Abstract

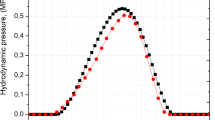

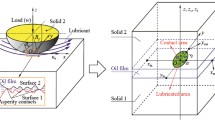

In this article, a Jacobian-free Newton Multigrid (JFNMG) method is used for obtaining the solution of isothermal, steady and compressible elastohydrodynamic lubrication (EHL) line contact problem with surface roughness. The lubricant is a couple stress fluid. A finite difference scheme is used for the solution of EHL equations. The proposed JFNMG method, for the solution of resulting nonlinear system of algebraic equations, comprises nonlinear Newton iterations on the outer loop and linear multigrid iterations on the inner loop. It overcomes the limitations of conventional schemes for the investigation of the problems covering wide range of physical parameters of interest. For increasing values of couple stress parameter, there is an increase in minimum film thickness and considerable decrease (in height as well as spread) of pressure spike. Also, the sensitivity of height and spread of pressure spike as a function of load, couple stress parameter and other parameters are investigated.

Similar content being viewed by others

Abbreviations

- \( a \) :

-

Amplitude of roughness \( \left( {\upmu{\text{m}}} \right) \)

- \( \overline{a} \) :

-

Dimensionless amplitude of roughness, \( \overline{a} = {{aR} \mathord{\left/ {\vphantom {{aR} {b^{2} }}} \right. \kern-0pt} {b^{2} }} \)

- A:

-

Normalized surface roughness amplitude, \( A = {{\overline{a} } \mathord{\left/ {\vphantom {{\overline{a} } {H_{\hbox{min} }^{DH} }}} \right. \kern-0pt} {H_{\hbox{min} }^{DH} }} \)

- \( b \) :

-

Half width of the Hertzian contact, \( b = 4R\sqrt {W/2\pi } \)

- \( E^{^{\prime}} \) :

-

Effective elastic modulus of rollers 1 and 2 (Pa)

- \( G \) :

-

Dimensionless materials parameter, \( \alpha E^{\prime} \)

- \( h \) :

-

Film thickness (m)

- \( H \) :

-

Dimensionless film thickness, \( H = hR/b^{2} \)

- \( h_{0} \) :

-

Offset film thickness (m)

- \( H_{0} \) :

-

Dimensionless constant/offset film thickness \( H_{0} = h_{0} R/b^{2} \)

- \( K_{ij} \) :

-

Discrete approximation of \( K \) logarithmic kernel Eq. (4.3)

- \( l \) :

-

Dimensionless wavelength of roughness, \( l = {\lambda \mathord{\left/ {\vphantom {\lambda b}} \right. \kern-0pt} b} \)

- \( L_{m} \) :

-

Dimensionless couple stress parameter, \( L_{m} = {{\lambda_{a} } \mathord{\left/ {\vphantom {{\lambda_{a} } R}} \right. \kern-0pt} R} \)

- \( N \) :

-

Number of nodes on grid

- \( p \) :

-

Pressure (pa)

- \( P_{h} \) :

-

Maximum Hertzian press \( P_{h} = (2w)/(\pi b) \)

- \( P \) :

-

Dimensionless pressure, \( P = p/P_{h} \)

- \( P_{0} \) :

-

Ambient pressure

- \( R \) :

-

Equivalent radius of contact

- \( u \) :

-

Velocity component

- \( u_{1} ,u_{2} \) :

-

Velocities of lower and upper surfaces respectively (m/s)

- \( u_{s} \) :

-

Sum velocity, \( u_{s} = \left( {u_{1} + u_{2} } \right)/2 \)

- \( U \) :

-

Dimensionless speed parameter, \( U = (\eta_{0} u_{s} )/(E^{\prime}R) \)

- \( \upsilon \) :

-

Surface displacement (m)

- \( \mathop \upsilon \limits^{ - } \) :

-

Dimensionless displacement, \( \mathop \upsilon \limits^{ - } = {{\upsilon R} \mathord{\left/ {\vphantom {{\upsilon R} {b^{2} }}} \right. \kern-0pt} {b^{2} }} \)

- \( w \) :

-

External load per unit width

- \( W \) :

-

Dimensionless load parameter, \( W = w/(E^{\prime}R) \)

- \( \Delta X \) :

-

Mesh size

- \( x \) :

-

Abscissa coordinate

- \( X \) :

-

Dimensionless coordinate \( x/b \)

- \( \left[ {X_{1} ,\;X_{2} } \right] \) :

-

Domain of interest \( \left[ { - 2,\;1.5} \right] \)

- \( X_{c} \) :

-

Dimensionless location of pressure spike

- \( z \) :

-

Pressure viscosity parameter

- \( \alpha \) :

-

Pressure viscosity index

- \( \eta \) :

-

Fluid viscosity

- \( \eta_{0} \) :

-

Viscosity at ambient pressure

- \( \bar{\eta } \) :

-

Dimensionless viscosity, \( \eta /\eta_{0} \)

- \( \lambda \) :

-

Surface roughness wavelength \( \left( {\upmu{\text{m}}} \right) \)

- \( \lambda_{a} \) :

-

Molecular length of additives (m)

- \( \xi \) :

-

Viscosity modification factor

- \( \rho \) :

-

Lubricant density at local pressure

- \( \rho_{0} \) :

-

Inlet density of the lubricant

- \( \bar{\rho } \) :

-

Dimensionless fluid density, \( \rho /\rho_{0} \)

References

Dowson D and Higginson G R 1977 Elasto-hydrodynamic lubrication, Second Edition. Oxford: Pergamon Press, pp 1–19

Hamrock B J and Dowson D 1976 Isothermal lastohydrodynamic lubrication of point contacts part I, J. Lub. Tech. Trans. ASME 98: 223–229

Hamrock B J and Dowson D 1981 Ball bearing lubrication. New York: Wiley

Hamrock B J and Jacobson B O 1984 Elastohydrodynamic lubrication of line contacts. ASLE Trans. 27(4): 275–287

Chittenden R J, Dowson D, Dunn J F and Taylor C M 1985 A theoretical analysis of the isothermal elastohydrodynamic lubrication of concentrated contacts I: direction of lubrication entrainment with the major axis of the horizontal contact elliptic. Proc. R. Soc. Lond. A 397: 245–269

Chittenden R J, Dowson D, Dunn J F and Taylor C M 1985 A theoretical analysis of the isothermal elastohydrodynamic lubrication of concentrated contacts II: general case with lubricant entrainment along either principal axis of the Hertizan contact ellipse or at some intermediate angle. Proc. R. Soc. Lond. A 397: 271–294

Okamura H 1982 Contribution to the numerical analysis of elastohydrodynamic lubrication. In: Proceedings of the Leeds-Lyon Symposium on Tribiology, pp 313–320

Petrusevich A I 1951 Fundamental conclusions from the contact hydrodynamic theory of lubrication. Izv. Akad, Nauk SSR (OTN) 3: 209–223

Kostreva M M 1984 Pressure spike and stability considerations in elastohydrodynamic lubrication models. Trans. ASME J. Tribol. 106: 386–395

Kostreva M M 1984 Elasto-hydrodynamic lubrication: a nonlinear complementary problems. Int. J. Num. Methods Fluid 4: 377–397

Habachi W and Issa J 2013, Fast and reduced full system finite element solution of elastohydrodynamic lubrication problem: line contact. Adv. Eng. Softw. 56: 5–62

Lubrecht A A 1987 Numerical solution of EHL line and point contact problems using multigrid techniques. Ph.D., Thesis, University of Twente, Enschede, The Netherlands

Brandt, A and Lubrecht, A A 1990 Multi-level matrix multiplication and fast solutions of integral equations. J. Comput. Phys. 90(2): 348–370

Venner, C H and Lubrecht A A 2000 Multilevel methods in lubrication. London: Elsevier, pp 57–100

Nurgat E, Berzins and Scales L E 1999 Solving EHL problems using iterative methods and homotopy methods. Trans. ASME J. Tribol. 12(1): 28–34

Briggs W L, Henson V E and McCormick S F 2000 A multigrid tutorial, 2nd Edition. Philadelphia: SIAM, pp 105–106

Houpert L G, Ioannides E, Kuypers J C and Tripp J 1987 The effect of the EHD pressure spike on rolling bearing fatigue. ASME J. Tribol. 109: 444–450

Hamrock, B J, Pan P and Lee R T 1988 Pressure spike in EHL lubricated conjunctions. ASME J. Tribol. 110: 279–284

Bissett E J and Glander D W 1988 A highly accurate approach that resolves the pressure spike of EHL. Trans. ASME J. Tribol. 110: 241–246

Venner C H and Napel W E T 1989 Numerical calculations of the pressure spike in EHL. Lub. Sci. 2: 321–334

Schlijper A G, ScalesL E and Rycroft J E 1996 Current tools and techniques in EHL modeling, Tribol. Int. 29: 669–673

Lugt P M and Morales-Espejel G E 2011 A review of elasto-hydrodynamic lubrication theory. Tribol. Trans. 54: 470–496

Bujurke N M, Kantli M H and Bharati M Shettar 2017 Wavelet preconditioned Newton–Krylov method for elastohydrodynamic lubrication of line contact problems. Appl. Math. Model. 46: 285–298

Kantli M H, Bharati M Shettar and Bujurke N M 2017 Jacobian-free Newton-GMRES method for analysing combined effects of surface roughness and couple stress character of lubricant on EHL line contact. Proc. Indian Nat. Sci. Acad. 83(1): 175–196

Oliver D R and Shahidullah M 1983 Load enhancement effects by polymer-thickened oils in short squeeze film flow. J. Non-Newton Fluid Mech. 3: 93–102

Oliver D R 1988 Load enhancement effects due to polymer thickening in a short model journal bearings, J. non-Newtonian Fluid Mech. 30: 185–196

Spikes H A 1994 The behavior of lubricants current understanding and future possibilities. Proc. Inst. Mech. Eng. 28: 3–15

Scott W and Sunniwattann P 1995 Effects of additives on performance of wet friction clutch materials. Wear 183: 850–855

Guangteng G, Smeeth M, Cann P M and Spikes H A 1996 Measurement and modeling of boundary film properties of polymeric lubricant additives. In: Proceedings of the Institution of Mechanical Engineers, Part J. The Journal of Engineering Tribology, pp 210–215

Guangteng G and Spikes H A 1996 Fractionation of liquid lubricants at solid surfaces. Wear 200: 336–345

Stokes V K 1966 Couple tresses in fluids. Phys. Fluids 9: 1709–1715

Chippa S P and Sarangi M 2013 Elastohydrodynamically lubricated finite line contact with couple stress fluids Tribol. Int. 67: 11–20

Das N C 1997 Elastohydrodynamic lubrication theory of line contacts couple stress fluid model, Tribol. Trans. 40: 353–359

Sarangi M, Majumdar B C and Sarkar A 2009 Elasthydrodynamically lubricated ball bearings in couple stress fluid, Part-I. Steady state analysis. Tribol. Trans. 48: 404–414

Saini P K, Kumar P and Tandon P 2007 Thermal elasthydrodynamic lubrication characteristics of couple stress fluids in rolling/sliding line contact. Proc. Inst. Mech. Eng. Part J, J. Eng. Tribol. 221: 141–153

Saini P K, Kumar P and Tandon P 2008 Surface roughness effects in elastohydrodynamic lubrication line contact using couple stress fluid. Proc. Inst. Mech. Eng. Part J 222: 151–15

Chu L M, Li W L, Lin J R and Chang R P 2010 Coupled effects of surface roughness and flow rheology on elastohydrodynamic lubrication. Tribol. Int. 43: 483–490

Patir N and Cheng, H S 1978 An average flow model for determine effects of three Ddmensional roughness on partial hydrodynamic lubrication. ASME J. Lub. Technol. 100: 12–17

Christensen H 1970 Stochastic models for hydrodynamic lubrication of rough surfaces. Proc. Inst. Mech. Eng. 1969–70 184 (Part 1, 55): 1013–1026

Shi F and Wang Q 1998A mixed-TEHD model for journal bearing conformal contacts, part I: models formulation and approximation of heat transfer considering asperity contacts. ASME J. Tribol. 120: 198–205

Tripp J H and Hamrock B J 1985 Surface roughness effects in elastohydrodynamic contacts. In: Proceedings of the 1984 Leeds-Lyon Symposium on Tribology, pp 30–39

Kumar P and Kumar N 2014 Surface roughness effects in ure sliding EHL line contact with carreau-type sheer thinning lubricant. Int. J. Mech. Aerosp. Industrial Mech. Eng. 8(6): 1087–1092. World Academy of Sciences, Engineering Technology

Ioannides E and Harris T A 1985 A new fatigue life made for rolling bearing. ASME J. Tribol. 107: 367–378

Xu G and Sadeghi F 1996 Thermal EHL analysis of circular contacts with measured surface roughness. ASME J. Tribol. 118: 473–482

Zhu D and Hu YZ 2001 A computer program package for the prediction of EHL and mixed lubrication characteristics, friction, subsurface stresses and flash temperatures based on measured 3-D surface roughness. Tribol. Trans. 44: 383–390

Wang W Z, Liu Y C, Hu Y Z, Wang H and Zhu D 2003 A comparative study of the methods for calculation of surface elastic deformation. Proc. Inst. Mech. Eng. Contacts Part J, J. Eng. Tribol. 217(J2): 145–153

Kelley C T 1999 Iterative methods for solving linear and nonlinear equations Philadelphia: Society for Industrial and Applied Mathematics (SIAM), pp 135–144

Knoll D A and Keyes D E 2004 Jacobian free Newton–Krylov methods: a survey of approaches and applications. J. Comput. Phys. 193: 357–397

Roelands C J A 1996 Correlational aspects of the viscosity-temperature-pressure relationship of lubricating oils. PhD Thesis, Technische Hogeschool Delft, V.R.B., Groningen, The Netherlands

Zargari E A, JimackP K and Walkley M A 2007 An investigation of the film thickness calculation for elastohydrodynamic lubrication problems. Int. J. Numer. Math. Fluids 00: 1–6

Durbin T and Delemos D 2007 Adaptive under-relaxation of picard iterations in ground water models. Ground Water 45(5): 648–651

Acknowledgements

Authors thank the Department of Science and Technology (SR/S4/MS: 771/12) and Indian National Science Academy (SP/HIS/2012/425), New Delhi, India for the financial support. Also, thank the reviewers for their useful suggestions and comments on the earlier draft of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shettar, B.M., Hiremath, P.S. & Bujurke, N.M. A novel numerical scheme for the analysis of effects of surface roughness on EHL line contact with couple stress fluid as lubricant. Sādhanā 43, 122 (2018). https://doi.org/10.1007/s12046-018-0906-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-018-0906-y