Abstract

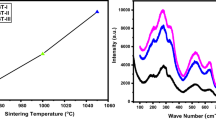

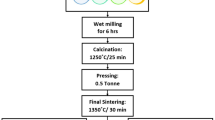

The parameters affecting the structural and physical properties of the material depends upon its method of preparation. The solid-state synthesis is a widely used commercial method due to its environmental stability, low-cost and large-scale production. This article describes the preparation of lead-free potassium bismuth titanate (KBT) ceramics by the conventional solid-state route. The effect of calcination temperature on the structural and electrical properties of KBT ceramics is studied systematically. The crystal structure and phase confirmation are analysed by using the X-ray diffraction technique. Raman spectroscopy analysis suggests that KBT ceramic has a better crystalline and perovskite structure. Dielectric study shows the diffusive phase transition behaviour of the material revealing its usage for high-temperature applications. Ferroelectric behaviour is confirmed by P–E loop tracer curve at different electric fields. The leakage current density decreases with the rise in calcination temperature and reveals linear ohmic conduction mechanism at higher electric fields.

Similar content being viewed by others

References

Sharma A, Kumar R, Vaish R and Chauhan V S 2014 J. Int. Mater. Syst. Struct. 25 1596

Yang S M and Chiu J W 1993 Compos. Struct. 25 381

Kumar S, Shandilya M and Thakur N 2021 Ferroelectr. Lett. Sect. 48 128

Hwang G T, Park H and Lee J H 2014 Adv. Mater. 26 4880

Ponnamma D, Cabibihan J J and Rajan M 2019 Mater. Sci. Eng. C Mater. Biol. Appl. 98 1210

Qi Y, Kim J and Nguyen T D 2011 Nano Lett. 11 1331

Ibn-Mohammed T, Koh S C L, Reaney I M, Sinclair D C, Mustapha K B, Acquaye A et al 2017 MRS Commun. 7 1

Panda P K 2009 J. Mater. Sci. 44 5049

Maeder M D, Damjanovic D and Setter N 2004 J. Electroceram. 131 385

Quan N D, Bac L H, Van Thiet D, Hung V N and Dung D D 2014 Adv. Mater. Sci. Eng. 1 365391

Isupov V A 2005 Ferroelectrics 315 123

Otoničar M, Škapin S D, Spreitzer M and Suvorov D 2010 J. Eur. Ceram. Soc. 30 971

Hiruma Y, Yoshii K, Nagata H and Takenaka T 2008 J. Appl. Phys. 103 084121

Yang J, Hou Y, Wang C, Zhu M, Yan H, Yang J et al 2014 J. Appl. Phys. 121 023118

Suchanicz J, Kania A, Czaja P, Budziak A and Niewiadomski A 2018 J. Eur. Ceram. Soc. 38 567

Wang P, Li Y and Lu Y 2011 J. Eur. Ceram. Soc. 31 2005

Pandirengan T, Arumugam M, Durairaj M, Suresh B and Anand M A 2016 Int. J. Mater. Res. 107 484

Verma M, Tanwar A, Haridas D, Mahajan S, Menon R, Kumar S et al 2022 Appl. Phys. A Mater. Sci. Process 128 1

Sharma S, Sharma H, Kumar, Thakur S, Kotnala R K and Negi N S 2020 J. Mater. Sci. Mater. Electron. 31 19168

Czaja P, Suchanicz J and Bochenek D 2018 Phase Transit. 91 1051

Yang J, Hou Y and Wang C 2007 Appl. Phys. Lett. 91 023118

Rao P V B, Ramana E V and Sankaram T B 2009 J. Alloys Compd. 467 293

Zhu M, Hou L and Hou Y 2006 Mater. Chem. Phys. 99 329

Mustapha S, Ndamitso M M and Abdulkareem A S 2019 Adv. Nat. Sci. Nanosci. Nanotechnol. 10 045013

Monshi A, Foroughi M R and Monshi M R 2012 World J. Nano Sci. Eng. 2 154

Nath D, Singh F and Das R 2020 Mater. Chem. Phys. 239 122021

Turki O, Slimani A, Sassi Z, Khemakhem H, Abdelmoula N and Lebrun L 2022 J. Electron. Mater. 128 1

Motevalizadeh L, Heidary Z and Abrishami M E 2014 Bull. Mater. Sci. 37 397

Kumar S and Thakur N 2019 J. Elect. Mater. 48 620348

Bartel C J, Sutton C, Goldsmith B R, Ouyang R, Musgrave C B, Ghiringhelli L M et al 2019 Sci. Adv. 5 1

Guo J, Zhu M, Li L, Zheng M and Hou Y 2017 J. Alloys Compd. 703 448

Lian H, Cheng R, Qiu Y, Shi J and Chen X 2020 J. Mater. Sci. Mater. Electron. 31 7927

König J and Suvorov D 2015 J. Eur. Ceram. Soc. 35 2791

Hanani Z, Mezzane D, Amjoud M and Fourcade S 2019 Superlattices Microstruct. 127 109

Kumar S, Shandilya M and Thakur N 2019 J. Sol-Gel Technol. 92 215

Swain S, Chandrasekhar M, Kumar P and Prakash C 2017 Ferroelectrics 516 185

Sun B, Xiao M, Zhou G, Ren Z, Zhou Y N and Wu Y A 2020 Mater. Today Adv. 6 100056

Liu, Xiong W, Liu Y, Chen K, Xu Z, Zhou Y et al 2020 Adv. Electron. Mater. 6 1

Yang R, Qin Y, Dai L and Wang Z L 2009 Nat. Nanotechnol. 4 34

Abazari M and Safari A 2010 Appl. Phys. Lett. 97 262902

Chiu F-C 2014 Adv. Mater. Sci. Eng. 2014 578168

Simmons J G 1967 Phys. Rev. 155 657

Korotkov A S and Atuchin V V 2008 Opt. Commun. 281 2132

Turki O, Slimani A, Sassi Z, Khemakhem H, Abdelmoula N and Lebrun L 2022 Appl. Phys. A 128 186

Acknowledgements

Saloni Bhardwaj is thankful to JOINT CSIR-UGC NET-JRF, fellowship F.No.16-6(Dec.2017)/2018(NET/CSIR), for financial assistance and Sophisticated Analytical Instrumentation Facility (SAIF)-Punjab University for recording structural characterizations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhardwaj, S., Kumar, S. & Thakur, N. Effect of calcination temperature on structural and electrical properties of K0.5Bi0.5TiO3 ceramics prepared by solid-state route. Bull Mater Sci 46, 170 (2023). https://doi.org/10.1007/s12034-023-03014-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-023-03014-1