Abstract

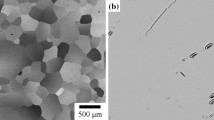

Correlation of microstructure and mechanical properties of hot-rolled Fe–7 wt.% Al with varying carbon contents has been investigated in detail. The microstructures of the alloys change significantly with an increase in the carbon content. An alloy with 0.012 wt.% carbon shows a single ferrite phase, whereas with increase in carbon up to 0.65 wt.%, the microstructure evolves into a dual phase consisting of ferrite and \(\upkappa \)-pearlite. At about 1.5 wt.% carbon, the alloy exhibits only \(\upkappa \)-pearlite and with a further increase in carbon to 2.2 wt.%, an additional phase starts precipitating in the form of graphite. The room temperature tensile strength of the alloy increased significantly with an increase in the carbon content, which is in agreement with the microstructure. The yield strength and hardness of the steels with different carbon contents can be correlated well with the inter-barrier spacing in different steels.

Similar content being viewed by others

References

Rana R 2014 JOM 66 1730

Rana R, Lahaye C and Ray R K 2014 JOM 66 1734

Pramanik S and Suwas S 2014 JOM 66 1868

Khaple S, Sankar M, Baligidad R G and Satya Prasad V V 2010 ISIJ Int. 50 1483

Herrmann J, Inden G and Sauthoff G 2003 Acta Mater. 51 2847

Khaple S, Baligidad R G, Satya Prasad V V and Satyanarayana D V V 2015 Mater. Sci. Technol. 31 1408

Jimenez J A and Frommeryer G 2011 J. Alloys Compd. 509 2729

Baligidad R G and Satya Prasad V V 2007 Trans. Indian Inst. Met. 60 1

Palm M and Inden G 1995 Intermetallics 3 443

Raghavan V 1987 Phase diagrams of ternary iron alloys, Part I (OH USA: ASM Metals Park)

Sang Y S, Hackcheol L, Han S Y, Chang-Hyo S, Kayoung C, Sunghak L et al 2010 Metall. Mater. Trans. A 41 138

Seung Y H, Sang Y S, Sunghak L, Nack J K, Jai-Hyun K and Kwang-Geun C 2011 Metall. Mater. Trans. 42A 138

Sohn S S, Lee B J, Lee S and Kwak J-H 2013 Acta Mater. 61 5626

Schneider A, Falat L and Sauthoff G 2005 Intermetallics 13 1322

Prakash U 2008 Indian Inst. Met. 61 193

Satya Prasad V V, Khaple S and Baligidad R G 2014 JOM 66 1785

Baligidad R G, Radhakrishna A and Prakash U 1998 Mater. Sci. Eng. A 257 235

Ishii H, Ohkubo K, Miura S and Mohri T 2003 Tetsuo Mater. Trans. 44 1679

Chen J H and Cao R 2015 Micromechanism of cleavage fracture of metals: a comprehensive microphysical model for cleavage cracking in metals (Oxford, UK: Elsevier Publication)

Calcagnotto M, Ponge D, Adachi Y and Raabe D 2009 Proceedings of the 2nd International symposium on steel science (Kyoto, Japan: The Iron and Steel Institute of Japan)

Acknowledgements

We are thankful to the Defence Research and Development Organization (DRDO), Ministry of Defence, New Delhi, for the funding. We wish to express our gratitude to Dr Vikas Kumar, Director, DMRL, Hyderabad, for his interest and granting permission for this publication.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khaple, S., Satyanarayana, D.V.V., Satya prasad, V.V. et al. Evolution of microstructure with increasing carbon content and its effect on mechanical properties of disordered iron–aluminium alloy. Bull Mater Sci 42, 234 (2019). https://doi.org/10.1007/s12034-019-1930-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-019-1930-1