Abstract

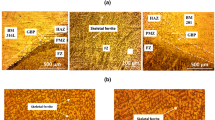

Stainless steels have been increasingly used for agricultural and food processing, biogas, architecture, automotive, machine-manufacturing, biomedicine, chemical, and petrochemical industry due to their corrosion resistance and sanitary qualities. Dissimilar stainless steels may need to be utilized together in various fields due to their different properties. Therefore, it is important to weld dissimilar stainless steel, which are employed in these fields, with strong mechanical properties. However, the requirement to join many metals, each of which has different properties, on the same construction may result in the emergence of some problems. The properties of the weld zone as well as the quality of the welded joints depend on the selection of the optimal welding parameters and the kind of shielding gas. Therefore, estimating the quality and service life of dissimilar stainless steel joints requires to understand the weld zone’s properties better. Therefore, it is important to investigate the effect of shielding gases and gas combinations on the welding of dissimilar stainless steels in the welding process. In this study, AISI 316 austenitic stainless steel and AISI 430 ferritic stainless steel were joined utilizing the metal inert gas (MIG) welding with different shielding gas combinations. In welding processes, 100% Ar, 97% Ar+3% H2, and 93% Ar+7% H2 gas combinations were used. The welded sheets were subjected to hardness, tensile, and bending tests in addition to metallographic testing. The effects of the shielding gas combinations on the mechanical and microstructural properties of AISI 316 austenitic and AISI 430 ferritic stainless steel connections were investigated through these tests.

Similar content being viewed by others

References

Zaffora A, Di Franco F and Santamaria M 2021 Corrosion of stainless steel in food and pharmaceutical industry. Current Opinion in Electrochemistry 29: 100760

Santamaria M, Tranchida G and Di Franco F 2020 Corrosion resistance of passive films on different stainless steel grades in food and beverage industry. Corrosion Science 173: 108778

Ettefagh A H, Guo S and Raush J 2021 Corrosion performance of additively manufactured stainless steel parts: A review. Additive Manufacturing 37: 101689

Tchoumi T, Peyraut F and Bolot R 2016 Influence of the welding speed on the distortion of thin stainless steel plates—Numerical and experimental investigations in the framework of the food industry machines. Journal of Materials Processing Technology 229: 216–229

Labiapari W S, Alcântara C M, Costa H L and de Mello J D B 2013 Stainless steel as an antiwear material for the bio-fuel industry. Wear 302: 1536–1545

Katsigiannis A S, Bayliss D L and Walsh J L 2021 Cold plasma decontamination of stainless steel food processing surfaces assessed using an industrial disinfection protocol. Food Control 121: 107543

Singh S S R, Praneeth R V, Sankalp V S, Sashank S S and Karthikeyan R 2022 Welding, mechanical properties and microstructure of different grades of austenitic stainless steels: A review. Materials Today: Proceedings 62: 3675–3680

Singh B, Reddy D, Chowdary S, Sashank S S and Karthikeyan R 2022 Dissimilar joining of different grades of ferritic stainless steel: A review. Materials Today: Proceedings 62: 4386–4391

Durgutlu A, Fındık T, Gülenç B, Cevik B, Kaya Y and Kahraman N 2015 Effect of continuous and pulsed currents on microstructural evolution of stainless steel joined by TIG welding. Practical Metallography 52: 627–637

Açar İ and Gülenç B 2021 Effect of shielding gas combination on microstructure and mechanical properties of MIG welded stainless steel 316. Materials Testing 63: 97–101

Kožuh S, Gojic M, Vrsalovic L and Ivkovic B 2013 Corrosion failure and microstructure analysis of AISI 316L SS for shio pipeline before and after welding. Kovove Materialy 51: 53–61

Fujita N, Ohmura K and Yamamoto A 2003 Changes of microstructures and high temperature properties during high temperature service of Niobium added ferritic stainless steels. Materials Science and Engineering: A 351: 272–281

Khattak M A, Zaman S, Tamin M N, Badshah S, Mushtaq S and Omran A A B 2017 Effect of welding phenomenon on the microstructure and mechanical properties of ferritic stainless steel-A review. Journal of Advanced Research in Materials Science 32: 13–31

Okayasu M and Ishida D 2019 Effect of microstructural characteristics on mechanical properties of austenitic, ferritic, and γ-α duplex stainless steels. Metallurgical and Materials Transactions A 50: 1380–1388

Taban E, Deleu E, Dhooge A and Kaluc E 2007 Gas metal arc welding of modified X2CrNi12 ferritic stainless steel. Kovove Materialy 45: 67–74

Rajput S K, Kumar A, Tripathi S S and Sachan E 2020 Investigation of microstructural behavior and mechanical properties of dissimilar weld joints of austenitic-ferritic stainless steel. Materials Today: Proceedings 25: 778–784

Çevik B 2018 Effect of welding processes on mechanical and microstructural properties of S275 structural steel joints. Materials Testing 60: 863–868

Çevik B and Koç M 2019 The effects of welding speed on the microstructure and mechanical properties of marine-grade aluminium (AA5754) alloy joined using MIG welding. Kovove Materialy 57: 307–316

Cevik B 2017 Investigation of mechanical and microstructure properties of S275 structural steel joined by using different flux cored wire. Journal of Polytechnic 20: 675–680

Cevik B 2018 Analysis of welding groove configurations on strength of S275 structural steel welded by FCAW. Journal of Polytechnic 21: 489–495

Cevik B 2018 The effect of pure argon and mixed gases on microstructural and mechanical properties of S275 structural steel joined by flux-cored arc welding. Kovove Materialy 56: 81–87

García-García V 2022 Microstructural and mechanical analysis of double pass dissimilar welds of twinning induced plasticity steel to austenitic/duplex stainless steels. International Journal of Pressure Vessels and Piping 198: 104665

Maurya A K, Pandey C and Chhibber R 2021 Dissimilar welding of duplex stainless steel with Ni alloys: A review. International Journal of Pressure Vessels and Piping 192: 104439

Dak G and Pandey C 2021 Experimental investigation on microstructure, mechanical properties, and residual stresses of dissimilar welded joint of martensitic P92 and AISI 304L austenitic stainless steel. International Journal of Pressure Vessels and Piping 194: 104536

Ramakrishnan A, Rameshkumar T, Rajamurugan G, Sundarraju G and Selvamuthukumaran D 2021 Experimental investigation on mechanical properties of TIG welded dissimilar AISI 304 and AISI 316 stainless steel using 308 filler rod. Materials Today: Proceedings 45: 8207–8211

Chuaiphan W and Srijaroenpramong L 2019 Optimization of gas tungsten arc welding parameters for the dissimilar welding between AISI 304 and AISI 201 stainless steels. Defence Technology 15: 170–178

Ghosh N, Pal P K and Nandi G 2017 GMAW dissimilar welding of AISI 409 ferritic stainless steel to AISI 316L austenitic stainless steel by using AISI 308 filler wire. Engineering Science and Technology, an International Journal 20: 1334–1341

Karthi S, Babu S K, Shanmugham S and Balaji V P 2020 Study on the dissimilar joining of martensitic stainless steel and carbon steel using TIG welding. In: Advances in Additive Manufacturing and Joining Springer, Singapore, pp 545–554

Bermejo M V, Karlsson L, Svensson L E, Hurtig K, Rasmuson H, Frodigh M and Bengtsson P 2015 Effect of shielding gas on welding performance and properties of duplex and superduplex stainless steel welds. Welding in the World 59: 239–249

Filho D F, Ferraresi V A and Scotti A 2010 Shielding gas influence on the ferritic stainless steel weldability. Journal of Engineering Manufacture Part B 224: 951–961

Açar İ, Cevik B and Gülenç B 2022 Analysis of mechanical and microstructural characteristics of AISI 430 stainless steel welded by GMAW. Kovove Materialy 60: 21–30

Zhang X Y, Zha X Q, Gao L Q, Hei P H and Ren Y F 2021 Influence of Shielding Gas on Microstructure and Properties of GMAW DSS2205 Welded Joints. Materials 14: 2671

Plaut R L, Herrera C, Escriba D M, Rios P R and Padilha A F 2007 A short review on wrought austenitic stainless steels at high temperatures: processing, microstructure, properties and performance. Materials Research 10: 453–460

Kah P and Martikainen J 2013 Influence of shielding gases in the welding of metals. The International Journal of Advanced Manufacturing Technology 64: 1411–1421

Sato T 2001 Influence of shielding gases on quality and efficiency in gas shielded arc welding. Welding International 15: 616–619

Gülenç B, Develi K, Kahraman N and Durgutlu A 2005 Experimental study of the effect of hydrogen in argon as a shielding gas in MIG welding of austenitic stainless steel. International Journal of Hydrogen Energy 30: 1475–1481

Katherasan D, Sathiya P and Raja A 2013 Shielding gas effects on flux cored arc welding of AISI 316L (N) austenitic stainless steel joints. Materials and Design 45: 43–51

Anand N R, Chavan V M and Sawant N K 2013 The effect of shielding gases on mechanical properties and microstructure of austenitic stainless steel weldments. International Journal Engineering and Robotics Research 2: 253–262

Acknowledgements

The authors would like to thank the Gazi University, Technology Faculty, Department of Metallurgical and Materials Engineering Laboratory for their valuable help.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Açar, I., Çevik, B. & Gülenç, B. Weldability of dissimilar stainless steels by MIG welding with different gas combinations. Sādhanā 48, 69 (2023). https://doi.org/10.1007/s12046-023-02129-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-023-02129-9