Abstract

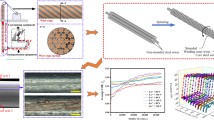

In this study, the mechanical behaviors of point contact wire rope (PCWR) and line contact wire rope (LCWR) were compared based on the finite element method. The three-dimensional models of PCWR and LCWR with the same diameter were established. Furthermore, the stress, deformation and contact slip characteristics of the two cases were analyzed with the aid of ABAQUS CAE software. The following findings were concluded. Stress is highly concentrated in PCWR, and its overall stress is higher than that of LCWR. In addition, for both PCWR and LCWR, the highest maximum principal stress occurs at the core wire in the independent wire strand, indicating that the independent wire strand is more likely to break and fail due to overload. The results obtained based on Costello’s theory and the finite element analysis are in good agreement. Meanwhile, for PCWR, the torsion at the loading end is smaller and the axial strain is larger under the identical axial stress; for both PCWR and LCWR, the steel wires at the contact positions of adjacent spiral strands are deformed most seriously. With the increase of axial stress, the contact stress between steel wires increases linearly, and the overall contact stress and the relative slip values of steel wires between spiral strands in PCWR are greater than those in LCWR.

Similar content being viewed by others

References

Wang X, Meng X, Wang J, Sun Y and Gao K 2015 Mathematical modeling and geometric analysis for wire rope strands. Applied Mathematical Modelling 39: 1019–1032

Argatov I I, Gomez X, Tato W and Urchegui M A 2011 Wear evolution in a stranded rope under cyclic bending: Implications to fatigue life estimation. Wear 271: 2857–2867

Zhang J, Wang D, Song D, Zhang D, Zhang C, Wan D and Araujo J A 2019 Tribo-fatigue behaviors of steel wire rope under bending fatigue with the variable tension. Wear 428: 154–161

Hu S, Qi C, Zhao S, Peng J and Lin L 2010 Discussion on China deep mine classification and critical depth. Coal Science and Technology 38: 10–13

Costello G A 1992 Theory of wire rope. Journal of Applied Mechanics 59: 469

Cardou A and Jolicoeur C 1997 Mechanical models of helical strands. Applied Mechanics Reviews 50: 1–14

Velinsky S A 1985 General nonlinear theory for complex wire ropes. International Journal of Mechanical Sciences 27: 497–507

Wang D, Zhang D and Ge S 2014 Effect of terminal mass on fretting and fatigue parameters of a hoisting rope during a lifting cycle in coal mine. Engineering Failure Analysis 36: 407–422

Cao X and Wu W 2018 The establishment of a mechanics model of multi-strand wire rope subjected to bending load with finite element simulation and experimental verification. International Journal of Mechanical Sciences 142: 289–303

Wang D, Zhang D, Wang S and Ge S 2013 Finite element analysis of hoisting rope and fretting wear evolution and fatigue life estimation of steel wires. Engineering Failure Analysis 27: 173–193

Zhang J, Wang D, Zhang D, Ge S and Araujo J A 2018 Dynamic contact and slip characteristics of bent hoisting rope in coal mine. Journal of the Brazilian Society of Mechanical Sciences and Engineering 40: 120

Nawrocki A and Labrosse M 2000 A finite element model for simple straight wire rope strands. Computers and Structures 77: 345–359

Kastratovic G, Vidanovic N, Bakic V and Rasuo B 2014 On finite element analysis of sling wire rope subjected to axial loading. Ocean Engineering 88: 480–487

Kastratovic G and Vidanovic N 2015 3D finite element modeling of sling wire rope in lifting and transport processes. Transport 30: 1–6

Ma J, Ge S and Zhang D 2008 Distribution of wire deformation within strands of wire ropes. Journal of China University of Mining and Technology 18: 475–478

Chen Z, Guo L, Liu H and Chen H 2021 Finite element study of behaviour and interface force conditions of locked coil wire rope under axial loading. Construction and Building Materials 272: 121961

Zhang W, Yuan X, Chen C and Yang L 2021 Finite element analysis of steel wire ropes considering creep and analysis of influencing factors of creep. Engineering Structures 229: 111665

Jiang W, Warby M K and Henshall J L 2008 Statically indeterminate contacts in axially loaded wire strand. European Journal of Mechanics A/Solids 27: 69–78

Jiang W 2012 A concise finite element model for pure bending analysis of simple wire strand. International Journal of Mechanical Sciences 54: 69–73

Erdonmez C and Imrak C E 2011 A finite element model for independent wire rope core with double helical geometry subjected to axial loads. Sadhana 36: 995–1008

Wang D, Zhang J, Ge S, Zhang D and Shi G 2019 Mechanical behavior of hoisting rope in 2km ultra deep coal mine. Engineering Failure Analysis 106: 104185–104185

Cruzado A, Hartelt M, Wäsche R, Urchegui M A and Gomez X 2010 Fretting wear of thin steel wires. Part 1: influence of contact pressure. Wear 268: 1409–1416

Kim H S and Mall S 2005 Investigation into three-dimensional effects of finite contact width on fretting fatigue. Finite Elements in Analysis and Design 41: 1140–1159

Acknowledgements

The research reported in this paper was supported by the Major Scientific and Technological Innovation Projects in Shandong Province (2019JZZY020505). We thank anonymous reviewers for their comments and suggestions to improve the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, Z., Wang, E., Jia, F. et al. Comparison between mechanical behaviors of wire ropes with distinct contact modes based on the finite element method. Sādhanā 47, 64 (2022). https://doi.org/10.1007/s12046-022-01851-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-022-01851-0