Abstract

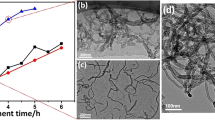

In the present study, carbon nanotube reinforced copper nanocomposites were fabricated using the powder metallurgy technique which includes ball milling and hot pressing. The carbon nanotube weight percentage in the nanocomposite was varied from 0.25 to 1.50% in the steps of 0.25%. Further, to improve the interfacial bonding between the carbon nanotubes and copper matrix, the carbon nanotubes were coated with silver using the electroless deposition method. The sintered and hot pressed copper nanocomposites with uncoated and silver-coated carbon nanotubes were subjected to optical and scanning electron microscope studies to understand the dispersion of nanotubes. The density, microhardness and electrical conductivity of developed nanocomposites were studied. The dispersion of nanotubes was found to be uniform throughout the copper matrix resulting in the improvement in microhardness. Especially when compared with sintered samples, the hot-pressed nanocomposites with silver-coated carbon nanotubes showed significant improvement in microhardness however beyond 0.75% content the microhardness for samples was found to drop. The electrical conductivity of nanocomposites was found to decrease with the increase in the MWCNT content which was attributed to the clustering of MWCNTs due to strong van der Waal forces and the increase in the number of interfaces between MWCNTs and copper matrix.

Similar content being viewed by others

References

Koppad P G, Ram H R A, Ramesh C S, Kashyap K T and Koppad R G 2013 On thermal and electrical properties of multiwalled carbon nanotubes/copper matrix nanocomposites. J. Alloys Compd. 580: 527–532

Varol T and Canakci A 2015 Microstructure, electrical conductivity and hardness of multilayer graphene/copper nanocomposites synthesized by flake powder metallurgy. Met. Mater. Inter. 21: 704–712

Han X, Huang Y, Wang J, Zhang S, Ding Z and Li T 2021 Fabrication of graphite films/copper composites by vacuum hot pressing for high-efficiency thermal management property. Compos. Commun. 24: 100665

Yu M, Files B S, Arepalli S and Ruoff R S 2000 Tensile Loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys. Rev. Lett. 84: 5552–5555

Wong E W, Sheehan P E and Lieber C M 1997 Nanobeam mechanics: Elasticity, strength, and toughness of nanorods and nanotubes. Science 277: 1971–1975

Ebbesen T W, Lezec H J, Hiura H, Bennett J W, Ghaemi H F and Thio T 1996 Electrical conductivity of individual carbon nanotubes. Nature 382: 54–56

Miyoshia K, Street K W Jr, Wal R L V, Andrews R and Sayir A 2005 Solid lubrication by multiwalled carbon nanotubes in air and in vacuum. Tribol. Lett. 19: 191–201

Izmailov V V, Drozdova E I, Chernogorova O P, Potapova I N, Novoselova M V and Ekimov E A 2015 Electrical contact properties of a composite material with a copper matrix reinforced by superelastic hard carbon. Russ. Metall. 2015: 376–380

Rajkumar K and Aravindan S 2011 Tribological studies on microwave sintered copper-carbon nanotube composites. Wear 270: 613–621

Nayan N, Shukla A K, Chandran P, Bakshi S R, Murthy S V S N, Pant B and Venkitakrishnan P V 2017 Processing and characterization of spark plasma sintered copper/carbon nanotube composites. Mater. Sci. Eng. A 682: 229–237

Babu R V and Kanagaraj S 2019 Sintering behaviour of copper/carbon nanotube composites and their characterization. Adv. Powder Technol. 30: 2200–2210

Koppad P G, Kashyap K T, Shrathinth V, Shetty T A and Koppad R G 2013 Microstructure and microhardness of carbon nanotube reinforced copper nanocomposites. Mater. Sci. Technol. 29: 605–609

Zheng Z, Liu J, Tao J, Li J, Zhang W, Li X and Xue H 2021 Effect of electroless coatings on the mechanical properties and wear behavior of oriented multiwall carbon nanotube-reinforced copper matrix composites. Nanomaterials 11: 2982

Zhao S, Zheng Z, Huang Z, Dong S, Luo P, Zhang Z and Wang Y 2016 Cu matrix composites reinforced with aligned carbon nanotubes: mechanical, electrical and thermal properties. Mater. Sci. Eng. A 675: 82–91

Junhui N, Chengchang J, Xian J, Yafeng Z, Na S and Yi L 2011 Fabrication, microstructures, and properties of copper matrix composites reinforced by molybdenum-coated carbon nanotubes. Rare Met. 30: 401–407

Shakibhamedan S, Sheibani S and Ataie A 2021 High performance Cu matrix nanocomposite fabricated through spark plasma sintering of Cu and Cu-coated CNT. Met. Mater. Inter. 27: 4271–4285

Lee D, Sim J, Kim W, Moon C, Cho W and Baik S 2015 Enhanced electrical conductivity and hardness of silver-nickel composites by silver-coated multi-walled carbon nanotubes. Nanotechnology 26: 295705

Nayan N, Murty S V S N, Sharma S C, Sreekumar K and Sinha P P 2012 Electroless coating of silver on multiwall carbon nanotubes. Mater. Sci. Forum 710: 774–779

Karthik L, Kumar G, Kirthi A V, Rahuman A A and Rao K V B 2014 Streptomyces sp. LK3 mediated synthesis of silver nanoparticles and its biomedical application. Bioprocess Biosyst. Eng. 37: 261–267

Choi J, Rhee K and Park S 2015 Influence of electrolessly silver-plated multi-walled carbon nanotubes on thermal conductivity of epoxy matrix nanocomposites. Compos. B. Eng. 80: 379–384

Burke J E 1957 Role of grain boundaries in sintering. J. Am. Ceram. Soc. 40: 80–85

Bembalge O B and Panigrahi S K 2019 Thermal stability, grain growth kinetics, and mechanical properties of bulk ultrafine-grained AA6063/SiC composites with varying reinforcement sizes. Metall. Mater. Trans. A 50: 4288–4306

Munoz A, Savoini B, Monge M A, Ortega Y and Dura O J 2021 Fabrication and characterization of Cu reinforced with Y-enriched particles following a novel powder metallurgy route. Nucl. Mater. Energy 29: 101075

Choi H J, Shin J H and Bae D H 2011 Grain size effect on the strengthening behavior of aluminum-based composites containing multi-walled carbon nanotubes. Compos. Sci. Technol. 71: 1699–1705

Chang S and Chang T 2007 Grain size effect on nanomechanical properties and deformation behavior of copper under nanoindentation test. J. Appl. Phys. 101: 033507

Mendoza M E, Campos A P, Xing Y, Belle D C and Solorzano I G 2020 Significant decrease of electrical resistivity by carbon nanotube networks in copper-MWCNTs nanocomposites: a detailed microstructure study. Diam. Relat. Mater. 110: 108083

Akbarpour M R, Alipour S, Farvizi M and Kim H S 2019 Mechanical, tribological and electrical properties of Cu-CNT composites fabricated by flake powder metallurgy method. Arch. Civ. Mech. Eng. 19: 694–706

Zuo T et al. 2020 Enhanced electrical conductivity and hardness of copper/carbon nanotubes composite by tuning the interface structure. Mater. Lett. 280: 128564

Lu L, Shen Y, Chen X, Qian L and Lu K 2004 Ultrahigh strength and high electrical conductivity in copper. Science 304: 422–426

Daoush W M, Lim B K, Mo C B, Nam D H and Hong S H 2009 Electrical and mechanical properties of carbon nanotube reinforced copper nanocomposites fabricated by electroless deposition process. Mater. Sci. Eng. A 513–514: 247–253

Uddin S M et al. 2010 Effect of size and shape of metal particles to improve hardness and electrical properties of carbon nanotube reinforced copper and copper alloy composites. Compos. Sci. Technol. 70: 2253–2257

Babu R V and Kanagaraj S 2018 Thermal, electrical and mechanical characterization of microwave sintered copper/carbon nanotubes (CNT) composites against sintering duration, CNT diameter and its concentration. J. Mater. Proc. Technol. 258: 296–309

Chapman D 2015 Copper in electrical contacts, Copper Development Association Publication No 223, Hemel Hempstead, UK

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koti, V., Mahesh, Murthy, K.V.S. et al. Hardness and electrical conductivity of uncoated and silver coated carbon nanotubes reinforced copper nanocomposites. Sādhanā 47, 179 (2022). https://doi.org/10.1007/s12046-022-01949-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-022-01949-5