watanabe C, Neittaanmäki P (2018) The transformative direction of innovation toward an IoT-based society - Increasing dependency on uncaptured GDP in global ICT firms. Technol Soc 53:23–46

Nayeri S, Sazvar Z, Heydari J (2023) Towards a responsive supply chain based on the industry 50 dimensions: A novel decision-making method. Expert Syst Appl 213:119267

Özdemir V, Hekim N (2018) Birth of Industry 5.0: Making Sense of Big Data with Artificial Intelligence, “the Internet of Things” and Next-Generation Technology Policy. OMICS 22:65–76

Piyathanavong V, Huynh VN, Karnjana J, Olapiriyakul S (2022) Role of project management on Sustainable Supply Chain development through Industry 4.0 technologies and Circular Economy during the COVID-19 pandemic: A multiple case study of Thai metals industry. Oper Manag Res 2022:1–25

Rada M (2015) INDUSTRY 5.0 - from virtual to physical. In: Linkedin. https://www.linkedin.com/pulse/industry-50-from-virtual-physical-michael-rada/. Accessed 27 Dec 2022

Rehman Khan SA, Ahmad Z, Sheikh AA, Yu Z (2022) Digital transformation, smart technologies, and eco-innovation are paving the way toward sustainable supply chain performance. Sci Prog 105 https://doi.org/10.1177/00368504221145648

Reyes J, Mula J, Díaz-Madroñero M (2023) Development of a conceptual model for lean supply chain planning in industry 4.0: multidimensional analysis for operations management. Prod Plan Control 34:1209–1224. https://doi.org/10.1080/09537287.2021.1993373

Romero D, Stahre J (2021) Towards The Resilient Operator 5.0: The Future of Work in Smart Resilient Manufacturing Systems. Procedia CIRP 104:1089–1094

Santhi AR, Muthuswamy P (2022) Pandemic, war, natural calamities, and sustainability: industry 4.0 technologies to overcome traditional and contemporary supply chain challenges. Logistics 6:81

Schiele H, Bos-Nehles A, Delke V et al (2022) Interpreting the industry 4.0 future: technology, business, society and people. J Bus Strateg 43:157–167

Sivarethinamohan R, Sujatha S (2021) Unraveling the Potential of Artificial Intelligence-Driven Blockchain Technology in Environment Management. Lecture Notes in Mechanical Engineering 693–700. https://doi.org/10.1007/978-981-16-0942-8_66/COVER

Spieske A, Birkel H (2021) Improving supply chain resilience through industry 4.0: a systematic literature review under the impressions of the COVID-19 pandemic. Comput Ind Eng 158:107452

Talari G, Cummins E, McNamara C, O’Brien J (2022) State of the art review of Big Data and web-based Decision Support Systems (DSS) for food safety risk assessment with respect to climate change. Trends Food Sci Technol 126:192–204

Wang Y, Chandrasekaran J, Haberkorn F et al (2022) DeepFarm: AI-Driven Management of Farm Production using Explainable Causality. Proceedings - 2022 IEEE 29th Annual Software Technology Conference. STC 2022:27–36. https://doi.org/10.1109/STC55697.2022.00013

Xiao Y, Watson M (2019) Guidance on Conducting a Systematic Literature Review. J Plan Educ Res 39:93–112

Zhang F, Wu X, Tang CS et al (2020) Evolution of Operations Management Research: from Managing Flows to Building Capabilities. Prod Oper Manag 29:2219–2229

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Agrawal, S., Agrawal, R., Kumar, A. et al. Can industry 5.0 technologies overcome supply chain disruptions?—a perspective study on pandemics, war, and climate change issues. Oper Manag Res 17, 453–468 (2024). https://doi.org/10.1007/s12063-023-00410-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12063-023-00410-y