Abstract

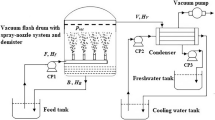

The paper presents the heat and mass transfer characteristics during spray drying of a saline solution using a full cone pressure-swirl nozzle of 0.2 mm diameter. The phase change behaviors are studied numerically using a 2D axisymmetric model and experimentally validated in a tailor-made apparatus. The operating conditions are chosen such that the magnitude of Weber and Ohnesorge numbers of spray liquid ensures the spray pattern is under atomization regime. The numerical model is validated experimentally using a commercially available saline solution with a concentration of 0.9% weight per volume at 1 g/s. The system uses air as a carrier gas with an inlet temperature and axial velocity maintained at 340°C and 1.2 m/s, respectively. Water-sensitive paper is used to validate droplet diameters for the said operating condition. The model is further extended to different operating conditions and saline mass fractions between 0.1 and 0.3. Based on the results, the particle heat and mass transfer characteristics are discussed.

Similar content being viewed by others

Abbreviations

- Q :

-

Heat flow, W

- Q eva :

-

Heat transferred to evaporate the water, W

- Q heat :

-

Heat transferred to heat the dried particle, W

- W :

-

Mass of evaporated water, kg/h

- Cp v :

-

Specific heat of water vapor, kJ/kg. K

- Cp w :

-

Specific heat of water, kJ/kg. K

- Ta in :

-

Inlet air temperature, °C

- Ta out :

-

Outlet air temperature, °C

- T fin :

-

Inlet precursor Temperature, °C

- mt p :

-

Total Mass flow rate of dried particle at outlet, kg/h

- Cp p :

-

Specific heat of dried particle, kJ/kg. K

- T p :

-

Temperature of particles at outlet of chamber, °C

- m f :

-

Mass flow rate of precursor, kg/h

- ΔT log :

-

Logarithmic mean temperature difference, K

- V :

-

Volume of the spray chamber, m3

- A d :

-

Particle surface area, m2

- c p :

-

Specific heat of continuous phase, J/kg K

- c pd :

-

Droplet specific heat, J/kg K

- D ab :

-

Diffusion coefficient, m2/s

- D :

-

Diameter of the particle, m

- d p :

-

Diameter of the particle, m

- E :

-

Total Energy, J

- F D :

-

Drag force per unit mass of the particle, N

- F r :

-

Surface and body force in the radial direction, N

- F x :

-

Surface and body force in the axial direction, N

- h :

-

Convective heat transfer coefficient, W/m2 K

- h :

-

Species Enthalpy, J/kg

- h fg :

-

Latent heat of vaporization of the droplet particle, J/kg

- h m :

-

Mass transfer coefficient, m/s

- J :

-

Mass flux, kg m2/s

- k g :

-

Thermal conductivity of the continuous phase, W/m K

- m p :

-

Droplet mass, kg

- Nu :

-

Nusselt number

- Oh :

-

Ohnesorge Number of the droplet

- P :

-

Pressure, N/m2, Pa

- Pr :

-

Prandtl Number

- R :

-

Radial position, m

- Re r :

-

Relative Reynolds Number

- Re d :

-

Droplet Reynolds number

- S :

-

Total Entropy, J/K

- Sh :

-

Sherwood number

- S mass :

-

Source term for mass added to the continuous phase from the discrete phase

- T :

-

Temperature of the continuous phase, K

- T p :

-

Droplet temperature, K

- u :

-

Axial velocity m/s

- u c :

-

Velocity of the continuous gas phase, m/s

- u d :

-

Velocity of the droplet in the discrete phase, m/s

- u r :

-

Radial Velocity m/s

- Pe:

-

Peclet Number

- t:

-

Time, s

- We :

-

Weber Number of the droplet

- ρ c :

-

Density of continuous phase, kg/m3

- ρ d :

-

Density of droplet in the discrete phase, kg/m3

- β:

-

Evaporation constant, m2/s

- ϑc :

-

Kinematic viscosity of continuous phase, m2/s

- ωA ,∞ :

-

Moisture content of the ambient, %

- ωA ,s :

-

Moisture content at the droplet surface, %

- ω 1 :

-

Moisture content of the precursor on wet basis, %

- ω 2 :

-

Moisture content of the particle at outlet on wet basis, %

- λ :

-

Enthalpy of evaporation of water at 0°C, kJ/kg

References

Cheng W L, Han F Y, Liu Q N, Zhao R and Fan H L 2011 Experimental and theoretical investigation of surface temperature non-uniformity of spray cooling. Energy. 36(1): 249–257

Kansy J, Kalmbach T, Loges A, Wetzel T and Wiebelt A 2021 Experimental investigation of the influences of fluid properties on heat transfer for spray cooling. J. Enhanc. Heat Transf. 28(5): 61–76

Nayak S K and Mishra P C 2019 Enhanced heat transfer from hot surface by nanofluid based ultrafast cooling: an experimental investigation. J. Enhanc. Heat Transf. 26(4): 415–428

Xu S, Zhong S, Pang K M, Yu S, Jangi M and Bai X S 2020 Effects of ambient methanol on pollutants formation in dual-fuel spray combustion at varying ambient temperatures: A large-eddy simulation. Appl. Energy. 279: 115774

Vehring R 2008 Pharmaceutical particle engineering via spray drying. Pharm. Res. 25(5): 999–1022

Benavides-Moran A, Cubillos A and Gomez A 2021 Spray drying experiments and CFD simulation of guava juice formulation. Dry. Technol. 39(4): 450–465

Medeiros A, Santos A, de Souza F, Junior I, Valdilanio J, Procopio J, de Santana D and Macedo R 2007 Thermal studies of pre-formulates of metronidazole obtained by spray drying technique. J. Therm. Anal. Calorim. 89(3): 775–781

Medeiros A F, Santos A F O, De Souza F S, Procopio J V V, Pinto M F and Macedo R O 2007 Thermal stability of paracetamol and its pre-formulates obtained by spray drying. J. Therm. Anal. Calorim. 88(2): 377–382

Dhakar B, Chatterjee S and Sabiruddin K 2017 Linear reciprocating wear behaviour of plasma-sprayed Al2O3–Cr2O3 coatings at different loading and sliding conditions. Sadhana 42(10): 1763–1772

Vertruyen B, Eshraghi N, Piffet C, Bodart J, Mahmoud A and Boschini F 2018 Spray-drying of electrode materials for lithium-and sodium-ion batteries. Materials. 11(7): 1076

Rajasekar K and Raja B 2021 Investigation on heat and mass transfer in spray drying process. J. Eng. Thermophys. 30(3): 433–448

Dolatabadi J E N, Valizadeh H and Hamishehkar H 2015 Solid lipid nanoparticles as efficient drug and gene delivery systems: recent breakthroughs. Adv. Pharm. Bull. 5(2): 151

Eslamian M and Ashgriz N 2006 Effect of precursor, ambient pressure, and temperature on the morphology, crystallinity, and decomposition of powders prepared by spray pyrolysis and drying. Powder Technol. 167(3): 149–159

Nijdam J J and Langrish T A G 2005 An investigation of milk powders produced by a laboratory-scale spray dryer. Dry. Technol. 23(5): 1043–1056

Maruyama Y and Hasegawa K 2020 Evaporation and drying kinetics of water-NaCl droplets via acoustic levitation. RSC Adv. 10(4): 1870–1877

Quilaqueo M and Aguilera J M 2016 Crystallization of NaCl by fast evaporation of water in droplets of NaCl solutions. Food Res. Int. 84: 143–149

Wu Z and Liu X 2002 Simulation of spray drying of a solution atomized in a pulsating flow. Dry. Technol. 20(6): 1101–1121

Olufemi B A, Popoola G O, Towobola O R and Awosanya O G 2021 Operational characterization of a spray dryer for drying water, caustic soda and sodium chloride solutions. ARPN J. Eng. Appl. Sci. 7(2): 222–228

Zbicinski I 1995 Development and experimental verification of momentum, heat and mass transfer model in spray drying. Chem. Eng. J. Biochem. Eng. J. 58(2): 123–133

Crowe C, Sommerfeld M, Tsuji Y and Crowe C 1998 Multiphase flows with droplets and particles. 2nd edn. CRC Press, Florida

Mezhericher M, Levy A and Borde I 2015 Multi-scale multiphase modeling of transport phenomena in spray-drying processes. Dry. Technol. 33(1): 2–23

Spalding D B 1954 The calculation of mass transfer rates in absorption, vaporization, condensation and combustion processes. Proc. Inst. Mech. Eng. 168(1): 545–570

Williams A 1973 Combustion of droplets of liquid fuels: a review. Combust. Flame. 21(1): 1–31

Ranz W 1952 Evaporation from drops 1. Chem. Eng. Prog. 48(3): 141–146

Huang D 2011 Modeling of particle formation during spray drying. Eur. Dry. Conf. - EuroDrying’2011. 26-28

Papadakis S E 1987 Air temperatures and humidities in spray drying. PhD Thesis. University of California, Berkeley, USA

Holman J P 2012 Experimental methods for engineers. 8th edn. McGraw- Hill, New York

Ohnesorge W V 1936 Die bildung von tropfen an düsen und die auflösung flüssiger strahlen. ZAMM J. Appl. Math. Mech. 16(6): 355–358

Reitz R D 1978 Atomization and Other Breakup Regimes of a Liquid Jet, PhD thesis. AMS Department, Princeton University, New Jersey

Nguyen D Q, Nguyen T H and Allaf K 2020 Volumetric heat transfer coefficient in spray drying of soymilk powder. Dry. Technol. 1-7

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajasekar, K., Raja, B. An investigation on heat and mass transfer characteristics during spray drying of saline water. Sādhanā 47, 90 (2022). https://doi.org/10.1007/s12046-022-01863-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-022-01863-w