Abstract

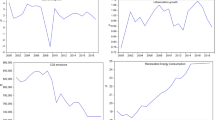

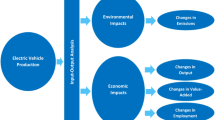

Since the government implemented the supply-side structural reform, the growth of electricity consumption in energy-intensive manufacturing industries has been contained in an all-round way, which poses greater challenges to overcapacity in the power sector. It is still a mystery that how to restrain the electricity consumption of energy-intensive manufacturing industry affects the installed capacity of power generation. Thereupon, this paper empirically studies the relationship between electricity consumption of the six energy-intensive manufacturing subsectors and provincial power generation capacity. The empirical results with line loss rate as instrumental variables indicate that the electricity consumption of the six energy-intensive manufacturing subsectors will increase or decrease the installed capacity of power generation by a one-to-one elastic coefficient. In terms of manufacturing subsectors, the power sector’s own electricity consumption has the highest capacity enhancement effect, followed by non-metallic minerals and chemical raw materials manufacturing subsectors. The resolution of overcapacity for power generation is fundamentally to reduce the electricity consumption intensity of the six high-energy-consuming manufacturing subsectors.

Similar content being viewed by others

Notes

The six energy-intensive manufacturing industries designated in the Statistical Communique of The People’s Republic of China on the 2010 National Economic and Social Development are Manufacture of Raw Chemical Materials and Chemical Products (raw chemical), Manufacture of Non-metallic Mineral Products (non-metallic mineral), Smelting and Pressing of Ferrous Metals (ferrous metals), Smelting and Pressing of Non-ferrous Metals (SPNM), Processing of Petroleum, Coking, Processing of Nuclear Fuel (Petroleum), and Production and Supply of Electricity and Heat (PSEH).

As a consequence of this situation, the average annual operating hours of power plants used to reflect capacity utilization have continued to decline in recent years. According to the China Electricity Council, the average annual operating hours (AAOH) of 6000 KW and above power plants fell to 3862 h in 2018, while the AAOH of thermal power plants was 4361 h, less than the baseline of 5000 h.

References

Alcántara, V., Tarancón, M. A., & del Río, P. (2013). Assessing the technological responsibility of productive structures in electricity consumption. Energy Economics, 40, 457–467. https://doi.org/10.1016/j.eneco.2013.07.012

Angrist, J. D., & Krueger, A. B. (2001). Instrumental variables and the search for identification: From supply and demand to natural experiments. Journal of Economic Perspectives, 15(4), 69–85.

Babanezhad, M. (2009). Measurement error and causal inference with instrumental variables. Ghent University.

Baum, C.F. (2009). Instrumental variables and panel data methods in economics and finance. Boston College and DIW Berlin.

Bound, J., Jaeger, D. A., & Baker, R. M. (1995). Problems with instrumental variables estimation when the correlation between the instruments and the endogenous explanatory variable is weak. Journal of the American Statistical Association, 90, 443–450.

Brandt, L., & Thun, E. (2016). Constructing a ladder for growth: Policy, markets, and industrial upgrading in China. World Development, 80, 78–95.

Cai, Y., & Aoyama, Y. (2018). Fragmented authorities, institutional misalignments, and challenges to renewable energy transition: A case study of wind power curtailment in China. Energy Research & Social Science, 41, 71–79. https://doi.org/10.1016/j.erss.2018.04.021

China Electricity Council (2022). https://cec.org.cn/detail/index.html?3-306014

Choi, J., Gu, J., & Shen, S. (2018). Weak-instrument robust inference for two-sample instrumental variables regression. Journal of Applied Econometrics, 33(1), 109–125. https://doi.org/10.1002/jae.2580

Dachs, B., Kinkel, S., Jäger, A., & Palčič,I .(2019).Backshoring of production activities in European manufacturing. Journal of Purchasing and Supply Management, 25(3). https://doi.org/10.1016/j.pursup.2019.02.003

Dong, K., & Sun, W. (2022). Would the market mechanism cause the formation of overcapacity? Evidence from Chinese listed firms of manufacturing industry. International Review of Economics and Finance, 79, 97–113. https://doi.org/10.1016/j.iref.2022.01.002

Dutta, M., & Mukherjee, S. (2010). An outlook into energy consumption in large scale industries in India: The cases of steel, aluminium and cement. Energy Policy, 38(11), 7286–7298.

Fan, X. C., Wang, W. Q., Shi, R. J., & Li, F. T. (2015). Analysis and countermeasures of wind power curtailment in China. Renewable and Sustainable Energy Reviews, 52, 1429–1436. https://doi.org/10.1016/j.rser.2015.08.025

Feng, Y., Wang, S., Yun, S., Ding, Q., Yuan, J., & Guo, X. (2018). Coal power overcapacity in China: Province-level estimates and policy implications. Resources Conservation & Recycling, 137, 89–100. https://doi.org/10.1016/j.resconrec.2018.05.019

Feng, C., Huang, J. B., & Wang, M. (2019). The sustainability of China’s metal industries: Features, challenges and future focuses. Resources Policy, 60, 215–224. https://doi.org/10.1016/j.resourpol.2018.12.006

Guo, Z. C., & Fu, Z. X. (2010). Current situation of energy consumption and measures taken for energy saving in the iron and steel industry in China. Energy, 35(11), 4356–4360. https://doi.org/10.1016/j.energy.2009.04.008

Hu, Z., Wen, Q., Wang, J., Tan, X., et al. (2010). Integrated resource strategic planning in China. Energy Policy, 38(8), 4635–4642. https://doi.org/10.1016/j.enpol.2010.04.019

Jiang, X., Shen, J. H., Lee, C. C., & Chen, C. (2021). Supply-side structural reform and dynamic capital structure adjustment: Evidence from Chinese-listed firms. Pacific-Basin Finance Journal,65. https://doi.org/10.1016/j.pacfin.2020.101482

Ji, X., Li, G., & Wang, Z. (2017). Allocation of emission permits for China’s power plants: A systemic Pareto optimal method. Applied Energy, 204, 607–619. https://doi.org/10.1016/j.apenergy.2017.07.033

Li, L. (2018). China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0.” Technological Forecasting and Social Change, 135, 66–74. https://doi.org/10.1016/j.techfore.2017.05.028

Li, X. Z., Chen, Z. J., Fan, X. C., & Cheng, Z. J. (2018). Hydropower development situation and prospects in China. Renewable and Sustainable Energy Reviews, 82, 232–239. https://doi.org/10.1016/j.rser.2017.08.090

Lin, B., & Xie, X. (2015). Energy conservation potential in China’s petroleum refining industry: Evidence and policy implications. Energy Conversion and Management, 91, 377–386. https://doi.org/10.1016/j.enconman.2014.11.058

Lin, B., Ankrah, I., & Manu, S. A. (2017). Brazilian energy efficiency and energy substitution: A road to cleaner national energy system. Journal of Cleaner Production, 162, 1275–1284. https://doi.org/10.1016/j.jclepro.2017.06.011

Lin, J., Kahrl, F., & Liu, X. (2018). A regional analysis of excess capacity in China’s power systems. Resources, Conservation and Recycling, 129, 93–101. https://doi.org/10.1016/j.resconrec.2017.10.009

Liu, M., Chen, M., & He, G. (2017). The origin and prospect of billion-ton coal production capacity in China. Resources, Conservation and Recycling, 125, 70–85. https://doi.org/10.1016/j.resconrec.2017.05.015

NBSC.2019. http://www.stats.gov.cn/tjsj/zxfb/201907/t20190701_1673407.html

National Energy Administration (NEA).(2019). Wind power grid-connected operation in 2018. http://www.nea.gov.cn/2019-01/28/c_137780779.htm.

Shen, G., & Chen, B. (2017). Zombie firms and over-capacity in Chinese manufacturing. China Economic Review, 44, 327–342. https://doi.org/10.1016/j.chieco.2017.05.008

Stojčića, N., Aralicab, Z., & Anić,I. D. (2019). Spatio-temporal determinants of the structural and productive transformation of regions in Central and East European countries. Economic Systems,43(3–4). https://doi.org/10.1016/j.ecosys.2019.100715

Szirmai, A., & Verspagen, B. (2015). Manufacturing and economic growth in developing countries, 1950–2005. Structural Change and Economic Dynamic, 34, 46–59. https://doi.org/10.1016/j.strueco.2015.06.002

Wang, Y. H., Luo, G. L., & Guo, Y. W. (2014). Why is there overcapacity in China’s pv industry in its early growth stage? Renewable Energy, 72(dec.), 188–194. https://doi.org/10.1016/j.renene.2014.07.008

Wang, H., Zhang, J., & Fang, H. (2017). Electricity footprint of China’s industrial sectors and its socioeconomic drivers. Resources, Conservation and Recycling, 124, 98–106. https://doi.org/10.1016/j.resconrec.2017.04.011

Wang, D., Wan, K., & Song, X. (2018). Quota allocation of coal overcapacity reduction among provinces in China. Energy Policy, 116, 170–181. https://doi.org/10.1016/j.enpol.2018.02.003

Wang, D., Wang, Y., Song, X., & Liu, Y. (2018). Coal overcapacity in China: Multiscale analysis and prediction. Energy Economics, 70, 244–257. https://doi.org/10.1016/j.eneco.2018.01.004

Wang, Y., Yan, W., & Komonpipat, S. (2019). How does the capacity utilization of thermal power generation affect pollutant emissions? Evidence from the panel data of China’s provinces. Energy Policy, 132, 440–451. https://doi.org/10.1016/j.enpol.2019.06.010

Wang, Y., Yan, W., Zhuang, S., & Zhang, Q. (2019). Competition or complementarity? The hydropower and thermal power nexus in China. Renewable Energy, 138, 531–541. https://doi.org/10.1016/j.renene.2019.01.130

Wen, Z., Wang, Y., Li, H., Yuan Tao, Y., & De Clercq, D. (2019). Quantitative analysis of the precise energy conservation and emission reduction path in China’s iron and steel industry. Journal of Environmental Management, 246, 717–749. https://doi.org/10.1016/j.jenvman.2019.06.024

Woo, W.T. (2019). China’s soft budget constraint on demand-side undermines its supply-side structural reforms. China Economic Review, 57.https://doi.org/10.1016/j.chieco.2017.09.010

Wooldridge, J. M. (2010). Econometric analysis of cross section and panel data (2nd ed.). The MIT Press.

Xie, J., Liang, Z., Zhang, X., & Zhu, L. (2019). Efficiency evaluation of thermal power plants in China based on the weighted Russell directional distance method. Journal of Cleaner Production, 222, 573–583. https://doi.org/10.1016/j.jclepro.2019.03.078

Xiong, T., Jiang, W., & Gao, W. (2016). Current status and prediction of major atmospheric emissions from coal-fired power plants in Shandong province, China. Atmospheric Environment, 124, 46–52. https://doi.org/10.1016/j.atmosenv.2015.11.002

Xu, Y., Hu, J., Ying, Q., Hao, H., Wang, D., & Zhang, H. (2017). Current and future emissions of primary pollutants from coal-fired power plants in Shaanxi, China. Science of the Total Environment, 595, 505–514. https://doi.org/10.1016/j.scitotenv.2017.03.267

Yang, Q., Hou, X., & Zhang, L. (2018). Measurement of natural and cyclical excess capacity in China’s coal industry. Energy Policy, 118, 270–278. https://doi.org/10.1016/j.enpol.2018.03.052

Yang, G., Fukuyama, H., & Song, Y. (2019). Estimating capacity utilization of Chinese manufacturing industries. Socio-Economic Planning Sciences, 67, 94–110. https://doi.org/10.1016/j.seps.2018.10.004

Yu, M., Zhao, X., & Gao, Y. (2019). Factor decomposition of China’s industrial electricity consumption using structural decomposition analysis. Structural Change and Economic Dynamics, 51, 67–76. https://doi.org/10.1016/j.strueco.2019.08.002

Yu, S., Lu, T., Hu, X., Liu, L., & Wei, Y. (2020). Determinants of overcapacity in China’s renewable energy industry: Evidence from wind, photovoltaic, and biomass energy enterprises. Energy Economics, 97.https://doi.org/10.1016/j.eneco.2020.105056

Yuan, J., Li, P., Wang, Y., Liu, Q., Shen, X., Zhang, K., & Dong, L. (2016). Coal power overcapacity and investment bubble in China during 2015–2020. Energy Policy, 97, 136–144. https://doi.org/10.1016/j.enpol.2016.07.009

Yuan, J., Lei, Q., Xiong, M., Guo, J., & Hu, Z. (2016). The prospective of coal power in China: Will it reach a plateau in the coming decade? Energy Policy, 98, 495–504. https://doi.org/10.1016/j.enpol.2016.09.025

Zeng, M., Zhang, P., Yu, S., & Liu, H. (2017). Overall review of the overcapacity situation of China’s thermal power industry: Status quo, policy analysis and suggestions. Renewable and Sustainable Energy Reviews, 76, 768–774. https://doi.org/10.1016/j.rser.2017.03.084

Zhang, H., Zheng, Y., Ozturk, U. A., & Li, S. (2016). The impact of subsidies on overcapacity: A comparison of wind and solar energy companies in China. Energy, 94, 821–827. https://doi.org/10.1016/j.energy.2015.11.054

Zhang, Y., Nie, R., Shi, R., & Zhang, M. (2018). Measuring the capacity utilization of the coal sector and its decoupling with economic growth in China’s supply-side reform. Resources, Conservation and Recycling, 129, 314–325. https://doi.org/10.1016/j.resconrec.2016.09.022

Zhang, W., Jiang,Y., Yuan,L., Yu, J.(2015). http://www.stats.gov.cn/tjzs/tjsj/tjcb/dysj/201507/t20150703_1205391.html

Zhao, X. G., Wan, G., & Yang, Y. (2015). The turning point of solar photovoltaic industry in China: Will it come? Renewable and Sustainable Energy Reviews, 41, 178–188. https://doi.org/10.1016/j.rser.2014.08.045

Zhao, C., Zhang, W., Wang, Y., Liu, Q., Guo, J., Xiong, M., et al. (2017). The economics of coal power generation in China. Energy Policy, 105, 1–9. https://doi.org/10.1016/j.enpol.2017.02.020

Zivot, E., Startz, R., & Nelson, C. R. (2004). Improved inference in weakly identified instrumental variables regression.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Zhang, Q. How does electricity consumption of energy-intensive manufacturing affect the installed capacity of power generation? Empirical evidence under the background of China’s supply-side structural reform. Energy Efficiency 15, 44 (2022). https://doi.org/10.1007/s12053-022-10043-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12053-022-10043-y