Abstract

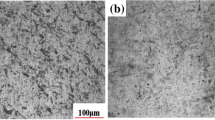

In this paper, an effective procedure of response surface methodology (RSM) has been utilized for finding the optimal values of process parameters while induction hardening of AISI 1040 under two different conditions of the material i.e., rolled and normalized. Various process parameters, such as feed rate (speed at which the induction coil moves, which is measured in mm/sec), current, dwell time (time after which heat intensity starts to heat work piece in seconds) and gap between the work piece and induction coil have been explored by experiments. Hardness at two different conditions has been considered as performance characteristic. The experiment plan was based on rotatable, central composite design (CCD). The experimental results showed that the proposed mathematical models suggested could describe the performance indicators within the limits of the factors being investigated. The obtained optimal process parameters have been predicted and verified by confirmation experiments. Microstructure and SEM (scanning electron microscope) analyses were also done for justification of the work.

Similar content being viewed by others

References

Bodart O, Bourean A V, Touzani R 2001 Numerical investigation of optimal control of induction heating process, Applied Mathematical Model, 25: 697–712

Cochran W G, Cox G M 1992 Experimental designs, 2nd ed., New York: Wiley, 335–339

Ge Y, Hu R, Zhang Z 2006 Optimization control of induction hardening process; qingtong shen mechatronics and automation, Proceedings of IEEE International Conference on Mechatronics and Automation, Luoyang; China, 1126–1130

Grum J, Slab J M 2004 The use of factorial design and response surface methodology for fast determination of optimal heat treatment conditions for different Ni–Co–Mo surface layers, J. Materials Processing Technol. 155–156: 2026–2032

Kansal H K, Singh S, Kumar P 2005 Parametric optimization of powder mixed electrical discharge machining by response surface methodology, J. Materials Processing Technol., 169(3): 427–436

Kayacan M C 1991 Design and construction of a Set-up for induction hardening, M Sc thesis, University of Gaziantep

Kayacan M C 2004 A fuzzy approach for induction hardening parameter selection, J. Materials and Design, 25(2): 155–161

Lai J, Ovize P, Kuijpers H, Bacchettto A, Ioannides S 2009 Case-depth and static capacity of surface induction-hardened rings, J. ASTM International 6(10): 1–16

Miller D A and Lagoudas D C 1980 Trends in the development of heat-treatment technology, J. Metal Science and Heat Treatment 22(11): 846–850

Oberg E, Green R E 1996 Machinery’s handbook, 25th ed., New York: Industrial Press

Oktem H, Erzumlu T, Kurtaran H 2005 Application of response surface methodology in the optimization of cutting conditions of surface roughness, J. Materials Processing Technol., 170(1–2): 11–16

Ozcelik B, Erzurmlu T 2005 Determination of effecting dimensional parameters on warpage of thin shell plastic parts using integrated response surface method and genetic algorithm, Int. Communication of Heat and Mass Transfer, 32(8): 1085–1094

Stich T J, Spoerre J K, Velasco T 2000 The application of artificial neural networks to monitoring and control of an induction hardening process, J. Industrial Technol., 16(1): 1–11

Tartaglia J M, Eldis G T 1984 Core hardenability calculations for carburizing steels. Metallurgical Transactions A, 15A(6): 1173–1183

Totik Y, Sadeler R, Altun H, Gavgali M 2003 The effects of induction hardening on wear properties of AISI 4140 steel in dry sliding conditions, Materials and Design, 24(1): 25–30

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

KOHLI, A., SINGH, H. Optimization of processing parameters in induction hardening using response surface methodology. Sadhana 36, 141–152 (2011). https://doi.org/10.1007/s12046-011-0020-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-011-0020-x