Abstract

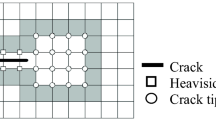

To simulate the crack growth and study the catastrophic fracture mechanisms of metal films, a computational methodology is developed to simulate the failure process from damage initiation to crack growth and eventually to rupture. In the computational methodology, a procedure is developed based on beam lattice model for considering the coupling interactions among damage and crack evolution. To verify the effectiveness of the developed computational methodology, fracture process of two copper film specimens were simulated and compared with the corresponding experimental results. The results show that the developed methodology is effective, and can be used to simulate the catastrophic fracture process of metal films. From the simulation results, we can find out that the fracture of metal films with initial flaws belongs to brittle fracture, and the regular lattice model can affect the crack path prediction, and random and irregular lattice model is more suitable to simulate crack growth in the developed computational methodology.

Similar content being viewed by others

References

LaVan D A, Boyce B L and Buchheit T E 2003 Int. J. Damage Mech. 12 357

Kivi A R, Azizi S and Khalkhali A 2016 Int. J. Mech. Mater. Des. 12 337

Li Y, Li J and Xu L 2018 Microelectron. Reliab. 85 38

Gao J, Chow P K, Thomas A V, Lu T M, Borca-Tasciuc T and Koratkar N 2014 Appl. Phys. Lett. 105 722

Sun B and Li Z 2019 Acta Mech. 230 2979

Sun B and Li Z 2019 Eur. J. Mech. A: Solid 75 82

Rogers J A 2010 Nature 468 177

Heremans P, Tripathi A K, De Meux A D J, Smits E C P, Hou B, Pourtois G et al 2016 Adv. Mater. 28 4266

Sun B, Huang X and Li Z 2019 Met. Mater. Int. 26 501

Sun Y, Zhai Z, Tian S and Chen X 2019 Appl. Surf. Sci. 480 1100

He X, Chen F and Yin H 2016 Int. J. Damage Mech. 71 423358

Li X, Wei Y, Lu L, Lu K and Gao H 2010 Nature 464 877

You Z S, Li X, Gui L, Lu Q, Zhu T, Gao H et al 2013 Acta Mater. 61 217

Su Y, Wang S, Huang Y A, Luan H, Dong W, Fan J A et al 2015 Small 11 367

Bastawros A F and Kim K S 2001 Int. J. Damage Mech. 10 195

An B and Xu M 2019 Mech. Mater. 136 103084

Zeng Z, Li X, Lu L and Zhu T 2015 Acta Mater. 98 313

Shan Z, Lu L, Minor A M, Stach E A and Mao S X 2008 JOM-US 60 71

Kim S, Li X, Gao H and Kumar S 2012 Acta Mater. 60 2959

Hintsala E, Kiener D, Jackson J and Gerberich W W 2015 Exp. Mech. 55 1681

Singh A, Tang L, Dao M, Lu L and Suresh S 2011 Acta Mater. 59 2437

You Z S, Qu S, Luo S and Lu L 2019 Materialia 7 100430

Yu S, Zhang X, Xiao X, Zhou H and Chen M 2015 Soft Matter 11 2203

An B 2019 Eur. J. Mech. A: Solid 75 1

Sadhukhan S, Kumar A, Kulkarni G U, Tarafdar S and Dutta T 2019 Bull. Mater. Sci. 42 197

Yun K, Wang Z, Chang M, Liu J, Kim T, Son N et al 2019 Comput. Struct. 215 65

Sun B, Wang X and Li Z 2015 Comput. Mater. Sci. 110 39

Amor H, Marigo J and Maurini C 2009 J. Mech. Phys. Solids 57 1209

Sun B and Li Z 2016 Int. J. Damage Mech. 25 750

Miehe C, Hofacker M and Welschinger F 2010 Comput. Methods Appl. Mech. Eng. 199 2765

Borden M J, Verhoosel C V, Scott M A, Hughes T J R and Landis C M 2012 Comput. Methods Appl. Mech. Eng. 217 77

Nguyen T T, Yvonnet J, Zhu Q, Bornert M and Chateau C 2015 Eng. Fract. Mech. 139 18

Erdogan F and Sih G C 1963 J. Basic Eng. 85 519

Sih G C 1974 Int. J. Fract. 10 305

Nuismer R J 1975 Int. J. Fract. 11 245

Azadi H and Khoei A R 2011 Int. J. Numer. Methods Eng. 85 1017

Belytschko T, Chen H, Xu J and Zi G 2003 Int. J. Numer. Methods Eng. 58 1873

Alfaiate J, Wells G N and Sluys L J 2002 Eng. Fract. Mech. 69 661

Bai Y L, Wang H, Xia M and Ke F 2005 Appl. Mech. Rev. 58 372

Sun B and Li Z 2015 Comput. Struct. 152 66

Sun B, Zheng Y and Li Z 2020 Constr. Build. Mater. 244 118396

Sun B 2020 Arab. J. Geosci. 13 1031

Acknowledgements

The works described in this paper are financially supported by National Natural Science Foundation of China (Grant No. 52008104) and National Program on Key R&D Project of China (2020YFB2103500-2), to which we are most grateful. We are very grateful to the reviewers and the editor for their constructive comments and suggestions, which helped us to improve our paper significantly.

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (AVI 57342 kb)

Rights and permissions

About this article

Cite this article

Sun, B., Xu, Zd. A continuum damage-based computational methodology for crack growth simulation of metal films. Bull Mater Sci 44, 200 (2021). https://doi.org/10.1007/s12034-021-02430-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-021-02430-5