Abstract

The implementation of energy efficiency measures in companies is the key to a successful energy transition. To that end, companies should improve their energy efficiency and achieve energy savings. The aim of this paper is to present the current status of energy efficiency in companies based on selected cross-cutting technologies and to empirically investigate the implementation status of these measures. For this purpose, a multiple case study was conducted with 386 companies from different industries. The data basis of the case study was generated by means of questionnaires, interviews, and expert visits, and the data were collected within the framework of the Network of Regional Competence Centers for Energy Efficiency, an EU-funded project. A comparison of the potentials of companies with an energy management system in accordance with ISO 50001 and companies without such a system was carried out on the basis of 12 cross-cutting technologies. Statistical evaluation methods and hypothesis testing of eleven hypotheses and nine expressions were used. Our case study showed that (1) the level of energy efficiency in companies is highly dependent on the measure considered. (2) Simple measures have lower potentials than more complex, cost-intensive measures. (3) A positive effect of energy management on energy efficiency in general and on individual measures such as lighting technology, energy monitoring, peak load management, and energy purchasing is empirically confirmed. Further studies should investigate the interaction and correlation of individual efficiency measures (e.g., investments and organizational measures in cross-cutting technologies) in companies to make more targeted statements about the companies' needs and to create efficient support programs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The climate protection goals demanded by the European Union (EU) cannot be achieved without improving the energy efficiency of companies. Increasing energy efficiency is an important success factor for the energy transition, but unfortunately, the potential for energy savings in Germany has been only insufficiently exploited (Gamst, 2019).

To promote energy efficiency, the EU is making a number of efforts to remove barriers in companies and to leverage the existing potential. Energy efficiency in companies is an important contribution to climate protection (Institut für Ressourceneffizienz und Energiestrategien [IREES], 2015).

The energy efficiency potentials in companies are often not known and, therefore, cannot be implemented. In addition to information deficits (Schmid, 2004) acceptance deficits regarding new technologies and solutions are often an obstacle (Hertel, 2014).

Many industries have little knowledge of the actual total energy consumption in companies (Schleich, 2009). Additionally, further breakdown of energy consumption by work area or at the plant level is not possible in most cases. The lack of transparency makes it difficult to identify and exploit existing energy efficiency potentials, which means that decision-makers are often unable to make an assessment on the basis of cost-effectiveness (Deutscher Industrie und Handelskammer [DIHK], 2018).

Another problem is that only a few papers deal with energy efficiency potentials as an actual measure of the technology level (Andrea Trianni et al., 2013), such as lighting technology. However, when papers do so, the relationships between these measures are not further considered (Sudhakara Reddy, 2013).

Therefore, Cagno et al. (2019) recommend analyzing a single company in relation to several different energy efficiency measures (EEMs) to understand the possible synergies (positive or negative) resulting from the implementation of multiple EEMs. Stefana et al. (2019) identify and recommend further research in relation to the mutual influence of individual measures and their interactions. Other studies cite the investigation of correlations between individual efficiency measures as possible research (A. Trianni et al., 2021). The correlation and influence of different measures are recommended in the form of further case studies (Stefana et al., 2019).

The correlations between the individual measures and potentials are an important parameter. For example, if a company has already implemented individual measures, one can estimate the company’s future needs. If there is a correlation, more targeted expansion and promotion concepts can be developed, and investments in energy efficiency can be triggered more quickly. Therefore, it is precisely these correlations and the effects of energy efficiency measures and potentials that should be further researched. In this case study, energy management systems (EnMSs) in accordance with ISO 50001 are first considered as an individual measure, and their connection with other measures is shown. The novelty here is that this study performs an empirical demonstration of how high the energy efficiency potential is at the technology level in companies with EnMSs and in companies without EnMSs. By comparing both potentials, the correlation between an EnMS and the implementation of efficiency measures is shown.

Schützenhofer (2021) is one of the few papers that addresses the fact that an EnMS impacts EEM. However, the study focuses on energy efficiency as a whole and not on individual measures or even potentials. Moreover, the scope considered is limited to large companies.

The following studies state that an EnMS has a positive effect on energy efficiency. In the work of Olsthoorn et al. (2017), a positive effect of EnMSs on energy efficiency is demonstrated. Furthermore, the results of Schulze et al. (2018) provide strong empirical evidence that EnMSs have a positive relationship with the energy efficiency performance of companies.

The positive and negative effects of EEM on other areas are examined in the work of A. Trianni et al. (2021).

Companies that have an EnMS are more likely to implement energy efficiency measures. In this case study, the positive effect is proven by the fact that the potential for efficiency measures in the selected cross-cutting technologies at the technology level is lower in companies with such a system than in companies without such a system.

Stefana et al. (2019) also show that the use of management systems is associated with the improvement and implementation of measures and vice versa. Thus, there is a low energy efficiency potential when an EnMS is implemented. In addition, the study shows potentials at the technology level, and studies are presented in which, for example, measures for lighting and compressed air are considered. The analysis is limited to foundries; thus, other industries and company sizes should also be examined in this context. The study by Mai et al. (2017) compares the implementation of efficiency measures at the technology level between companies with a management system and companies that were legally required to conduct energy audits. Companies with a management system implemented more efficiency measures.

Research questions and hypotheses are derived from our own observations and from the literature. In this work, they investigated by means of suitable qualitative methods. The main focus of this study is to compare the energy efficiency potential of companies with an EnMS and that of companies without an EnMS.

Research questions

-

What are the current energy efficiency potentials in companies in terms of individual measures at the technology level?

-

Is the existing potential in companies with an EnMS in accordance with ISO 50001 lower than that in companies without an EnMS in accordance with ISO 50001?

-

Can a positive effect in companies with an EnMS in accordance with ISO 50001 in terms of implemented EEM at the technology level be identified and proven?

Hypotheses from the literature

-

Hypotheses by Schützenhofer (2021):

-

“Barriers to energy efficiency are lowered by energy and environmental management systems, so that more savings measures are implemented in companies with such systems than in companies with conventional management practices.”

-

“Energy and environmental management systems are a profitable means of designing organizational processes in companies in such a way that economic energy efficiency measures are implemented.”

-

-

Hypothesis by Olsthoorn et al. (2017):

-

“Organizations that have an energy management system (EnMS) in place are more likely to adopt EEM.”

-

-

Hypothesis by Schulze et al. (2018):

-

“The extent of adoption of energy management control systems is positively related to firms' energy efficiency performance.”

-

Own hypotheses on the selected cross-cutting technologies at the technology level

-

H1: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of heat recovery/waste heat recovery is lower than that in companies without an EnMS in accordance with ISO 50001.

-

H2: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of lighting technology is lower than that in companies without an EnMS in accordance with ISO 50001.

-

H3: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of compressed air is lower than that in companies without an EnMS in accordance with ISO 50001.

-

H4: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of electric drives is lower than that in companies without an EnMS in accordance with ISO 50001.

-

H5: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of energy monitoring, peak load management and energy purchasing is lower than that in companies without an EnMS in accordance with ISO 50001.

-

H6: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of ventilation and air conditioning technology is lower than that in companies without an EnMS in accordance with ISO 50001.

-

H7: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of the building envelope and windows is lower than that in companies without an EnMS in accordance with ISO 50001.

-

H8: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of the heating system, hydraulic balancing and heating distribution is lower than that in companies without an EnMS in accordance with ISO 50001.

-

H9: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of building automation/building control systems is lower than that in companies without an EnMS in accordance with ISO 50001.

-

H10: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of refrigeration is lower than in companies without an EnMS in accordance with ISO 50001.

-

H11: If an EnMS in accordance with ISO 50001 exists, the energy efficiency potential of energy self-generation is lower than in companies without an EnMS in accordance with ISO 50001.

All of our hypotheses have nine expressions, as the distinction between company size (all companies, SMEs and non-SMEs) and industry (manufacturing and nonmanufacturing) plays a crucial role in testing them. The data collected during the case studies at the technology level are used to test the hypotheses.

The 12 selected cross-cutting technologies are

-

Compressed air distribution and compressors

-

Lighting technology

-

The building an automation/building management system (BMS)

-

Ventilating and air-conditioning systems

-

Energy monitoring, peak load management and energy purchasing

-

The heating system, hydraulic balancing and heating distribution

-

Electric drives

-

Heat recovery/waste heat utilization

-

Refrigeration

-

Energy self-generation

-

The building envelope and windows

-

An energy management system (EnMS) in accordance with ISO 50001

The cross-cutting technologies in each company are evaluated by experts and are intended to describe the efficiency potential in the study.

To date, a study that analyzes which measures are influenced by other measures and that provides empirical evidence of these interactions and interdependencies has been lacking. Therefore, first, this study attempts to generate a qualitative statement from the collected research data. The observation is to be directed to companies with and without EnMSs, and a comparison of the energy efficiency potentials is to be presented.

To that end, the European Regional Development Fund (ERDF) and the Ministry of Environment of Baden-Württemberg (UM BW) have set up a funding program that is intended to provide companies with a free, neutral and holistic view of their energy efficiency potential. The Energy Efficiency Competence Centre (KEFF) funding program was initiated for this purpose and implemented at regional support organizations (Umwelttechnik BW GmbH, 2021). The support organizations (e.g., chambers of commerce and industry) have recruited energy efficiency experts, so-called efficiency moderators, who go to companies and advise them on site about their energy efficiency potential. In total, there are approximately 30 experts in the project. For the region considered in this study, there are three of these experts. They all have advanced training in the 12 cross-cutting technologies listed. It is recommended that the opinion of an expert be consulted and that the statements of company employees be critically questioned and checked for plausibility (Fernández-Viñé et al., 2010).

The activity follows a standardized procedure, which consists of a preliminary meeting with standardized questions, an inspection of the company and a final meeting. Afterward, the company receives an individual written consulting protocol with the energy efficiency potentials and possible EEM for the company.

The rest of the paper is organized as follows:

-

The “Introduction” section highlights the challenge of the topic by referring to the current state of research on energy efficiency in enterprises and the relationships and interactions of individual EEMs and by presenting recommendations from other authors.

-

The “Methods” section presents the methodology of the paper. It follows a multiple case study and integrates interviews, questionnaires, and field notes from site visits. In addition, the type of data collected, the data basis and the evaluation methodology applied are described.

-

The “Results” section presents the findings of the research and leads to the discussion in the “Discussion” section, where the findings are critically evaluated.

-

The “Conclusions” section summarizes the main findings of the research.

Methods

Research design

To obtain a meaningful picture of energy efficiency in companies, this study was conducted using a multiple case study with semistructured interviews and questionnaires due to the exploratory nature of this study. Figure 1 shows the broad flow of the research design.

The research data were collected as part of the KEFF between 2016 and 2020 and are anonymized.

The questionnaires (Adams, 2007), based on guiding questions on cross-cutting technologies, were always administered at the beginning with the employees responsible for the energy topic in the form of an interview (Adams, 2007).

Subsequently, an inspection of the entire company was carried out together with the employees. The energy efficiency expert took field notes during this on-site company inspection. After the inspection, the energy efficiency potentials were again discussed and agreed upon in a final meeting. As a result, the companies then received an individual consulting protocol, which followed a holistic approach. The consulting protocol contained information and calculations on possible individual measures, showed the companies suitable funding opportunities and subject area experts, and served as the basis for the data matrix in the “Data matrix” section.

The selection of participating companies was random, as the companies interested in the project voluntarily and proactively contacted the Energy Efficiency Competence Center (KEFF). Due to this self-determined active participation of companies, the procedure could always be repeated, and a complete collection of data could take place.

In the process, 12 cross-cutting technologies and their potential were considered. Where measures had already been implemented, this was also noted. The complete questionnaire with the guiding questions on the cross-cutting technologies can be found in Appendix A.

First, we chose a face-to-face interview method for the preliminary discussion. Here, the questionnaire was administered with the responsible persons, and the answers were recorded. Depending on the input, the questions could be individually refined, and additional information could be generated. Compared to just sending a questionnaire by e-mail, this method had the big advantage that the company could interact directly with the interviewer; thus, any uncertainties or gaps in knowledge that arose could be resolved immediately. This also helped to ensure that the responses were fully captured (Adams, 2007)

During the inspection, field notes were taken by the expert, and questions were also asked of the employees. This had the advantage that previously given answers could be corrected or changed if necessary. Thus, the answers to the questionnaires and the inspection of the company with the field notes could be integrated into the method and repeated again in the final interview.

A structured and fixed set of questions was developed in advance (asked in a fixed order) so that it was easy to repeat (replicate) the interview and compare the available information. Depending on the company, additional industry-specific questions were asked by the expert.

The chosen method and the integration of questionnaires, interviews and on-site visits were carried out in a multiple case study (Yin, 2009).

Guiding questions from the questionnaires

Holistic approach

A holistic approach ensures, on the one hand, that all companies are treated equally and, on the other hand, that the expert does not overlook any measures during the survey and on-site visit. To that end, standardized questions were asked that were specifically tailored to the 12 technologies already mentioned. The questions always followed the same sequence and were therefore easy to replicate.

Cross-cutting technologies and their potential at the technology level

The cross-cutting technologies and their potentials relate to technical, financial and organizational measures for energy efficiency. In this study, the concept of potential is considered to be purely technical since the economic consideration of other parameters such as energy prices (electricity and gas), the purchasing conditions for materials, labor and assembly costs, the type of profitability calculation itself and the interpretation of the economic return on investment (ROI) from company to company makes comparability difficult. LED refurbishment, for example, is one possibility. If LED refurbishment has already been completed, there is no more potential for this technology. The focus is not on the kilowatt hours saved per cross-cutting technology but purely on the presence or absence of the potential. The overall consideration of all companies then extends to the frequency of the individual potentials per cross-cutting technology.

To obtain answers with regard to the cross-cutting technologies, standardized questions were asked by means of a questionnaire, which was administered with the company in a preliminary meeting (face-to-face interview) before the on-site appointment. Depending on the use case in the company, the cross-cutting technologies were expanded situationally to include additional topics such as employee training, IT and electrical equipment. These additional topics were not evaluated in this study but should be mentioned here for the sake of completeness. A question about current energy consumption and costs was also asked at the beginning. Company size and industry were matched in the internal databases of the sponsoring organizations and researched on the internet, if necessary.

Inspection of the company by the expert

After the questionnaire was administered, the inspection of the company began. The previously discussed contents could be checked directly for plausibility. Depending on the answers to the key questions and the subsequent inspection by the expert, the potential in the selected technologies could be determined.

The expert was also equipped with various measuring devices, such as a thermal imaging camera, electricity meter, anemometer and compressed air leakage meter, and was trained in their practical use. This had the advantage that potentials could be identified in a practical way. One example of this is the topic of compressed air. When answering the questionnaires, the potential for compressed air distribution was often denied by the responsible employees. The reasons for this are that compressed air leaks are not visible and are often not perceptible to human hearing. Only above a certain diameter and pressure level are leakages audible. Leakages were detected by ultrasonic measurements, and the questionnaire answer could thus be corrected.

As this example shows, the information provided by companies could be directly checked for plausibility during the on-site visit by the expert and agreed upon by the company. In principle, all production areas and administration buildings of the sites visited were taken into account. To cover the 12 cross-cutting technologies, the heating system, the ventilation system, the refrigeration system, the building control system, the technical control center, production, the administration area, supply systems such as the power supply, sanitary facilities, sales rooms, etc., were inspected. Any anomalies were noted, and questions were posed directly to those responsible.

Description of the data basis

The cross-cutting technologies were discussed face to face with company employees. During the subsequent joint inspection with the expert, any ambiguities and information deficits could be immediately and directly checked for plausibility.

-

Type and amount of company data

Anonymized company data from a total of 386 participating companies are used. The companies are not named in the study. Therefore, any inference to the companies themselves and their internal processes is completely excluded.

-

Company size and industry

The companies partly differ considerably in size and industry. Company size is divided into SMEs (small companies) and non-SMEs (large companies) and is based on the definition of the European Commission ((2003/361/EG), 2003/20.5.2003). In terms of the industry, the companies are divided into manufacturing and nonmanufacturing enterprises. Nonmanufacturing enterprises are assigned to the trade and service sectors, for example.

-

Cross-cutting technologies and potentials

The query of the contents and the inference of the potential per technology are carried out in a highly aggregated manner in this study. Initially, no distinction is made in the strength of the potential. If, in the opinion of the expert, there is a potential per technology, a potential is indicated. It is sufficient if a key question on a technology (see Appendix A) reinforces a potential. If the technology is already sufficiently considered in the company, no potential is indicated. The questionnaire and the on-site visit are always used to assess the potential. Finally, the assessed potential is summed for each cross-cutting technology, and frequencies are formed. These frequencies are later compared with each other. The higher the frequency in a cross-cutting technology is, the higher the efficiency potential. Conversely, the lower the frequency in a cross-cutting technology is, the higher the implementation rate of efficiency measures in the companies.

Data matrix

A total of 386 consulting protocols were anonymously transferred to an Excel data matrix and analyzed. The companies are listed by number from 1 to 386. Table 1 shows examples of the contents queried for four companies.

The first step in this approach is to qualitatively show in which of the cross-cutting technologies energy efficiency potentials exist and in which they do not.

The cross-cutting technologies are mapped equally for all companies in the data matrix. If a company receives a “1” for a cross-cutting technology, this means that a potential has been identified; if a “0” is entered, the cross-cutting technology has been implemented in the company. Since the participating companies have extremely heterogeneous structures (size, industry, etc.), it is only logical that not all companies have, for example, compressed air distribution or ventilation systems installed. This is particularly the case in regard to SMEs from the nonmanufacturing sector. Therefore, these companies have been removed from the statistics to avoid distorting the results.

Definition of the potential using the example of manufacturing SMEs (see company 2 in Table 1): The energy efficiency potential of all manufacturing SMEs is summed for each cross-cutting technology. The sum of the individual cross-cutting technologies is then set in relation to the total number of manufacturing SMEs. This value is used to calculate the frequency as a percentage. This percentage can be classified using the scale in Table 2. This percentage is used to show the current status of energy efficiency in the companies in relation to the cross-cutting technologies considered and to test the 11 hypotheses. In addition, the results are used to try to test the hypotheses from the literature.

Evaluation method

Statistical methods are used for the analysis of the research data.

First, under I., the existing potential of the companies is analyzed using descriptive statistics in the data matrix. Minimum and maximum observations, frequencies, mean values and sum values are formed.

Then, in II., an analysis of two groups (companies with EnMSs and companies without EnMSs) is conducted. Here, the frequencies per cross-cutting technology are compared, and whether the potential of companies with an EnMS is lower than that of companies without an EnMS is examined.

To test the statistical significance of the variables (nominal scaled level), a chi-square test is performed. Subsequently, the hypotheses are tested with the validated data. In III., the frequencies are classified into an ordinal scale. IV. deals with the limitations of the method.

-

I.

General overview of existing potentials

-

First, an overview of the existing potentials of all companies in the selected cross-cutting technologies is shown.

-

Subsequently, the research data are divided into SMEs and non-SMEs.

-

In addition, the companies are divided into manufacturing and nonmanufacturing companies.

The results are assessed and presented using the qualitative scale created in Table 2.

-

II.

Energy management in accordance with ISO 50001

The next step of the analysis focuses on EnMSs in accordance with 50001. The main objective of the analysis is to examine whether companies with an EnMS in accordance with 50001 have less energy efficiency potential than companies without an EnMS in accordance with 50001. This examination is performed by classifying the company size and industry, and the results are qualitatively compared and examined. Only an EnMS in accordance with ISO 50001 is considered; other static energy consulting standards, such as DIN EN 16247 or VDI 3922, are not included in the evaluation.

This evaluation also allows existing hypotheses from the literature to be critically considered and evaluated.

In addition, 11 own hypotheses (H1-11) are qualitatively evaluated in relation to the individual technology. Each of these hypotheses has 9 expressions (a-i). The energy efficiency potentials (sum of frequencies) of the individual cross-cutting technologies are compared with each other. A hypothesis is considered confirmed if the energy efficiency potential of companies with EnMSs is smaller than that of companies without EnMSs. If the potential is equal or greater, the hypothesis is considered to be rejected.

The method is based on a comparison of the frequencies of both groups (with and without EnMSs). To justify the comparison of the frequencies statistically, the variables of the two groups are tested for independence. Since the variables are nominally scaled and frequencies are compared, the chi-square test is used (Adams, 2007). It tests the dependencies and whether there is a statistically significant association between the variables. If the result indicates that a dependency exists, the dependency is statistically confirmed. The greater the difference between the variables is, the greater the dependence. The test is performed using statistical software.

-

III.

Qualitative scale for assessing the potential

A qualitative scale is used to assess the potential. The ordinal scale chosen refers to the potential and allows it to be ranked. A distinction is made between a very high potential (80–100% of companies), a high potential (60–79% of companies), a medium potential (40–59% of companies), a low potential (20–39% of companies), a very low potential (1–19% of companies) and no potential (0% of companies). The results move along the ordinal scale and can thus be qualitatively assigned (Adams, 2007).

-

IV.

Limitations of the method

Data collection

There are 12 cross-cutting technologies captured in the case study. One company has significantly more topics than these 12. Nevertheless, the intention is for this study to use these 12 technologies to assess the current energy efficiency status of companies.

Data evaluation

Based on the standardized questionnaire, the interview and the inspection, the expert evaluates in which cross-cutting technologies energy efficiency potential exists. Only if no potential exists (measure already sufficiently implemented) is no potential evaluated. In addition, a “1” always enters the statistics if there is potential in a technology, regardless of the strength of the potential.

Analysis

Descriptive statistics and the chi-square test are used to answer the research questions and test the hypotheses. The subsequent comparison of frequencies leads to a certain fuzziness because the potentials (“0” and “1”) previously included in the statistics if they were in the borderline range do not make it possible to exclude the subjectivity of the expert.

Results

General overview of the existing energy efficiency potentials of the participating companies

All participating companies

Table 3 provides an overview of the existing energy efficiency potentials of the selected cross-cutting technologies in absolute and relative terms and differentiates between company size and industry. This results in the most frequently occurring energy efficiency potentials as well as an overall assessment of the current energy efficiency potentials.

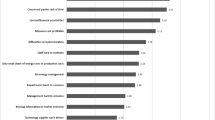

The top 4 potentials are located in the building envelope and windows with 92% of the examined companies, the heating system, hydraulic balancing and heating distribution with 91%, the building automation/building management system (BMS) with 91% and lighting technology with 76%.

The lowest potentials are found in refrigeration technology with 18%, electric drives with 31%, compressed air distribution and compressors with 37% and heat recovery/waste heat utilization with 42%.

Of the 386 companies considered, 91 had an implemented energy management system in accordance with ISO 50001, accounting for approximately a quarter of the companies in this study.

In the 12 selected cross-cutting technologies, an average energy efficiency potential of 60% was identified among the companies. Thus, a high potential can be assumed.

All larger enterprises (non-SME)

Of the 386 participating companies, 100 larger companies (non-SMEs) are included in the research, accounting for 25.9% of the companies.

The top 4 potentials are available in building automation/building control technology (BMS) with 96% of the examined companies, the building envelope and windows with 95%, the heating system, hydraulic balancing and heating distribution with 94% and ventilation and air conditioning technology with 86%.

The lowest potentials are in refrigeration technology with 30%, energy monitoring, peak load management and energy purchasing with 43%, electric drives with 51% and lighting technology with 52%.

Of the 100 companies considered, 70 companies had an implemented energy management system in accordance with ISO 50001, accounting for 70% of these companies in the present study.

In the 12 selected cross-cutting technologies, an average energy efficiency potential of 66% was identified for non-SMEs. Thus, a high potential can be assumed.

All smaller enterprises (SMEs)

Of the 386 participating companies, 286 SME companies are included in the research, accounting for 74.1% of the companies.

The top 4 potentials can be found in the building envelope and windows with 91% of the examined companies, building automation/building management system (BMS) with 90%, the heating system, hydraulic balancing and heating distribution with 90% and lighting technology with 84%.

The lowest potentials are in refrigeration technology with 14%, electric drives with 24%, compressed air distribution and compressors with 28% and heat recovery/waste heat utilization with 29%.

Of the 286 companies considered, 21 companies had an implemented energy management system in accordance with ISO 50001, representing 7% of these companies in this study.

In the 12 selected cross-cutting technologies, an average energy efficiency potential of 58% was identified for SMEs. Thus, a medium potential can be assumed.

General overview of existing potentials by company industry and size

All manufacturing companies

At approximately 47%, the share of manufacturing companies is just under half of all the companies examined. Thus, the ratio between manufacturing and nonmanufacturing companies is balanced.

The share of manufacturing non-SMEs is 40.6%, and the share of manufacturing SMEs is 59.4%.

The top 4 potentials for all manufacturing companies can be found in building automation/building control technology with 95% of the examined companies, the building envelope and windows with 92%, the heating system, hydraulic balancing and heating distribution with 89% and lighting technology with 67%.

The lowest potentials are in refrigeration technology with 28%, electrical drives with 51%, ventilation and air conditioning technology with 55% and compressed air distribution and compressors with 58%.

Of the 180 companies considered, 67 had an implemented energy management system in accordance with ISO 50001, representing 37% of all manufacturing companies in the present study.

In the 12 selected cross-cutting technologies, an average energy efficiency potential of 66% was identified for manufacturing companies. Thus, a high potential can be assumed.

Manufacturing non-SMEs

The top 4 potentials for manufacturing non-SMEs are found in building automation/building control technology with 97% of the companies examined, the building envelope and windows with 96%, the heating system, hydraulic balancing and heating distribution with 96% and ventilation and air conditioning technology with 86%.

The lowest potentials are in energy monitoring, peak load management and energy purchasing with 38%, refrigeration technology with 38%, lighting technology 52% and compressed air distribution and compressors with 62%.

Of the 73 non-SMEs considered, 49 companies had an implemented energy management system in accordance with ISO 50001, representing 67% of the manufacturing non-SMEs in this study.

In the 12 selected cross-cutting technologies, an average energy efficiency potential of 67% was identified for manufacturing non-SMEs. Thus, a high potential can be assumed.

Manufacturing SMEs

The top 4 potentials for manufacturing SMEs are found in building automation/building control technology with 93% of the companies examined, the building envelope and windows with 90%, the heating system, hydraulic balancing and heating distribution with 84% and energy monitoring, peak load management and energy purchasing with 80%.

The lowest potentials are in refrigeration technology with 21%, ventilation and air conditioning technology with 34%, electric drives with 42% and heat recovery/waste heat utilization with 52%.

Of the 107 SMEs considered, 18 companies had an implemented energy management system in accordance with ISO 50001, representing 17% of the manufacturing SMEs in this study.

In the 12 selected cross-cutting technologies, an average energy efficiency potential of 64% was identified for manufacturing SMEs. Thus, a high potential can be assumed.

All nonmanufacturing companies

At approximately 53%, the share of manufacturing companies is just over half of all the companies examined.

The share of nonmanufacturing non-SMEs is 13.1%, and the share of nonmanufacturing SMEs is 86.9%.

The top 4 potentials for all nonmanufacturing companies can be found in the heating system, hydraulic balancing and heating distribution with 92% of the companies examined, the building envelope and windows with 91%, building automation/building control technology with 88% and lighting technology with 83%.

The lowest potentials are in refrigeration technology with 10%, electric drives with 13%, compressed air distribution and compressors with 18% and heat recovery/waste heat utilization with 24%.

Of the 206 companies considered, 24 had an implemented energy management system in accordance with ISO 50001, representing 12% of all nonmanufacturing companies in this study.

In the 12 selected cross-cutting technologies, an average energy efficiency potential of 56% was identified for nonmanufacturing companies. Thus, a medium potential can be assumed.

Nonmanufacturing non-SMEs

The top 4 potentials for all nonmanufacturing non-SMEs are found in building automation/building control technology with 93% of the companies examined, the building envelope and windows with 93%, heating system, hydraulic balancing and heating distribution with 89% and ventilation and air conditioning technology with 85%.

The lowest potentials are in refrigeration technology with 7%, electric drives with 15%, lighting technology 52% and energy monitoring, peak load management and energy purchasing with 56%.

Of the 27 non-SMEs considered, 21 companies had an implemented energy management system in accordance with ISO 50001, representing 78% of all nonmanufacturing companies in this study.

In the 12 selected cross-cutting technologies, an average energy efficiency potential of 62% was identified for nonmanufacturing non-SMEs. Thus, a high potential can be assumed.

Nonmanufacturing SMEs

The top 4 potentials for all nonmanufacturing SMEs are found in the heating system, hydraulic balancing and heating distribution with 93% of the companies examined, the building envelope and windows with 91%, building automation/building control technology with 88% and lighting technology with 88%.

The lowest potentials are in refrigeration technology with 10%, compressed air distribution and compressors with 11%, electric drives with 13% and heat recovery/waste heat utilization with 15%.

Of the 179 nonmanufacturing SMEs considered, 3 companies had an implemented energy management system in accordance with ISO 50001, representing 2% of all nonmanufacturing SMEs in this study.

In the 12 selected cross-cutting technologies, an average energy efficiency potential of 55% was identified for nonmanufacturing SMEs. Thus, a medium potential can be assumed.

The results of the energy efficiency potentials in the selected cross-cutting technologies provide information on the current state of energy efficiency in companies.

If building issues are excluded from the analysis, the energy efficiency potential

-

of all companies is 47% (−13% pts.),

-

of all non-SMEs is 60% (−6% pts.),

-

of all SMEs is 42% (−16% pts.),

-

of all manufacturing companies is 56% (−10% pts.),

-

of all manufacturing non-SMEs is 61% (−6% pts.),

-

of all manufacturing SMEs is 53% (−11% pts.),

-

of all nonmanufacturing companies is 39% (−17% pts.),

-

of all nonmanufacturing non-SMEs is 56% −6% pts.), and

-

of all nonmanufacturing SMEs is 36% (−19% pts.).

With these input parameters, the energy efficiency potential is evaluated on a scale from low to high potential.

Energy management in accordance with ISO 50001

An EnMS in accordance with ISO 50001 has been implemented in 91 companies (21 SMEs and 70 non-SMEs). Of these companies, 67 are in the manufacturing sector, and 24 are in the nonmanufacturing sector. Of the 67 manufacturing companies, 49 are non-SMEs, and 18 are SMEs. Among the nonmanufacturing companies, the breakdown is 21 non-SMEs and 3 SMEs.

In Table 4, the energy efficiency potentials of companies with EnMSs and without EnMSs are listed and directly compared at the technology level.

When comparing the frequencies between companies with EnMSs and without EnMSs, significant differences emerge. Three frequencies from Table 4 are given as examples. Looking at lighting technology, the research data indicate that the frequencies occurring in all nine manifestations are lower for companies with an EnMS than for those without an EnMS. This is also true for energy monitoring, peak load management, and energy purchasing. In the case of electric drives, 8 out of 9 expressions show lower frequencies.

By means of a chi-square test, the statistical significance of the two groups (companies with EnMSs and without EnMSs) can be proven, as the calculated p value is smaller than the significance level alpha (=0.05). This result can be proven for all companies, for manufacturing companies and for nonmanufacturing companies. The procedure was adapted from the study by Umweltbundesamt (2018). The results of the test can be seen in Appendix B.

The comparisons of frequencies at the technology level are now used to test the hypotheses.

Table 5 presents and evaluates the results of our eleven hypotheses (H1-11) and their nine expressions (a–i) listed in the “Introduction” section. The green cells show the confirmed hypotheses, and the red cells show the rejected hypotheses. In addition, the two frequencies to be compared are transferred into the cells. If the quotient of both frequencies is greater than or equal to 1, then the hypothesis can be rejected; if the quotient is less than 1, then the hypothesis is confirmed.

Overall, 47 of 99 hypotheses are confirmed, and 52 hypotheses are rejected.

For measures such as lighting (H2), the hypothesis can be assessed as provisionally confirmed across all characteristics. All companies with an EnMS have less potential here than companies without an EnMS.

This can also be seen in Hypothesis H5, where energy monitoring, peak load management and energy purchasing show a higher level of implementation.

H4, which deals with electric drives in companies, is also an example. Here, eight out of nine statements can also be rated as confirmed.

For the remaining measures, which are associated with a higher complexity of individual measures and a higher investment sum, the results are no longer so clear. For example, for Hypothesis 6 ventilation and air conditioning technology and Hypothesis 7 the building envelope and windows, all hypotheses and characteristics are refuted. In addition, for Hypothesis 1, heat recovery/waste heat recovery, only for expression e) is it possible to assert that this hypothesis is confirmed for non-SMEs.

Positive effect of an EnMS in accordance with ISO 50001 in terms of energy efficiency potentials

A positive effect in companies with an EnMS in accordance with ISO 50001 with regard to energy efficiency potentials can be determined and proven with the collected data. However, this effect cannot be generalized equally to all individual measures. The reason is that of the total of 99 observations (eleven hypotheses and nine expressions), 47 are evaluated as confirmed and 52 as refused. Therefore, the question of whether the existing potential is lower in companies with an EnMS than in companies without an EnMS cannot be stringently answered. The answer depends on the efficiency measure examined. The analysis at the technology level shows that, among other things, a clear effect can be perceived in the areas of lighting technology, energy monitoring, peak load management and energy purchasing with regard to the energy efficiency potential of companies with an EnMS. These energy efficiency measures were implemented more and have a lower potential.

The hypotheses from the literature listed in Table 6 can be examined with the research findings of our own study. The evaluation can only be approximate due to the degree of abstraction of the hypotheses.

Discussion

Starting point of this work and the objective

The correlation and interaction of individual energy efficiency measures are underrepresented in current research. One important measure is the implementation of an energy management system in accordance with ISO 50001, which can be used to make energy consumption more transparent. In addition, several studies have already shown that energy management has a positive effect on further energy efficiency measures. This evidence is currently based on a high level of flux level and does not address the level of the individual technology, such as lighting technology.

Therefore, this study presents a qualitative comparison of energy efficiency potentials in small and large companies from different industries. Subsequently, energy management as a measure is specifically addressed, and whether companies with such a system have less energy efficiency potential than companies without such a system is examined. This comparison is made at the technology level and includes energy efficiency measures in 12 cross-cutting technologies. These are evaluated with the help of a qualitative scale, and our hypotheses and hypotheses from the literature are tested.

Research questions

The current status of energy efficiency at the technology level in companies can only be approximated with the available data, especially from the region under consideration. Additionally, correlations between the individual measures at the technology level can only be compared for the EnMS measure with the other measures. Moreover, the correlation between the cross-cutting technologies queried and the energy efficiency of a company is not completely congruent since a company consists of more than 12 technologies and further topics could be integrated.

However, it was important to consider major cross-cutting energy technologies that are present in as many companies as possible to be able to make a comparative statement with a probabilistic orientation. Therefore, a certain degree of fuzziness in the analysis must be accepted. The results of the selected cross-cutting technologies provide a statement about the current state of energy efficiency in companies.

A medium to high energy efficiency potential can be output for the companies considered. Therefore, there is a medium to high need for the implementation of energy efficiency measures. The examination of the individual cross-cutting technologies also shows that high potentials are represented in the building topics. These are represented with a very high potential in all companies, regardless of size and industry.

High potentials include the building envelope and windows, building automation/building control technology and the heating system, hydraulic balancing and heating distribution. This result can be attributed to the older building stock of the companies participating.

In practice, these potentials are also directly related to each other. If, for example, the building envelope is renovated, old inefficient heating systems are usually oversized after this individual measure. If only the heating system is replaced first, a 1-to-1 replacement is usually carried out, which still means an oversized heating system. If the heating system is replaced first and the building envelope is refurbished later, the heating system will continue to be too large over a long period of use, as less heating energy is required as a result of the refurbishment. It is therefore advisable to coordinate these measures. Thus, the already cost-intensive individual measures become even more expensive in total. In addition, companies are often tenants in buildings, which also leads to an inhibition in implementation. The building control systems/building automation in existing buildings are also frequently linked to the building envelope, as this also involves measures on the building itself. Most of the companies investigated were housed in existing buildings. If the potentials of building topics are removed from the mean value analysis, new mean values of the remaining cross-cutting technologies result.

With these input parameters, the energy efficiency potential is evaluated on a scale from low to high potential. This shows the strong dependence on individual parameters, which at the same time shows the limits of this evaluation.

Hypothesis testing

The eleven hypotheses with nine different expressions make it possible to present a comprehensive picture of energy efficiency in companies. They show whether there is an interaction between energy management and energy efficiency potential. With the help of the hypotheses, it is possible to make a probabilistic statement as to whether the existing energy efficiency potential is lower in companies with an EnMS in accordance with ISO 50001 than in companies without an EnMS in accordance with ISO 50001. In addition, the overall picture tends to explain whether a positive effect in companies with an EnMS in accordance with 50001 can be determined and proven with regard to implemented energy efficiency measures at the technology level.

The results show that 47 hypotheses are confirmed and 52 rejected. This means that although the effect of an EnMS is present, it is not universally transferable to all measures. It also shows that not all barriers (financial, technical and organizational) can be solved by an EnMS. This can be observed particularly in the case of expensive measures such as building insulation and heating system renewal.

It follows that the research question about the difference in energy efficiency potential in companies with an EnMS and without an EnMS can, with the limitations described here, be provisionally confirmed. Nevertheless, the level of potential is very strongly dependent on the efficiency measures considered.

The research question following from the previous research question, whether a positive effect of EnMSs on EEM can be established and proven at the technology level, is answered, and such an effect is provisionally confirmed. The empirical evidence is provided in this paper.

The critical examination of the hypotheses from the literature also tends to point in the direction of the results regarding our own hypotheses. Certainly, the hypotheses from the literature are more abstract and are formulated for a larger context, but nevertheless, statements can be transferred to the study presented here. The authors argue that there is a positive effect of energy management on energy efficiency in companies and partly confirm this effect empirically. Nevertheless, in most cases the level of consideration is based on energy efficiency as a whole and not on individual measures at the technology level. The present study is one of the few that approximates and proves this effect. The study by Mai et al. (2017) compares the implementation of efficiency measures at the technology level between companies with a management system and companies that were legally required to conduct energy audits. In both studies, the implementation of efficiency measures is higher for companies with a management system. In the results on the identified measures, there are similarities in the areas of compressed air and electric drives, and differences in the areas of lighting technology and heat recovery. Considering the chronology of the two studies, it can be assumed that the companies have implemented some measures in lighting technology. The identified measures of Mai et al. (2017) were about 77% and in our study 34% of the companies.

In the area of compressed air, both studies indicate a possible potential in about half of all companies. This could be due to the fact that continuous activity is required in this area, since, for example, leakages occur again and again.

In the case of electric drives, both studies show potential in about one-third of all companies. On the one hand, there has been a lot of technical progress in electric drive development, which could explain why there is still a high potential. On the other hand, electric drives are available in large numbers in most companies, which could therefore explain this potential from a purely quantitative point of view.

In the case of heat recovery, the results of Mai et al. (2017) with 29% and our study with 77% differ significantly. One reason could be the technical improvements in the use of heat recovery.

However, the difference could also be due to the companies considered. In our study, about 50% are companies in the manufacturing sector, which tend to require more diverse concepts for heat recovery.

Limitations of our work

Due to the strong dependence of the input parameters, the data acquisition and evaluation model used must be optimized. Nevertheless, it is sufficient to make a tendency statement. When considering interactions at the technology level, individual measures must differ in the strength of the respective potential, i.e., the evaluation must be quantitatively representable. This can be achieved with an evaluation scale of the individual measures. Only then can statistical outliers be eliminated and a more well-founded statement be made. To date, a potential has either existed or not existed. In perspective, potentials should be divided into low, medium and high so that the interactions can be quantitatively calculated. The 12 cross-cutting technologies were selected and surveyed because, to the knowledge of the Energy Efficiency Competence Center (KEFF), they represent the measures that are most likely to be found in many companies in different industries. However, this does not mean that these 12 technologies represent a definitive picture of the energy efficiency of the companies considered and could not be supplemented by other important topics.

The participating companies voluntarily approached the Energy Efficiency Competence Center (KEFF) for a variety of reasons. However, these companies have already seen a certain need for action on the topic of energy efficiency on their own or have recognized the awareness of this important topic. It would therefore be interesting to see what results the present study would have produced with companies without these attributes. This purely hypothetical consideration makes it clear that a simple transfer to all companies will therefore be difficult.

The assessment of the potential at individual companies was carried out by an expert. The participating experts have the necessary expertise from many years of consulting work and can assess the potential objectively and, thus, comprehensively. In this way, the subjective assessment of the company can be corrected if necessary, but the subjectivity of the expert him- or herself with regard to the potential remains. For the companies considered in the study, three out of approximately 30 experts carried out the assessment. The three experts were engineers in energy and environmental technology and had training in cross-cutting technologies.

In addition, the classification of company size and industry should be modified since the division into non-SMEs and SMEs as well as manufacturing and nonmanufacturing enterprises omits the heterogeneity of enterprises. A classification into precise economic sectors and classification based on a detailed number of employees per enterprise are missing thus far.

The aim of the study is to focus exclusively on a dynamic energy management system in accordance with ISO 50001. Only this system ensures the continuous monitoring and review of energy flows and processes in companies. All other energy consulting standards, such as VDI 3922 or DIN EN 16247-1, are static snapshots without any tracking of actual improvement in a company. Therefore, it was actively decided not to include them in the study. In addition, the companies considered in our case, which had an obligation to implement DIN EN 16247-1 according to EDL-G, have implemented an EnMS in accordance with ISO 50001 without exception, on the one hand, for the reason mentioned and, on the other hand, because doing so was the only way to obtain a refund of the energy tax. Nevertheless, the results are distorted by these general conditions, which must therefore be mentioned here.

Finally, there is also a lack of differentiation between family-owned companies and capital-owned companies. On average, family-owned companies show significantly better efficiency performance than capital-owned companies, regardless of whether they comply with ISO 50001. This also limits the results and is mentioned here.

Further research and contribution

The research question can be applied arbitrarily to other circumstances, such as the tenant-landlord dilemma, with regard to the implementation of energy efficiency potentials. In addition, each individual measure can be used analogously to consider companies with energy management. These topics are still underrepresented and can be investigated and empirically proven in a research paper.

The correlation of the individual measures and their interactions should be further investigated in future research. Doing so will enable a more targeted response to the needs of companies, depending on their size, branch, ownership structure, individual cross-cutting technologies (e.g., rented buildings, contracting), reinvestment cycles, participation in energy efficiency networks and age of the production site. In this way, a support program tailored to the companies can be set up, and advisory services can be improved.

However, the results must be seen as an approximation, as a quantitative study with the different weighted potentials is still pending. In addition, further relationships between individual measures remain to be investigated.

This paper makes a theoretical contribution to the understanding of energy efficiency measures in companies and shows the current state of implementation.

Conclusions

The aim of this work was to answer the research question about the current status of energy efficiency at the cross-cutting energy technology level in companies. This could be statistically presented with the multiple case study and the data collected through it. Through the combination of questionnaires, interviews and expert visits, a good data basis was created, which can be extended in further research.

Novelty of the study

This study considers small and large companies from the manufacturing and nonmanufacturing sectors and compares energy efficiency potentials at the cross-cutting energy technology level. Furthermore, in addition to the current status of energy efficiency, the results provide empirical evidence that companies with an EnMS often have fewer opportunities to invest in the energy efficiency of cross-cutting technologies than companies without an EnMS. This evidence is provided with our own hypotheses with reference to 12 cross-cutting technologies. The energy efficiency potential in companies varies greatly, not least due to the heterogeneity of the participating companies. It also became clear that the implementation status is highly dependent on the energy efficiency measures considered in each case.

Furthermore, to the best of our knowledge, few studies empirically prove that existing energy management has concrete effects on the energy efficiency of a company. Therefore, establishing this connection and empirically proving the positive effect of energy management were another goal. In addition, with the help of our own hypotheses, this study made efforts to derive this evidence at the technology level.

The results show that energy management has a positive effect on energy efficiency. Furthermore, evidence could be provided at the technology level.

Recommendations

In the next step, the present research will be further expanded with the help of a quantitative method. The aim is to present the recorded energy efficiency potentials not only based on their existence but also based on their characteristics in companies. For this purpose, the surveyed potentials must be classified by the expert for each company. To that end, a scale is introduced that classifies the potentials as low (1), medium (2), and high (3). Such a classification allows the correlation of energy management to be quantitatively calculated at the technology level. Furthermore, all 12 cross-cutting technologies can then be correlated with each other, and the effect can be empirically proven.

Further studies should examine the interplay and correlation of the individual efficiency measures in companies to make more targeted statements about the needs of the companies and to create efficient support programs. If the correlations between individual measures can be better evaluated, for example, funding programs can be aligned in such a way that the funds can be used more sustainably. At the same time, companies that have implemented individual measures can see exactly where their next implementation steps lie. This knowledge will help in the training of energy managers and help all the stakeholders involved, such as trade associations, chambers of commerce, energy agencies, engineering companies, and contractors, take more targeted measures. Doing so will help to increase energy efficiency, reduce energy consumption and thus minimize greenhouse gas emissions and climate change.

References

Adams, J. (2007). Research methods for graduate business and social science students (1. publ). Response. https://doi.org/https://doi.org/10.4135/9788132108498

Cagno, E., E., Moschetta, D., & Trianni, A., A. (2019). Only non-energy benefits from the adoption of energy efficiency measures? A novel framework. Journal of Cleaner Production, 212, 1319–1333. https://doi.org/10.1016/j.jclepro.2018.12.049

Deutscher Industrie und Handelskammer (2018). Strompreise drücken auf die Stimmung: Energiewende-Barometer 2018. https://www.dihk.de/resource/blob/12568/912c6ffc0c20b318294acce30e1fc83b/energiewende-barometer-2019-data.pdf. Accessed 4 May 2020.

Empfehlung der Kommission vom 6. Mai 2003 betreffend die Definition der Kleinstunternehmen sowie der kleinen und mittleren Unternehmen, https://op.europa.eu/en/publication-detail/-/publication/6ca8d655-126b-4a42-ada4-e9058fa45155/language-en (2003 & rev. 20.5.2003). https://op.europa.eu/en/publication-detail/-/publication/6ca8d655-126b-4a42-ada4-e9058fa45155/language-en

Fernández-Viñé, M. B., Gómez-Navarro, T., & Capuz-Rizo, S. F. (2010). Eco-efficiency in the SMEs of Venezuela. Current status and future perspectives. Journal of Cleaner Production, 18(8), 736–746. https://doi.org/10.1016/j.jclepro.2009.12.005

Gamst, G. (2019). Die Energiewende beginnt im Gebäude. Wie Unternehmen von grüner Gebäudetechnik profitieren. In A. Hildebrandt & W. Landhäußer (Eds.), Management-Reihe Corporate Social Responsibility. CSR UND ENERGIEWIRTSCHAFT (pp. 119–132). Gabler. https://doi.org/10.1007/978-3-662-59653-1_9

Hertel, M.. (2014). Adoption energieeffizienter Techniken in KMU: Das Management im Fokus einer empirischen Untersuchung. Zugl.: München, Techn. Univ., Diss., 2013. Springer Gabler. http://gbv.eblib.com/patron/FullRecord.aspx?p=1731410https://doi.org/10.1007/978-3-658-05744-2. Accessed 5 May 2020.

Institut für Ressourceneffizienz und Energiestrategien. (2015). Klimaschutz durch Energieeffizienz: Konzept zur Erhöhung der Energieeffizienz, insbesondere durch die Weiterentwicklung der Energiebesteuerung sowie flankierender Maßnahmen. https://irees.de/wp-content/uploads/2020/04/160202_IREES_Endbericht_03KSE029.pdf. Accessed 5 May 2020.

Mai, M., Edelgard Gruber, Natalja Ashley-Belbin, Anna Schulz, Anton Barckhausen, & Gunnar Will & Jan-Erik Thie. (2017). Analysis of the Development of the Market and Goal Achievement Monitoring for Legally Required Energy Audits: Final Report for the Federal Office for Economic Affairs and Export Control (BAFA). Karlsruhe and Berlin. Institut für Ressourceneffizienz und Energiestrategien (IREES) & adelphi consult GmbH. https://irees.de/2020/06/15/analyse-der-entwicklung-des-marktes-und-zielerreichungskontrolle-fuer-gesetzlich-verpflichtende-energieaudits-2017/. Accessed 28 Jan 2023.

Olsthoorn, M., Schleich, J., & Hirzel, S. (2017). Adoption of Energy Efficiency Measures for Non-residential Buildings: Technological and Organizational Heterogeneity in the Trade, Commerce and Services Sector. Ecological Economics, 136, 240–254. https://doi.org/10.1016/j.ecolecon.2017.02.022

Schleich, J. (2009). Barriers to energy efficiency: A comparison across the German commercial and services sector. Ecological Economics, 68(7), 2150–2159. https://doi.org/10.1016/j.ecolecon.2009.02.008

Schmid, C. (2004). Energieeffizienz in Unternehmen: Eine handlungstheoretische und wissensbasierte Analyse von Einflussfaktoren und Instrumenten. Zugl.: Zürich, Diss., Eidgenössische Technische Hochschule ETH Zürich, Nr. 15398, 2004. https://doi.org/10.3929/ethz-a-004691310

Schulze, M., Heidenreich, S., & Spieth, P. (2018). The Impact of Energy Management Control Systems on Energy Efficiency in the German Manufacturing Industry. Journal of Industrial Ecology, 22(4), 813–826. https://doi.org/10.1111/jiec.12625

Schützenhofer, C. (2021). Overcoming the efficiency gap: energy management as a means for overcoming barriers to energy efficiency, empirical support in the case of Austrian large firms. Energy Efficiency, 14(5). https://doi.org/10.1007/s12053-021-09954-z

Stefana, E., Cocca, P., Marciano, F., Rossi, D., & Tomasoni, G. (2019). A Review of Energy and Environmental Management Practices in Cast Iron Foundries to Increase Sustainability. Sustainability, 11(24), 7245. https://doi.org/10.3390/su11247245

Sudhakara Reddy, B. (2013). Barriers and drivers to energy efficiency – A new taxonomical approach. Energy Conversion and Management, 74, 403–416. https://doi.org/10.1016/j.enconman.2013.06.040

Trianni, A., A., Cagno, E., E., Dolšak, J., & Hrovatin, N. (2021). Implementing energy efficiency measures: do other production resources matter? A broad study in Slovenian manufacturing small and medium-sized enterprises. Journal of Cleaner Production, 287, 125044. https://doi.org/10.1016/j.jclepro.2020.125044

Trianni, A., A., Cagno, E., E., & Worrell, E. (2013). Innovation and adoption of energy efficient technologies: An exploratory analysis of Italian primary metal manufacturing SMEs. Energy Policy, 61, 430–440. https://doi.org/10.1016/j.enpol.2013.06.034

Umweltbundesamt (2018). Branchen- und unternehmensgrößenbezogene Ermittlung von Klimaschutzpotenzialen (Schwerpunkt KMU) durch verstärkte Umsetzung von Energiemanagementmaßnahmen in der Wirtschaft: Abschlussbericht. https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2018-07-19_climate-change_21-2018_umsetzung-energiemanagementmassnahmen_0.pdf. Accessed 5 May 2020.

Umwelttechnik BW GmbH. (2021). Regionale Kompetenzstellen Netzwerk Energieeffizienz (KEFF). www.keff-bw.de

Yin, R. K. (2009). Case study research: Design and methods (4. ed.). Applied social research methods series: Vol. 5. SAGE. Accessed 5 May 2020.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Questionnaire on cross-cutting technologies

Company data | Which business sector? (manufacturing or nonmanufacturing) |

How many employees does the company have? (company size, SME or non-SME) | |

What is the company's energy consumption? | |

Is there an energy officer or energy team? | |

Standardized questions on cross-cutting technologies | |

Technologies | Key questions |

Compressed air distribution and compressors | Are compressors switched off outside of operating hours? |

Is a smaller compressor used for the required nighttime demand (if applicable)? | |

Is the compressor idle percentage less than 30% (for peak load compressors)? | |

Is there a superordinate control for several compressors? | |

Are the peak compressors speed controlled (if useful)? | |

Is the pressure level optimized (below 7.5 bar), or is a further pressure reduction not possible? (depending on the required pressure level!) | |

Are there any conspicuous drops in pressure (e.g., after reprocessing)? | |

Is there regular leakage testing and elimination (e.g., monthly, quarterly)? | |

Are leakages audible? (inspection outside of operating hours) | |

Can leakages be detected with a leakage detection device? (inspection also during operating hours) | |

Are unnecessary compressed air power supplies disconnected? (e.g., night, conversion, solenoid valve) | |

Are compressed air accumulators or boosters used? (e.g., before discontinuous consumers) | |

Are consumers supplied with the appropriate pressure level? (not too high, not too low; use of boosters if necessary). | |

Is the compressed air supply for equipment shut off outside of operating hours? | |

Is compressed air used for cooling or cleaning? | |

Lighting technology | Is the window light incidence unobstructed (cleaning)? |

Are areas with sufficient daylight artificially illuminated? | |

Are the lights switched off outside of operating hours and in unoccupied rooms? | |

Are lamp groups divided into zones (circuits with switches), and are areas thus illuminated depending on occupancy and/or daylight? | |

Is a daylight and/or time-dependent lighting control available, and is it used (dimmer or time control)? | |

Is there a presence control (motion detector) in important areas? | |

Are the lights equipped with reflectors? | |

What lighting technology is installed? | |

Do workplaces with high lighting requirements have targeted lighting? | |

Is the lighting system more than 10 years old? | |

Have fluorescent tubes been replaced by T5 fluorescent lamps with electronic ballasts? | |

Are incandescent lamps used only in special cases (only for uses of less than 500 h per year or max. 2 h per day)? | |

Are the exterior lights turned off during the day? | |

Is regular maintenance of equipment (lamp replacement, cleaning) carried out? | |

Building automation/building management system (BMS) | Is a building control system available? |

Is a building automation system installed? | |

Are the possibilities of automation known? | |

Ventilating and air-conditioning systems | Are the switch-on times minimized, i.e., no fan runs without immediate demand? |

Are existing step circuits or speed controls used? (for variable demand: e.g., day, night, load, season) | |

Are there large fans that are constantly throttled? (if information about building services or system diagrams are available) | |

Are there fans that ventilate differently used in (separable) areas? (better: several small fans than one large fan). | |

Are the filters replaced regularly and are the criteria for replacement set correctly? (e.g., differential pressures or time intervals set for this, optimized filter stage). | |

Are there any leaks in the pipe network? (especially inspection doors on the unit itself) | |

Are local exhaust systems switched off during machine stops? | |

Is there a maintenance book or instructions for regular inspection, maintenance and servicing? | |

Are more efficient motors, belts and fans being procured for replacement investments? | |

Are new ventilation ducts primarily round instead of rectangular? | |

Is care taken with new ventilation ducts to ensure that the ducts are installed in such a way that the air flow is favorable? | |

Energy monitoring, peak load management and energy purchasing | How is energy purchased in the company and by whom? |

Does the company have load profile data? (if RLM customer: electricity consumption < 100 MWh/a; gas consumption < 1,000 MWh/a) | |

Are the load profile data evaluated in the company? | |

Do the load profile and peak load management exist? | |

Is there an energy monitoring system, and if so, which one? | |

Heating system, hydraulic balancing and heating distribution | Are the operating times of the boiler minimized? |

Is partial load operation minimized, e.g., by switching off, buffer storage? | |

Is there evidence of significant oversizing? (check switching cycles) | |

Is regular maintenance/servicing of the boiler carried out? (CO2, CO, O2, soot measurement, flue gas loss, burner adjustment, cleaning) | |

Are the flue gas losses optimal? (1-6%, 6-8% unfavorable, from 10% above the limit value, biomass boiler optimal approx. 14%, limit value 19%) | |

Is the boiler more than 15 years old? (then replace the boiler if necessary, incl. checking the necessary boiler size and condensing technology). | |

Does the boiler have modulating control? | |

Is regulation dependent on operating times? (weekend, night setback) | |

Are circulation pumps switched off outside the heating period? | |

Are manually adjustable circulating pumps, if possible, set to the lowest operating level? (old pumps have 3 operating levels; the lowest level reduces consumption by 50% and is often sufficient). | |

Is the pump connected to a heating control system? (if possible, i.e., speed-controlled pumps should be connected to the control system of the heating system; for manually controlled pumps, integration into the heating system must be checked by an expert) | |

Is the thermal insulation of pipes, valves, and fittings in good condition and sufficiently dimensioned? (2/3 of the pipe diameter) | |

Is the thermal insulation of the storage tank and the external heat exchanger in order? | |

Are the hot water tanks switched off outside of operating hours? | |

Is the domestic hot water temperature significantly higher than the hygiene regulations specify? | |

Are unnecessarily long hot water pipes installed? | |

Has hydraulic balancing been carried out on radiator valves? (unscrew the thermostatic head, no balancing has yet been carried out in the full opening). | |

Is room control carried out via room thermostats, and are thermostatic valves present? (e.g., screw valve, handwheel, old/new) | |

Has the room temperature been reduced? (temperature level reduction by 1.5 °C leads to 10% savings) | |

Are only the necessary rooms heated, and is there a targeted temperature control of zones? | |

Electric drives | Are the switch-on times of pumps optimized? (pumps do not run outside of operating hours and only depending on demand). |

Are noisy pumps present? (bearing wear/damage) | |

Are there pumps with high maintenance requirements? | |

Are there pumps with heavily throttled flow? | |

Are pumps with highly fluctuating demand controlled? | |

Are pumps automatically operated at maximum speed? | |

Do pumps supply several consumers with different pressure levels? | |

Are high-efficiency motors used for pumps with a long running time? (energy efficiency class A for glandless motors; Eff1 for standard motors) | |

In case of V-belt drive, is a regular inspection of the belts carried out? (check replacement with highly efficient belts) | |

Is the pipe network regularly maintained? (filter exchange, throttle valves are functional) | |

Are any noticeable pressure losses known? (e.g., through heat exchangers, valves...) | |

Do motors run only during the required time? (e.g., motors are switched off outside of the operating time of the supplied machines and processes) | |

Are motors in use that are operated entirely in the partial load range? | |

Are there any uncontrolled motors whose load curve fluctuates greatly? | |

Are there any hot gears? (bearing wear/defect) | |

Are V-belts replaced regularly? | |

Are bearings worn? | |

Are pulleys correctly aligned? | |

Are high-efficiency motors procured for new and replacement investments? | |

Heat recovery/waste heat utilization | Is there already waste heat or heat recovery in the company? |

Is heat recovery available in the compressed air area? (ideally, the process supplied with it requires heat all year round). | |

Is heat recovery installed in the ventilation system, and is it used? (e.g., for ventilated rooms that are air-conditioned or heated) | |

Is heat recovery also used for hot water preparation? (solar system also possible) | |

Is there a heat recovery system in the refrigeration system that supplies an appropriate consumer? (capacity, running time) | |

Refrigeration | Are passive cooling systems used? |