Abstract

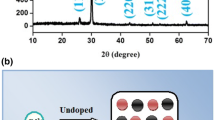

In the present work, rare earth (RE)-doped PbO thin films are characterised for their structural, morphological, electrical, optical and gas sensing properties. Thin films of PbO and Ce-, Nd- and Eu-doped PbO are deposited on a glass substrate using ultrasonic spray pyrolysis technique. We have considered 1, 5 and 10 mol% concentration of RE elements in PbO. X-ray diffraction patterns confirmed the formation of polycrystalline PbO and RE-doped PbO thin films with tetragonal structure. Scanning electron micrographs and optical absorption spectra of RE-doped PbO thin films revealed the decrease in average particle size and band gap with an increase in RE dopant concentration in PbO. The band gap of undoped PbO thin film is 2.58 eV. The concentration-dependent variations in the band gap of RE:PbO thin film are observed. The band gap of RE:PbO varies from 1.75 to 3.05 eV. At room temperature, the RE:PbO systems are found to be highly sensitive towards a wide concentration range (333 to 3330 ppm) of \(\hbox {CO}_2\) compared to the undoped PbO film. Ce- and Nd-doped PbO thin films show enhanced sensitivity towards \(\hbox {CO}_{{2}}\) gas compared to Eu-doped PbO thin films. At room temperature, significant increase in the gas sensor response of doped samples have been corroborated to their increased surface area, morphological changes and oxygen vacancies present.

Similar content being viewed by others

References

J K H Orbeck and R J Hamers, J. Vac. Sci. Technol. A 38, 021001 (2020)

M Martos, J Morales, L Sanchez, R Ayouchi, D Leinen, F Martin and J Barrado, Electrochim. Acta 46, 2939 (2001)

E Alnabi and F Hashim, TEST Eng. Manag. 83, 22026 (2020)

S K Pasha, K Chidambaram, L J Kennedy and J J Vijaya, Sensor. Trans. J. 122, 113 (2010)

S Aze, J-M Vallet, V Detallem, O Grauby and A Baronnet, Phase Transit. 81, 145 (2008)

B Jaffe, R Roth and S Marzullo, J. Res. Natl Bur. Stand. 55, 239 (1955)

W H Dumbaugh and J C Lapp, J. Am. Ceram. Soc. 75, 2315 (1992)

A V Borhade, D R Tope and B K Uphade, E-J. Chem. 9, 705 (2012)

F Hashim and A Mohaimeed, Al-Quadisiyah J. Pure Sci. 23, 175 (2018)

S Venkaratraj, J Geurts, H Weis, O Kappertz, W Njoroge, R Jayavel and M Wuttig, J. Vac. Sci. Tech. A Vacc. Surf. Films. 19, 2870 (2001)

M Suganya, V Narasimman, J Srivind, V Nagarethinam, K Usharani and A Balu, J. Elect. Devices 15, 1842 (2015)

M Liao, S Takemoto, Z Xiao, Y Toda, T Tada, S Ueda, T Kamiya and H Hosono, J. Appl. Phys. 119, 165701-1 (2016)

Y Kalandaragh, J. Semicond. Technol. Sci. 18, 91 (2018)

A Aliakbari, E Najafi, M Amini and S Ng, Monatsh. Chem. 145, 1277 (2014)

G Joshi, S Pasha and K Chindambaram, Compos. Interface. 20, 331 (2013)

V Suryawanshi, A Varpe and M Deshpande, Thin Solid Films 645, 87 (2018)

M Mythili and K Arulmozhi, J. Mater. Sci. Mater. Electron. 25, 3984 (2014)

D Daksh and Y Agrawal, Rev. Nanosci. Nanotechnol. 5, 1 (2016)

P Sakthivel, S Asaithambi, G Karuppaiah, S Sheikfareed, R G Yuvakkumar and G Ravi, J. Mater. Sci. Mater. Electron. 30, 9999 (2019)

W Guan, N Tang, K He, X Hu, M Li and K Li, Front. Chem. 8, 76 (2020)

G Xi, Y Peng, L Xu, M Zhang, W Yu and Y Qian, Inorg. Chem. Commun. 7, 607 (2004)

Y-F Sun, S-B Liu, F-L Meng, J-Y Liu, Z Jin, L-T Kong and J-H Liu, Sensors 12, 2610 (2012)

S Mahajan and S Jagtap, Appl. Mater. Today 18, 1 (2020)

C Wang, L Yin, L Zhang, D Xiang and R Guo, Sensors 10, 2088 (2010)

A Mirzaei, H W Kim, S S Kim and G Neri, Chemsensors 7, 56 (2019)

M Y Rezk, J Sharma and M R Gartia, Nanomater. 10, 2251 (2020)

C Willa, A Schmid, D Briand, J Yuan and D Koziej, ACS Appl. Mater. Interfaces 9, 25553 (2017)

National Research Council (NRC), Natl Acad. Press 5, 112 (2008)

K Azuma, N Kagi, U Yanagi and H Osawa, Env. Int. 121, 51 (2018)

G S Thool, A K Singh, R S Singh, A Gupta and M A B H Susan, J. Saudi Chem. Soc. 18, 712 (2014)

Acknowledgements

The authors gratefully acknowledge the financial support by the BCUD, Pune. Authors are thankful S. P. Pune University, Pune and Department of Physics, Kavayitri Bahinabai Chaudhari North Maharashtra University, Jalgaon for providing characterisation facilities.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Suryawanshi, V.N., Varpe, A.S. & DESHPANDE, M.D. The influence of rare earth (RE) dopants on structural, optical and gas sensing properties of spray deposited PbO thin films, where RE = Ce, Nd and Eu. Pramana - J Phys 96, 38 (2022). https://doi.org/10.1007/s12043-021-02280-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12043-021-02280-0