Abstract

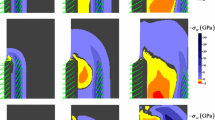

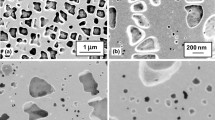

Micro-sized IN718 superalloy powder with an average particle size of 70 μm has been explosively shock-processed with high pressure of the order of 41.3 GPa. A hydrocode, AUTODYNE-2D, with Eulerian mesh is used to simulate and to compute the detonation pressure, particle velocity and shock pressure on the superalloy in the reactive zone. The grazing shock pressure at different regions in the compaction system has been calculated and compared with the experimental work. Axisymmetric cylindrical compaction geometry has been used for the shock-loading of IN718 superalloy. The shock pressure at different points was calculated experimentally by pin-oscillography with the help of electrical as well as fibre optical probes. Wide-angle X-ray diffraction study indicates the intact crystalline FCC structure within the shock-processed specimen having dominating \(\gamma^{ }\)[Ni-Cr-Fe] and strengthening \(\gamma^{\prime}\)[Ni3(Ti,Al)] phases. Laser diffraction particle size measurement points towards the reduced particle size of the shock-loaded specimen. The Line-broadening Williamson-Hall method shows a very small amount of locked-in microstrain of the order of 0.23%. Energy-dispersive analysis using X-ray examination shows no evidence of any chemical segregation within the compacts. Field-emission scanning electron microscopy shows satisfactory sub-structural strengthening and desired morphology at different regions in the fractographs of the compacted specimen without melting of the core of the specimen. Micro-indentation testing at variable loads of 0.98, 1.96 and 4.9 N shows a good hardness of the order of 642 Hv. The monolith cut-along the consolidation axes show tensile and compressive strengths of the order of 1.126 and 1.04 kN mm–2, respectively. Uniform crack/void-free compacts have been obtained with a density close to 99.2% of the theoretical value with negligible porosity.

Graphical abstract

Similar content being viewed by others

References

Wahll M J, Maykuth D J and Hucek H J 2007 Handbook of Superalloys International alloy composition and designation series 1st edn. (USA: Battalle Press)

Donalchie M J and Donalchie S J 2002 Superalloys: a technical guide 2nd edn. (USA: ASM International)

Davis J R 2000 Nickel, cobalt and their alloys 1st edn. (USA: ASM International)

El-Bagoury N 2016 Int. J. Eng. Sci. Res. Technol. 5 108

Kracke A 2010 Superalloys: the most successful alloy system of modern times-past, present and future Seventh Inter. Symp. Superalloys 718 and Derivatives (TMS)

Yan S, Wang Y, Wang Q, Zhang C, Chen D and Cui G 2019 Materials 12 3336

Mostafa A, Rubio I P, Brailovski V, Jahazi M and Medraj M 2017 Metals 7 196

Shivakumar K, Bhat T B and Ramakrishnan P J 1998 Mater. Process. Technol. 73 268

Bhadeshia H K D H 2003 Nickel based superalloys (UK: University of Cambridge)

Nagayama K 1993 Shock wave interaction in solid materials (Japan: Springer) p195

Sharma A D, Sharma A K and Thakur N 2019 J. Met. Mater. Res. 2 26

Zohoor M and Mehdipoor A 2009 J. Mater. Process. Technol. 209 4201

Sivakumar K and Hokamoto K 2000 J. Mater. Sci. 35 5823

Zukas J A 2000 Introduction to hydrocodes 1st edn. (USA: Elsevier)

ANSYS AUTODYN: Explicit software for nonlinear dynamics 2005 (SPH user manual)

Nellis W J 2001 Dynamic experiments: an overview University of California, Lawrence Livermore National Laboratory

Häggblad H A 1993 Modeling and simulations of metal powder pressing PhD Thesis (Luleå University of Technology)

Wehrenberg C 2012 Phase transformations in shock compacted magnetic materials PhD Thesis (Georgia Institute of Technology)

Sharma A D 2014 Shock wave synthesis of newer materials of Ni-based superalloys and their characterization PhD Thesis (Himachal Pradesh University-India)

Meyers M A 1994 Dynamic behavior of materials (University of California-JWS)

Batsanov S S 1994 Effect of explosions on materials 1st edn. (Springer-Verlag)

Chen T, Hampikian J M and Thadhani N N 1999 Acta Mater. 47 2567

Meyers M A, Benson D J and Olevsky E A 1999 Acta Mater. 47 2089

Shang S S, Benson D J and Meyers M A 1992 J. de. Phys. 4 521

Rice M H, McQueen R G and Walsh J W 1958 Solid State Physics 1st edn. (Elsevier) p 1

Wei P, Lang H, Liu T and Xia D 2017 Sensors 17 2552

Kabwe E J 2018 Rock Mech. Geotech. Eng. 10 523

PegueroII J C 2019 Measurement of shock and detonation 886 propagation PETN thin films 1st edn. (New Mexico: Institute of Mining and Technology)

Sharma A D, Sharma A K and Thakur N 2013 Appl. Phys. A 111 783

Mandal A, Jensen B J, Aslam T D and Everson A J 2018 Dynamic compaction of nickel powder examined by X-ray phase contrast imaging, AIP Conf. Proc. 1979 110010

Sharma A D, Sharma A K and Thakur N 2011 Shock wave processing of metal powers and their microstructural characterization AIP Conf. Proc. 119 1393

Jinoop A N, Subbu S K and Kumar R A 2018 Int. J. Add. Sub. Mater. Manuf. 2 1

Bridges D, Xu R and Hu A 2019 Mater. Des. 174 107784

Sanchez S, Smith P, Xu Z, Gaspard G, Hyde C J, Wits W W et al 2021 Int. J. Mach. Tool. Manuf. 165 103729

Slamaa C and Abdellaoui M 2000 J. Alloys Comp. 306 277

Sharma A D, Sharma A K and Thakur N 2012 Phil. Mag. 92 2108

Zheng Z H A O, Xiao-jie K, Gang T A O and Chang-Xing D U 2009 Trans. Nonfer. Met. Soc. China 19 626

Zhao Z, Li X J, Yan H H and Liu D H 2008 Combust. Explos. Shock Waves 44 119

Sharma A D, Sharma A K and Thakur N 2015 Shock wave loading of nickel based superalloy and microstructural features of the compacts IOP Conf. Series: Mater. Sci. Eng. 73 012059

Meyers M A, Jarmakani H, Bringa E M and Remington B A 2009 Dislocations in shock compression and release (USA: Elsevier)

Williamson G K and Hall W H 1953 Acta Metall. 1 22

Armstrong R W, Ammon H L, Du Z Y, Elban W L and Zhang X J 1993 Mat. Res. Soc. Symp. Proc. 296 227

Thadhani N N 1994 J. Appl. Phys. 76 714

Khan M, Mostafa A O, Aljarrah M, Essadiqi E and Medraj M 2014 J. Mater. 657647 1

Shi X, Duan S, Yang W, Guo H and Guo J 2018 Materials 11 2398

Stogner J, Terock M and Glatzel M 2015 Adv. Eng. Mater. 17 1099

Sharma A D, Sharma A K and Thakur N 2016 Metall. Mater. Trans. B 47 2479

Odabasi A, Unlu N, Guller G and Eruslu M N 2010 Metall. Mater. Trans. A 41A 2357

Salas W, Alba-Baena N G and Murr L E 2007 Metall. Mater. Trans. A 38 2928

Sharma A D, Sharma A K and Thakur N 2014 J. Alloys Comp. 597 175

Morris D G 1986 J. Mater. Sci. 21 1111

Alba-Baena N G, Salas W and Murr L E 2008 Mater. Charact. 59 1152

Mukhtarova1 K S, Shakhov R V, Smirnov V V, Mukhtarov S K 2019 IOP Conf. Series: Mater. Sci. Eng. 672 012049

Bukaemskii A A and Fedorova E N 2008 Combust. Explos. Shock Waves 44 717

Zin Z Q, Thadhani N N, McGill M, Ding Y, Wang Z L, Chen M et al 2005 J. Mater. Res. 20 599

Tsao T, Yeh A, Kuo C, Kakehi K, Murakami H, Yeh J et al 2017 Sci. Rep. 12658 1

Bhujangra T, Veiga F, Suárez A, Iriondo E and Mata F G 2020 Crystals 10 689

Page N W, Killen P D and Jon D H 1990 Mater. Sci. Eng. A 130 231

Yong C K, Gibbons G J, Wong C C and West G 2020 Metals 10 1576

Acknowledgements

We acknowledge the Defence Research and Development Organization (DRDO), India, for Grant-in-aid Project No. ERIP/ER/0703665/M/01/1044. Special thanks to the University Grants Commission (UGC-New Delhi), India, for providing Research Fellowship No. F.4-1/2006 (BSR)/11-08/2008. Thanks also to USIC facility at H.P. University, Shimla and SAIF/CIL Laboratory at Panjab University, Chandigarh, and the entire trial team. Distinctive thanks to Madan K Sharma, Yugal K Yoshi and Rajendra S Bisht for their necessary assistance and guidance in carrying out the field experiments and numeric simulations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, A.D., Sharma, A.K. & Thakur, N. Influence of high detonation pressure on the structural, microstructural and mechanical behaviour of IN718 superalloy: numeric simulation vis-à-vis experimental explosive shock processing. Bull Mater Sci 45, 70 (2022). https://doi.org/10.1007/s12034-021-02646-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-021-02646-5