Abstract

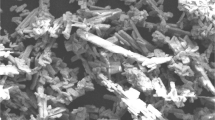

Aerospace and automobile industries are facing challenges in developing lightweight materials with high corrosion and wear resistance. The magnesium (Mg) alloys are superior to their monolithics, as they have maximum strength-to-weight ratio. These challenges can be solved with application of Mg-based hybrid composites. Therefore, this study investigated the hybridizing effect of molybdenum disulphide (MoS2) reinforcement on tribological performance of magnesium–boron carbide (Mg–B4C) hybrid composites, fabricated by powder metallurgy technique. Wear tests under dry sliding condition were carried out on the prepared composite samples with different proportions/weight percentage (wt%), using a pin-on-disc apparatus. Mg, MoS2, B4C and their various composites were characterized, using X-ray diffraction, thermogravimetric analysis, scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy analysis. The experiments were conducted using L27 orthogonal array with five factors at three levels that affected the tribological performance. The wear resistance of the hybrid Mg–B4C–MoS2 composites significantly increased when compared with Mg–B4C and Mg–MoS2 composites, due to the refined effect of both reinforcements. Analysis of variance and grey-relational analysis result showed that increase in MoS2, sliding distance (DSl) and load (LSl) significantly influenced the tribological performance of the hybrid composites. Mg–10wt%B4C–5wt%MoS2 exhibited significant best improvement on the multi-response tribological performance. The optimum quantity of MoS2 reinforcement was around 7 wt%. Beyond this threshold proportion, wear was significantly increased, due to the agglomeration of MoS2 particles. Hardness of the composites increased with hybridized reinforcements. SEM micrographs depicted the homogeneous dispersion of reinforcements in the Mg matrix. Also, SEM micrographs of the worn surfaces confirmed that delamination wear mechanism was dominant on the Mg hybrid composites.

Similar content being viewed by others

References

Mordike B L and Ebert T 2001 Mater. Sci. Eng. 302 37

An J, Li R G, Lu Y, Chen C M, Xu Y C, Chen X et al 2008 Wear 265 97

Chelliah N M, Pambannan P and Surappa M K 2019 J. Compos. Mater. 53 3741

Ye H Z and Liu X Y 2004 J. Mater. Sci. 39 6153

Cao G, Choi H, Konishi H, Kou S, Lakes R and Li X 2008 J. Mater. Sci. 43 5521

Aydin F, Sun Y and Turan M E 2020 J. Compos. Mater. 54 141

Selvam B, Marimuthu P, Narayanasamy R, Anandakrishnan V, Tun K S, Gupta M et al 2014 Mater. Des. 58 475

Cai Y, Tan M J, Shen G J and Su H Q 2000 Mater. Sci. Eng. 282 232

Wang X J, Wu K, Huang W X, Zhang H F, Zheng M Y and Peng D L 2007 Compos. Sci. Technol. 67 2253

Ramachandra M and Radhakrishna K 2005 J. Mater. Sci. 40 5989

Ramachandra M and Radhakrishna K 2007 Wear 262 1450

Jiang Q C, Wang H Y, Ma B X, Wang Y and Zhao F 2005 J. Alloys Compd. 386 177

Poddar P, Srivastava V C, De P K and Sahoo K L 2007 Mater. Sci. Eng. 460 357

Jalilvand M M and Mazaheri Y 2020 Ceram. Int. 46 20345

Turan M E, Zengin H, Cevik E, Sun Y, Turen Y and Ahlatci H 2016 Inter. J. Mater. Metallurg. Eng. 10 1224

Rao R N, Das S, Mondal D P and Dixit G 2009 Wear 267 1688

Paydar S, Jafari A, Bahrololoom M E and Mozafari V 2015 Tribol. Mater. Surf. Interf. 9 105

Thuault A, Marinel S, Savary E, Heuguet R, Saunier S, Goeuriot D et al 2013 Ceram. Int. 39 1215

Rajkumar P R, Kailasanathan C, Senthilkumar A, Selvakumar N and John Rajan A 2020 Mater. Res. Exp. 7 1

Rahmani K and Majzoobi G H 2020 J. Compos. Mater. 54 2297

Sharma S C, Anand B and Krishna M 2000 Wear 241 33

Turan M E, Sun Y, Aydin F and Akgul Y 2018 J. Compos. Mater. 52 3127

Ravindran P, Manisekar K, Rathika P and Narayanasamy P 2013 Mater. Des. 45 561

Narayanasamy P, Selvakumar N and Balasundar P 2015 Trans. Indian. Inst. Met. 68 911

Beall C J 1999 Met. Finish. 100 513

Zhao B, Ding W, Kuang W and Fu Y 2019 Ind. Lub. Tribol. 71 712

Donnet C, Martin J M, Le Mogne T and Belin M 1996 Tribol. Int. 29 123

Vazirisereshk M R, Martini A, Strubbe D A and Baykara M Z 2019 Lubricants 7 57

Zeng C, Pu J, Wang H, Zheng S and Chen R 2020 Ceram. Int. 46 13774

Narayanasamy P and Selvakumar N 2017 Trans. Nonf. Met. Soc. China 27 312

Ravindran P, Manisekar K, Narayanasamy P, Selvakumar N and Narayanasamy R 2012 Mater. Des. 39 42

Baradeswaran A and Perumal A E 2014 Compos Part B 56 464

Bayhan M and Önel K 2010 Mater. Des. 31 3015

Kumar K A, Pillai U T, Pai B C and Chakraborty M 2013 Wear 303 56

Chiranth B P, Siddaraju C, Mishra R K, Sasikumar R, Sathiskumar R and Ram Prabhu T 2019 Mater. Sci. Forum. 969 86

Hiratsuka K, Enomoto A and Sasada T 1992 Wear 153 361

Baradeswaran A E and Perumal A E 2013 Compos. Part B 54 146

Aatthisugan I, Rose A R and Jebadurai D S 2017 J. Mag. Alloys 5 20

Joseph J D, Kumaragurubaran B and Sathish S 2019 Silicon 12 1

Chen L, Yao Y 2014 Acta Metallurg. Sinica. 27 762

Vani V V and Chak S K 2018 Manuf. Rev. 5 1

Mohan Raj A P, Selvakumar N, Narayanasamy R and Kailasanathan C 2013 Mater. Des. 49 791

Mohan Raj A P, Kailasanathan C and Seenikannan P 2014 Int. J. Chemtech. Res. 6 4777

Ravindran P, Manisekar K, Narayanasamy R and Narayanasamy P 2013 Ceram. Int. 39 1169

Ghosh S, Sahoo P and Sutradhar G 2013 J. Compos. 2013 1

Senthilkumar M, Saravanan S D and Shankar S 2015 J. Compos. Mater. 49 2241

Basavarajappa S, Chandramohan G and Davim J P 2007 Mater. Des. 28 1393

Basavarajappa S, Chandramohan G, Mahadevan A, Thangavelu M, Subramanian R and Gopalakrishnan P 2007 Wear 262 1007

Tsao C C 2009 Int. J. Adv. Manuf. Technol. 40 41

Chandrasekar G, Kailasanathan C and Verma D K 2017 Trans. Indian. Inst. Met. 70 671

Khatkar S K, Verma R, Kharb S S, Thakur A and Sharma R 2021 Silicon 13 1461

Kumar P N, Rajadurai A and Muthuramalingam T 2018 Silicon 10 1723

Shamekh M, Pugh M and Medraj M 2012 Mater. Chem. Phys. 135 193

Nandagopal K and Kailasanathan C 2016 J. Alloys Compd. 682 503

Acknowledgments

We hereby acknowledge and sincerely appreciate unalloyed supports from the managements of the following institutions: Sethu Institute of Technology, Pulloor, Kariapatti, Virudhunagar District, Tamilnadu, India, as well as the Kalasalingam Academy of Research and Education, Virdhunagar, Tamilnadu, India.

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kailasanathan, C., Rajkumar, P.R., Rajini, N. et al. Characterization and optimization of influence of MoS2 hybridization on tribological behaviours of Mg–B4C composites. Bull Mater Sci 44, 192 (2021). https://doi.org/10.1007/s12034-021-02423-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-021-02423-4