Abstract

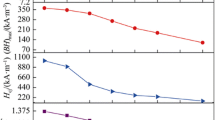

Substitution of Nd element with misch metal (MM) element in the RE–Fe–B magnets has been set off as an effective method to decrease the cost of RE–Fe–B materials and ensure a more balanced utilization of rare-earth elements. In the present work, the composition of MMxFe94−xB6 (x = 14 and 16) alloys are fabricated by the melt-spinning method with wheel speeds of 20 and 25 m s−1, respectively. It is demonstrated that with increasing wheel speed and MM content, can effectively suppress the formation of α-Fe soft phase and refine grain size. The maximum energy product (BH)max of 10.03 MGOe is obtained for the MM16-V25 alloy, which is a result of its higher intrinsic coercivity Hcj (Hcj: 9.15 kOe) and squareness Hk/Hcj (Hk/Hcj: 0.49). Meanwhile, the analysis of Henkel plots δM(H) and microstructure show that the MM16-V25 alloy obtains the strongest exchange coupling effect and more uniform microstructure with fine grain size. In addition, the compositions of 2:14:1 grain and grain boundary from energy dispersive spectroscopy for the MM16-V25 alloy are also discussed in detail.

Similar content being viewed by others

References

Saramolee P, Lertsuriwat P, Hunyek A and Sirisathitkul C 2010 Bull. Mater. Sci. 33 597

Zhou Y, Liu W, Zhao X G and Zhang Z D 2004 J. Magn. Magn. Mater. 278 1

Yin W Z, Chen R J, Tang X, Ju J Y and Yan A R 2019 J. Magn. Magn. Mater. 482 9

Liu Z W, Qian D Y, Zhao L Z, Zheng Z G, Gao X X and Ramanujan R V 2014 J. Alloys Compd. 606 44

Kosobudskii I D, Sevost’yanov V P and Kuznetsov M Y 2000 Inorg. Mater. 36 584

Liao X F, Zhang J S, Li W, Khan A J, Yu H Y, Zhong X C et al 2020 J. Alloys Compd. 834 155226

Sugimoto S 2011 J. Phys. D: Appl. Phys. 44 064001

Jin J, Ma T, Zhang Y, Bai G and Yan M 2016 Sci. Rep. 6 32200

Skokov K P and Gutfleisch O 2018 Scr. Mater. 154 289

Ito M, Yano M, Sakuma N, Kishimoto H, Manabe A, Shoji T et al 2016 AIP Adv. 6 56029

Yu X Q, Yue M, Liu W Q, Li Z, Zhu M G and Dong S Z 2016 J. Rare Earths 34 614

Zuo W L, Zuo S L, Li R, Zhao T Y, Hu F X, Sun J R et al 2017 J. Alloys Compd. 695 1786

Zhang M, Li Z B, Shen B G, Hu F X and Sun J R 2015 J. Alloys Compd. 651 144

Rehman S U, Jiang Q Z, He L K, Xiong H D, Liu K, Wang L et al 2019 Phys. Lett. A 383 125878

Kelly P E, O’Grady K, Mayo P I and Chantrell R W 1989 IEEE Trans. Magn. 25 3881

Wohlfarth E P 1958 J. Appl. Phys. 29 595

Bollero A, Yan A, Gutfleisch O, Müller K H and Schultz L 2003 IEEE Trans. Magn. 39 2944

Szmaja W, Grobelny J, Cichomski M, Hirosawa S and Shigemoto Y 2011 Acta Mater. 59 531

Jiang Q Z, Lei W K, Zeng Q W, Quan Q C, Zhang L L, Liu R H et al 2018 AIP Adv. 8 056203

Lei W K, Jiang Q Z, Rehman S U, He L K, Hu X J, Zeng Q W et al 2019 J. Magn. Magn. Mater. 473 155

Acknowledgements

This work is supported by the National Key R&D Program of China (no. 2022YFB3504800), the National Natural Science Foundation of China (no. 52271191), the Special Support Plan for High Level Talents of Zhejiang Province (no. 2022R52005), the Key R&D Program of Zhejiang Province (nos. 2021C01190 and 2021C01191) and the Key R&D Program of Ningbo City (no. 2021Z093).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Q., Yang, H., Yu, N. et al. Improved magnetic properties and optimized preparation process of (MM)–Fe–B magnets. Bull Mater Sci 47, 5 (2024). https://doi.org/10.1007/s12034-023-03090-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-023-03090-3