Abstract

Energy efficiency (EE) is our “first fuel” and an essential resource in reaching climate goals, reducing dependence on fossil fuels, increasing security of supply, and many other “Multiple Benefits.” However, by their nature, savings are intangible. Demand-side EE measures are typically decentralized, heterogeneous, and small-scale opportunities. The difficulties in measurement and verification (M&V) of “Negawatts” are an important and often overlooked barrier to their greater application.

M&V is a prerequisite to assess the performance of any energy, water, or CO2-saving measure, and to quantify the savings into physical and monetary units for reporting, re-financing, GHG accounting, or other purposes. However, in practice, M&V is often perceived (particularly by clients) as cumbersome, incomprehensible, and costly.

In the broader context, energy cost savings alone are often not a sufficiently strong project driver because they lack strategic relevance for decision makers. As “Multiple Benefits” of EE become better understood, the value of quantifying savings to a high degree of accuracy may be declining, creating opportunities for more flexible M&V standards.

As a new methodology, this conceptual paper proposes to combine simplified M&V (sM&V) for individual EE measures with quality assurance instruments (QAIs) to verify functionality. This “sM&V + QAI” approach is less cumbersome, less costly, and easier to comprehend than standard M&V approaches, particularly by clients, financiers, and other non-M&V experts. It has been reviewed by international experts and successfully tested and evaluated in the field. Multiple case studies are reported to verify its practical feasibility.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Energy efficiency (EE) and related energy savings are essential resources in the transition towards “Net Zero by 2050” and imperative to reaching our climate goals (International Energy Agency, 2021a). Emission models have shown that significant improvements in overall EE are necessary for top emitting countries to meet their climate commitments (Anasis et al., 2019). Since 2013, the International Energy Agency (IEA) has prominently labeled EE as the “first fuel” (IEA. and Organisation for Economic Co-operation and Development, 2013). Fatih Birol, Executive Director of the IEA, has summarized this imperative for EE and its “Multiple Benefits”: “I consider energy efficiency to be the very ‘first fuel’ because it is crucial to address climate change and make our energy supplies more secure while also leaving money in our pockets” (International Energy Agency (IEA), 2021).

EE retrofits and associated savings can also reduce energy costs for end-users by lowering energy consumption (Abd Alla et al., 2020; He et al., 2021). Of equal importance, EE induces many other “Multiple Benefits” such as reducing dependence on fossil fuels, and its political and economic implications (through imports) may lead to an increase in security of supplies (International Energy Agency, 2013).

However, research shows that there are numerous barriers to the implementation of EE measures (EEMs), (Jaffe & Stavins, 1994; Trianni et al., 2016), creating what has been described as the “energy efficiency gap” and “energy service gap” (Hirst & Brown, 1990; Schleich & Gruber, 2008), which exist between the significant potential for EE projects and the number of projects actually being implemented. Considering an EE project cycle value stream (planning, financing, implementation, and operation), an important and often overlooked barrier to the greater application of EE is the difficulty in monitoring and evaluating the resulting savings during operation. By their very nature, savings are intangible, coined as “Negawatts” by Amory Lovins (Lovins, 1990). Savings represent the absence of consumption, which can only be assessed indirectly by comparing an ex ante reference “Baseline” period and an ex-post “Reporting” period (Efficiency Valuation Organization, 2022; CEN/CLC/TC 14, 2012; International Organization for Standardization, 2014), (see “Appendix: basic methodology and equations for savings calculations” for some background on M&V fundamentals). Moreover, demand-side EE potentials are typically decentralized, heterogeneous, and small-scale opportunities (Seefeldt et al., 2013, 2016). This adds to their perceived complexity and obfuscates their value, especially in comparison with renewable generation, the benefits of which are easier to comprehend and measure.

The process of quantifying savings from EEMs is commonly known as measurement and verification (M&V) and includes creating M&V plans, data collection, savings calculations, statistical analysis and adjustments, and reporting (Efficiency Valuation Organization, 2022). M&V is the basis to translate physical energy or demand savings into a related reduction in CO2 emissions (World Business Council for Sustainable Development and World Resources Institute, 2005), as well as into monetary units. It can be used to derive verifiable future cash flows from savings for reporting, EE financing, performance-based energy services company (ESCo) contracts, or other purposes (Bleyl et al., 2014). Reliable M&V of EEM savings is critical for the financial settlement of utility incentives and energy performance contracts (Newsham, 2019). Evaluating the impacts of EEMs also supports the ongoing success and promotion of EE (Kissock & Eger, 2008).

The literature describes a number of barriers to M&V, including lack of human and financial resources, difficulties preparing an efficient and clear M&V plan, and the availability and reliability of data (Efficiency Valuation Organization, 2022). Savings verifications are often complicated by a lack of comparability between Baseline and Reporting Periods because utilization of the facility, energy prices, or climate conditions may have changed over this timeframe (Kissock & Eger, 2008; Walter et al., 2014). M&V can also be expensive and time-consuming (Díaz et al., 2018). Particularly in the case of in-house EEM implementations (those done without the help of expert EE contractors), suitable M&V options and details of their potential application may not be well-understood, resulting in no M&V at all. The issue of transaction costs is particularly prohibitive for smaller projects, where M&V costs are high relative to total project costs and expected energy-cost savings (Bleyl-Androschin et al., 2009). However, the academic literature has scarcely researched the issue of complexity and comprehensibility of M&V methodologies for non-M&V experts such as end-users, financiers, or other stakeholders, a common issue the authors have seen in the field.

An overarching and rarely discussed issue in the field is the perceived complexity and incomprehensibility of M&V, particularly for the large stakeholder group of non-M&V experts. Writing and understanding M&V reports require expertise and resources that are not necessarily available to a facility owner or other key decision-makers of EE projects. On occasion, M&V is driven by dedicated engineers who strive to be exact but lose sight of how M&V efforts fit within the overall business case. Oftentimes, M&V needs to be outsourced and conducted by external project or program evaluators; consequently, a savings verification that is costly and difficult to understand will likely serve as a barrier for EE project owners to engage in EEMs and to pursue M&V (Vine & Sathaye, 2000a). Another concerned stakeholder group are financiers who may hesitate to fund efficiency projects if the risks cannot be easily translated into terms they comprehend.

In many European markets, such as the long-established performance-based ESCo markets in Germany or Austria, M&V is typically done by examining utility meters and invoices using a “whole facility” approach (Energiespar-contracting et al., n.d.); “retrofit isolation” techniques are either unknown or not accepted as common practice for the verification of cash flows from energy savings. Whole facility approaches require project savings to be significant enough to be “visible” at the utility meter (typically > 10% of consumption), and the techniques may only be comprehensible to those with significant M&V experience. However, retrofit isolation is a common practice in North American-influenced markets and is an approach supported by the US Department of Energy (Federal Energy Management Program, 2015). There may be an opportunity in Europe to improve M&V comprehensibility to a wide audience, as well as the applicability of M&V more generally, by adopting retrofit isolation techniques as common practice.

Demand side management (DSM) program administrators also face challenges with M&V. Despite typically reporting program-level savings (comprised of many individual projects), and generally being motivated to conduct projects on a timescale that does not allow for fulsome Baseline and Reporting Period measurements, they may be obligated by regulation or convention to comply with rigorous M&V standards that were developed for the ESCo industry and were designed to produce highly accurate measure-level savings.

From a broader perspective, there are additional benefits from EE investment projects such as local employment creation, health improvements, increases in comfort, and productivity of building occupants or product quality, termed “Multiple Benefits of Energy Efficiency” by the International Energy Agency (2014). These strategic benefits sometimes constitute more important motivations for stakeholders to invest in EEMs than cost savings (Bleyl et al., 2014, 2019; Ürge-Vorsatz et al., 2016), which are traditionally thought to be the main drivers of projects. The significance of these other benefits may reduce the value of a very rigorous M&V regime that is based only on quantification of energy cost savings.

All of the aforementioned adds to the inherently complex and abstract nature of EE projects and savings. This complexity may lead to insecurity and risk perception of stakeholders, such as energy managers, project developers, and ESCos, as well as financiers with a vested interest in verifiable future cash flows. As a result, EE projects may entail additional efforts, cost, risk surcharges, or no project implementation at all.

Bonneville Power Administration (BPA) recognizes the opportunity to tailor M&V approaches to different stakeholder needs. Their M&V Protocol Selection Guide states “Perhaps the most challenging issue in conducting measurement and verification (M&V) activities is deciding how good is good enough. There is never absolute certainty when determining energy efficiency savings; one is always making an estimate because of the counter-factual circumstances.” (Bonneville Power Administration, 2018a).

With the exception of some jurisdictional guides, little attention has been paid in the literature to simplified M&V solutions and the practical challenges outlined above. The literature review revealed a scarcity of papers focussing specifically on the issue of aligning the M&V approach with end-user needs; in particular, the challenge of comprehensibility for non-M&V experts and its impact on investor and financier confidence in EE projects. The scarcity of scientific knowledge on simplified M&V (sM&V) have led to the following research questions:

-

1.

How can M&V be structured to be more easily accessible and more broadly applicable?

-

2.

How can M&V be made more comprehensible and convincing to non-M&V experts?

-

3.

How can verification be strengthened to reduce reliance on costly measurement and complex analyses?

-

4.

Can M&V be made simpler while retaining a level of accuracy that is acceptable to project stakeholders?

The aim of this conceptual paper is to address the questions above by presenting a novel approach of simplified M&V combined with quality assurance instruments (referred to as sM&V + QAIs) and discuss its beneficiaries and applications. As a result, this proposed methodology should increase comprehensibility and reduce the perceived risks of EE projects. We believe the sM&V + QAI approach will enable the implementation of a greater range of EE projects by making their benefits quantifiable and comprehensible to all stakeholders at a reasonable cost, effort, and timeline.

The paper is structured as follows: the iterative development approach of the new methodology is described in the “Methods” section, followed by a literature review of academic and non-academic sources in the “M&V in the literature” section. The sM&V + QAI methodology is introduced in the “A new M&V methodology: simplified measurement and verification (sM&V) combined with quality assurance instruments (QAI)” section, with a proposed categorization scheme of QAIs and examples for each. The “Multiple case studies of sM&V + QAI within IEC framework” section validates the methodology through multiple cases studies conducted under the Integrated Energy Contracting (IEC) model in Europe. A concluding discussion of the proposed methodology and its opportunities and applications for the EE industry and other beneficiary stakeholders follows in the “Concluding discussion” section, also discussing the evolving relevance of exact savings quantification compared to identification and quantification of MBs. Basic M&V definitions and equations are presented in the “Appendix: basic methodology and equations for savings calculations” section.

Methods

This novel sM&V + QAI methodology provides a conceptual framework for a practical application, and the tools, principles, and rules by which simplified M&V practice may be structured. The methodology was built by iterating on the core concept through four main development steps. Referring to the numbered points in Fig. 1, these were:

-

1.

Conceptualization and development of a combined energy savings and supply ESCo model (“Integrated Energy Contracting” (IEC) model) that produced and relied on an early iteration of the sM&V + QAI concept.

-

2.

Pilot application and refinement of the new sM&V + QAI within the IEC-ESCo model, including the sM&V + QAI methodology in nine market-based projects in the field.

-

3.

The development and piloting were accompanied by reviews from international ESCo and M&V experts.

-

4.

A comprehensive review of academic and grey literature during preparation of this paper.

This partly parallel and iterative development process (steps 1–4) is visualized in Fig. 1.

Expanding on the above overview, the sM&V + QAI methodology was originally developed in the framework of the IEC model, which combines savings and (in our case studies, mostly renewable) supply of energy in a performance-based energy service model (Bleyl, 2011). In IEC projects, sM&V + QAIs are designed to quantify and verify the performance of energy-saving measures in the integrated energy service package. In most cases, a “retrofit isolation” technique is suggested.

For empirical testing and further development, nine market-based pilot projects were implemented in the field in Austria. The case studies conducted for this paper were based on Yin (2013). They included both thermal and electricity EEMs and were extracted from ESCo contracts of IEC projects implemented between 2010 and 2017Footnote 1 (LIG, 2017). Empirical validation of the sM&V + QAI methodology was achieved through its successful application in nine real-world pilot projects (see the “Multiple case studies of sM&V + QAI within IEC framework” section). These projects were evaluated by an independent third party and resulted in operational feasibility and wide stakeholder acceptance by clients as well as ESCos (Wabl, 2021). However, it is important to note that no quantitative comparison with more thorough M&V methods was completed.

Accompanying the real-world pilots, the development process has received support through reviews by international ESCo and M&V experts affiliated with the International Energy Agency’s Demand-Side Management Technology Collaboration Program (IEA DSM TCP). This evaluation process led to the publication of a conference paper by Bleyl et al. in 2014, demonstrating the credibility and acceptance of the sM&V + QAI approach within the expert community (Bleyl et al., 2014). Furthermore, German experts from the ESCo Competence Centre of the German Energy Agency (dena) discussed and endorsed the concept. As a result, dena has published a guidebook on M&V in Energy Performance Contracting based on the DSM TCP Task 16 publication (Deutsche Energie-Agentur GmbH (dena), 2015).

To confirm that the sM&V + QAI concept is new and useful to the academic literature on an international scale, a literature review was conducted (“M&V in the literature” section). The academic literature review was accomplished through the Web of Science database using 11 unique search strings, each comprised of various combinations of the terms “measurement,” “verification,” “evaluation,” “energy,” “saving,” “efficiency,” “simplified,” “ESCo,” “demand side management,” and “IPMVP.” A search string that required only the terms “measurement” and “verification” was eliminated, as it returned 17,993 results, most of which were not related to EE projects. Of the remaining 2331 papers, most were eliminated based on a review of their titles, which suggested they were not related to quantification of energy savings. Papers already known to the authors were also included, resulting in approximately 80 papers undergoing a full review. These papers were classified according to their key themes, the specific M&V issues they addressed, whether they referenced the IPMVP, and whether they identified a need for new practices and guidelines to be developed. Besides reviewing current topics of discussion, the existence of any such M&V methods which follow a simplified approach, as well as end-user and other stakeholder perspectives on quantifying and verifying EE resources, was investigated.

Non-academic literature sources were either already known to the authors or found through web searches with similar keywords as above. In parallel with the real-world case studies, the sM&V + QAI concept was peer-reviewed and validated by experts from the IEA DSM Technology Collaboration Program (TCP), which led to a conference paper (Bleyl et al., 2014). Furthermore, German experts from the ESCo Competence Centre of the German Energy Agency (dena) discussed and endorsed the concept. As a result, dena has published a guidebook on M&V in Energy Performance Contracting based on the DSM TCP Task 16 publication (Deutsche Energie-Agentur GmbH (dena), 2015).

Where sensible, the terminology in this paper is aligned with IPMVP’s terminology (Efficiency Valuation Organization, 2022), which is a de facto international industry standard.

M&V in the literature

Academic literature

An academic and grey literature review was conducted to explore current research and practice on M&V methodologies. Results have been structured according to the following overarching M&V themes identified: 1, balancing accuracy and cost; 2, the role of automation; 3, comparability and accuracy; and 4, challenges and opportunities for simplification. An overview of non-academic literature is also presented, with a short analysis of leading industry and jurisdictional guides that incorporate both in-depth and simplified approaches to M&V into their practices.

Balancing of accuracy and cost

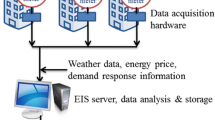

The overarching issue regarding design of an M&V plan, as discussed in the literature, is finding the appropriate balance between the level of effort (i.e., time and cost) with the desired level of accuracy in reported savings. M&V methods often require time-consuming manual data acquisition, potentially delivering final results years after a project has ended (Granderson et al., 2016). An example of this type of data acquisition is raised in a report by Kramer et al. where the benefits of Energy Management Information Systems (EMIS) for M&V are discussed. Most of the EMIS systems studied are used to perform M&V in accordance with IPMVP Option C, where post-implementation energy usage at the facility level is compared to an adjusted baseline. This approach typically requires 12 months of post-implementation data to report on annual savings and an enhanced need for understanding of the EMIS system (Kramer et al., 2013).

As referenced in the US Dept. of Energy Guide on M&V (2015), estimates put overall annual M&V costs at 2 to 5% of typical annual project cost savings with some EEMs entailing greater M&V costs (Federal Energy Management Program, 2015). These cost figures can impact the ability for smaller or more complex efficiency projects to move forward.

Vine et al. recognized that the higher the cost of M&V activities, the less likely organizations are to develop and implement EE projects (Vine & Sathaye, 2000b). As Mills et al. note, there is increased interest in measurement and verification, and insufficient resources to “measure everything.” They state that there is a need to prioritize the options, as some measures merit measurement more so than others, depending on the uncertainties and level of risk acceptable to the customer (Mills et al., 2006).

The issue of large M&V expenses led some researchers to explore the need for flexibility and cost reduction. Though not explicitly stated as a simplified approach to M&V, Cabrera et al. established that simple engineering estimations of savings based on information collected could achieve similar results to enhanced engineering estimations from measurements and prove more time- and cost-effective (Cabrera et al., 2012). Vine et al. highlight this idea in their discussion on short-term monitoring, stating that short-term measurements produce gains in accuracy nearly equivalent to that of longer-term metering at a fraction of the cost (Vine & Sathaye, 2000b).

Role of automation

The advancement of information and communication technologies has led to a developing field sometimes called “M&V 2.0,” which takes advantage of increased data availability and enhanced analytical techniques, such as machine learning, to perform M&V activities (Nowak et al., 2017), (Díaz et al., 2018). A goal of M&V 2.0 is to reduce the cost of M&V performed as part of program savings evaluations through reduced need for site visits to perform on-site measurement (Rogers et al., 2015). The field is primarily being developed for use as part of program evaluations, which does not necessarily include validation of savings at a high level of accuracy for each individual project or facility (Franconi et al., 2017), as performance of these initiatives is typically managed and reported at the program, rather than project or measure level.

In regard to commercial building modelling, Granderson et al. suggest that the growing availability of data from smart meters and devices, combined with advanced data analytics, offers the potential to streamline the M&V process through increased levels of automation, maintaining or improving the accuracy of the result (Granderson et al., 2016) while potentially reducing both time and cost of M&V.

Comparability

When selecting an M&V approach, the balance between time and cost is typically decided through consultation between M&V experts and the energy end-user and may be selected differently for projects of the same type (in different applications, with different clients and M&V experts), raising the issue of comparability of project savings. Standards have emerged in the form of “interpretations” of the IPMVP, which aim to standardize practices and improve comparability of savings.

Bertoldi and Kromer state that the IPMVP is the only international standard for assessing efficiency impacts, although there are still large gaps to be filled before the methods are accepted globally (Bertoldi & Kromer, 2006). One of these gaps lies in the issue of comparability. Though discussed at the national and program level, Thomas et al. mention the need for harmonization, and the importance of a method that looks at how calculated energy savings can be made comparable between countries (Thomas et al., 2012).

Xia et al. address the problem of accuracy in IPMVP methodologies, stating that there is too much reliance placed on professional judgement, and that this could be resolved through the use of mathematical modelling to more consistently select the optimal M&V plan (Xia & Zhang, 2013). Another issue identified by Walter et al. is that most statistical methods reported in the literature do not quantify the uncertainty in baseline energy use predictions. They assert that there is substantial uncertainty in baseline estimates, and a better method to address this uncertainty would be a critical addition to existing IPMVP M&V tools (Walter et al., 2014). Mills et al. agree, stating that the risks in the measurement and verification of savings range from simulation and metering accuracy to measurement bias (Mills et al., 2006).

Challenges and opportunities for simplification

The literature reflects some concerns with oversimplifying M&V approaches in order to maintain an appropriate degree of accuracy. Walter et al. state that external factors such as weather, occupancy, and operating hours, which have complex relationships to the energy consumption, can impact the uncertainty associated with baseline predictions (Walter et al., 2014). Kissock et al. have expressed concerns with over-simplifying M&V and ignoring the significance of adjusted vs. unadjusted savings. They advise that a regression analysis method that identifies weather-dependent, production-dependent, and independent components is necessary to determine the energy savings from an industrial retrofit and state that if these variables are not accounted for in M&V methods, resulting savings will be erroneous (Kissock & Eger, 2008).

It was also observed that the academic literature provides no evidence on the issue of complexity and comprehensibility of M&V methodologies for non-M&V experts such as end-users, financiers, or most other stakeholders.

Industry and jurisdictional guides

A review of non-academic literature was conducted to examine how various M&V methodologies have been put into practice by different industries and jurisdictions and how industry has attempted to address the issues mentioned above. Non-academic literature is particularly important to this subject as industry practices are typically driven by standards developed within industry and prior to recognition in academic literature. In this review, both industry and jurisdictional guides were considered.

Industry guides

The IPMVP is an international standard used in many countries to guide M&V activities (Xia & Zhang, 2013). It defines one general framework for M&V and four options for M&V. Its predecessor, the North American Measurement and Verification Protocol, was originally developed by a committee under the US Department of Energy. The IPMVP is maintained by Efficiency Valuation Organization (EVO), a non-profit organization, which publishes the protocol in several languages as “IPMVP: Core Concepts” (Efficiency Valuation Organization, 2022). Its use is widespread and serves as the basis for several other standards (Natural Resources Canada—CanmetENERGY, 2008).

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), in their Guideline 14–2014, describe in-depth and rigorous approaches both for retrofit isolation and whole-building analysis techniques which are similar to IPMVP (ASHRAE, 2014). The standards set out in the document are intended for use by ESCos, providing calculation procedures for determining the savings from energy, demand, and water EEMs.

The Federal Energy Management Program (FEMP) under the US Department of Energy has developed a 4th version of their M&V Guidelines for performance-based contracts explicitly based on procedures that are consistent with the IPMVP and provides suggestions for which of the four IPMVP options could be used for different measure types (Federal Energy Management Program, 2015).

The Uniform Methods Project, an initiative of the US Department of Energy, provides explicit M&V protocols for common measures, which are based on the IPMVP and other standards. It is intended to bring consistency and comparability to utility electricity efficiency programs and is widely referenced among DSM organizations in North America (Li et al., 2018).

On an international level, ISO 50015 “Measurement and verification of energy performance of organizations—General principles” provides an M&V framework for organizations (International Organization for Standardization, 2014). It does not give concrete guidance on how to perform M&V, but establishes general principles and guidelines.

While not directly related to M&V, the National Standard Practice Manual’s (NSPM) novel Jurisdiction Specific Test (JST) may stem from a similar philosophy as the sM&V + QAI concept. EE programs in North America are typically economically justified through the application of one or more cost-effectiveness tests originally defined in the California Standard Practice Manual, none of which may accurately reflect modern policy goals. Rather than justify programs using one of these traditional tests, the costs and benefits included in the JST are defined by stakeholders involved in its development; it therefore encourages inclusion of only what is deemed important and expulsion of everything else (Woolf et al., 2020).

Jurisdictional guides

Some jurisdictions have developed their own set of standards in regard to EE programming. The Australian Government built the Energy Savings Measurement Guide 2.0 as a technical framework under the Energy Efficiency Opportunities program and is intended for use by corporations who are significant energy users. These corporations are required to undertake thorough assessments of their energy consumption and to identify energy conservation measures (Australian Department of Resources Energy and Tourism, 2013). The guide provides procedures and calculations to estimate, measure, and report on EE guidelines, with a focus on accuracy and precision of data collection, and the use of regression and statistical analysis in pre- and post-retrofit scenarios.

An example of a simplified approach is present in the Ontario Power Authority’s (OPA’s) 5th version of the Project Measurement and Verification Procedures (2014) for the Save on Energy Retrofit Program (Ontario Power Authority, 2014). Though these procedures are explicitly based on IPMVP, the document provides both “basic” and “enhanced” M&V options for specific EEMs, with the selection dependent on the size of the incentive the retrofit project is receiving from the OPA. The OPA’s development of simplified M&V approaches suggests an industry need for more clearly defined standards for sM&V.

Classifying projects into those that require “basic” M&V versus “enhanced,” the OPA focuses on the primary considerations for comparability of a measure: Is the load constant and are the operating hours constant? Spot measurements suffice for constant loads and stipulated values are used when hours are constant—if either of these are variable, short-term or continuous measurement may be needed. For smaller projects with more certainty, stipulated values may be accepted, and with larger projects with more uncertainty, spot- or short-term measurement on a representative sample of loads or hours is completed. Extended post retrofit monitoring is generally not undertaken (Ontario Power Authority, 2014).

The Bonneville Power Administration (BPA) is another jurisdiction employing a simplified approach to M&V referred to as Energy Calculation with Verification (ECwV). Custom projects that save less than 200 MWh per year adhere to the ECwV protocol; projects above 200 MWh that have implemented more comprehensible and straightforward measures may also be suitable for following the simplified ECwV approach. The guidelines for this protocol require fewer resources and lower costs, often relying on methods such as spot measurements and nameplate verification. In a sample of Custom projects that were evaluated with the ECwV protocol and compared with a standard M&V approach, savings calculated with ECwV resulted in a conservative 73% of the savings using traditional M&V methods (Rodrigues-Anderson et al., 2022). The BPA has developed a full document stipulating the guidelines for the ECwV protocol, outlining the methods and approaches for M&V for both existing and new construction buildings (Bonneville Power Administration, 2018b). The Measurement and Verification Protocol Selection Guide and Example M&V Plan provides guidance to the M&V practitioner by outlining the criteria to evaluate a Custom project in terms of level of effort and rigor required, and how factor such as cost, safety, and time may influence the selected M&V approach (Bonneville Power Administration, 2018a). A flow chart in the guide provides a set of boundaries and questions that determine whether the ECwV protocol is the most appropriate approach for a Custom project.

The industry literature indicates a clear desire for further development of M&V practices: in 2017, Lawrence Berkeley National Laboratory summarized 11 evaluation, measurement and verification research gaps identified in an earlier paper from the American National Standards Institute, which included several gaps regarding standardization of approaches on project and program levels, as well as a desire for more research regarding how to characterize efficiency projects in financial terms (Schwartz et al., 2017).

A new M&V methodology: simplified measurement and verification (sM&V) combined with quality assurance instruments (QAI)

This results section presents the novel M&V approach, based on the development process outlined in the methods section. The methodology consists of two core elements applied to EEMs: simplified measurement and verification (sM&V) options, combined with quality assurance instruments (QAIs), together forming the sM&V + QAI methodology. An empirical validation of the methodology through multiple case studies is presented in the “Multiple case studies of sM&V + QAI within IEC framework” section.

Simplified measurement and verification options for EEMs

Savings from EE projects cannot be measured directly, with a few exceptions to the rule.Footnote 2 Instead, savings can only be calculated indirectly by comparing between an ex ante reference period (prior to EEM implementation, called the Baseline Period or BP) and an ex post period (after EEM implementation, called the Reporting Period or RP) (Efficiency Valuation Organization, 2022).

This difference calculation approach presupposes that a valid comparison can be made between the energy use (or demand) of BP and the RP. Comparability between BP and RP usually requires making adjustments for changes in conditionsFootnote 3 (Kissock & Eger, 2008; Walter et al., 2014). A more exact comparison requires excluding differences due to alterations in external variables like energy prices, climate conditions, utilization of the facility, or different accounting periods. These adjustments can be applied in all kinds of M&V approaches including sM&V + QAI, if so desired, or could be deliberately left out for simplicity, if stakeholders agree to such an approach.

Table 1 summarizes M&V options used in literature sources and the IEC case studies. The options have been classified according to their scope of application for I. Whole facility and II. Individual, isolated EEMs. All M&V options have been assigned number codes (e.g., M I-1). The table also references respective calculation formulae for each option (e.g., F E-1) with formulae details described in the “Appendix: basic methodology and equations for savings calculations” section. For the purpose of sM&V + QAI, we focus on isolated measure-based options as in section II of Table 1. This subset of options could serve as the basis for a future sM&V standard.

The individual, isolated EEM savings options encompass sub-metering (M II-1), combinations of metering of selected key parameters and computational factors (M II-3), purely computational verifications (M II-4), and savings calculated from feed-in sub-meters after a retrofit (M II-5). All individual, isolated EEM savings assessment methodologies listed in section II of Table 1 can be applied in the sM&V + QAI concept.

In order to maintain focus on the core principle of the sM&V + QAI methodology, all referenced basic savings calculations, as well as detailed sM&V equations, can be found in “Appendix: basic methodology and equations for savings calculations” section.

Quality assurance instruments for EEMs

The second core element of the suggested sM&V + QAI methodology concerns quality assurance for the EEMs. As Waltz posits, “As a practical matter, try thinking of measurement and verification in the reverse: Verification is perhaps more important than measurement and should be done first. In verification, the retrofit work is physically examined to confirm that the project can produce savings.” (Waltz, 2002).

The concept of QAIs for EEMs operationalizes this approach: In order to ensure and verify proper implementation and operation of an energy saving measure, and the validity and persistence of its savings, we propose to employ QAIs of various kinds. The purpose of a QAI is to assure the functionality or quality of an EEM. It can be used to verify that a specific EEM has been implemented correctly and is performing according to specifications, but not necessarily to measure its exact quantitative outcome. The IPMVP recommends a similar concept of “operational verifications” after the RP, referring to it as verification of the “potential to perform and generate savings” and to help “ensure persistence of savings year after year.” Examples given are visual inspections, sample spot measurements, short-term performance testing, and data trending and control-logic review. However, IPMVP does not consider this part of its formal process (Efficiency Valuation Organization, 2022).

For any given EEM, various QAIs can be used, depending on the nature of the EEM, availability of data, the level of comprehensibility and perceived risk to stakeholders, and other factors. We suggest grouping QAIs into four categories following a standard project lifecycle: Design, Commissioning and Operation, Performance, and Administrative. The intent of each category as well as some examples are presented in Table 2.

The selection of QAIs, as well as their exact design, will depend on the specific requirements of the project scope and the parties involved. QAIs can be specified in-house by an EE project owner, a facility manager, or an ESCo if involved in the project. In addition to selecting the most appropriate QAIs, the verification intervals also need to be defined. Similar to direct measurements, QAIs can be applied to an EEM once, immediately after implementation, or could be recurring throughout the project lifecycle (e.g., monthly or annually). Recurring QAIs help ensure that first-year savings are maintained in each subsequent year and can identify any potential maintenance issues that may arise with the EEM equipment.

Simplified M&V approaches may also, in some instances, rely on direct measurements of key parameters, where the measurement is relatively straightforward. For certain measures, direct measurement may not be practical, increasing the relative usefulness of QAIs as a mechanism to back up savings estimates. For example, a traditional M&V approach might utilize regression models that attempt to quantify the impact of an EEM by monitoring facility energy consumption and removing the effects of weather and other factors, thereby isolating the impact of the EEM. An example sM&V + QAI approach requires two measurements—instantaneous energy consumption before and after implementation—and three QAIs: (a) the “after” measurement is within the expected range, (b) expected savings are calculated by an independent third party and account for weather and interactive effects, and (c) the equipment is included in a preventive maintenance program. If those requirements are met, the parties would assume that the expected savings are occurring, ensuring the project owners or ESCos are realizing the benefits from their investment in the EE. If the final energy measurement was not within the expected range, this would indicate a potential error in the commissioning or savings calculations and prompt a review and corrective action. The appropriate actions triggered by “failing” QAIs should be determined by stakeholders and agreed to before implementation.

In summary, QAIs cannot determine the exact quantitative savings of an EEM, which may be subject to a number of external and dynamic parameters that are not accounted for in sM&V and may change over the project lifecycle (see “Appendix: basic methodology and equations for savings calculations” section on differences in circumstances between BP and RP). However, QAIs can provide assurance and verification that an EEM is operating as designed that the EEM upgrades are providing at least the same functionality as the system that was replaced, that the EEM was designed and installed with suitable expert oversight, and that EEM savings may persist year after year.

Multiple case studies of sM&V + QAI within IEC framework

The sM&V + QAI methodology has been extensively tested in the field to validate its relevance and practical feasibility. Twelve case studies are reported on in this section, where the sM&V + QAI approach has been successfully implemented under private ESCo contracts within the Integrated Energy Contracting (IEC) project framework from 2010 until 2017 (Bleyl, 2011; LIG, 2017).

For all case studies of electricity EEMs in Table 3 and thermal EEMs measures in Table 4, the sM&V options applied are referenced with the methodologies and formulae introduced in the “Appendix: basic methodology and equations for savings calculations” section.

Electricity conservation measures within IEC framework

Table 3 provides six case studies of electricity EEMs that were implemented under IEC contracts in Austria using a sM&V + QAI approach. For example, the expected savings of a lighting retrofit (first item in Table 3) are calculated based on measured power demand in the Baseline and Reporting Periods and estimated operating hours. Three QAIs were determined to verify implementation completeness, quality, and ongoing functionality: replacement of all lights was confirmed via a walkthrough audit and invoice review, illuminance was measured at several representative locations around the facility and compared to minimum specifications, and proper equipment operation is verified annually.

In general, simple measurement approaches were used for at least one key parameter, as savings in electricity use or demand from individual measures are easier to isolate and physically easier to measure (e.g., power × operating time) than is the case for thermal EEMs as can be seen in the next subsection.

Thermal energy conservation measures within IEC framework

Table 4 provides six examples of thermal EEMs using an sM&V + QAI approach that were implemented in the same ESCo contracts as above. For example, the expected savings of a thermal building envelope insulation measure (second item in Table 4) are quantified through a heat-demand calculation (incl. specification of simulation program) with Baseline and Reporting Period conditions and factored into a flat-rate cash flow for reporting or reimbursement. Two QAIs were selected to verify the implementation quality: A blower-door test to ensure the infiltration rate is within acceptable tolerances, and a thermographic analysis of the building to ensure that the insulation was built in according to technical specifications. In addition, annual visual inspections are agreed to verify status of retrofit measure.

Most cases use “computational verifications” (see M II-4), which is to say that the M&V approach does not actually include direct measurements impacting final savings, but that the savings estimates are robust enough to satisfy stakeholder needs when paired with appropriate QAIs.

Evaluation supports acceptance and viability

The selection of the sM&V and QAIs combinations for each EEM was determined through discussion between the client and ESCo and followed the approach as described in the previous “A new M&V methodology: simplified measurement and verification (sM&V) combined with quality assurance instrumentS (QAI)” section. The risks of these approaches and the ability of different partners to mitigate those risks were discussed, as well as the client’s ability to understand and willingness to participate in the M&V plan.

The multiple IEC case studies demonstrate the wide range of practical applications of the sM&V + QAI methodology for thermal and electricity EEMs in the field. Furthermore, a recent evaluation of nine IEC projects implemented in the province of Styria, Austria, which relied on the sM&V + QAI methodology for the savings part of the comprehensive ESCo package, also verified its practical feasibility. Wabl’s evaluation included semi-structured interviews with building occupants, building owners, and ESCos, and revealed no relevant problems or concerns with the sM&V + QAI savings verifications (Wabl, 2021).

Concluding discussion

Reducing dependence from fossil fuels is not only a climate protection imperative (Anasis et al., 2019), but also a political and economic necessity (IEA, 2021b). EE has been identified as the “first fuel” and will have to play a leading role in the transition to low carbon, less import-dependent, and more locally based resource economies (Anasis et al., 2019; International Energy Agency, 2013, 2021b).

Despite this clear and obvious strategy, the academic literature has repeatedly observed an “EE gap” (Hirst & Brown, 1990) and identified several significant barriers to the greater application of EE resources (Backlund & Thollander, 2011; Jaffe & Stavins, 1994; Johansson & Thollander, 2018; Schleich & Gruber, 2008; Trianni et al., 2016). However, the invisible and intangible nature of EE and the related difficulties in measuring and verifying “Negawatts” are important and often overlooked barriers to greater implementation of EE projects. In the scientific literature, there are few papers that discuss the impact of existing thorough M&V protocols, such as IPMVP, and the impediment they may present to stakeholders looking to implement energy-saving projects.

The concluding discussion is structured as follows: First, we assess how the proposed sM&V + QAI methodology is designed to contribute to closing the EE gap. Second, the multiple beneficiaries and applications of the proposed sM&V + QAI methodology are discussed. Third, an assessment of the new methodology regarding other M&V methods as well as possible further activities and developments is addressed. Finally, we discuss the need for EE projects to be recognized as strategically relevant (Cooremans, 2011), which includes valuation of more than energy cost reductions at the project level (Bleyl et al., 2019); these “Multiple Benefits” should also be included in planning of EE policies and programs to help close the EE gap.

Simplified M&V + QAI methodology to contribute to narrowing the EE gap

This flexible approach allows for a reduction in unnecessary reliance on costly measurement and complex analysis that can in some cases be a barrier to implementation. This makes M&V more broadly applicable in practice and may create additional potential for energy and GHG reduction projects.

The novel methodology—the systematic combination of simplified measurement techniques with quality assurance instruments (sM&V + QAIs)—addresses the research questions listed in the introduction. First, it lowers the barrier for entry into M&V by not necessarily requiring practitioners to understand complex measurement and adjustment techniques in order to participate; it is an accessible and readily comprehensible approach that allows newcomers to make and execute simple M&V plans for their own projects. Second, by simplifying the measures of success for such projects, it lowers the comprehension barrier, and thus perceived risk for outside financiers to understand and become involved. Third, M&V costs can be reduced relative to existing practices by placing greater emphasis on QAIs to ensure proper installation and ongoing commissioning. Finally, allowing a wider range of approaches within an M&V plan (up to and including no measurement at all) allows for stakeholders to select an appropriate measurement approach for each EEM.

Additionally, our approach helps to address the issue of balancing time and cost by providing greater flexibility, which was identified in the literature as an ongoing challenge with application of M&V (Cabrera et al., 2012; Vine & Sathaye, 2000b). The use of repetitive QAIs (or “operational verifications” as termed by EVO) also supports the persistence of energy savings and protects organizations against the decay of energy savings as equipment ages (Efficiency Valuation Organization, 2022). The sM&V + QAI approach does not address all issues identified in the literature review, such as the role of automation, comparability, and accuracy of M&V. It is primarily designed to address challenges with comprehensibility to non-experts, an issue that was not found to be discussed in the academic literature so far but is a barrier that should be addressed.

With this novel sM&V + QAI approach, the question is not simply whether or not to do M&V for a project, but what level of M&V rigor is desired by stakeholders. Verifying proper functionality of an EEM can help stakeholders arrive at a reasonably accurate savings figure with comparatively little effort to traditional methods. Our proposal to make QAIs a mandatory part of the M&V process is consistent with Waltz’s approach of prioritizing verification over measurement: “Verification is perhaps more important than measurement and should be done first” (Waltz, 2002). The IPMVP also suggests the concept of “operational verifications,” referring to the “verification of the potential to achieve savings”; however, the IPMVP does not consider these operational verifications as part of its formal M&V process (Efficiency Valuation Organization, 2022).

The selection of an appropriate M&V approach should depend on the willingness and availability of expertise and resources to engage in and to follow up on a simplified or more comprehensive M&V plan. Among others, this will depend on the motivations of project stakeholders, types of EEMs, available data, and expected monetary savings that will justify (potentially recurring) M&V costs in order to balance effort and accuracy (Cabrera et al., 2012; Vine & Sathaye, 2000b). Thus, the selection of an appropriate M&V approach should be decided on a project-by-project basis and must consider the views of all project stakeholders and their ability to comprehend the approach, not just the desired approach of M&V experts. The concept is universally applicable; a small or simple project may rely more on QAIs and less on measurement, and a large or complex project may rely more on measurement and less on QAIs.

Kissock and Eger promote the idea that EEMs producing benefits that cannot be readily quantified through M&V are not worth pursuing, and the funds should instead be directed towards EEMs that have a higher likelihood of producing quantifiable savings (Kissock & Eger, 2008). However, in practice, EEMs do not only compete with other EEMs for funding, nor do they all produce the same magnitude or type of benefits per dollar of investment, nor are they pursued solely for the energy cost savings (Bleyl et al., 2019; Cooremans, 2011). In contrast to the position advanced by Kissock, the proposed methodology supports the notion that investments in EEMs which stakeholders agree are very likely to produce savings (and very unlikely to increase costs) should not be overlooked due to uncertainty about whether actual savings can be quantified after the EEM is implemented, if such proof is not actually required by stakeholders. This way of thinking about conservation projects is more in line with other strategic business decisions that follow a probabilistic “no regrets” decision-making approach, which does not invariably concern itself with ex post quantification.

By acknowledging that rigorous M&V is sometimes a barrier to the implementation of EEMs, one can also examine proposed changes to M&V standards through the lens of their impact on future emissions reduction potential. Global potential for conservation projects can potentially be increased by shifting to a mindset where EEMs are considered regardless of how easily they lend themselves to ex post quantification. Changes to M&V standards can therefore be seen as a policy tool to drive deeper savings.

The sM&V + QAI approach is a methodology, providing a conceptual framework for a practical application, and the tools, principles, and rules by which simplified M&V practice may be structured. The novelty of this paper is in the documentation and formalization of a method that has already proved to work in industry. It addresses issues with commonly used M&V approaches, which hopefully can hopefully be studied further and generalized into standards to maximize its practical usefulness.

Beneficiaries and applications of sM&V + QAI

There are multiple beneficiaries of the sM&V + QAI methodology, including clients, financial institutions, the operators of DSM programs that provide funding to produce EE savings, and ESCos. Applications that would favor sM&V + QAI include, but are not limited to, measures implemented in-house, small-scale ESCo projects, and the introduction of retrofit isolation techniques where they are not commonly used, e.g., in Europe. Finally, sM&V can aid in the quantification of “Multiple Benefits,” a concept of increasing importance in evaluating EE projects.

Clients’ perspective

The sM&V + QAI methodology has significant value from the client’s perspective, as it improves the comprehensibility of the M&V process. The complexity, perceived uncertainty, and cost of conventional M&V methodologies can be an impediment to securing funding for efficiency projects and may prevent M&V, or the efficiency project, from happening at all. This paper argues that sM&V + QAI methods can remove barriers to the implementation of EE projects (Vine & Sathaye, 2000b) by reducing M&V cost and complexity, thereby increasing comprehensibility of the verification process to non-practitioners of M&V (Wabl, 2021), while maintaining suitable levels of verification accuracy.

Financial institutions

Financiers may be hesitant to invest in projects where the reliability of future cash flows from savings is difficult for them to understand, with methods and results that are determined by engineers and perceived as inscrutable by others. Investors unfamiliar with EE are not accustomed to having their profits directly determined by engineering calculations of what might have happened in a counterfactual baseline scenario; they are typically more comfortable with verifiable facts, e.g., sales from the past quarter. By shifting focus from measurement to pre-project engineering calculations and QAIs to ensure proper functionality, the measures of success can be made relatively more comprehensible to financiers, reducing perceived risk compared to more comprehensive M&V approaches. From a financing institutions’ perspective, sM&V + QAI approaches may provide sufficient evidence to value cash flows from future savings as a basis for repayment of debt or equity incurred from project investments.

In particular, retrofit isolation techniques allow the option of using different time schedules for each EEM, e.g., a one-off measurement resulting in a constant flat-rate savings approach for one measure, and periodic tests at annual or monthly intervals for another. sM&V + QAI using retrofit isolation could demonstrate that partial cash flows are secure in a shorter timeframe than whole-facility analysis of savings. Use of this technique where applicable may reduce overall project risk from the perspective of financial institutions, without requirements to make adjustments due to weather conditions or use of the building for certain measures within a performance contract.

DSM organizations

The sM&V + QAI approach is well-suited to the type of energy saving reporting desired by DSM “Resource Acquisition” program administrators, who are often pressed to complete projects on timelines that do not allow for data collection over a full season. For those DSM organizations that report on lifetime energy savings, the use of periodic QAIs could substantiate or even extend the lifetime over which they claim savings, increasing total savings and improving overall cost-effectiveness. QAIs are a tool to demonstrate that energy savings from a project are real and allow the project owner to make timely corrections to the measures if any issues have arisen. Further development of these concepts into formal standards or guidelines would fill a gap identified in the M&V literature. There is likely industry demand for this type of simplified standard, as evidenced by the Ontario Power Authority’s saveONenergy program’s prescribed use of both basic and enhanced M&V techniques (Ontario Power Authority, 2014) and the BPA’s ECwV approach, which has allowed them to extend their engineering resources to more efficiency projects and use limited financial resources more efficiently (Rodrigues-Anderson et al., 2022).

Taking a broader look at the evolving energy efficiency industry, there is a parallel between the sM&V + QAI concept and the Jurisdiction-Specific Test (JST) concept from the National Standard Practice Manual (Woolf et al., 2020), which is considered a best practice in North American DSM program markets. Both approaches seek to replace the existing practice of attempting (and often failing) to adapt rigid standards for new situations, and instead promote development of bespoke methodologies where project or program stakeholders decide what is important to them and consider only that—regardless of whether or not such an approach resembles existing practices elsewhere (Woolf et al., 2020).

In-house M&V

Comprehensibility and the time and effort required for rigorous M&V can also be a barrier for in-house implemented projects. A lower-cost M&V option could allow for the following: (a) Smaller projects to become “verifiable”; (b) reductions in overall project costs when compared to more comprehensive M&V, potentially leaving more funding available for other EEMs; and (c) more accurate calculation of cash flows from savings when compared to no M&V at all. Simplified approaches can be a reasonable compromise between no M&V at all and a more comprehensive M&V approach, allowing for more consistent comparison of project savings without adding undue cost burdens to project proponents.

ESCos and smaller projects

A sM&V + QAI approach can reduce risk for both the ESCo and project stakeholders. With an agreed sM&V + QAI plan, all parties have established an acceptable, comprehensible, and cost-effective approach to quickly verifying energy savings. For instance, instantaneous measurements at determined intervals in the pre- and post-implementation scenarios ensure the ECM is operating within the expected range. This demonstrates the savings are being realized for the project owner, and the ESCo may then be reimbursed based on the calculated savings in their performance contract.

When proposed by an ESCo, QAIs can also be used as part of the competition of solutions during a procurement process, or the detailed project design phase.

The sM&V + QAI methods can also remove barriers to M&V of smaller projects, while maintaining suitable levels of verification accuracy. For small-scale Energy Performance Contracts (EPC) or combinations of Energy Supply Contracts (ESC) and EPCs (such as in the IEC model), or other performance-based energy service projects, the initial and periodic time and effort to conduct an IPMVP-compliant M&V approach may be prohibitively high or simply not desired for various reasons as mentioned in the introduction.

IPMVP “Option C” only markets

From a European perspective, it is interesting to note that “retrofit isolation” techniques are the exception rather than the rule, as evidenced by the German Energy Agency dena’s guidebook (Deutsche Energie-Agentur GmbH (dena), 2015), whereas IPMVP Options A or B are common practice in North America and many North American-influenced markets. Accordingly, we have included references to the IPMVP methods in this paper. The availability of an M&V standard that addresses small projects through retrofit isolation techniques may, more broadly, encourage the use of retrofit isolation techniques in Europe, thereby allowing for projects both within and outside of the scope of sM&V + QAI to be included in performance contracts.

Policy implications

Article 7 of the European Energy Efficiency Directive (EED) requires its Member States to monitor, verify, and report their mandated and achieved savings. Annex V to the EED sets out four basic methodological options for the “calculation of energy savings.” The European Commission has also published guidelines and recommendations for the implementation of the EED (Directive, 2023). However, European Horizon 2020 projects such as “ENSMOV” and streamSAVE have identified the need for further guidance and knowledge-sharing among Member States in the areas of “clear and specified guidelines for monitoring, reporting and verification” and “cost-efficient provision of monitoring, reporting and verification for Article 7 EED” (ENSMOV Project, 2022) and for “streamlining energy savings calculations “ (streamSAVE Project, 2020). The QAI dimension of the sM&V + QAI methodology could provide valuable contributions in this context.

Path forward for sM&V + QAI in industry

The authors would like to encourage a broader discussion on awareness, acceptability, and added value of sM&V + QAI approaches in the context of performance-based projects and programs, DSM administrator-supported projects, as well as those implemented in-house.

Simplified M&V approaches in combination with QAIs should be seen as additional options available to M&V practitioners and are not meant to replace other comprehensive M&V methodologies, wherever these are suitable, feasible, and desired by all project stakeholders.

With regard to sources for computational factors (M II-3 and M II-4), it would be worthwhile to study related norms and standards such as DIN V 18599 (Deutsches Institut für Normung, 2011). Looking to future development of sM&V + QAI into a formal guideline or standard, we suggest investigating other M&V approaches and experiences such as ASHRAE Guideline 14, building certification schemes like BREEAM or LEED or related UNFCC methodologies developed in the framework of international climate policy negotiations (2011).

Initial steps for industry adoption

The adoption of sM&V + QAI could begin with administrators of energy efficiency programs. These entities typically manage numerous small to medium-sized projects and prioritize operational efficiency and program-level results over detailed project-level savings. Their focus on overall energy savings across multiple projects and the need for expedient project cycles make them ideal candidates for the sM&V + QAI approach.

These administrators often seek methods that streamline processes, allowing for quick project completion and rebate distribution. Given their goals and the volume of projects they handle, they can accommodate more uncertainty in energy savings quantification compared to traditional large-scale ESCo project clients. This flexibility aligns well with the sM&V + QAI methodology, which simplifies M&V processes while maintaining reasonable accuracy.

There is evidence that these organizations have already begun deviating from stringent IPMVP methodologies, indicating a readiness to embrace more streamlined approaches. Additionally, the program participants, primarily motivated by program requirements rather than a deep interest in M&V details, are likely to welcome a less burdensome M&V process.

Pilot programs with these administrators can serve as an excellent testing ground for sM&V + QAI. Success in this context can demonstrate the approach’s viability, leading to broader adoption in the energy efficiency sector. This initial focus, coupled with engagement and training for program administrators, will be key steps in the wider implementation of sM&V + QAI methodologies. BPA’s M&V selection guide, offering a simplified approach and the development of their ECwV protocol, is a case in point (Bonneville Power Administration, 2018a, b).

Quantitative validation

For a quantitative comparison and validation of sM&V + QAI approaches, an assessment of margins of error in comparison with more thorough and adherent M&V methods would be desirable. The IPMVP proposes methodological approaches for doing this. BPA’s results in this regard are encouraging. As the ECwV approach is intended to balance the need for DSM program administrators to report on verified energy savings to stakeholders with the efficient allocation of engineering resources and program funding, the results of the aforementioned study (where the ECwV approach produced 73% of traditional M&V savings) are not a deterrent but rather a motivation to refine parameters of the ECwV protocol and pursue more accurate savings results (Rodrigues-Anderson et al., 2022). The difference in final savings compared with traditional M&V approaches should be considered as part of a benefit–cost analysis that also includes factors such as overall M&V expense, decreased project lifecycles, and improved comprehensibility to non-experts. This should allow formulation of some rules about the kinds of approaches that are most effective in terms of balancing cost and accuracy for different sizes and types of projects.

“Strategicity” and “Multiple Benefits” of EE

In the bigger picture, energy cost savings are often not a sufficiently strong project driver or a standalone business case. As Cooremans has stated in the context of businesses, energy saving projects are often not perceived as strategically relevant for a company, and therefore are not recognized on the decision-making level of an organization: “An investment is strategic if it contributes to creating, maintaining, or developing a sustainable competitive advantage.” Thus, an EE investment decision must fit into the “strategicity” decision triangle, composed of three interrelated constituents, and improve (1) cost savings, (2) value proposition to its customers, and (3) risk reduction (Cooremans, 2011). Accordingly, the need for quantifying savings to a high degree of accuracy may be less relevant.

Furthermore, the identification and recognition of “Non-Energy Benefits” or “Multiple Benefits” (MB) of EE (International Energy Agency, 2014) have demonstrated that energy-cost savings may represent a smaller portion of its total benefits than previously understood. Evidence of the significance of MBs can also be found in the European Commission’s EED recast in its new article 3 “Energy Efficiency First principle” which calls for an “assessment of wider benefits of energy efficiency solutions from the societal perspective” (European Commission, 2020). Projects increasingly recognize and try to quantify these benefits on program or macro-economic levels (COMBI Project Consortium, 2015; EERAdata Project, 2022; Fraunhofer ISI, 2022). On the individual project level, benefits like increased productivity or comfort, reduced maintenance cost, environmental compliance, better air quality, or a green image may already constitute as much as 2.5 times the value of energy savings by themselves for some project types, as described by Bleyl et al. (2019) and Rohde and Cooremans (2019). If these “Multiple Project Benefits” of EE (MPB) can be effectively quantified and presented to project proponents, the industry should put more focus on factoring MPBs into the business case than trying to quantify energy savings too exactly. If an accounting of MPBs increases the project benefits significantly, the required level of accuracy on the energy saving benefits could be reduced accordingly, as they represent a less significant portion of the overall economic rationale. This further supports the case for simplified M&V methods backed by QAIs.

The future growth of the EE industry, and its necessary contribution to the realization of climate protection and security of supply-related energy policy goals, will depend in large part on the ability to effectively build trust and engage more than just the energy stakeholders and experts within corporations and governments. Exact quantification of energy savings may be of lesser relevance in this regard, and possibly even inhibit the fulfillment of this necessary growth, as the time and resource cost or perceived complexity may prove prohibitive. A simpler and comprehensible sM&V + QAI approach that can reach a wider audience—particularly on the client side—may reduce risk perception, prove more effective, and hopefully enhance the uptake of much-needed EE projects that are required to meet our emissions reduction objectives.

Notes

Case studies: nine private ESCo contracts between Landesimmobilien-Gesellschaft mbH, Austria and several ESCo companies, which are available to the lead author.

In some cases, it is possible to directly measure demand-side savings at a customer’s premises behind a utility supply meter, provided 100% of the metered energy substitutes on-site consumption and can be used on-site: e.g., technologies like demand-side distributed solar thermal, photovoltaic or combined heat and power units, heat recovery systems, and also external heat or cold supplies. These meter readings can reflect a direct measurement of energy saved (see M II-5 in Table 1).

A “control group” could possibly be used, provided comparability, but this option is not investigated here.

Due to uncertainties and inherent inaccuracies of all savings calculations, some experts prefer to talk about “estimation of savings” instead of their (more or less) exact calculation.

In principle, also a “control group” could be used for a comparison (provided comparability in conditions), but this option is not investigated here.

References

AbdAlla, S., Bianco, V., Tagliafico, L. A., & Scarpa, F. (2020). Life-cycle approach to the estimation of energy efficiency measures in the buildings sector. Applied Energy, 264, 114745. https://doi.org/10.1016/j.apenergy.2020.114745

Anasis, J. G., Khalil, M. A. K., Butenhoff, C., Bluffstone, R., & Lendaris, G. G. (2019). Optimal energy resource mix for the US and China to meet emissions pledges. Applied Energy, 238, 92–100. https://doi.org/10.1016/j.apenergy.2019.01.072

ASHRAE. (2014). ASHRAE Guideline 14–2014: Measurement of energy, demand, and water savings.

Australian Government Department of Resources Energy and Tourism (2013) Energy savings measurement guide version 2.0

Backlund, S., & Thollander, P. (2011). The energy-service gap: What does it mean? In ECEEE 2011 Summer Study Proceedings (pp. 649–656). Stockholm.

Bertoldi, P., & Kromer, S. (2006). Risk assessment in efficiency valuation: Concepts and practice. ACEEE summer study on energy efficiency in buildings (pp. 13–22). American Council for an Energy-Efficient Economy (ACEEE).

Bleyl, J.W. (2011). Conservation first! The new integrated energy-contracting model to combine energy efficiency and renewable supply in large buildings and industry. In ECEEE 2011 Summer Study Proceedings (pp. 183–193).

Bleyl, J. W., Bareit, M., & Sattler, P. (2014). Simplified measurement & verification + quality assurance instruments for energy, water and CO2 savings – Methodologies and examples. ECEEE 2014 industrial summer study proceedings (pp. 133–142). European Council for an Energy Efficient Economy (ECEEE).

Bleyl, J. W., Bareit, M., Casas, M. A., Chatterjee, S., Coolen, J., Hulshoff, A., et al. (2019). Office building deep energy retrofit: Life cycle cost benefit analyses using cash flow analysis and multiple benefits on project level. Energy Efficiency, 12(1), 261–279. https://doi.org/10.1007/s12053-018-9707-8

Bleyl-Androschin, J. W., Seefeldt, F., & Eikmeier, B. (2009). Energy contracting: How much can it contribute to energy efficiency in the residential sector? In ECEEE 2009 summer study proceedings (pp. 985–996). European Council for an Energy Efficient Economy (ECEEE).

Bonneville Power Administration. (2018a). Measurement & verification (M&V) protocol selection guide and example M&V plan, version 2.0.

Bonneville Power Administration. (2018b). Engineering calculations with verification protocol, version 2.0.

Cabrera, D., Seal, T., Bertholet, J.-L., Lachal, B., & Jeanneret, C. (2012). Evaluation of energy efficiency program in Geneva. Energy Efficiency, 5(1), 87–96. https://doi.org/10.1007/s12053-011-9110-1

COMBI Project Consortium. (2015). General information and timeline. https://combi-project.eu/project/general-information-and-timeline/. Accessed 28 July 2022.

Cooremans, C. (2011). Make it strategic! Financial investment logic is not enough. Energy Efficiency, 4(4), 473–492. https://doi.org/10.1007/s12053-011-9125-7

Deutsche Energie-Agentur GmbH (dena). (2015). Einsparnachweise im Energiespar-Contracting: Praxishilfe der Deutschen Energie-Agentur (Translation: M&V in Energy Performance Contracting: Practical guideline of German Energy Agency). Berlin.

Deutsche Energie-Agentur GmbH (dena). (2016). Leitfaden Energiespar-Contracting. Arbeitshilfe für die Vorbereitung und Durchführung von Energiespar-Contracting. (Translation: Guide to Energy Performance Contracting. Guideline for the preparation and implementation of Energy Performance Contracting.).

Deutsches Institut für Normung. (2011). DIN V 18599–4: Energetic evaluation of buildings - Calculation of the net, final and primary energy demand for heating, cooling, ventilation, domestic hot water and lighting - Part 4: Net and final energy demand for lighting. Berlin.

Díaz, J. A., Ramos, J. S., Delgado, M. C. G., García, D. H., Montoya, F. G., & Domínguez, S. (2018). A daily baseline model based on transfer functions for the verification of energy saving. A case study of the administration room at the Palacio de la Madraza, Granada. Applied Energy, 224, 538–549. https://doi.org/10.1016/j.apenergy.2018.04.060

Directive (EU) 2023/1791 of the European Parliament and of the Council of 13 September 2023 on energy efficiency and amending Regulation (EU) 2023/955 (recast) ELI. https://data.europa.eu/eli/dir/2023/1791/oj

E.V.A. Energieverwertungsagentur. (1998). Einspar-Contracting in der Praxis. Ein Leitfaden (Translation: Energy Performance Contracting in practice. A guide). Vienna.

EERAdata Project. (2022). EERAdata. https://eeradata-project.eu/. Accessed 28 July 2022

Efficiency Valuation Organization. (2022). International performance measurement and verification protocol (IPMVP). Core Concepts 2022. https://doi.org/10.1201/9780849338960.ch108

Energiespar-Contracting, E., Energie-agentur, P. D. D., Holz, D., Bleyl, J. W., & Solutions, E. (n.d.). Einsparnachweise im Energiespar-Contracting.

ENSMOV Project. (2022). The energy efficiency directive: Article 7 EED. https://article7eed.eu/?page_id=421. Accessed 28 July 2022

European Commission. (2020). Proposal for a Directive of the European Parliament and of the Council. In Fundamental texts on European private law. Brussels. https://doi.org/10.5040/9781782258674.0035

CEN/CLC/TC 14 (2012) CSN EN 16212 Energy efficiency and savings calculation, Top-down and Bottom-up Methods. European standard norme.

Federal Energy Management Program. (2015). M&V guidelines: Measurement and verification for performance-based contracts -version 4.0.

Franconi, E., Gee, M., Goldberg, M., Granderson, J., Guiterman, T., Li, M., & Smith, B. A. (2017). The status and promise of advanced M&V: An overview of “M&V 2.0” methods, tools, and applications. Lawrence Berkeley National Laboratory.

Fraunhofer ISI. (2022). Multiple benefits of energy efficiency: Project summary. https://www.mbenefits.eu/about-the-project/project-summary/. Accessed 11 Dec 2022

Granderson, J., Touzani, S., Custodio, C., Sohn, M. D., Jump, D., & Fernandes, S. (2016). Accuracy of automated measurement and verification (M&V) techniques for energy savings in commercial buildings. Applied Energy, 173, 296–308. https://doi.org/10.1016/j.apenergy.2016.04.049

He, Z., Hong, T., & Chou, S. K. (2021). A framework for estimating the energy-saving potential of occupant behaviour improvement. Applied Energy, 287, 116591. https://doi.org/10.1016/j.apenergy.2021.116591

Hirst, E., & Brown, M. (1990). Closing the efficiency gap: Barriers to the efficient use of energy. Resources, Conservation and Recycling, 3(4), 267–281. https://doi.org/10.1016/0921-3449(90)90023-W

IEA., & Organisation for Economic Co-operation and Development. (2013). Energy efficiency market report 2013: Market trends and medium-term prospects. IEA.

International Energy Agency (IEA). (2021). Energy Efficiency Hub launched to boost cooperation on world’s ‘first fuel.’

International Energy Agency. (2013). Energy efficiency: Market report 2013 (Vol. 9789264206). IEA. https://doi.org/10.1787/9789264191709-en

International Energy Agency. (2014). Capturing the multiple benefits of energy efficiency. Paris.

International Energy Agency. (2021a). Net zero by 2050: A roadmap for the global energy sector.

International Energy Agency. (2021b). Energy efficiency hub launched to boost cooperation on world’s ‘first fuel.’ https://www.iea.org/news/energy-efficiency-hub-launched-to-boost-cooperation-on-world-s-first-fuel. Accessed 28 July 2022

International Organization for Standardization. (2014). ISO 50015:2014 - Energy management systems -- Measurement and verification of energy performance of organizations -- General principles and guidance. Geneva.