Abstract

The aim of this paper is to describe the performance of reinforced concrete (RC) beams retrofitted with a self-compacting ultra-high-performance fibre-reinforced concrete (UHPFRC) under three-point bend cyclic loading. It is found that retrofitting the RC beams with a thin UHPFRC strip on the tension face increases their endurance limit under a non-zero mean stress cyclic loading from approximately 40% to approximately 60% of their static three-point flexural strength. Moreover, the retrofitted beams behave as a composite structure, with no delamination of the retrofit strip being observed in any of the fatigue tests.

Similar content being viewed by others

References

RILEM 1984 Long term random dynamic loading of concrete structures. Mater. Struct. 17: 1–27

Derkowski W and Zych T 2004 Modern composite materials for strengthening of building structures (in Polish). Czasopismo Tech. 14-B: 15–25

Jones R, Swamy R N and Charif A 1988 Plate separation and anchorage of reinforced concrete beams strengthened by epoxy-bonded steel plates. Struct. Eng. 66(5): 85–94

Nanni A 1995 Concrete repair with externally bonded FRP reinforcement: examples from Japan. Concr. Int. 97: 22–26

Sen R, Mullins G, Shahawy M and Spain J 2000 Durability of CFRP–epoxy–concrete bond. Composites in the transportation industry. In: Proceedings of the ACUN-2 International Composite Conference, University of South Wales, Sydney, Australia, pp. 259–265

Heffernan P J and Erki M A 2004 Fatigue behavior of reinforced concrete beams strengthened with carbon fiber reinforced plastic laminates. J. Compos. Constr. 8(2): 132–140, https://doi.org/10.1061/(asce)1090-0268

El-Saikaly G, Chaallal O and Godat A 2014 Fatigue behaviour of RC beams retrofitted in shear with externally bonded CFRP sheets. In: Proceedings of the 7th International Conference on FRP Composites in Civil Engineering, CICE, Vancouver, Canada

Buyukozturk O and Hearing B 1998 Failure behavior of precracked concrete beams retrofitted with FRP. J. Compos. Constr. 2(3): 138–144, https://doi.org/10.1061/(asce)1090-0268

Bakis C E, Bank L C, Brown V L, Cosenza E, Davalos J F, Lesko J J, Machida A, Rizkalla S H and Triantaillou T C 2002 Fiber-reinforced polymer composites for construction state-of-the-art review. J. Compos. Constr. 6(2): 73–78, https://doi.org/10.1061/(ASCE)1090-0268

Karbhari V M 1998 Material and design considerations in FRP rehabilitation of concrete structures. In: Proceedings of FRAMCOS-3. Freiburg, Germany: AEDIFICATIO Publishers, pp. 1805–1816

Zhen M and Chung D D L 2000 Effects of temperature and stress on the interface between concrete and its fibre–matrix composite retrofit, studies by electrical resistance measurement. Cem. Concr. Res. 30: 799–802

Sharmila S and Thirugnanam G S 2013 Behavior of reinforced concrete flexural member with hybrid fibre under cyclic loading. Int. J. Sci. Environ. Technol. 2(4): 725–734

Khan M I, Abbas Y M and Fares G 2017 Review of high and ultrahigh performance cementitious composites incorporating various combinations of fibres and ultrafines. J. King Saud. Univ. – Eng. Sci., https://doi.org/10.1016/j.jksues.2017.03.006

Makita T and Brühwiler E 2014 Tensile fatigue behaviour of ultra-high performance fibre reinforced concrete combined with steel rebars (R-UHPFRC). Int. J. Fatig. 59: 145–152

Li X, Wang J, Bao Y and Chen G 2017 Cyclic behavior of damaged reinforced concrete columns repaired with high-performance fiber-reinforced cementitious composite. Eng. Struct. 136: 26–35

Benson S D P and Karihaloo B L 2005 CARDIFRC – development and mechanical properties. Part 1: development and workability. Mag. Concr. Res. 57(6): 347–352

Benson S D P and Karihaloo B L 2005 CARDIRFC – development and mechanical properties. Part III: uniaxial tensile response and other mechanical properties. Mag. Concr. Res. 57(8): 433–443

Benson S D P, Nicolaides D and Karihaloo B L 2005 CARDIFRC – development and mechanical properties. Part II: fibre distribution. Mag. Concr. Res. 57(7): 412–432

Karihaloo B L, Alaee F J and Benson S D P 2002 A new technique for retrofitting damaged concrete structures. Proc. Inst. Civ. Eng. – Struct. Build. 152(4): 309–318

Karihaloo B L, Benson S D P, Didiuk P M, Fraser S A, Hamill N and Jenkins T A 2000 Retrofitting damaged RC beams with high-performance fibre-reinforced concrete. In: Proceedings of the 10th Annual BCA, British Cement Association, Birmingham University, pp. 153–164

Alaee F J and Karihaloo B L 2003 Fracture model for flexural failure of beams retrofitted with CARDIFRC. J. Eng. Mech. 129(9): 1028–1038, https://doi.org/10.1061/(ASCE)0733-9399

Alaee F J and Karihaloo B L 2003 Retrofitting of reinforced concrete beams with CARDIFRC. J. Compos. Constr. 7(3), 174–186, https://doi.org/10.1061/(ASCE)1090-0268

Farhat F A, Nicolaides D, Kanellopoulos A and Karihaloo B L 2007 High performance fibre-reinforced cementitious composite (CARDIFRC) – performance and application to retrofitting. Eng. Fract. Mech. 74: 151–167

Farhat F A, Nicolaides D, Kanellopoulos A and Karihaloo B L 2010 Behavior of RC beams retrofitted with CARDIFRC after thermal cycling. J. Mater. Civ. Eng. 22(1): 21–28, https://doi.org/10.1061/(ASCE)1943-5533.0000008

Al-Azzawi B S and Karihaloo B L 2017 Mechanical and fracture properties of a self-compacting version of CARDIFRC Mix II. Sadhana 42(5): 795–803, https://doi.org/10.1007/s12046-017-0641-9

Al-Azzawi B S and Karihaloo B L 2017 Flexural fatigue behaviour of a self-compacting ultra-high performance fiber-reinforced concrete. ASCE J. Mater. Civ. Eng. 29(11): 04017210, https://doi.org/10.1061/(asce)mt.1943-5533.0002051

Farshid J A 2002 Retrofitting of concrete structures using high performance fibre reinforced cementitious composite (HPFRCC). PhD Thesis, Cardiff University, UK

ACI 215R-74 1992 Considerations for design of concrete structures subjected to fatigue loading. ACI Committee Report, American Concrete Institute

Halgason T and Hanson J M 1974 Investigation of design factors affecting fatigue strength of reinforcing bars—statistical analysis. In: Proceedings of the Abeles Symposium on Fatigue of Concrete, SP-41, ACI Detroit, pp. 107–138

Papakonstantinou C G, Petrou M F and Kent A H 2001 Fatigue behavior of RC beams strengthened with GFRP sheets. J. Compos. Constr. 5(4): 246–253, https://doi.org/10.1061/(asce)1090-0268/01/0004-0246-02535

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

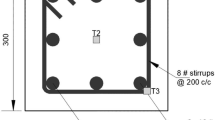

Applying the traditional transformed area methodology to the retrofitted RC beam subjected to the three-point bend cyclic load range 1.5–35 kN, it is found that the neutral axis lies at 91.3 mm from the extreme compression fibre and the second moment of area of the cross section is 56.08×106 mm4. Accordingly, at the lower load limit of 1.5 kN, the stresses in concrete extreme fibre, steel reinforcing bar and the extreme fibre of the retrofitting UHPFRC strip are 0.61, 1.47 and 0.75 MPa, respectively.

Assuming that the UHPFRC strip had reached its tensile strength of 12.02 MPa (Al-Azzawi and Karihaloo [25]) but not cracked at the upper load limit of 35 kN, the corresponding stresses in concrete would be 14.25 MPa and in the steel bar, 203.1 MPa. The cyclic stress range in the steel bar would be 201.63 MPa at a stress ratio of 1.47/203.1 = 0.0072. This cyclic stress range is very close to the allowable limit in the supplier’s data sheet (cyclic stress range 200 MPa and a stress ratio of 0.2 for a fatigue life in excess of five million cycles).

However, as noted in the text a major flexural crack formed in the UHPFRC strip in this cyclic load range after approximately 5000 cycles. The reduced tension carrying capacity of the UHPFRC strip can be estimated from its known stress–crack opening relation (Al-Azzawi and Karihaloo [25]), figure 19). At a crack opening of, say, 1 mm, the tensile strength of UHPFRC reduces from 12.02 to 9.86 MPa, so that its contribution to the tensile capacity of the retrofitted beam reduces from 42.07 to 34.5 kN and that of the reinforcing steel must increase to 30.53 kN, from 22.97 kN (figure 20). As a result the stress in steel increases to 269.93 MPa. The cyclic stress range in the steel bar is 268.46 MPa at a stress ratio of 1.47/269.93 = 0.0054, which is well in excess of the supplier’s recommended stress range of 200 MPa for this steel.

Rights and permissions

About this article

Cite this article

Al-Azzawi, B.S., Karihaloo, B.L. Application of a self-compacting ultra-high-performance fibre-reinforced concrete to retrofit RC beams subjected to repeated loading. Sādhanā 43, 145 (2018). https://doi.org/10.1007/s12046-018-0876-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-018-0876-0