Abstract

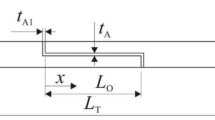

The effect of adherend recessing on the strength of full (spew)-fillet-formed bi-adhesively bonded single-lap joint (SLJ) was investigated using the finite-element (FE) method under pure tension (i.e., 20 dissimilar recess length and depth and two-type bi-adhesive bond). A three-dimensional (3D) FE model was developed for bi-adhesively bonded SLJ, which had fillet and recessed adherend, assuming that both adhesive and adherend have geometrical non-linearity and exhibit linear material behaviour. The novelty of present study is the application of recessing process on the fillet-formed bi-adhesively bonded SLJs. The bondline characteristics of bi-adhesively bonded joints with the effect of adherend recessing have been investigated by examining the distributions of the peel and maximum principle stresses (MPS) at the mid-plane of the bondline. The results from the FE simulations in which varying geometric parameters are used reveal that the combined effects of adherend recessing spew fillet and bi-adhesive bondline led to a major decrease in the peak values of the peel stress, which is the governing failure stress and MPS. A novel design that may be beneficial to improve the strength characteristics of aluminium SLJ is presented.

Similar content being viewed by others

References

Ouinas D 2012 Strength of aluminium single-lap bonded joints in various disbond size at circular and semi-circular notches. J. Sandwich Struct. Mater. 14(6): 753–768

Doru M O, Özel A, Akpinar S and Aydin M D 2013 Effect of the spew fillet on adhesively bonded single-lap joint subjected to tensile loading: experimental and 3-D non-linear stress analysis. J. Adhes. 90(3): 195–209

Zehsaz M, Vakili-Tahami F and Saeimi-Sadigh M A 2014 Creep analysis of adhesively bonded single lap joint using finite element method. J. Mech. Sci. Technol. 28(7): 2743–2748

Brockmann W, Geiß P, Klingen J, Schröder B and Mikhail B 2009 Adhesive bonding. Weinheim: Wiley–VHC

He X 2011 A review of finite element analysis of adhesively bonded joints. Int. J. Adhes. Adhes. 31(4): 248–264

Nemes O and Lachaud F 2009 Modeling of cylindrical adhesively bonded joints. J. Adhes. Sci. Technol. 23(10–11): 1383–1393

Her S C 1999 Stress analysis of adhesively-bonded lap joints. Compos. Struct. 47(1): 673–678

Gleich D, Van Tooren M and Beukers A 2001 Analysis and evaluation of bondline thickness effects on failure load in adhesively bonded structures. Int. J. Adhes. Adhes. 15(9): 1091–1101

Lang T and Mallick P 1998 Effect of spew geometry on stresses in single lap adhesive joints. Int. J. Adhes. Adhes. 18(3): 167–177

Tsai M and Morton J 1995 The effect of a spew fillet on adhesive stress distributions in laminated composite single-lap joints. Compos. Struct. 32(1): 123–131

Akpinar S, Doru M O, Özel A, Aydin M D and Jahanpasand H G 2013 The effect of the spew fillet on an adhesively bonded single-lap joint subjected to bending moment. Composites B: Eng. 55: 55–64

Belingardi G, Goglio L and Tarditi A 2002 Investigating the effect of spew and chamfer size on the stresses in metal/plastics adhesive joints. Int. J. Adhes. Adhes. 22(4): 273–282

You M, Zheng Y, Zheng X L and Liu W J 2003 Effect of metal as part of fillet on the tensile shear strength of adhesively bonded single lap joints. Int. J. Adhes. Adhes. 23(5): 365–369

Fessel G, Broughton J, Fellows N, Durodola J and Hutchinson A 2007 Evaluation of different lap-shear joint geometries for automotive applications. Int. J. Adhes. Adhes. 27(7): 574–583

Pires I, Quintino L and Miranda R 2006 Numerical simulation of mono-and bi-adhesive aluminium lap joints. J. Adhes. Sci. Technol. 20(1): 19–36

Sato C and Ikegami K 2000 Dynamic deformation of lap joints and scarf joints under impact loads. Int. J. Adhes. Adhes. 20(1): 17–25

Fitton M and Broughton J 2005 Variable modulus adhesives: an approach to optimised joint performance. Int. J. Adhes. Adhes. 25(4): 329–336

Adin H and Temiz Ş 2014 Experimental and numerical strength analysis of double lap joints subjected to tensile loads. Mater. Test. 56(2): 160–168

Aydin M D, Özel A and Temiz Ş 2004 Non-linear stress and failure analyses of adhesively-bonded joints subjected to a bending moment. J. Adhes. Sci. Technol. 18(14): 1589–1602

Tang J H, Sridhar I and Srikanth N 2013 Static and fatigue failure analysis of adhesively bonded thick composite single lap joints. Compos. Sci. Technol. 86: 18–25

Ozel A, Yazici B, Akpinar S, Aydin M D and Temiz Ş 2014 A study on the strength of adhesively bonded joints with different adherends. Composites B: Eng. 62: 167–174

Akpinar S, Temiz Ş, Aydin M D and Özel A 2012 Effect of protrusion at the ends of bondline in single lap joints under tension and bending. J. Adhes. Sci. Technol. 26(23): 2591–2602

Apalak Z G, Apalak M K and Davies R 1996 Analysis and design of adhesively bonded tee joints with a single support plus angled reinforcement. J. Adhes. Sci. Technol. 10(8): 681–724

Gültekin K, Akpinar S and Özel A 2015 The effect of moment and flexural rigidity of adherend on the strength of adhesively bonded single lap joints. J. Adhes. 91(8): 637–650

İşcan B 2015 Strength of lap joints with embedded cover plate. J. Mech. Sci. Technol. 29(5): 2105–2110

Solmaz M Y and Topkaya T 2013 Progressive failure analysis in adhesively, riveted, and hybrid bonded double-lap joints. J. Adhes. 89(11): 822–836

Pinto A M G, Ribeiro N F Q R, Campilho R D S G and Mendes I R 2014 Effect of adherend recessing on the tensile strength of single lap joints. J. Adhes. 90(8): 649–666

Afkar A and Camari M N 2014 Finite element analysis of mono- and bi-adhesively bonded functionally graded adherend. J. Fail. Anal. Prev. 14(2): 253–258

Özer H and Öz Ö 2014 A comparative evaluation of numerical and analytical solutions to the biadhesive single-lap joint. Math. Probl. Eng. 2014: 1–16

Kumar S and Pandey P C 2010 Behaviour of bi-adhesive joints. J. Adhes. Sci. Technol. 24(7): 1251–1281

Luo Q and Tong L 2015 Solutions for clamped adhesively bonded single lap joint with movement of support end and its application to a carbon nanotube junction in tension. J. Adhes. 92(5): 349–379

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Çalik, A., Yildirim, S. Effect of adherend recessing on bi-adhesively bonded single-lap joints with spew fillet. Sādhanā 42, 317–325 (2017). https://doi.org/10.1007/s12046-017-0603-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-017-0603-2