Abstract

This paper addresses the urgent need to meet increasing energy demand while avoiding greenhouse gas emissions by improving energy efficiency. One significant challenge is the energy losses that occur during gas pressure reduction at city gates in natural gas distribution systems. To tackle this issue, this study proposes installing pressure reduction turbines (PRTs) parallel to existing reduction valves, which can generate electricity and enhance system efficiency. This research mainly focuses on Brazil’s natural gas supply, where the potential for installing PRTs is evaluated. The methodology analyzes the country’s distribution network and estimates the electricity generation capacity achievable from PRTs. The results indicate a potential power generation of 66 MW, capable of avoiding the emission of 235,800 tons of CO2 annually and generating 333 GWh/year of electricity, all at a LCOE of $27/MW. These contribute to the environment using the energy efficiency achieved through the installation of PRTs, consequently, Brazil can help to a cleaner and more sustainable energy future.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

One of the industrialization consequences, demographic expansion, and concentration in urban areas has been the consistent increase in electric power consumption (Koc et al., 2019; Neseli et al., 2015). Energy efficiency is one of the sustainability pillars because it allows better use of natural resources (Esquivel-Patiño et al., 2017; Gibson et al., 2016; Hunt et al., 2020; Johansson & Söderström, 2014; Seifert et al., 2019). The increase of energy efficiency indicators in the various economic segments is a global aspiration, especially in the energy transition we are experiencing (Afana syeva and Mingaleeva 2015; Pfeifer et al., 2021). There are many studies intended to increase the efficiency of natural gas plants. He and Lin (2020) show the energy savings from waste heat from the gas turbine exhaust. A recent study suggests integrating energy storage heat systems to combine heat and power plants (Pfeifer et al., 2019). Energy storage systems can be used to store the cold resulting from gas expansion. The use of rolling piston expanders can increase the efficiency of PRT (Kolasiński et al., 2017). Another alternative is the inclusion of pressure reduction turbines (PRT) for power generation (Ebrahimi et al., 2021; Hannachi et al., 2021; Lee & Gurgenci, 2020; Leite et al., 2021; Li et al., 2019; Pagaimo et al., 2021; Sheikhnejad et al., 2020; Tahadjodi Langroudi et al., 2020).

There are reports of the use of turboexpanders in the USA at some natural gas delivery points (Hedman, 2008). A study done in Iran showed positive results in relation to the use of turbo expanders in the city gate, with energy production ranging from 0.2 to 1.1 MWh in the months. As expected, the difference is due to the consumption variation during the year in the analyzed station (Ardali & Heybatian, 2008). There is also a study in Russia that calculated the possible inclusion of a PRT, with power generation results of around 1.1 to 1.7 MW (Poživil, 2004).

The Brazilian energy matrix is predominantly renewable, with hydropower representing 65.2% in 2021 (Antunes Campos et al., 2020; Brazilian Energy Research Company 2021a; Flórez-Orrego et al., 2014; Szklo & Tolmasquim, 2003). Cogeneration has significant participation due to the strong presence of mills that process sugarcane (Borges et al., 2021; Ensinas et al., 2007; Flórez-Orrego et al., 2014; Landini and de Mello Sant’Ana 2017; Lora & Salomon, 2005; Renó et al., 2014; Vendrusculo et al., 2009). Waste gasification has been studied as a promising alternative to reduce landfills and contribute to electricity generation (Carneiro & Gomes, 2019; Gotelip Correa Veloso et al. 2018a, b; Luz et al., 2015; Morawski et al., 2021; Real Guimarães et al., 2021; Renó et al., 2013). Natural gas represents 8.3% of the Brazilian supply. Its demand has been growing over the last years. In 2020, there was a 6% reduction in consumption compared to 2019, mainly attributed to the fall in industrial consumption that year, regressing about 13.3% as the main consequence of the economic effects of the COVID-19 pandemic. In the year 2021, there was an increase in gas consumption due to the water crisis in Brazil, causing the National Electric Systems Operator (ONS) to increase the frequency and intensity of gas-fired thermal power stations (TPS) (Brazilian Energy Research Company 2021a). According to the latest energy balance for 2021, the energy matrix is distributed as shown in the chart in Fig. 1.

Brazilian energy supply by source in 2020 (Brazilian Energy Research Company 2021a)

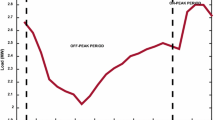

According to the Energy Planning and Development of the Mines and Energy Ministry, gradual economic growth is expected for a 10-year horizon, mainly in the service, construction, transformation, and industrial sectors (Brazilian Energy Research Company 2021b). Figure 2 presents a perspective of thermoelectric demand for natural gas from 2021 to 2031, including existing facilities and those planned for entry into the system. These thermoelectric plants should operate at peak demand to ensure system reliability. This contributes to a rapid expansion of this energy matrix in Brazil and, consequently, to the demand for natural gas.

Maximum demand for gas in thermoelectric per subsystem (Brazilian Energy Research Company 2021b)

Currently, the Brazilian natural gas transportation network has 9409 km (Centro Brasileiro de Infraestrutura 2019), as shown in Fig. 3. The system has 16 national and 3 international natural gas processing plants and several delivery points to final consumers. The Brazil-Bolivia pipeline (GASBOL) and Uruguaiana-Porto Alegre are interconnected and are part of an integrated grid. The Lateral-Cuiabá, Uruguaiana-Porto Alegre, and Urucu-Coari-Manaus pipelines (as well as the Urucu Processing Pole) are considered isolated systems. The isolated system in Maranhão, in the Parnaíba Basin, also deserves mention (Brazilian Energy Research Company 2022). Natural gas consumption is expected to increase due to growth in the agriculture, livestock industry, and services sectors (Brazilian Energy Research Company 2021b). Consequently, the demand for natural gas is expected to increase, which justifies the development of new pipelines and the increase in the capacity of existing pipelines. The Brazilian 10-year energy plan 2031 foresees large investments in natural gas, with the projects for the natural gas infrastructure expansion amounting to approximately R$ 137.86 billion (R$ 8.87 billion foreseen and R$ 128.99 billion in indicative projects) (Brazilian Energy Research Company 2022).

Brazilian natural gas transmission and production network (Brazilian Energy Research Company 2019)

Given the large demand for natural gas in Brazil and the perspective of increased consumption over the next few years, this paper seeks to quantify the national potential for power generation through the use of PRT, increasing the energy efficiency of natural gas transportation process.

This article presents a modeling approach to estimate the generation potential at each natural gas delivery point in Brazil. It demonstrates the methodology employed using the example of the Brazilian transmission network, utilizing historical data on gas consumption and each delivery point’s characteristics. This methodology fills a gap in the literature by providing an estimate for real transmission lines, emphasizing Brazil’s non-application of PRTs at any city gate. It not only benefits gas distribution companies in Brazil but also serves as a valuable resource for other countries looking to assess the potential of pressure-reducing turbines in their own contexts, because of the dadas range used. This article shows that Brazil has the potential to generate 333 GWh/year of electricity with PRTs, quantifying the potential of each federation state and the main natural gas delivery points. This article has five sections. The “Methodology” section presents the methodology used to determine the generation potential in Brazil. The “Results” section shows the results obtained. The “Discussion” section discusses these results and, the “Conclusions” section concludes the paper.

Methodology

The first step in the methodological development was to identify the natural gas transmission pipelines and delivery points in Brazil and their respective utilities. To calculate the PRT power capacity and estimate of electric generation, the inlet and outlet pressures and the natural gas consumption at the city gates were found. With this data, it was possible to obtain the power capacity of each point and the estimated annual generation. Figure 4 presents a flowchart of the methodological framework.

Pressure reduction valves and turbines

Natural gas is transported by pipelines under high pressure. This is necessary to reach the flow demanded by consumers and overcome the pressure losses due to the extensive gas pipeline in the country. At the delivery points (city gate), the gas must have lowered pressure before being supplied to the consumers (industry, commerce, TPSs, etc.). The pressure lowering is typically performed by a pressure-reducing valve, as shown in Fig. 5a. Besides lowering the pressure, other physical processes are also performed at the city gate, such as filtration and flow measurement, and the gas is then distributed to consumers.

The natural gas arrives at the city gate with pressures higher than the distribution pressures to consumers and must be reduced to be delivered to consumers. Pressure-reducing valves perform this by imposing a controlled pressure drop on the system, causing the gas to flow through a throttled section. As a consequence of the pressure reduction, a gas temperature decrease is observed after the valve. This is an isenthalpic process, with no work performed.

Currently, city gates use pressure-reducing valves that perform this function without taking advantage of the pressurized natural gas enthalpy, i.e., without doing any work but simply giving the process a pressure loss. This article evaluates the use of pressure-reducing turbines (recovery turbines) installed in parallel to the current reducing valves to take energy advantage, as illustrated in Fig. 5b. Its operation is substitutive to the valve, obtaining in the pressure-lowering process shaft work and generating electrical power and cold.

To perform the thermodynamic modeling of the pressure-reducing turbine, one must consider the irreversibilities that exist in the systems. It is desirable to have some parameters to quantify the degree of energy degradation in engineering devices working in isolation under steady-state flow conditions, such as turbines. However, in the first place, it is necessary to adopt an ideal process that serves as a model, although some heat transfer between these devices and their surroundings is inevitable. The process that can serve as a suitable model for devices with steady-state and adiabatic flow is the isentropic process.

The mathematical model that describes the pressure-reducing turbine behavior follows the mass and energy conservation laws (first thermodynamics law), as presented in Eq. 1.

where \(dE/dt\) is the energy variation over time. ϕ is the heat flow, \(\dot{\mathrm{W}}\) is work, \({h}_{1}\) is the inlet-specific enthalpy, \({h}_{2}\) is the outlet-specific enthalpy, \({V}_{1}\) is the inlet speed, \({V}_{2}\) is the outlet speed, \(g\) is the gravitational acceleration, \({Z}_{1}\) is the inlet height, and \({Z}_{2}\) is the outlet height.

Since the model adopts a steady-state operation, that is, there is no variation in the total energy over time, therefore \(dE/dt=0\). The model can be simplified by considering that the input and output velocities are equal (\({V}_{1}= {V}_{2})\), and there is no differential in the inlet and outlet heights (\({Z}_{1}= {Z}_{2})\). The energy conservation general equation was reduced to Eq. 2.

The kinetic and potential energy variations in a fluid stream flowing through the turbine are small compared to the enthalpy variation and can be neglected. Considering that there is no change in the gas mass in the turbine \(\left({\dot{\mathrm{m}}}_{1}-{\dot{\mathrm{m}}}_{2}=0)\right)\), Eq. 2 can be simplified to Eq. 3.

Isentropic efficiency \(({\eta }_{s})\) shows how close the real process is to the ideal process. For a turbine operating under steady-state and isentropic conditions, the efficiency is the ratio between the actual work produced (\({w}_{r})\) and the isentropic work (\({w}_{s})\), as shown in Eq. 4.

The isentropic turbine efficiency can be given by the enthalpy variation, as Eq. 5, where \({h}_{2}\) e \({h}_{2s}\) are respectively the enthalpy values in the output state for the real and isentropic processes. Figure 6 shows a typical enthalpy versus entropy plot for ideal and real processes.

Knowing the isentropic efficiency \(({\eta }_{s})\) value, it is possible to determine the output enthalpy of the actual process \(({h}_{2})\), and by the difference between the inlet and outlet enthalpy, multiplied by the gas mass flow (Eq. 2), it is possible to find the shaft work \((\dot{\mathrm{W}})\) done by the turbine. To obtain the electrical power of the pressure-reducing turbine \(({\dot{\mathrm{W}}}_{e})\), the shaft work was multiplied by the speed reducer efficiency \(({\eta }_{r})\) that typically exists between the turbine connection and the generator, and by the generator efficiency \(({\eta }_{g})\) itself, as presented in Eq. 6.

The isentropic efficiency depends on each turbine design. For large and well-designed turbines, the efficiency obtained is above 90%. In the smaller turbines case, this efficiency varies between 70 and 80%, and the value of 75% was used in this paper (Vankeirsbilck et al., 2011). For the gear reducer and generator efficiency, this paper considered the values of 98% and 96% (Burger & Kranzer, 2009), respectively. The conversion efficiency of the turbine shaft work to electrical energy can be estimated to be about 91.2%.

To make the pressure reduction turbine installation viable, it must be guaranteed that the natural gas will be delivered at the same pressure conditions provided by the existing valve. On the other hand, it must be taken into account that the natural gas leaves the reduction turbine at temperatures considerably lower than those at the valve outlet due to the shaft work. Therefore, the need for heating this gas before the firing process must be evaluated, and it can be used, for example, in the cooling process due to its low delivery temperature. This refrigeration could be stored and then used in many possible applications.

Mathematical models

The system’s mathematical model was used in a computational algorithm implemented in the EES software (Engineering Equation Solver), which allows the verification of the energy generation capacity with the implementation of the pressure-reducing turbine at the natural gas delivery points in all the transportation pipelines in Brazil. The software makes calculations easier as it has a vast thermodynamic database and allows for easy input variation data without the need to modify the algorithm.

The first step was to map all the existing natural gas delivery points in Brazil and which are the transport operators. This information is available on the WEBMAP platform from the Brazilian Energy Research Office (Brazilian Energy Research Company 2021c). To obtain the data for average inlet pressure and natural gas volume at each delivery point, the data released by the Petroleum, Natural Gas, and Biofuels National Agency (ANP) were used [37]. Knowing the utility for each delivery point, it was possible to access the technical operating reports where the average delivery pressure at these points is provided. These data are presented in Table 1 for TPSs.

The gas inlet temperatures in all city gates were considered equal due to the unavailability of this information for all points. As a reference for this temperature, the value of 30 °C informed by TPS Cuiabá was considered. Some points with inconsistent values were eliminated from the analysis, and the following criteria were adopted for exclusion: average inlet pressure value is lower than the outlet pressure; there is no flow data for the entire period evaluated; there is no information on outlet pressure.

With all model input parameters properly identified (inlet pressure, outlet pressure, temperature, average flow, and maximum flow), it was possible to calculate the average generation potential \({(\dot{\mathrm{W}}}_{e\_\mathrm{med}})\) and maximum \({(\dot{\mathrm{W}}}_{e\_\mathrm{m\acute{a} }\mathrm{x}})\) of each delivery point using Eq. 6 for the average and maximum flows. In addition, the annual electric generation \({(E}_{\mathrm{anual}})\) of these same points was also calculated using the average generation potential \({(\dot{\mathrm{W}}}_{e\_\mathrm{med}})\) multiplied by the number of hours in the year (8.760 h) using Eq. 7.

Another point that can be analyzed based on these data is the refrigeration capacity. Assuming an isentropic efficiency of 75%, the energy calculation is performed by Eq. 8.

Finally, one can estimate the total CO2 emission avoided for each delivery point using the PRT energy generated in kWh (Eq. 9). The methodology takes into account the emission factor calculated over electricity reductions (United States Environmental Protection Agency 2019).

The data for the average and maximum gas flows supplied at each delivery point and the average pressures were obtained for the data period from 05/01/2021 to 11/31/2021. Since these data do not cover the 12 months of the year, the annual electricity generation estimates presented in the following section were calculated based on the average potential for the available period.

Results

In total, 147 delivery points were analyzed. Those with inconsistent data were eliminated from the analysis, such as points with volumes close to zero and points for which the outlet pressure values were not available. Brazil’s potential was calculated by considering 15 delivery points for TPS and 132 points for other consumers. To facilitate the analysis of the results, the TPS was separated from the other consumers due to some of the particular operating characteristics, such as gas volume or operating model through dispatch, being subject to the decisions made by ONS. Models like this one aim to operate the Brazilian electrical system at the lowest cost, with reliability and optimization of all the energy resources available in the country.

There is a dependence of some TPSs on hydric and climatic conditions since they operate with greater intensity to compensate a lack of hydroelectric generation. In this way, their dispatch model can change considerably annually and interannually, and the generation values obtained for these TPSs should be analyzed properly. Table 2 shows the maximum power, average power, annual generation, avoided CO2 emissions, and average cooling potential, calculated for each natural gas delivery point in TPS. Figure 7 presents the maximum and average power in thermal power stations with the implementation of the pressure-reducing turbine, classified by order of average power.

Analyzing Fig. 7, it is possible to identify which TPS work with the lowest capacity factor, the main ones being Termorio I, Termorio II, and TPS Cuiabá. The total maximum power for the TPS is 15.4 kW, compared to approximately 10.6 kW for the average power. Considering the thermoelectric production cost of around R$ 1340 per MWh, the use of these turbines will provide a R$ 125,000 cost reduction in the plant while avoiding 65.8 tons of \({\mathrm{CO}}_{2}\) per year. Another interesting point is evident from Table 2, where the maximum and average power are close in most cases. This indicates a relatively small variation in flow rate from the maximum, making the turbine application advantageous.

For the other consumer delivery points, the results of the analysis for the 21 largest consumers concerning average generation potential are presented in Fig. 8. The data for the other 109 consumers was summarized in a single point in Table 3. Figure 9 presents the distribution by federation state, considering the total turbine installed capacity. Figure 10 presents the Brazilian power potential with natural gas pressure reduction turbines.

Analyzing Table 3, the annual production capacity is around 23.4 MWh avoiding 51.1 tons of \({\mathrm{CO}}_{2}\) per year. Figure 10 shows that São Paulo and Rio de Janeiro are the states with the highest potential for PRT generation.

To better visualize the energy potential and the geographical location, Fig. 10 shows in scale the relation of the energy potential with the Brazil map. As anticipated, there is a concentration of energy potential in the Brazilian Southeastern region, which can be attributed to its high natural gas consumption.

Cost estimation

A market analysis was conducted in Brazil, considering possible suppliers to develop and locally produce a PRT with a power output of 1.6 MW, and SICHUAN ZJ-TIBO, ROTOFLOW.

AIR PRODUCTS and SIMMS MACHINERY have presented their offer. These turbine manufacturers are great candidates to supply natural gas pressure-reducing turbines. In addition to these candidates, companies outside the country were consulted, considering equipment already available on the market. Considering only the turbine’s cost, the average value that best represents the equipment cost in Brazil today is USD 1500/kW. When analyzing this value, one must consider the power considered in the analysis—1.6 MW. The estimated cost of the energy generated by the PRT can be obtained using the simple LCOE methodology, considering, lifespan = 20 years; discount rate = 3%; capital cost = 1500 USD/kW; capacity factor = 57.1%; fixed O&M cost = 25 USD/kW-yr; variable O&M cost = 0.002 USD/kWh. The estimated value is $27/MWh in a 20-year performance analysis. As a comparison, in Brazil, the LCOE for solar photovoltaic energy is estimated at $30/MWh and for wind energy at $27/MWh (Brazilian Energy Research Company 2021d).

Discussion

Brazil has a power potential of about 66 MW to be installed through PRTs, considering the maximum natural gas volume at each delivery point. Considering the average gas volume consumed between May and November 2021, the average power supplied by the PRTs would be 38 MW, representing a potential energy generation of about 333 GWh/year. Of this amount, about 93 GWh (28%) corresponds to the generation potential at TPS delivery points, while 240 GWh (72%) corresponds to the potential at the other delivery points. Moreover, São Paulo and Rio de Janeiro are the states with the greatest potential for PRT installation, which is related to the fact that they concentrate the largest industrial activity in Brazil. As shown in Fig. 2, according to the PDE, there is a forecasted increase of approximately 60% in natural gas consumption concerning 2021, which would raise the energy production by the PRTs to 533 GWh per year. If we consider the year 2020, when natural gas-fired TPS generation was 53,464 GWh, the generation potential using PRT for the year 2031 would be equivalent to about 1% of Brazil’s thermoelectric generation. To quantify the contribution relevance of generation through PRT, let us consider the generation of the Pernambuco TPS, which, according to ONS data, generated a total of 2497 GWh in 2020. The PRT generation potential for Brazil was estimated at 333 GWh or 13% of the total generated by this TPS in 2020. If we consider the estimate for the year 2031 (533 GWh), the amount would represent 21% of the generation realized in 2020.

It is important to note that, in addition to contributing to electricity generation, PRTs can also be employed in refrigeration services due to the low gas exit temperature after passing through the turbine’s expansion chamber (Poživil, 2004b). Because they are sometimes far from large consumption centers, this cooling can be used by nearby industries or even a cogeneration system in the operation of the generating plant (Hedman, 2008). As an example, TPS Cuiabá may use this potential to contribute to cooling the water in the condensate cooling tower of its steam turbine, further increasing the TPS efficiency. PRTs can also be used as an energy storage device, considering that the pipeline operator can control the gas pressure with a compressor and PRTs in both pipeline ends.

From the technological challenges point of view, the natural gas risk leakage must be taken into account for the implementation of the PRTs (Liu et al., 2021). Methane, the main natural gas component, is a potent greenhouse gas, and its leakage also creates an explosions risk (Hendrick et al., 2016; Luna & Nicholas, 2022). One way to significantly decrease this risk is to use a magnetic shaft (Seo et al., 2019). Another relevant point is the possibility of gas freezing in the turbine (Romero Gómez et al., 2014). These factors have to be well analyzed by the equipment manufacturer in order not to generate damages to the PRT.

In addition to natural gas transportation infrastructure, future applications such as hydrogen transportation and distribution are worth mentioning (Wietschel & Ball, 2010). Hydrogen is a gas with very low volumetric energy density. For transportation, depending on the tank material used, a pressure of approximately 700 bar is required (Abdalla et al., 2018), and a negative part is the loss of 20% of the energy contained in the hydrogen by performing compression (Edwards et al., 2008). Due to high transport and distribution pressures, pressure-reducing turbines can be an alternative for delivery points.

Conclusions

This paper presented a summary of the potential power generation from the substitution of pressure regulating valves by pressure reduction turbines for the natural gas delivery points in Brazil, increasing the energy efficiency of the Brazilian energy matrix through the production of 333 GWh/year of electricity. The methodology employed in this paper is a major contribution to the literature, which lacks in analyzing a continental natural gas distribution network potential identification. The proposed method can easily be extrapolated to other countries.

Counting on a total of 147 viable delivery points, it is possible to install 66 MW of pressure reduction turbines in the natural gas transportation pipelines, avoiding the emission of 235,800 tons of CO2 per year and having 13.89 MW of average cooling potential. The São Paulo and Rio de Janeiro states stand out, representing 65% of the potential for PRT installation in the country since they are the states with the most significant economic activity.

The use of PRTs is an option for electrical generation without the need to burn fuel and without CO2 emissions. In addition, the low temperature of the output gas from the PRTs could be used as a cold source for cooling systems for natural gas consumers. Importantly, energy efficiency helps reduce dependence on imported energy resources, strengthening Brazil’s energy security by minimizing the impact of global geopolitical events that typically affect the oil and gas sector. The introduction of PRTs in Brazil would contribute to new market creation. On the other hand, Brazil has great potential for nationalization of this technology since it has numerous manufacturers of steam turbines with the capacity for development. Additionally, a study such as the one proposed presents results aligned with the energy transition process in the country.

The PRT use in the natural gas delivery points into various transportation pipelines in Brazil presents a great potential for energy increase for the Brazilian energy matrix, including as a measure of energy efficiency for a potential that until now is unexploited in the country. It is, therefore, not only an additional source of energy but also a renewable and clean energy source. It is estimated that the current cost in Brazil for the acquisition of natural gas PRTs would be around USD 1500/kW and the energy generated cost (LCOE) would be around $27/MW.

Data availability

Data will be available on the request from the authors.

Abbreviations

- ANP:

-

Biofuels National Agency

- FU:

-

Federated Unit

- GASBOL:

-

Brazil-Bolivia pipeline

- LCOE:

-

Levelized cost of electricity

- ONS:

-

National Electric Systems Operator

- PRT:

-

Pressure reduction turbine

- TEP:

-

Ten-Year Energy Expansion Plan

- TPS:

-

Thermal Power Stations

- WEBMAP:

-

Platforma from the Brazilian Energy Research Office

- E :

-

Energy

- Φ:

-

Heat flow

- \(\dot{\mathrm{W}}\) :

-

Work flow

- \(h\) :

-

Enthalpy

- \(V\) :

-

Speed

- \(g\) :

-

Gravitational acceleration

- \(\dot{\mathrm{m}}\) :

-

Mass flow

- \(\eta\) :

-

Efficiency

- \(p\) :

-

Pressure

- \(1\) :

-

Inlet

- \(2\) :

-

Outlet

- \(\mathrm{s}\) :

-

Isentropic

- \(r\) :

-

Real

- \(g\) :

-

Generator

- \(e\_\mathrm{med}\) :

-

Average generation potential

- \(e\_\mathrm{max}\) :

-

Maximum generation potential

- \(ref\) :

-

Refrigeration

- \(red\) :

-

Reducer

- \(e\) :

-

Eletrical

References

Abdalla, A. M., Hossain, S., Nisfindy, O. B., Azad, A. T., Dawood, M., & Azad, A. K. (2018). Hydrogen production, storage, transportation and key challenges with applications: A review. Energy Conversion and Management, 165, 602–627 . https://doi.org/10.1016/j.enconman.2018.03.088

Afanasyeva, O. V., & Mingaleeva, G. R. (2015). Comprehensive exergy analysis of the efficiency of a low-capacity power plant with coal gasification and obtaining sulfur. Energy Efficiency, 8(2), 255–265. https://doi.org/10.1007/s12053-014-9290-6

Antunes Campos, R., Rafael do Nascimento, L., & Rüther, R. (2020). The complementary nature between wind and photovoltaic generation in Brazil and the role of energy storage in utility-scale hybrid power plants. Energy Conversion and Management, 221, 113160. https://doi.org/10.1016/J.ENCONMAN.2020.113160

Ardali, E. K., & Heybatian, E. (2008). Energy regeneration in natural gas pressure reduction stations by use of gas turbo expander. Evaluation of available potential in IRAN.

Brazilian Energy Research Company. (2019, November 7). Indicative natural gas processing and outflow plan. https://www.epe.gov.br/pt/publicacoes-dados-abertos/publicacoes/plano-indicativo-de-processamento-e-escoamento-de-gas-natural-pipe. Accessed 15 April 2022

Brazilian Energy Research Company. (2021c). WEBMAP Interaction of the Brazilian energy system. https://www.epe.gov.br/pt/publicacoes-dados-abertos/publicacoes/webmap-epe. Accessed 29 March 2022.

Brazilian Energy Research Company. (2021d). Generation Price Book 2021. Generation Price Book. https://www.epe.gov.br/pt/publicacoes-dados-abertos/publicacoes/caderno-de-precos-da-geracao. Accessed 15 April 2022.

Brazilian Energy Research Company. (2021a). Brazilian Energy Balance 2020.

Brazilian Energy Research Company. (2022). Ten year energy expansion plan 2031. 2022. https://www.epe.gov.br/sites-en/publicacoes-dados-abertos/publicacoes/Paginas/PDE-2031---English-Version.aspx. Accessed 10 April 2022.

Brazilian Energy Research Company. (2021b). Natural gas studies of the ten year energy expansion plan 2031. Studies of the Ten-Year Energy Expansion Plan 2031. https://www.epe.gov.br/pt/publicacoes-dados-abertos/publicacoes/plano-decenal-de-expansao-de-energia-2031. Accessed 7 May 2022.

Burger, B., & Kranzer, D. (2009). Extreme high efficiency PV-power converters; Extreme high efficiency PV-power converters. FRAUNHOFER INSTITUTE FOR SOLAR ENERGY SYSTEMS ISE. http://www.ise.fraunhofer.de. Accessed 18 April 2022.

Carneiro, M. L. N. M., & Gomes, M. S. P. (2019). Energy, exergy, environmental and economic analysis of hybrid waste-to-energy plants. Energy Conversion and Management, 179, 397–417. https://doi.org/10.1016/J.ENCONMAN.2018.10.007

Centro Brasileiro de Infraestrutura. (2019). Quantos quilômetros de dutos temos no Brasil hoje? https://cbie.com.br/artigos/quantos-quilometros-de-dutos-temos-no-brasil-hoje/. Accessed 17 March 2022

do Borges, A. V., Fuess, L. T., Alves, I., Takeda, P. Y., & Damianovic, M. H. R. Z. (2021). Co-digesting sugarcane vinasse and distilled glycerol to enhance bioenergy generation in biofuel-producing plants. Energy Conversion and Management, 250, 114897. https://doi.org/10.1016/J.ENCONMAN.2021.114897

Ebrahimi, S., Riasi, A., & Kandi, A. (2021). Selection optimization of variable speed pump as turbine (PAT) for energy recovery and pressure management. Energy Conversion and Management, 227, 113586. https://doi.org/10.1016/J.ENCONMAN.2020.113586

Edwards, P. P., Kuznetsov, V. L., David, W. I. F., & Brandon, N. P. (2008). Hydrogen and fuel cells: Towards a sustainable energy future. Energy Policy, 36(12), 4356–4362. https://doi.org/10.1016/j.enpol.2008.09.036

Ensinas, A. V., Nebra, S. A., Lozano, M. A., & Serra, L. M. (2007). Analysis of process steam demand reduction and electricity generation in sugar and ethanol production from sugarcane. Energy Conversion and Management, 48(11), 2978–2987. https://doi.org/10.1016/J.ENCONMAN.2007.06.038

Esquivel-Patiño, G. G., Serna-González, M., & Nápoles-Rivera, F. (2017). Thermal integration of natural gas combined cycle power plants with CO2 capture systems and organic Rankine cycles. Energy Conversion and Management, 151, 334–342. https://doi.org/10.1016/j.enconman.2017.09.003

Flórez-Orrego, D., Silva, J. A. M., & de Oliveira, S. (2014). Renewable and non-renewable exergy cost and specific CO2 emission of electricity generation: The Brazilian case. Energy Conversion and Management, 85, 619–629. https://doi.org/10.1016/J.ENCONMAN.2014.04.058

Gibson, C. A., Meybodi, M. A., & Behnia, M. (2016). A methodology to compare combined heat and power systems operating under emissions reduction policies considering biomass co-fired, coal- and natural gas-fuelled steam turbines. Energy Efficiency, 9(6), 1271–1297. https://doi.org/10.1007/s12053-016-9423-1

Gotelip Correa Veloso, T., Sotomonte, C. A. R., Coronado, C. J. R., & Nascimento, M. A. R. (2018). Multi-objective optimization and exergetic analysis of a low-grade waste heat recovery ORC application on a Brazilian FPSO. Energy Conversion and Management, 174, 537–551. https://doi.org/10.1016/J.ENCONMAN.2018.08.042

Hannachi, M., Ketata, A., Sinagra, M., Aricò, C., Tucciarelli, T., & Driss, Z. (2021). A novel pressure regulation system based on Banki hydro turbine for energy recovery under in-range and out-range discharge conditions. Energy Conversion and Management, 243, 114417. https://doi.org/10.1016/j.enconman.2021.114417

He, T., & Lin, W. (2020). Energy saving research of natural gas liquefaction plant based on waste heat utilization of gas turbine exhaust. Energy Conversion and Management, 225, 113468. https://doi.org/10.1016/j.enconman.2020.113468

Hedman, B. A. (2008). Waste energy recovery opportunities for interstate natural gas pipelines. Energy and Environmental Analysis, Inc., an ICF International Company. February 2008. https://ingaa.org/waste-heat-recovery-opportunities-for-interstate-natural-gas-pipelines/. Accessed 12 April 2022.

Hendrick, M. F., Ackley, R., Sanaie-Movahed, B., Tang, X., & Phillips, N. G. (2016). Fugitive methane emissions from leak-prone natural gas distribution infrastructure in urban environments. Environmental Pollution, 213, 710–716. https://doi.org/10.1016/J.ENVPOL.2016.01.094

Hunt, J. D., Zakeri, B., Nascimento, A., Garnier, B., Pereira, M. G., Bellezoni, R. A., et al. (2020). High velocity seawater air-conditioning with thermal energy storage and its operation with intermittent renewable energies. Energy Efficiency. https://doi.org/10.1007/s12053-020-09905-0

Johansson, M. T., & Söderström, M. (2014). Electricity generation from low-temperature industrial excess heat—an opportunity for the steel industry. Energy Efficiency, 7(2), 203–215. https://doi.org/10.1007/s12053-013-9218-6

Koc, Y., Kose, O., & Yagli, H. (2019). Exergy analysis of a natural gas fuelled gas turbine based cogeneration cycle. International Journal of Exergy, 30(2), 103–125.

Kolasiński, P., Pomorski, M., Blasiak, P., & Rak, J. (2017). Use of rolling piston expanders for energy regeneration in natural gas pressure reduction stations-selected thermodynamic issues. Applied Sciences (Switzerland), 7(6), 535. https://doi.org/10.3390/app7060535

Landini, C. L., & de Mello Sant’Ana, P. H. (2017). Technical, economic, and regulatory analysis of the implementation of micro-cogeneration technology in the Brazilian manufacturing sector. Energy Efficiency, 10(4), 957–971. https://doi.org/10.1007/s12053-016-9496-x

Lee, S., & Gurgenci, H. (2020). A comparison of three methodological approaches for meanline design of supercritical CO2 radial inflow turbines. Energy Conversion and Management, 206, 112500. https://doi.org/10.1016/J.ENCONMAN.2020.112500

Leite, C. A. A. F., Alcântara, S. C. S., Ochoa, A. A. V., dos Santos, C. A. C., Dutra, J. C. C., Costa, J. A. P., et al. (2021). Natural gas based cogeneration system proposal to a textile industry: A financial assessment. Energy Efficiency, 14(2), 20. https://doi.org/10.1007/s12053-021-09927-2

Li, C., Zheng, S., Li, J., & Zeng, Z. (2019). Optimal design and thermo-economic analysis of an integrated power generation system in natural gas pressure reduction stations. Energy Conversion and Management, 200, 112079. https://doi.org/10.1016/j.enconman.2019.112079

Liu, C., Liao, Y., Liang, J., Cui, Z., & Li, Y. (2021). Quantifying methane release and dispersion estimations for buried natural gas pipeline leakages. Process Safety and Environmental Protection, 146, 552–563. https://doi.org/10.1016/j.psep.2020.11.031

Lora, E. E. S., & Salomon, K. R. (2005). Estimate of ecological efficiency for thermal power plants in Brazil. Energy Conversion and Management, 46(7–8), 1293–1303. https://doi.org/10.1016/J.ENCONMAN.2004.06.028

Luna, M., & Nicholas, D. (2022). An environmental justice analysis of distribution-level natural gas leaks in Massachusetts, USA. Energy Policy, 162, 112778. https://doi.org/10.1016/j.enpol.2022.112778

Luz, F. C., Rocha, M. H., Lora, E. E. S., Venturini, O. J., Andrade, R. V., Leme, M. M. V., & del Olmo, O. A. (2015). Techno-economic analysis of municipal solid waste gasification for electricity generation in Brazil. Energy Conversion and Management, 103, 321–337. https://doi.org/10.1016/J.ENCONMAN.2015.06.074

Morawski, A. P., de Araújo, L. R., Schiaffino, M. S., de Oliveira, R. C., Chun, A., Ribeiro, L. C., et al. (2021). On the suitable superstructure thermoeconomic optimization of a waste heat recovery system for a Brazilian diesel engine power plant. Energy Conversion and Management, 234, 113947. https://doi.org/10.1016/J.ENCONMAN.2021.113947

Neseli, M. A., Ozgener, O., & Ozgener, L. (2015). Energy and exergy analysis of electricity generation from natural gas pressure reducing stations. Energy Conversion and Management, 93, 109–120. https://doi.org/10.1016/j.enconman.2015.01.011

Pagaimo, M. C., Fernandes, J. F. P., Pérez-Sánchez, M., Amparo López-Jiménez, P., Ramos, H. M., & Costa Branco, P. J. (2021). Transient study of series-connected pumps working as turbines in off-grid systems. Energy Conversion and Management, 245, 114586. https://doi.org/10.1016/J.ENCONMAN.2021.114586

Pfeifer, A., Krajačić, G., Ljubas, D., & Duić, N. (2019). Increasing the integration of solar photovoltaics in energy mix on the road to low emissions energy system–Economic and environmental implications. Renewable Energy, 143, 1310–1317. https://doi.org/10.1016/J.RENENE.2019.05.080

Pfeifer, A., Herc, L., Batas Bjelić, I., & Duić, N. (2021). Flexibility index and decreasing the costs in energy systems with high share of renewable energy. Energy Conversion and Management, 240, 114258. https://doi.org/10.1016/J.ENCONMAN.2021.114258

Poživil, J. (2004). Use of expansion turbines in natural gas pressure reduction stations. Acta Montanistica Slovaca Ročník, 9(3), 258–260.

Real Guimarães, H., Marcon Bressanin, J., Lopes Motta, I., Ferreira Chagas, M., Colling Klein, B., Bonomi, A., et al. (2021). Bottlenecks and potentials for the gasification of lignocellulosic biomasses and Fischer-Tropsch synthesis: A case study on the production of advanced liquid biofuels in Brazil. Energy Conversion and Management, 245, 114629. https://doi.org/10.1016/J.ENCONMAN.2021.114629

Renó, M. L. G., Torres, F. M., da Silva, R. J., Santos, J. J. C. S., & Melo, M. D. L. N. M. (2013). Exergy analyses in cement production applying waste fuel and mineralizer. Energy Conversion and Management, 75, 98–104. https://doi.org/10.1016/J.ENCONMAN.2013.05.043

Renó, M. L. G., del Olmo, O. A., Palacio, J. C. E., Lora, E. E. S., & Venturini, O. J. (2014). Sugarcane biorefineries: Case studies applied to the Brazilian sugar–alcohol industry. Energy Conversion and Management, 86, 981–991. https://doi.org/10.1016/J.ENCONMAN.2014.06.031

Romero Gómez, M., Ferreiro Garcia, R., Romero Gómez, J., & Carbia Carril, J. (2014). Review of thermal cycles exploiting the exergy of liquefied natural gas in the regasification process. Renewable and Sustainable Energy Reviews, 38, 781–795. https://doi.org/10.1016/j.rser.2014.07.029

Seifert, V., da Silva, J. A. M., & Torres, E. (2019). Residual steam recovery in oil refineries: Technical and economic analyses. Energy Efficiency, 12(8), 2039–2053. https://doi.org/10.1007/s12053-018-9731-8

Seo, J., Choi, W. C., Lim, H., Park, M., Kim, D. H., Lee, K., & Yoon, E. (2019). Development of a 250-kWe class supercritical carbon dioxide rankine cycle power generation system and its core components. In Volume 9: Oil and Gas Applications; Supercritical CO2 Power Cycles; Wind Energy (Vol. 9). American Society of Mechanical Engineers. https://doi.org/10.1115/GT2019-90337

Sheikhnejad, Y., Simões, J., & Martins, N. (2020). Energy harvesting by a novel substitution for expansion valves: Special focus on city gate stations of high-pressure natural gas pipelines. Energies, 13(4), 956. https://doi.org/10.3390/en13040956

Szklo, A. S., & Tolmasquim, M. T. (2003). Analysis of Brazil’s cogeneration legal framework. Energy Conversion and Management, 44(3), 369–380. https://doi.org/10.1016/S0196-8904(02)00067-5

Tahadjodi Langroudi, A., Zare Afifi, F., Heyrani Nobari, A., & Najafi, A. F. (2020). Modeling and numerical investigation on multi-objective design improvement of a novel cross-flow lift-based turbine for in-pipe hydro energy harvesting applications. Energy Conversion and Management, 203, 112233. https://doi.org/10.1016/J.ENCONMAN.2019.112233

United States Environmental Protection Agency. (2019). Greenhouse gases equivalencies calculator-calculations and references|US EPA. Energy and the Environment. https://www.epa.gov/energy/greenhouse-gases-equivalencies-calculator-calculations-and-references. Accessed 15 April 2022

Vankeirsbilck, I., Gusev, S., & de Paepe, M. (2011). Efficiency comparison between the steam cycle and the organic Rankine cycle for small scale power generation. In 2nd European Conference on Polygeneration – 30th March-1st April, 2011– Tarragona, Spain.

Vendrusculo, E. A., de Queiroz, G. C., Jannuzzi, G. D. M., da Silva Júnior, H. X., & Pomilio, J. A. (2009). Life cycle cost analysis of energy efficiency design options for refrigerators in Brazil. Energy Efficiency, 2(3), 271–286. https://doi.org/10.1007/s12053-008-9034-6

Wietschel, M., & Ball, M. (2010). The future of hydrogen–opportunities and challenges. In The Hydrogen Economy (pp. 613–639). Cambridge University Press. https://doi.org/10.1017/cbo9780511635359.022

Funding

Open access funding provided by International Institute for Applied Systems Analysis (IIASA). This research was funded by the project entitled “Eficientização Energética de Usina Termelétrica a Gás Através do Aproveitamento Termodinâmico do Gás Natural” within the scope of R&D ANEEL program and financed by Âmbar Energia LDTA.

Author information

Authors and Affiliations

Contributions

This research study was possible with the valuable contributions from the following: writing (original draft preparation), G.A.C.; writing (review and editing), J.R.G.; conceptualization, J.D.H.; methodology, N.P.J.; software, R.M.G.V; validation, V.L.B.; formal analysis, J.D.H.; investigation, F.M.C.T; data curation, C.L.S; supervision, F.T.B.; project administration, J.R.G. All of these authors have read and agreed to submit the revised version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

- Methodology for estimating a country generation potential from pressure reduction turbines.

- Investment costs for natural gas pressure reduction turbine of USD 1500/kW.

- Levelized electricity cost of around $27/MW.

- Brazilian potential for electricity generation of 333 GWh/year.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Condessa, G.Á., Ismail, K.A.R., Hunt, J.D. et al. Electricity generation potential from natural gas pressure reduction turbines in Brazil. Energy Efficiency 16, 97 (2023). https://doi.org/10.1007/s12053-023-10176-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12053-023-10176-8