Abstract

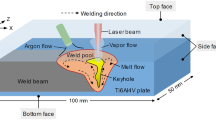

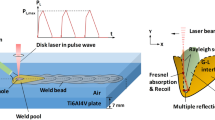

The study of keyhole (KH) instability in deep penetration laser beam welding (LBW) is essential to understand welding process and appearance of weld seam defects. The main cause of keyhole collapse is the instability in KH dynamics during the LBW process. This is mainly due to the surface tension forces associated with the KH collapse and the stabilizing action of vapour pressure. A deep penetration high power CW CO2 laser was used to generate KH in mild steel (MS) in two different welding conditions i.e. ambient atmospheric welding (AAW) and under water welding (UWW). KH, formed in case of under water welding, was deeper and narrower than keyhole formed in ambient and atmospheric condition. The number and dimensions of irregular humps increased in case of ambient and under water condition due to larger and rapid keyhole collapse also studied. The thermocapillary convection is considered to explain KH instability, which in turn gives rise to irregular humps.

Similar content being viewed by others

References

Aalderink B J, Lange de D F, Aarts R G K M, Meijer J 2007 Keyhole shapes during laser welding of thin metal sheets. J. Phys. D: Appl. Phys. 40: 5388–5393

Amara E H, Fabbro R 2008 Modelling of gas jet effect on the melt pool movements during deep penetration laser welding. J. Phys. D: Appl. Phys. 41: 055503–055513

Beretta S, Previtali B 2009 Estimate of maximum pore size in keyhole laser welding of carbon steel. Sci. Technol. Weld. Join. 14: 106–116

Binda B, Capello E, Previtali B 2004 A semi-empirical model of the temperature field in the AISI 304 laser welding. J. Mater. Proc. Technol. 155–156: 1235–1241

Dowden J, Postacioglu N, Davis M, Kapadia P 1987 A keyhole model in penetration welding with a laser. J. Phys. D: Appl. Phys. 20: 36–44

Fabbro R, Chouf K 2000 Dynamical description of the keyhole in deep penetration laser welding. J. Laser Appl. 12: 142–148

Golubev V S 1998 Nonstationary hydrodynamics in processes of laser beam-material interaction. Proc. SPIE 3688: 108–118

Heyn H, Decker I, Wohlfahrt H 1994 Tools and requirements for in-process quality control in laser beam welding. Proc. SPIE 2207: 381–91

Kamotani Y, Wang L, Hatta S, Wang A, Yoda S 2003 Free surface heat loss effect on oscillatory thermocapillary flow in liquid bridges of high Prandtl number fluids. Inter. J. Heat Mass Trans. 46: 3211–3220

Klein T, Vicanek M, Kroos J, Decker I, Simon G 1994 Oscillations of the keyhole in penetration laser beam welding. J. Phys. D: Appl. Phys. 27: 2023–2030

Klein T, Vicanek M, Simon G 1996 Forced oscillations of the keyhole in penetration laser beam welding. J. Phys. D: Appl. Phys. 29: 322–332

Kou S 2002 Welding metallurgy, Second edition (New York: John Wiley & Sons, Inc.)

Krauss G 2005 Processing, structure, and performance. ASM Inter. Materials Park, Ohio, USA, OH 44073-0002

Kroos J, Gratzke U, Simon G 1993a Towards a self-consistent model of the keyhole in penetration laser beam welding. J. Phys. D: Appl. Phys. 26: 474–80

Kroos J, Gratzke U, Vicanek M, Simon G 1993b Dynamic behaviour of the keyhole in laser welding. J. Phys. D: Appl. Phys. 26: 481–486

Kumar N, Dash S, Tyagi A K, Baldev Raj 2007 Hydrodynamical phenomena in the process of laser welding and cutting. Sci. Technol. Weld. Join. 12: 540–548

Kumar N, Kataria S, Sanmugarajan B, Dash S, Tyagi A K, Padmnabham G, Baldev Raj 2010 Contact mechanical studies on CW CO2 laser beam weld of mild steel with ambient and under water medium. Materials and Design 31: 3610–3617

Limmaneevichitr C, Kou S 2000 Experiments to simulate effect of Marangoni convection on weld pool shape. Weld. J. 5: 126–135

Matsunawa A, Kim J D, Seto N, Mizutani M, Katayama S 1998 Dynamics of keyhole and molten pool in laser welding. J. Laser Appl. 1: 247–254

McNaught W, Deans WF, Watson J 1997 High power laser welding in hyperbaric and water environments. J. Laser Appl. 9: 129–136

Mirzoev F K 1994 Evaporation-capillary instability in a deep vapour-gas cavity. Kvant. Elektr. 24: 138–140

Nakata K, Oishi M 1998 Nuclear Power Systems. Proc. Int. Conf. Env. Deg. Mat

Rai R, Kelly S M, R. Martukanitz P, DevRoy T 2008 A convective heat-transfer model for partial and full penetration keyhole mode laser welding of a structural steel. Metall. Mater. Trans. A 39A: 98–112

Semak V V, Bragg WD, Damkroger B, Kempka S 1999 Transient model for the keyhole during laser welding. J. Phys. D: Appl. Phys. 32: 61–64

Trappe J, Tix C, Kroos J, Simon G 1994 On the shape and location of the keyhole in penetration laser welding. J. Phys. D: Appl. Phys. 27: 2152–2154

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, N., Dash, S., Tyagi, A.K. et al. Keyhole depth instability in case of CW CO2 laser beam welding of mild steel. Sadhana 35, 609–618 (2010). https://doi.org/10.1007/s12046-010-0040-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-010-0040-y